Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Lower temperature conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive Filler

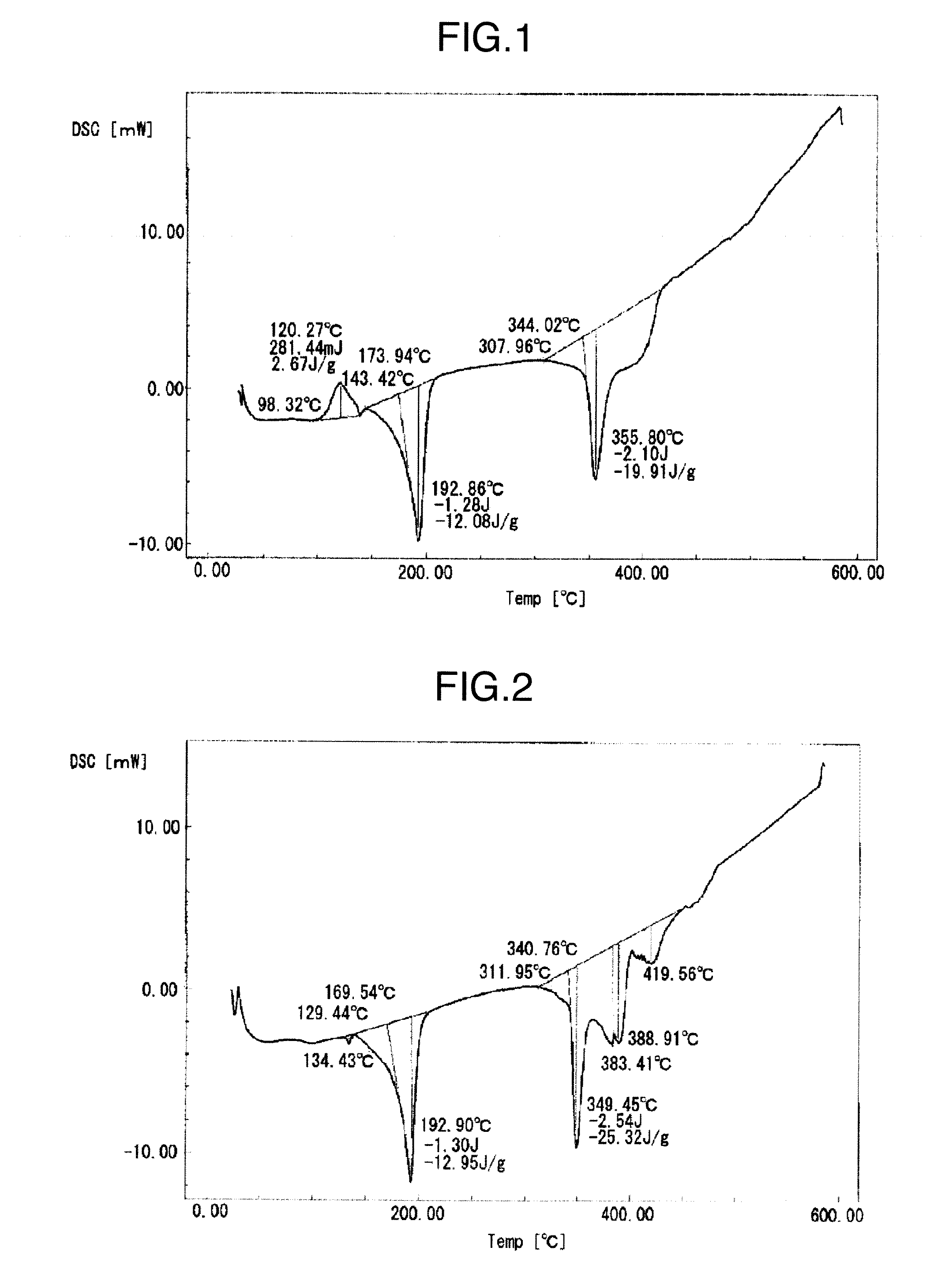

ActiveUS20090194745A1Reduce heat damageReduce manufacturing costPrinted circuit aspectsConductive materialChemical compositionMetal particle

Disclosed is a conductive filler which can be fusion-bonded under lower temperature conditions (with the peak temperature of not less than 181° C.) than the reflow heat treatment conditions for an Sn-37Pb eutectic solder. This conductive filler is applicable to heat-resistant uses similar to those of the Sn-37Pb eutectic solder. The conductive filler is a mixture of first metal particles composed of an alloy having a chemical composition including 25-40% by mass of Ag, 2-8% by mass of Bi, 5-15% by mass of Cu, 2-8% by mass of In and 29-66% by mass of Sn, and second metal particles composed of an alloy having a chemical composition including 5-20% by mass of Ag, 10-20% by mass of Bi, 1-15% by mass of Cu and 50-80% by mass of Sn. In the mixture, 20-10,000 parts by mass of the second metal particles are contained per 100 parts by mass of the first metal particles.

Owner:KOKI

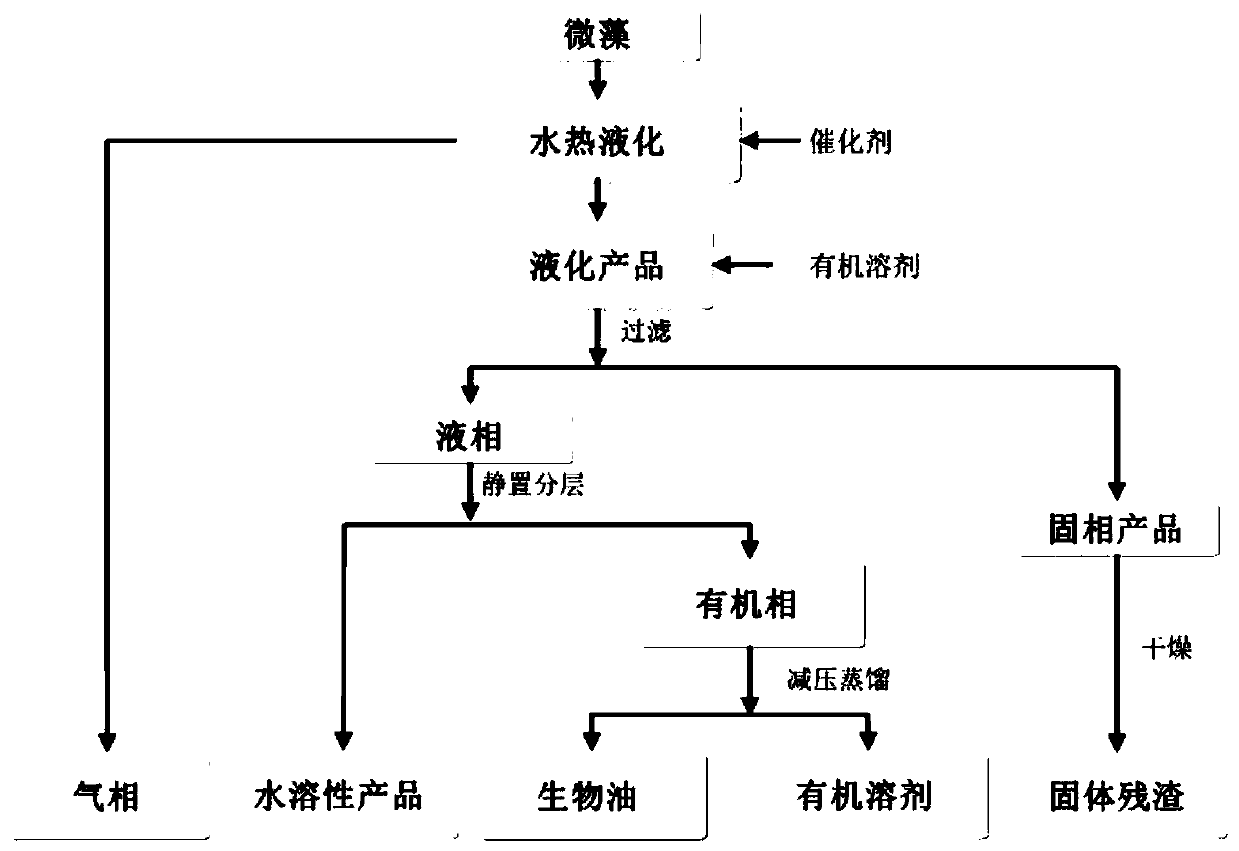

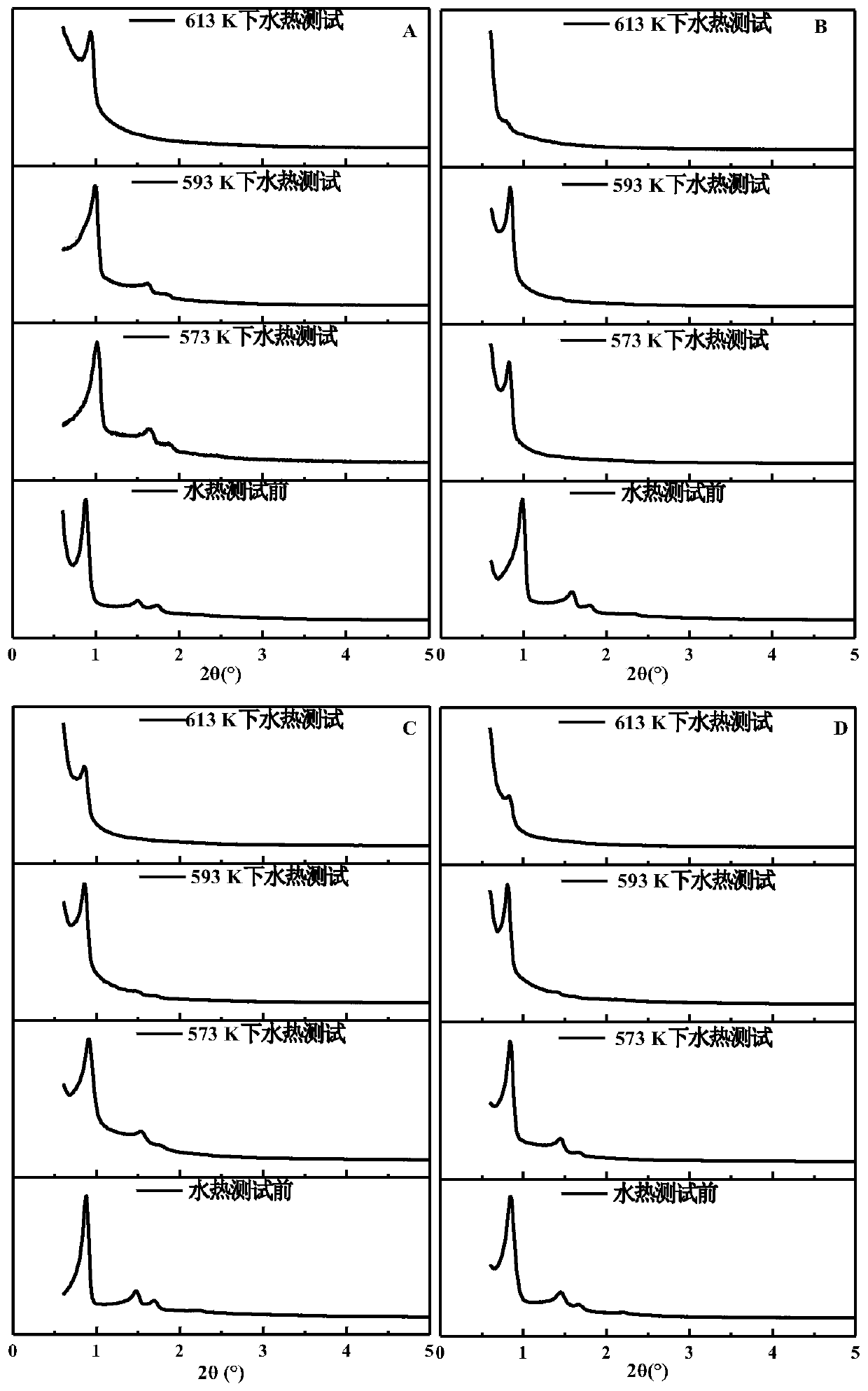

A mesoporous catalyst with hydro-thermal stability, a preparing method thereof and a method of catalyzing microalgae hydrothermal liquefaction with the catalyst to prepare bio-oil

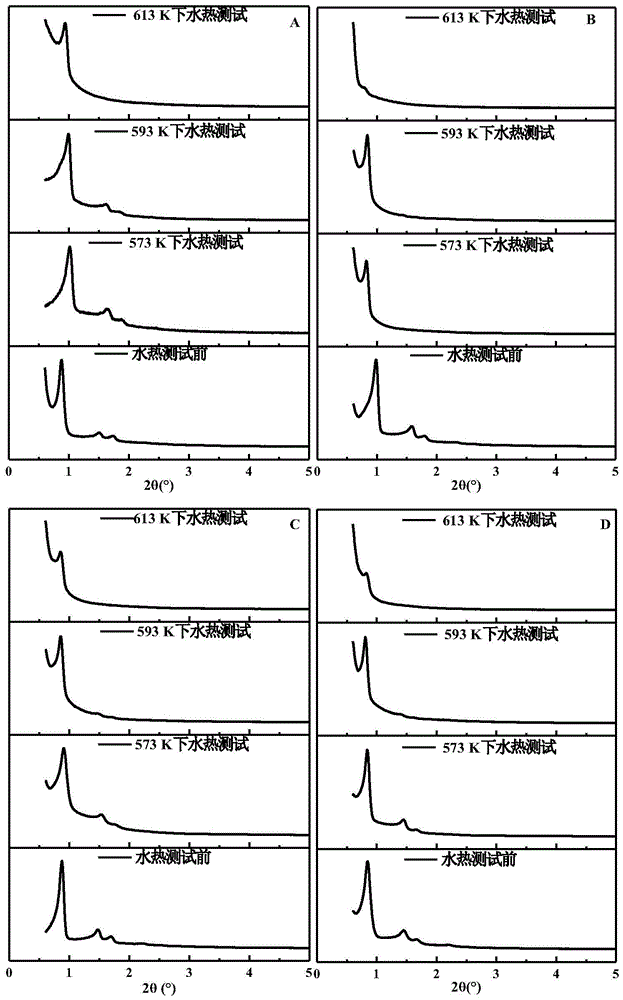

ActiveCN105536849AOvercoming and mitigating pollution problemsReduce energy consumptionMolecular sieve catalystsLiquid carbonaceous fuelsMolecular sieveThermal stability

The invention discloses a mesoporous catalyst with hydro-thermal stability. The catalyst is prepared by subjecting a mixture containing a dual-template, an active metal salt and a silicon source to one-step hydrothermal crystallization under a sealed condition so as to introduce the metal to a mesoporous molecular sieve SBA-15, wherein the active metal is one or more of Pt, Pd, Zr, Ru, Ni, Co and Mo. The invention also discloses a method of catalyzing microalgae hydrothermal liquefaction with a mesoporous catalyst material with hydro-thermal stability to prepare bio-oil. The method includes introducing the prepared mesoporous catalyst material with hydro-thermal stability into a process of preparing the bio-oil through the microalgae hydrothermal liquefaction. After the bio-oil prepared by liquefaction is separated and purified, the liquefaction product mainly comprises furfural and furfural derivatives.

Owner:TSINGHUA UNIV

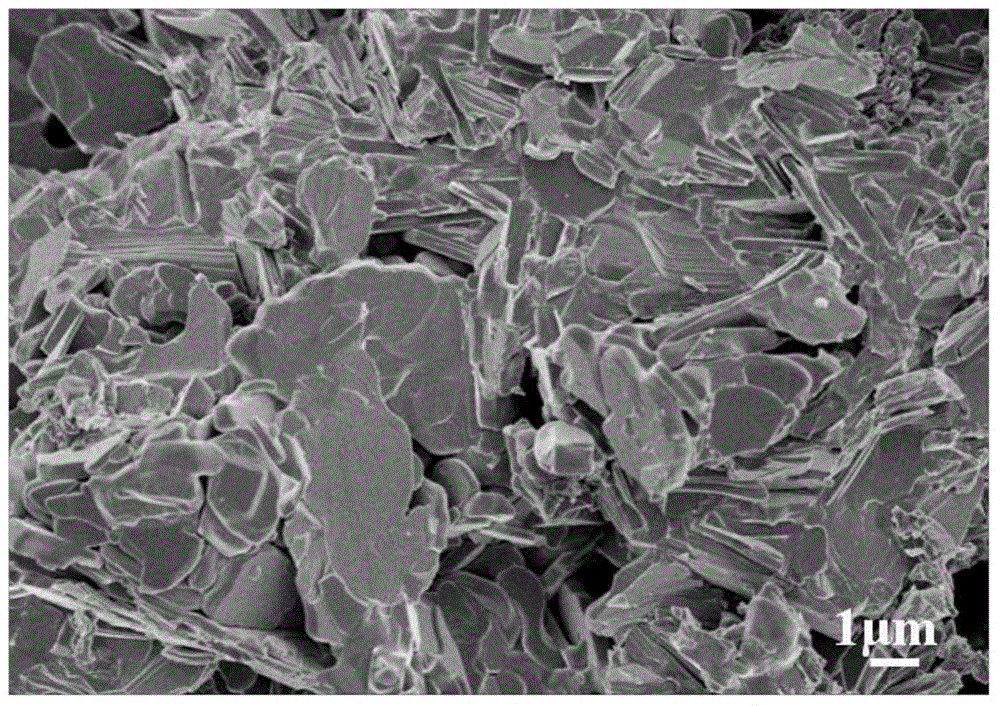

Preparation method and application of ZnO/TiO2 composite powder

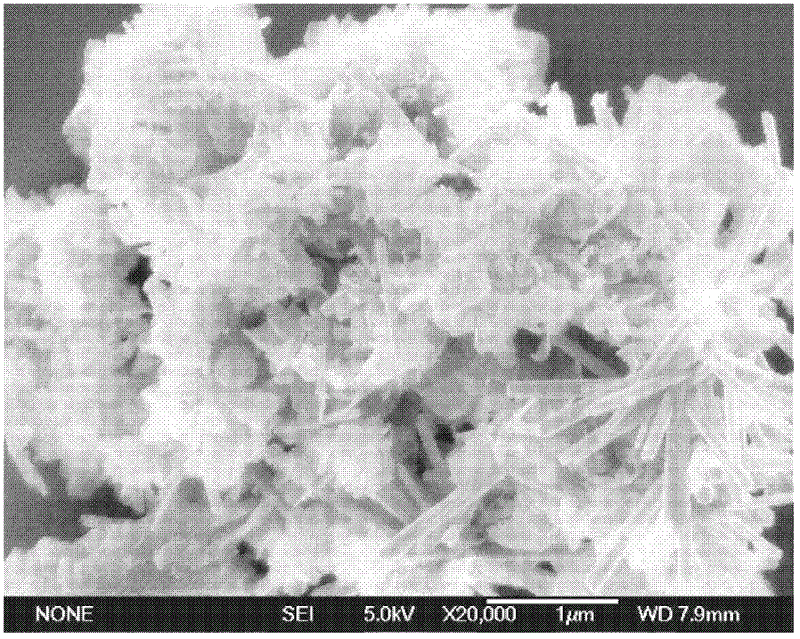

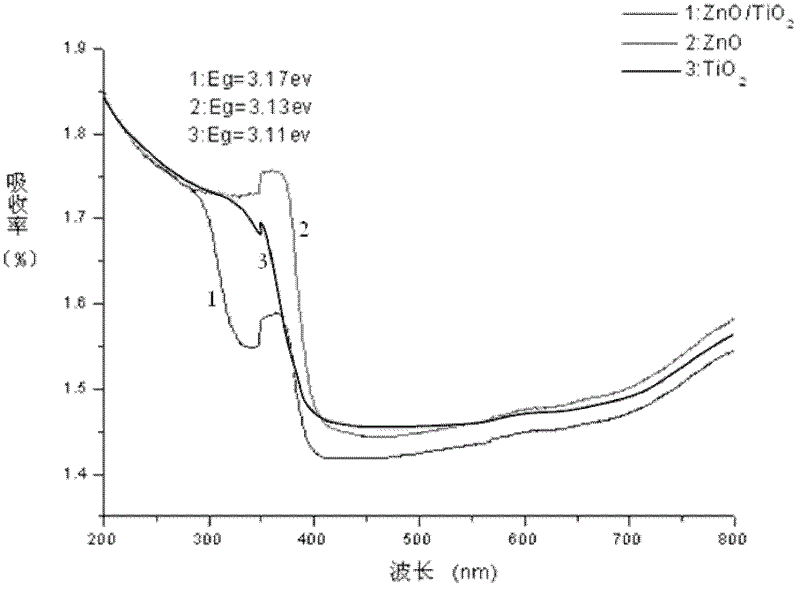

ActiveCN102618109ALower temperature conditionsGood controllabilityAntifouling/underwater paintsPaints with biocidesChemistryLacquer

The invention discloses a preparation method and application of ZnO / TiO2 composite powder. The preparation method comprises the following steps: dissolving soluble a zinc salt, a surfactant and butyl titanate in alcohol, and mixing to obtain a raw material liquid; adding a strong base aqueous solution to the raw material liquid under the stirring condition to obtain a mixed liquid; and reacting the mixed liquid at 120-180 DEG C for 8-16h, washing and drying to obtain the ZnO / TiO2 composite powder. The preparation method is relatively low in temperature conditions, good in controllability, simple in preparation and strong in operability, is favorable to industrialized popularization and production, and has wide application prospects. The obtained ZnO / TiO2 composite powder is complete in crystallization, small in original granularity, uniform in distribution and low in agglomeration, and is particularly suitable to be used as an additive for an automobile paint to be applied to the automobile paint, so that the automobile finish coat has the advantages of being plump in lacquer film, level and bright, strong in adhesion force, high in hardness, good in light retention rate, excellent in natural solarization performance and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

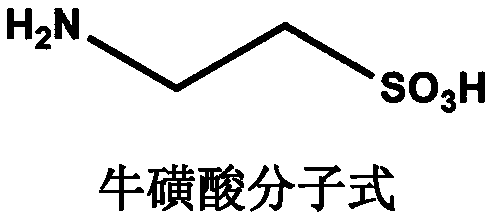

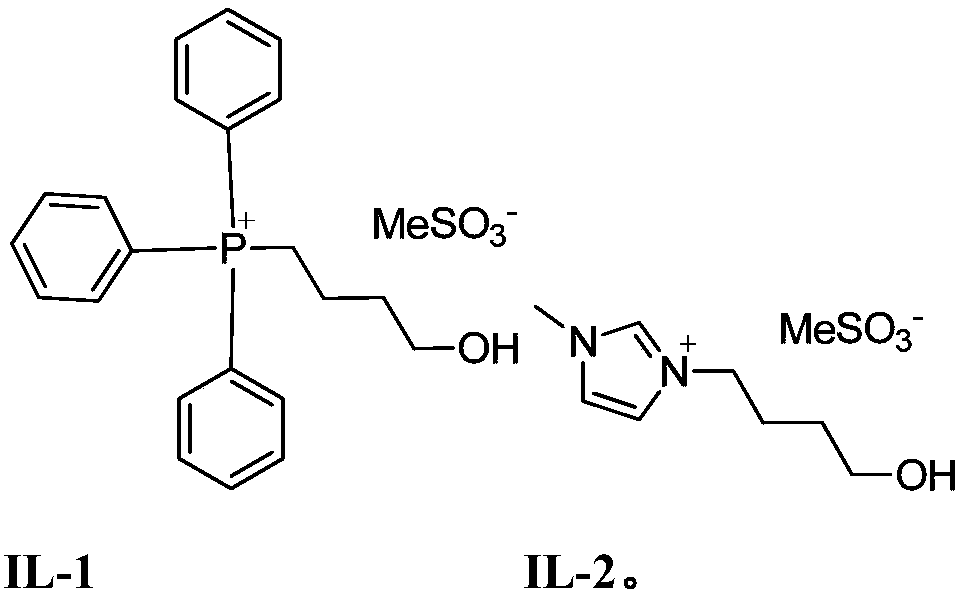

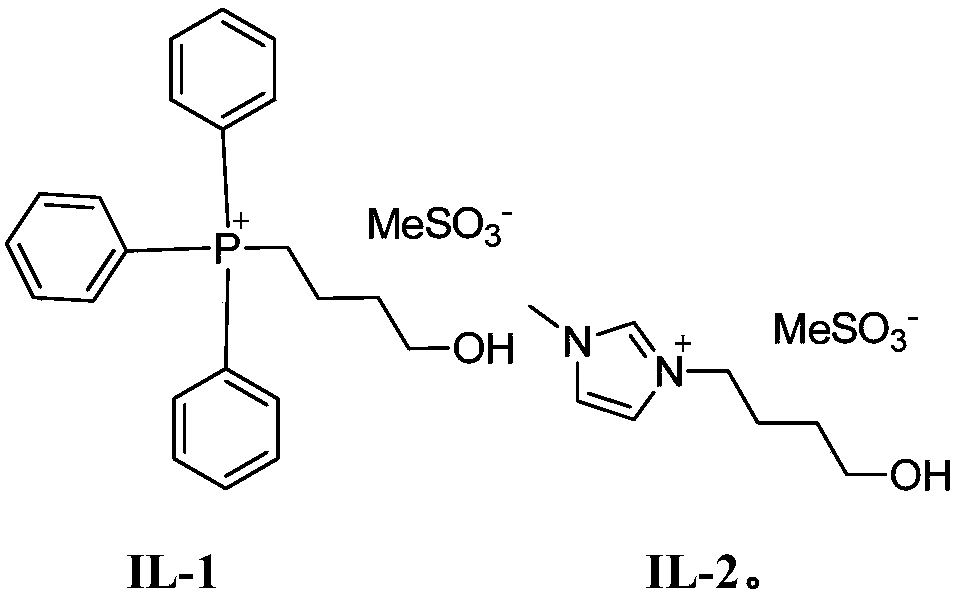

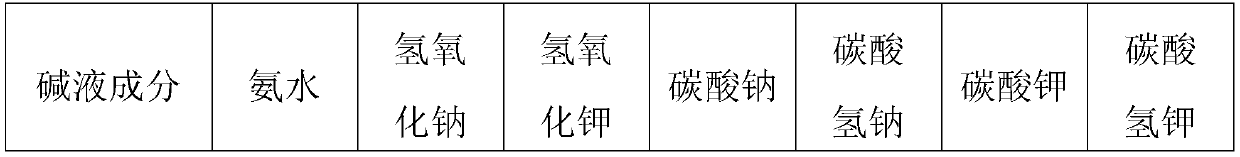

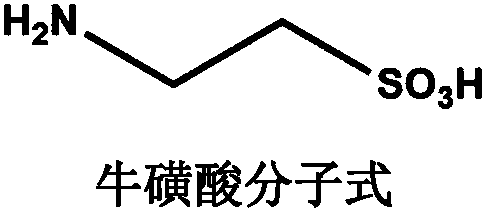

Method for preparing taurine from sodium hydroxyethyl sulfonate

InactiveCN109535043AEasy to removePromote offenseSulfonic acids salts preparationSulfonic acid preparationTaurineAmmonia

The invention provides a method for preparing taurine from sodium hydroxyethyl sulfonate. An ionic liquid homogeneous catalyst is adopted to catalyze an ammonolysis reaction of sodium hydroxyethyl sulfonate, and then steps of neutralization, crystallization separation and the like are carried out to obtain the finished taurine. Compared with a conventional alkaline catalyst, the ionic liquid homogeneous catalyst adopted in the process can significantly reduce the temperature and pressure of the ammonolysis reaction of the sodium hydroxyethyl sulfonate, so that the reaction time is shortened, and industrial production is facilitated.

Owner:WANHUA CHEM GRP CO LTD

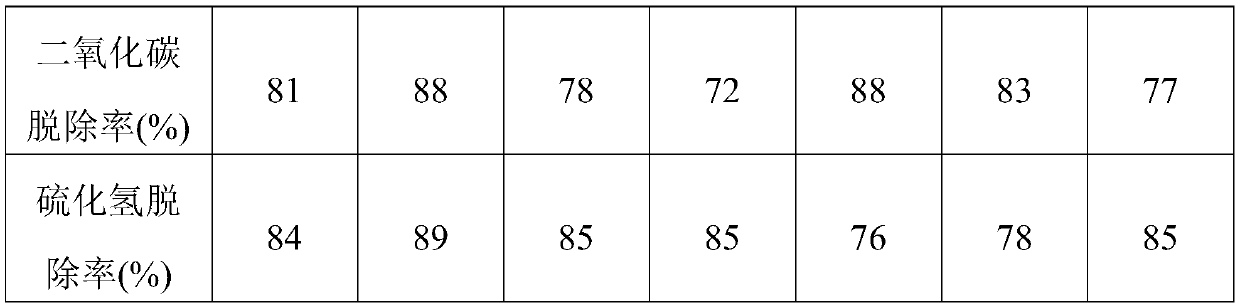

Composite adsorbent for biogas desulfurization and decarburization as well as preparation method and application of the composite adsorbent

InactiveCN111569821AHigh removal rateIncrease concentrationOther chemical processesGaseous fuelsSorbentPhysical chemistry

The invention discloses a composite adsorbent for biogas desulfurization and decarburization as well as a preparation method and application of the composite adsorbent, and belongs to the technical field of biogas impurity removal and purification. A metal oxide additive is loaded in the multi-layered pore structure of an alkaline oxide solid waste carrier subjected to negative pressure degassing,and metal oxide and alkaline oxide solid waste can synergistically play the roles of desulfurization and decarburization, so that the removal rate of CO2 and H2S can be effectively improved, and theconcentration of a prepared biomass natural gas product is improved. With the composite adsorbent as well as the preparation method and the application of the composite adsorbent adopted, the utilization rate of the basic oxide solid waste can be improved; the activity and capacity of the composite desulfurization and decarburization adsorbent can be improved; the service life of the composite desulfurization and decarburization adsorbent can be prolonged; the reaction rate can be accelerated; carbon dioxide and hydrogen sulfide in biogas can be simultaneously removed; and an efficient and low-cost biogas purification technology is provided.

Owner:CHINA HUANENG GRP CO LTD +1

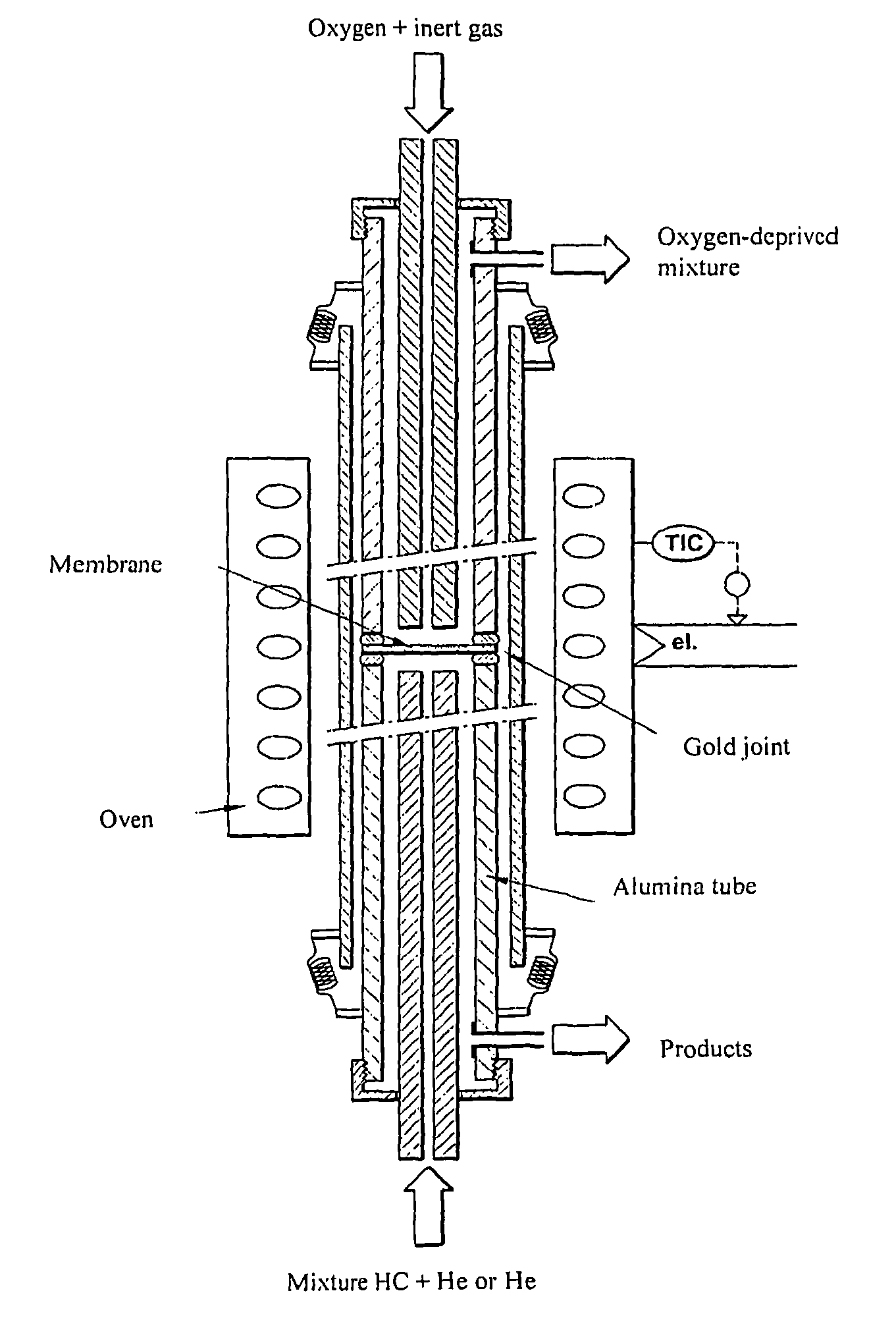

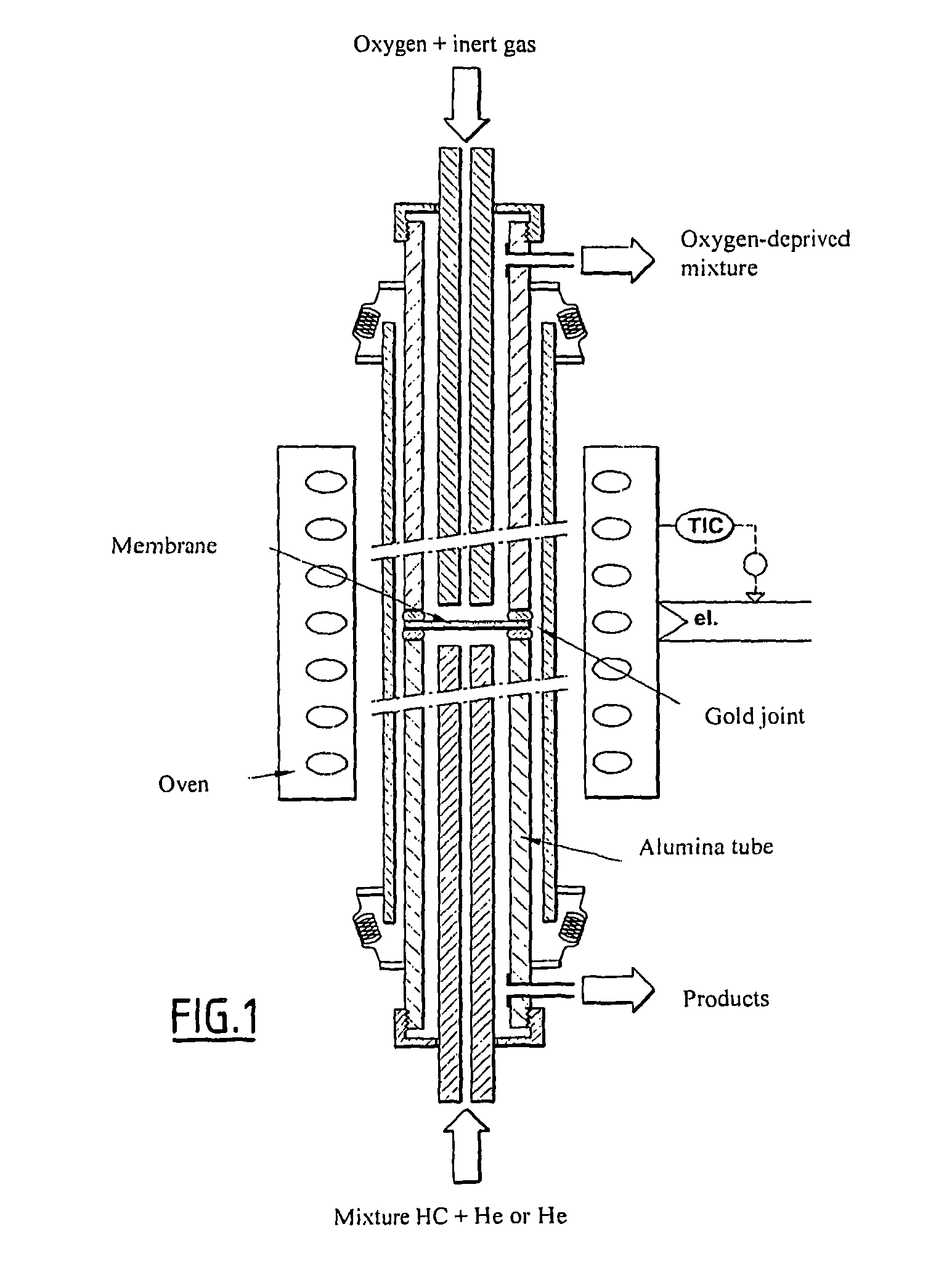

Oxygen conducting membranes, preparation method thereof, and reactor and method using same

InactiveUS7893002B2Low yieldSpecific yieldSludge treatmentIsotope separationOxygenMedicinal chemistry

Owner:CENT NAT DE LA RECHERCHE SCI

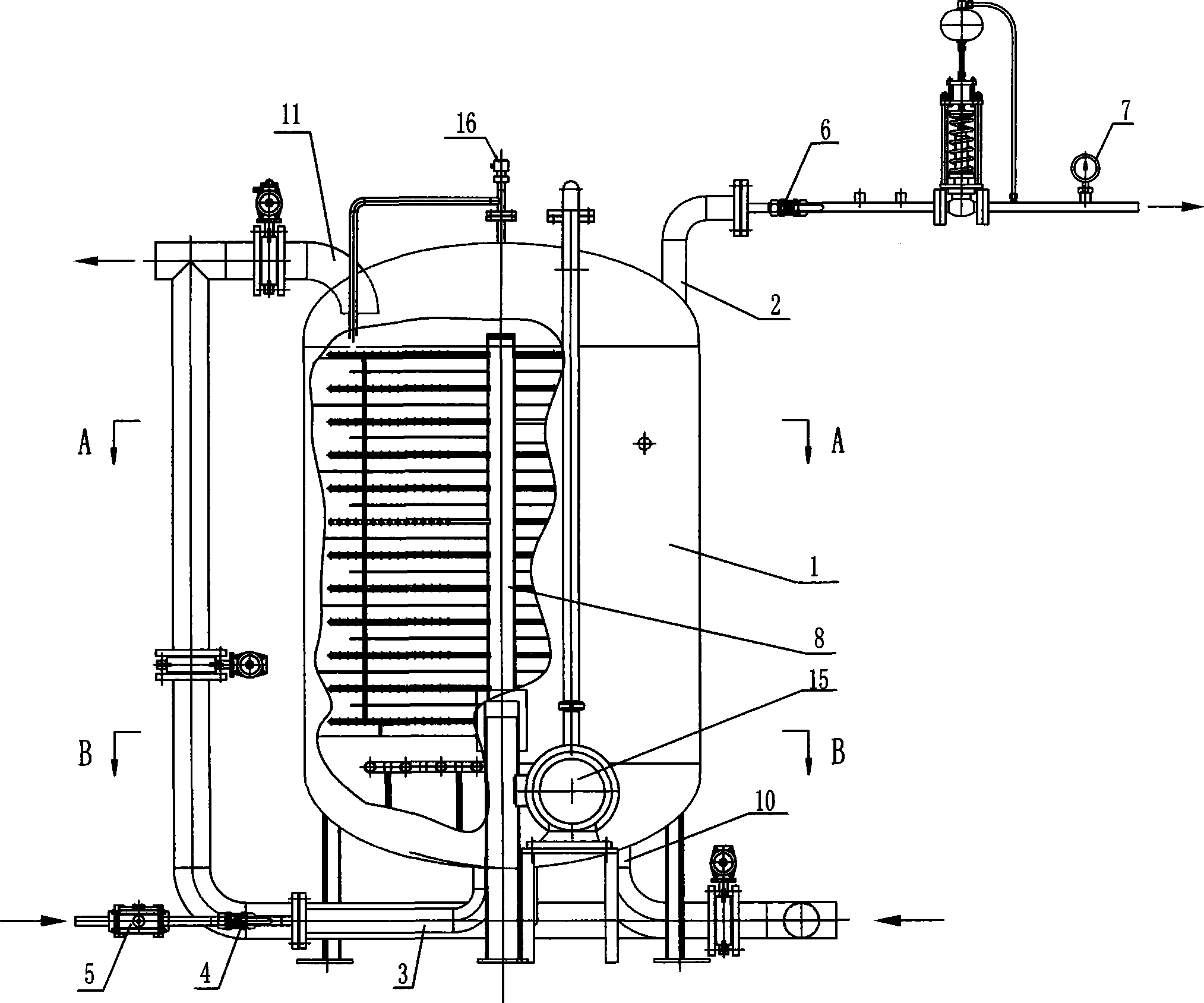

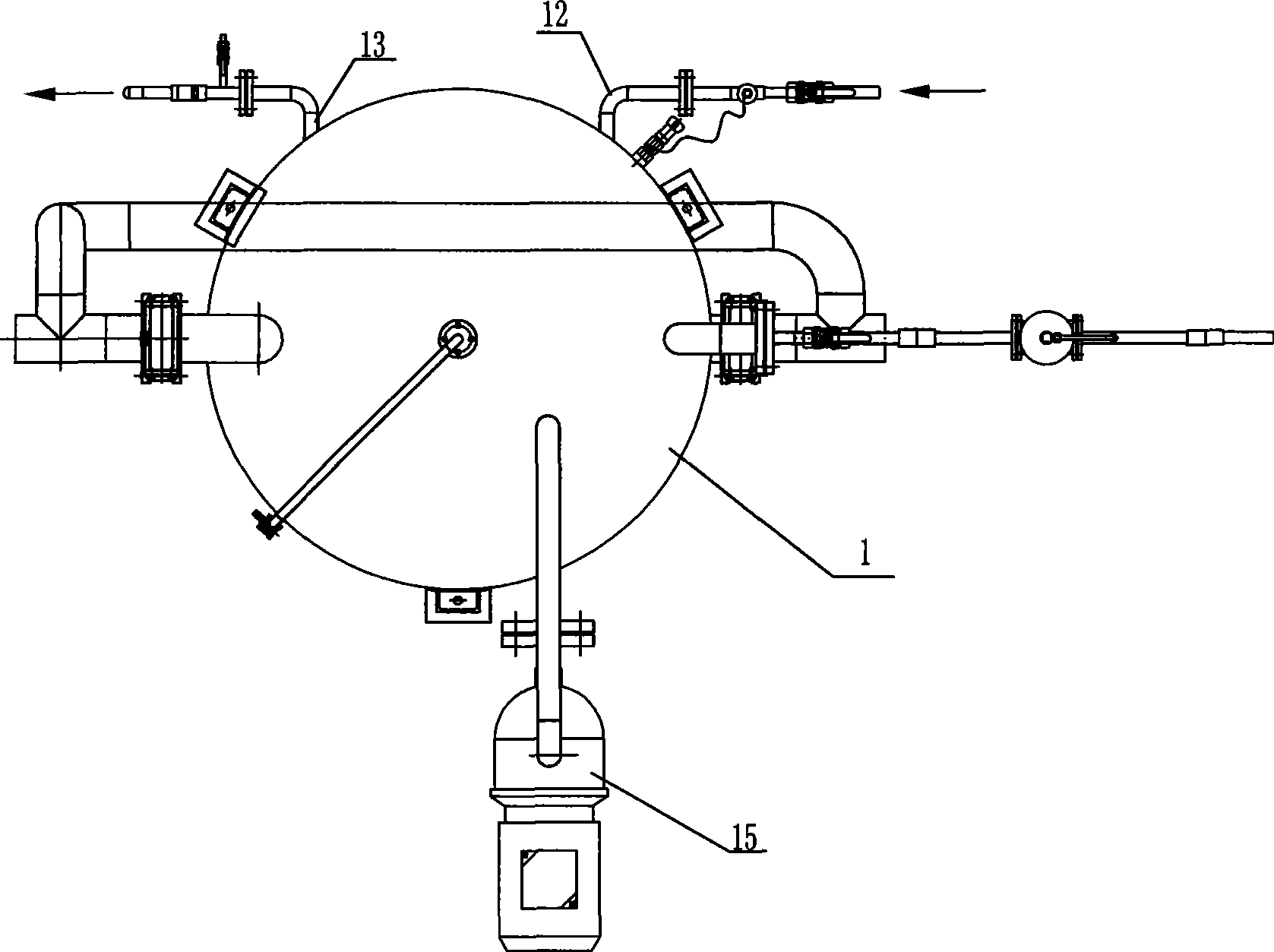

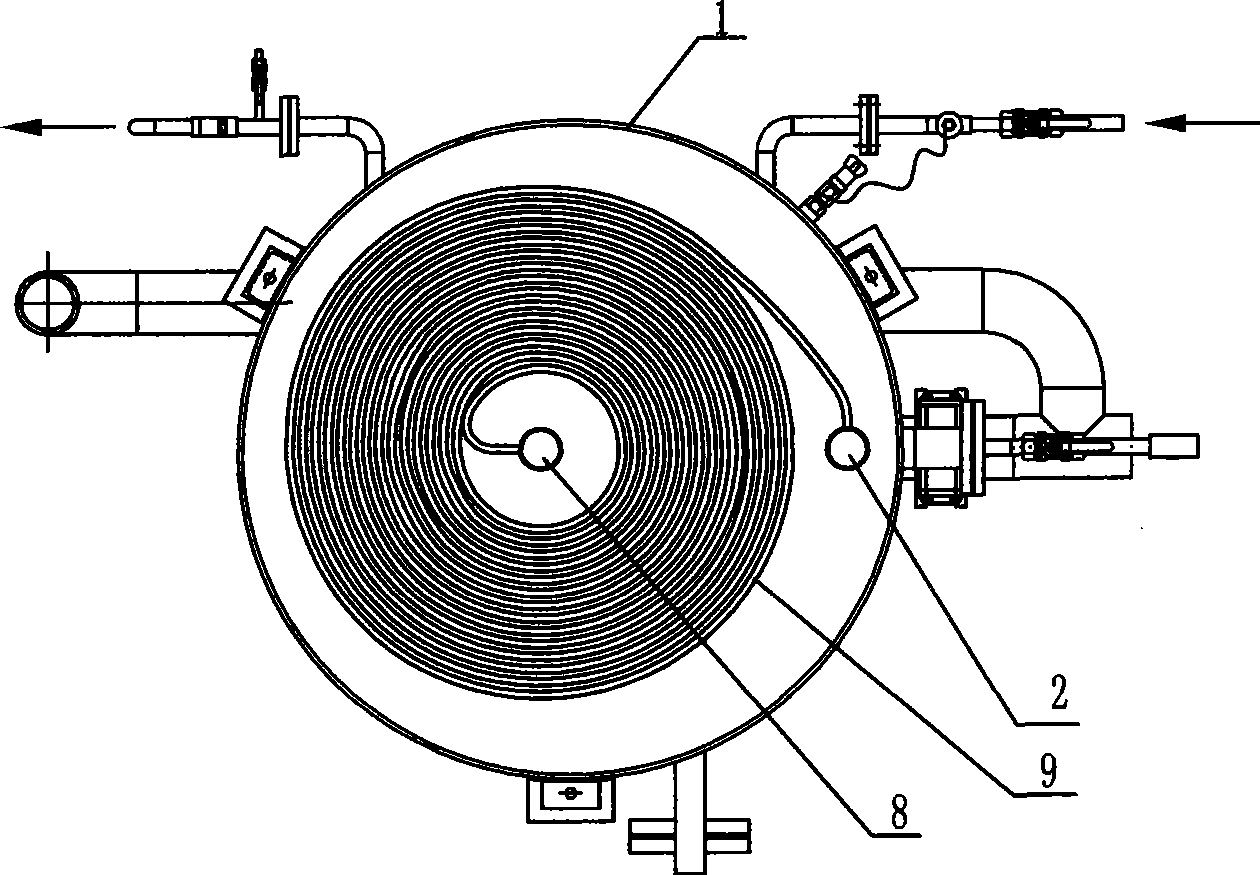

Water-bath type carbon dioxide carburettors

InactiveCN101481641AMeet production requirementsPure tasteContainer filling methodsPressure vesselsWater bathsBeer manufacturer

A water bath type carbon dioxide vaporizer relates to the technical field of the structure a heat exchange tank. A carbon dioxide air outlet pipe and a carbon dioxide liquid inlet pipe are respectively connected at the upper and the lower ends of the tank body, a main pipeline is vertically arranged in the tank body, the upper end of the main pipeline is a closed end, and the lower end thereof id connected with the carbon dioxide liquid inlet pipe; coil pipes are evenly arranged along the length direction of the main pipeline, one end of the coil pipe is communicated with the main pipeline, and the other end thereof is connected with the carbon dioxide air outlet pipe; the tank body is respectively provided with a water inlet and a water outlet which are communicated with an inner cavity of the tank body, wherein, the water outlet is arranged higher than the water inlet; the tank body is provided with a steam inlet and a condensed water outlet, and a steam-heating pipe is connected between the steam inlet and the condensed water outlet in the inner cavity of the tank body in a sealing way. The invention has reasonable structure, even temperature, high heat exchange benefit and obvious energy-saving effect, and is in accordance with the production requirements of beer manufacturer; the prepared beer has pure taste and sufficient air content.

Owner:YANGZHOU RUNMING LIGHT IND MACHINERY

Method for preparing taurine

InactiveCN109485586ALow process conditionsReduce generationSulfonic acids salts preparationSulfonic acid preparationHydrogenEthylene oxide

The invention provides a method for preparing taurine. The method comprises the following steps: carrying out an addition reaction on ethylene oxide and sodium hydrogen sulfite in the presence of a heterogeneous catalyst so as to obtain sodium hydroxyethyl sulfonate at high selectivity; carrying out an ammonolysis reaction on the synthesized sodium hydroxyethyl sulfonate under catalysis of a homogeneous catalyst; and neutralizing, crystallizing, separating and the like, thereby obtaining the finished taurine. Compared with the traditional production process, the process disclosed by the invention has the advantages that by-products in the addition reaction process can be obviously reduced, the temperature and pressure of the ammonolysis reaction are reduced, the reaction time is shortened,and industrial production is easily realized.

Owner:WANHUA CHEM GRP CO LTD

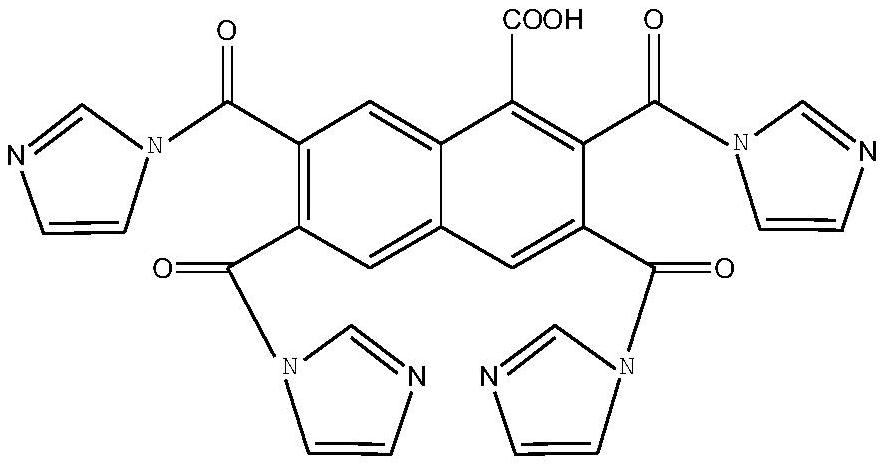

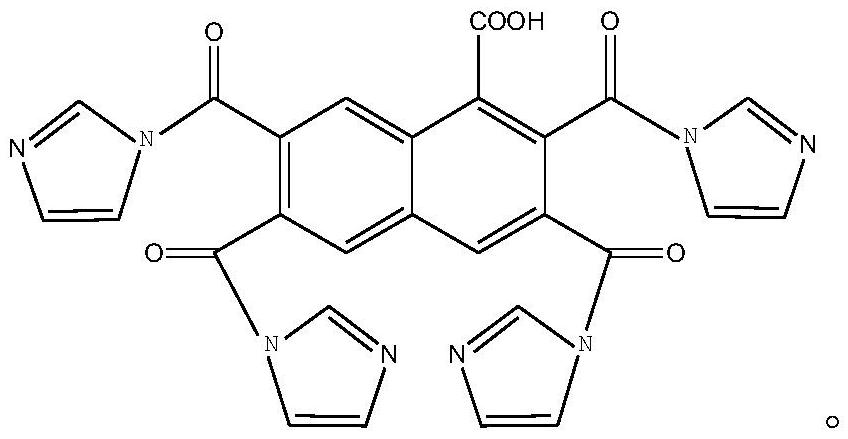

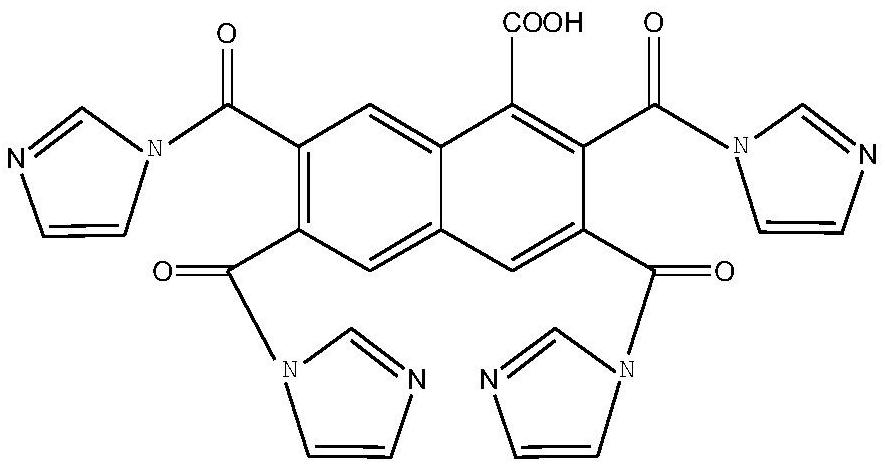

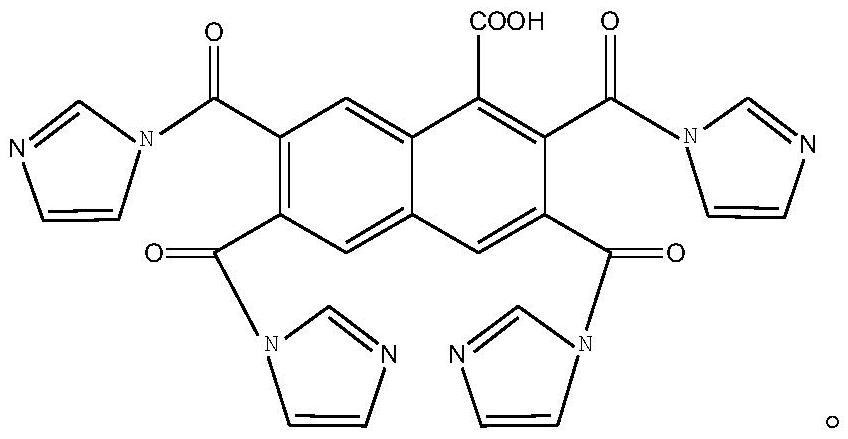

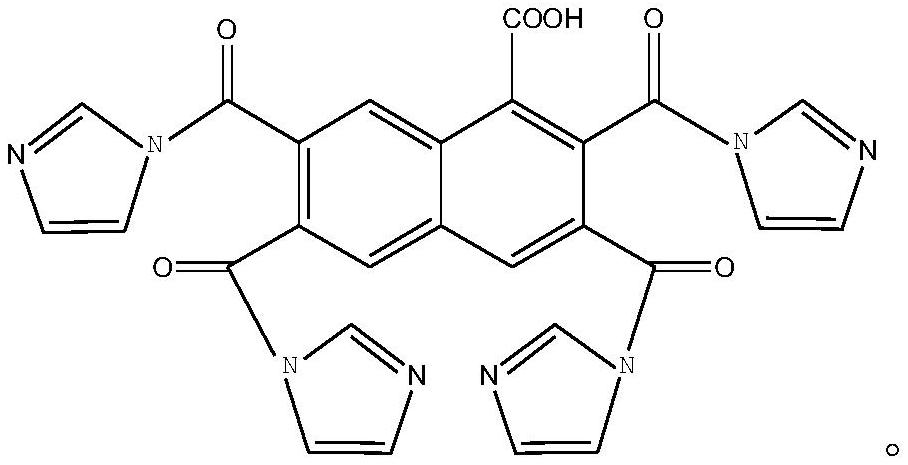

Naphthyl ligand MOF activated carbon composite catalyst and preparation method and application thereof

ActiveCN111905828AReduce vacuumLower temperature conditionsOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsActivated carbonPtru catalyst

The invention provides a naphthyl ligand MOF composite activated carbon catalyst and a method for preparing high-purity lactide from Llactic acid by using the naphthyl ligand MOF composite activated carbon catalyst, which are characterized in that a polymerization reaction of Llactic acid is catalyzed by using an MOF organic metal framework activated carbon composite catalyst, metal elements are used as active components, and 2, 3, 6, 7tetraformyl imidazolyl alpha naphthoic acid is used as an MOF catalyst ligand. Activated carbon is used as carrier. Raw material of the catalyst has the advantages of cheap raw materials, high thermal stability, certain acid resistance, is not easily decomposed under low pressure and easily made. The catalyst has good catalytic activity. The application of the catalyst in synthesis of lactide can greatly reduce vacuum degree required by the process, yield of lactide is increased and industrial cost is reduced. The invention has certain potential in industrial application.

Owner:WANHUA CHEM GRP CO LTD

Hydrogel composition for masking pack containing water-soluble polyurethane

ActiveCN105456056AIncrease elasticityImprove ventilationCosmetic preparationsToilet preparationsPolyolPlasticizer

The present invention relates to a hydrogel composition and, more specifically, to a hydrogel composition having improved elasticity and air permeability by including water-soluble polyurethane. Based on the total weight of the hydrogel composition, the hydrogel composition comprises 0.01 to 5.0 wt% of water-soluble polyurethane; 0.4 to 5.0 wt% of a natural polymer gelating agent; 1.0 to 60.0 wt% of a functional cosmetic component for imparting a skin beautifying function; 0.1 to 1.0 wt% of an electrolyte; 10.0 to 30.0 wt% of polyalcohol as a plasticizer; a preserving agent; and a solvent including other water. The hydrogel composition of the present invention is a cosmetic mask distributed after being pre-produced in a face shape or patch shape. The hydrogel composition has improved elasticity so as to be excellently adhered on the skin without an additional adhesive component, and the shape thereof can be maintained for a long time. Air permeability is improved, so that a useful component for skin can be easily transferred to the skin without concern over skin irritation.

Owner:株式会社伊思韩佛

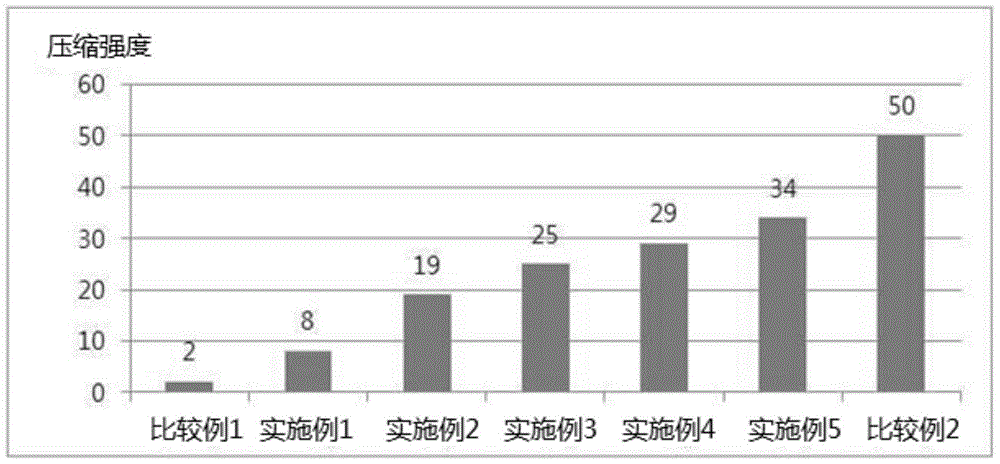

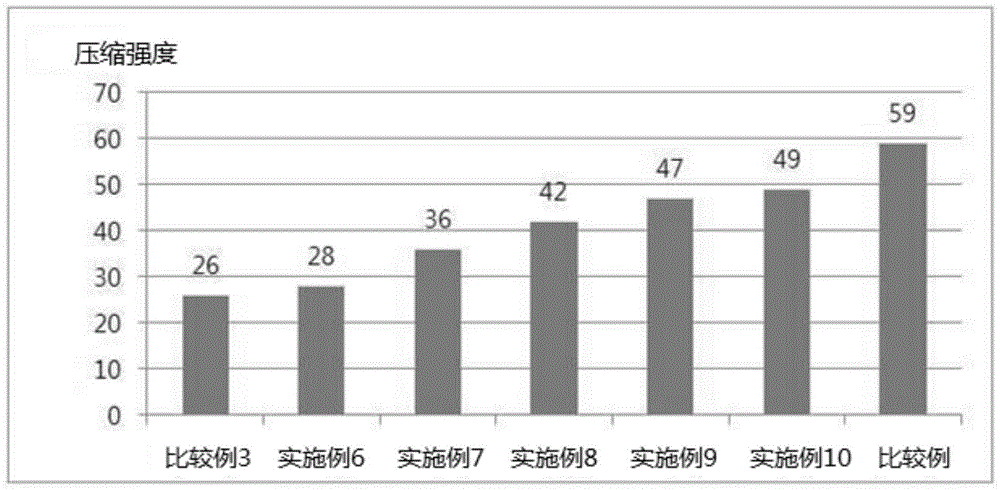

Method for preparing Ti2AlC ceramic material at low temperature

A method for preparing Ti2AlC ceramic material at the low temperature comprises steps as follows: Ti powder, Al powder and TiC powder are selected as raw materials, firstly, the raw materials are subjected to ball milling and mixing in a certain mole ratio and then are pressed to form blocks, the pre-pressed blocks are put in an air furnace to be subjected to a thermal explosion reaction, the reacted block samples are taken out and cooled to the room temperature, oxidation layers on surfaces of the samples are rubbed off, the block samples without the oxidation layers are broken and subjected to ball milling, powder is obtained, and the high-purity Ti2AlC ceramic material can be obtained after acid treatment, washing and drying. The prepared Ti2AlC ceramic material has stable technological parameters, the method is suitable for large-scale production of the Ti2AlC ceramic material, and the method has the characteristics that the process is simple, the synthesis temperature is low, the preparation time is short and the purity is high.

Owner:SHAANXI UNIV OF SCI & TECH

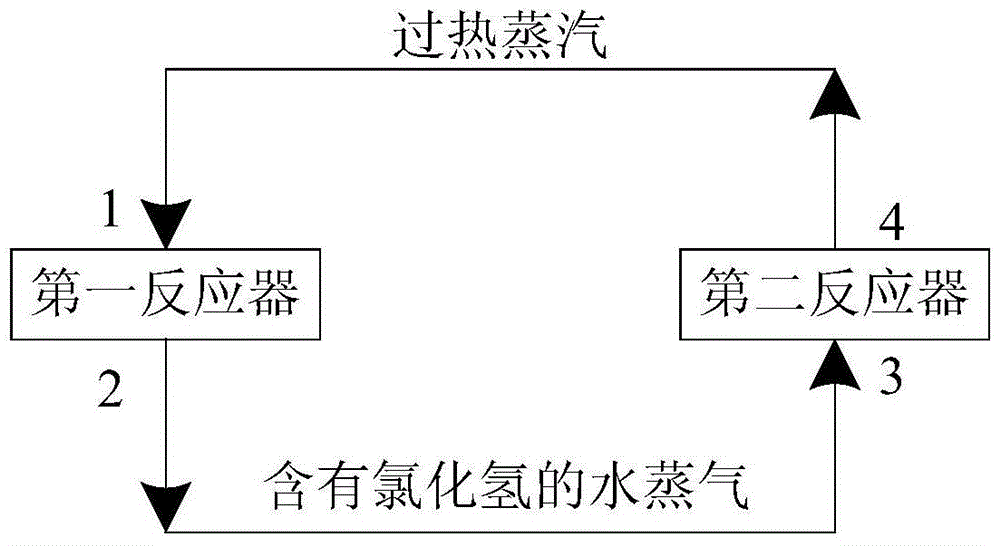

Method for joint production of potassium sulphate and calcium chloride dihydrate

ActiveCN105329920AMove quicklyLower energy requirementsCalcium/strontium/barium chloridesSulfate/bisulfate preparationCalcium Chloride HexahydrateHigh energy

The invention relates to a method for joint production of potassium sulphate and calcium chloride dihydrate. The method comprises the steps of 1, adding potassium chloride and sulfuric acid to a first reactor, and introducing superheated steam to the first reactor to generate potassium sulphate and vapor containing hydrogen chloride through reaction; 2, introducing the vapor containing hydrogen chloride to a second reactor to generate calcium chloride dihydrate and superheated steam through reaction with calcium oxide or calcium hydroxide, and circulating the superheated steam to the step 1. By the adoption of the method, high energy consumption during production of potassium sulphate and calcium chloride dihydrate is avoided, the byproduct hydrogen chloride is well utilized, and environment pollution is basically avoided.

Owner:LONGYAN ZIYUN CHEM TECH

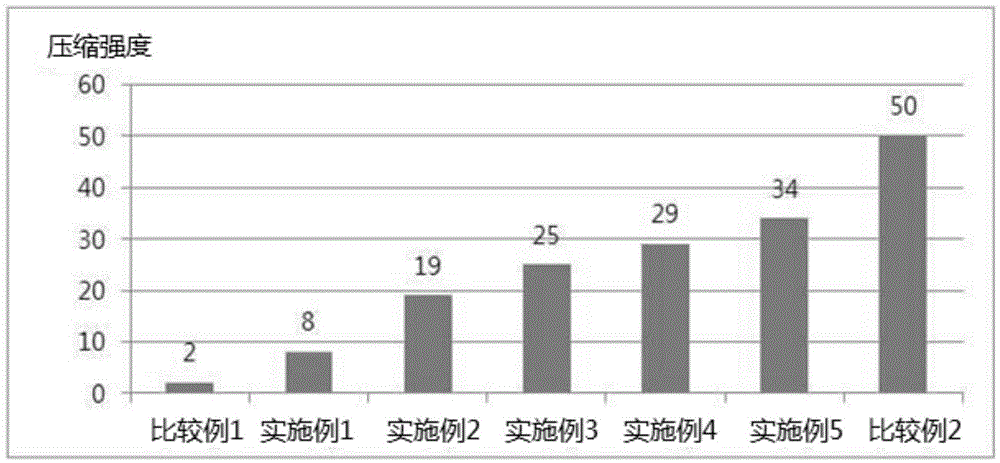

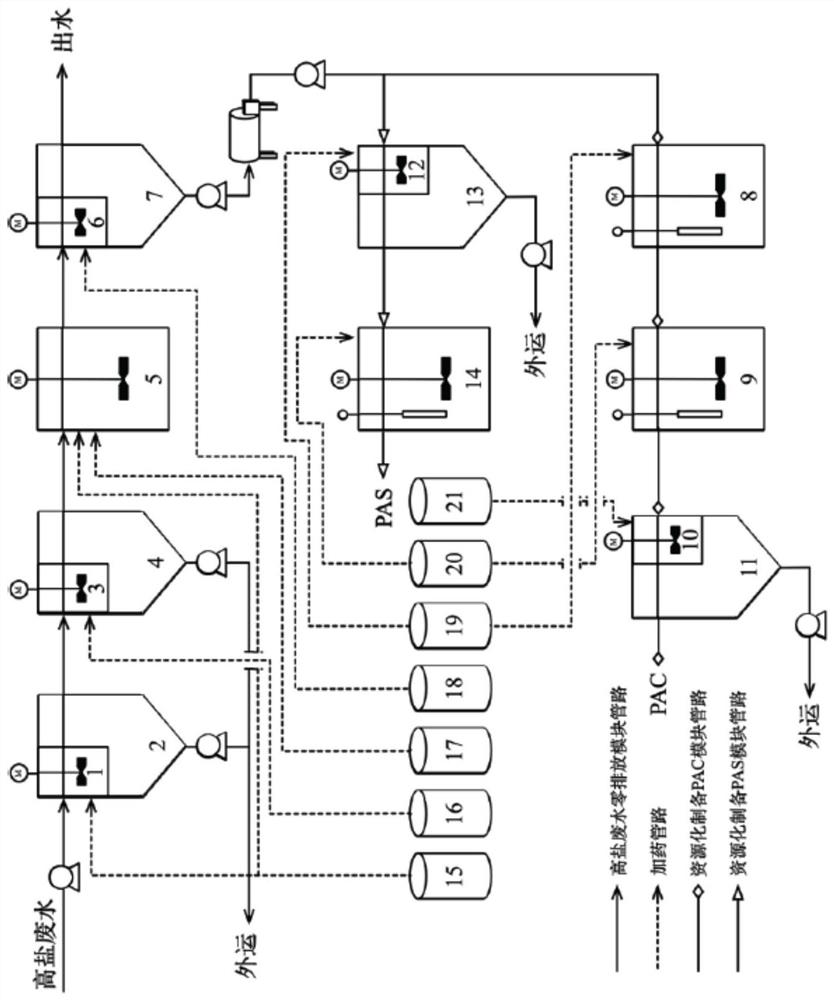

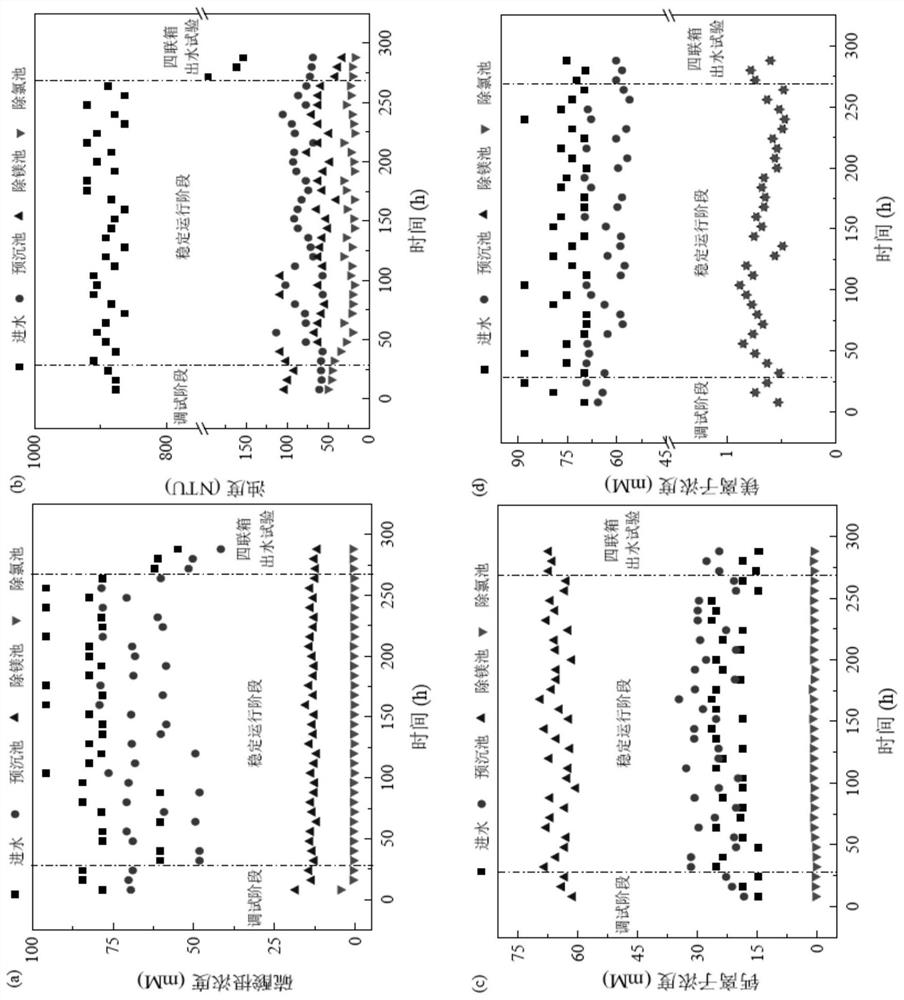

Device and process for preparing macromolecular aluminum salt coagulant by utilizing sludge of high-salinity wastewater zero discharge system

PendingCN112759143AAchieve step-by-step removalRealize classified resourcesWater contaminantsMultistage water/sewage treatmentAluminium chlorideSludge

The invention relates to a device and a process for preparing a high-molecular aluminum salt coagulant by using sludge of a high-salinity wastewater zero discharge system. Impurities in wastewater are removed in advance through optimal design of a process flow, and the content of Al2O3 in dechlorination precipitates is increased; and the dechlorination precipitate is used as a raw material to prepare a polymer aluminum salt coagulant such as PAC or polyaluminum sulfate (PAS), so that the problem of solid waste discharge is solved, and the running cost of a zero emission system is compensated at the same time. The indexes such as the mass fraction, the basicity and the heavy metal content of the prepared PAC or PAS aluminum oxide respectively meet the requirements of water treatment agent national standards of water treatment agent polyaluminum chloride (GB / T22627-2014) and water treatment agent polyaluminum sulfate (HG / T5006-2016), and the concept of solid waste recycling can be realized.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

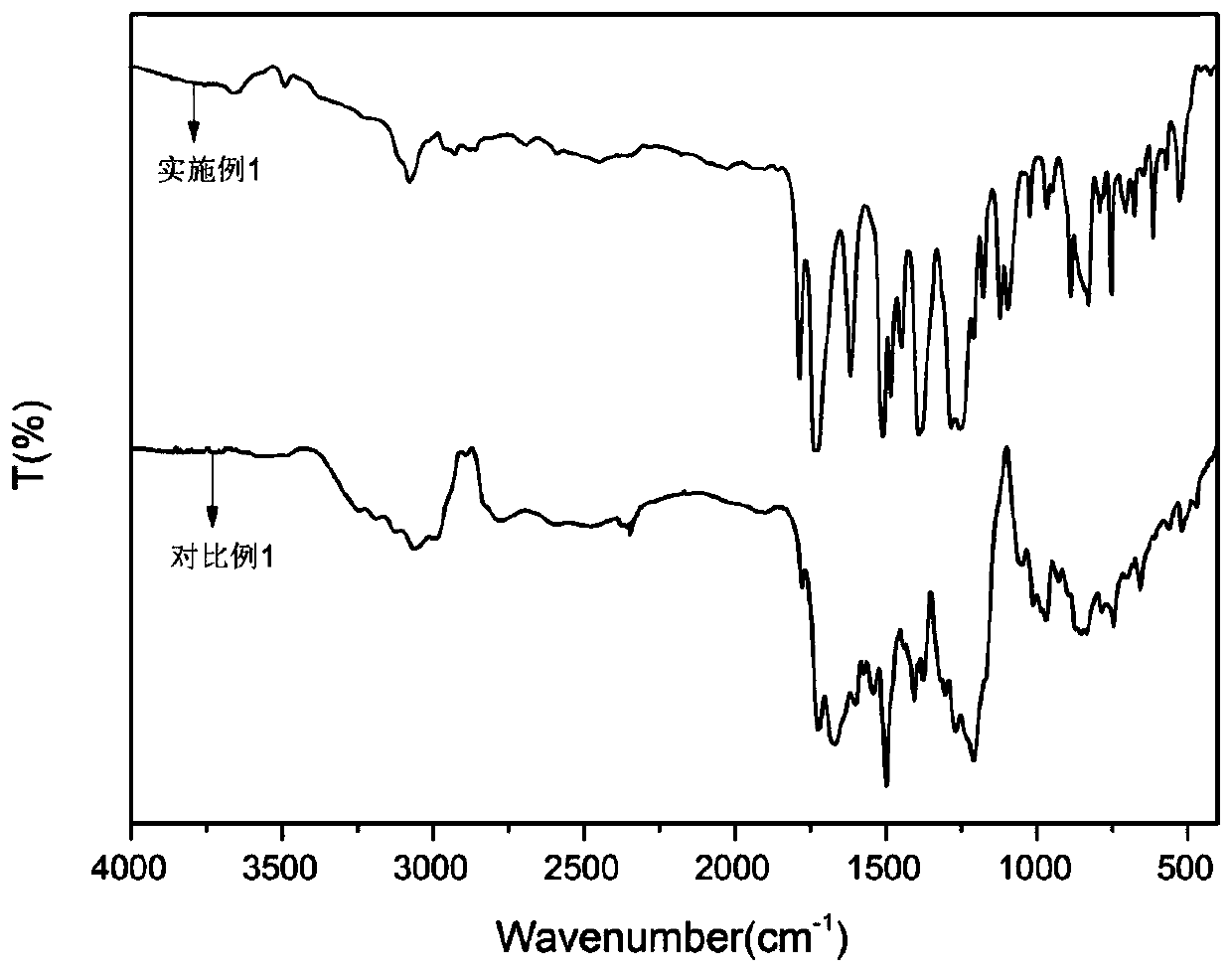

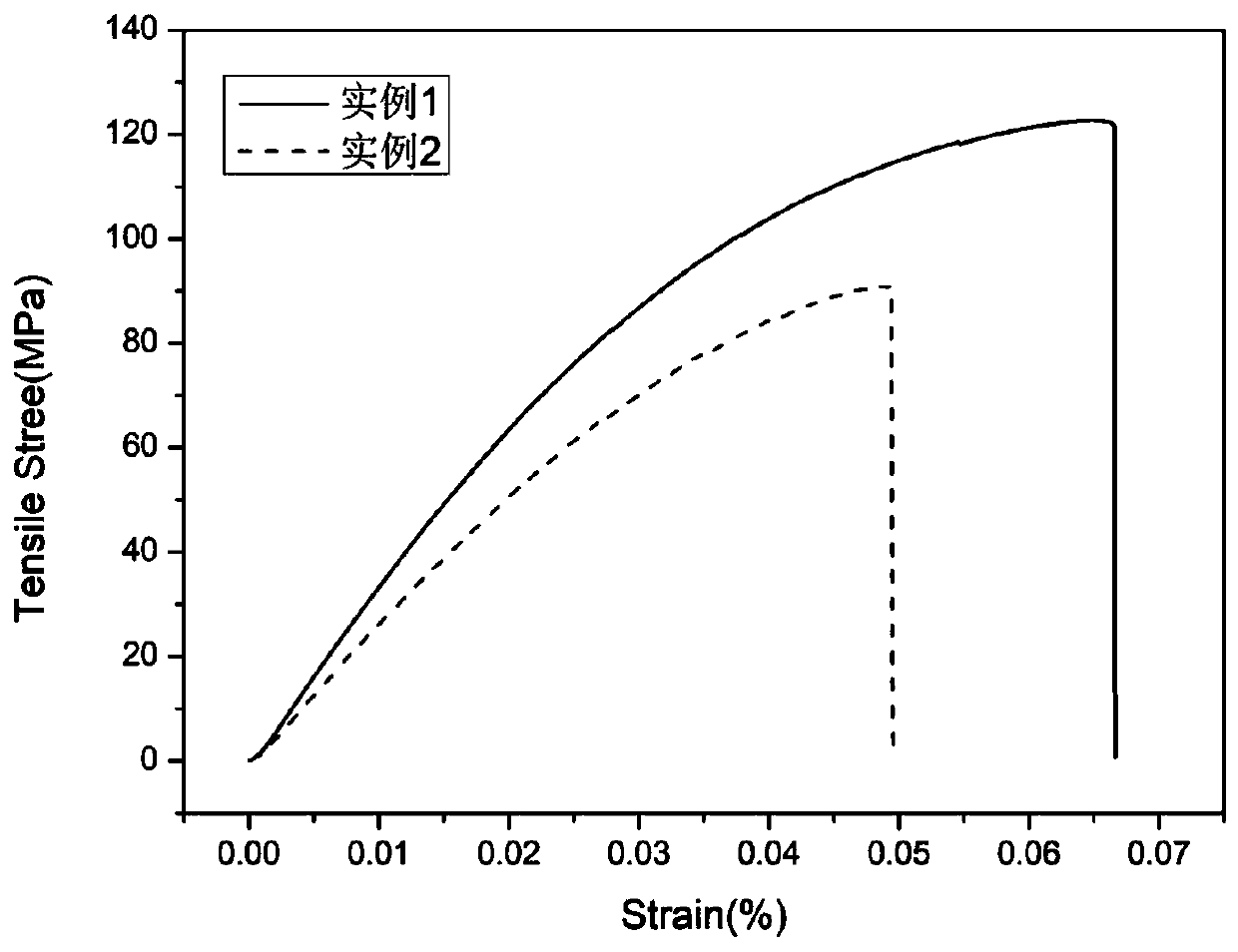

Method for preparing polyimide film by microwave radiation at low temperature

ActiveCN110358121AImproved mechanical and thermal performanceReduce energy consumptionChemistryPolyimide

The invention discloses a method for preparing a polyimide film by microwave radiation at a low temperature. The method comprises the following steps: 1, preparing a polyimide precursor solution to obtain a product A; 2, performing microwave radiation on the product A to obtain a product B; 3, carrying out film spreading treatment on the product B to obtain a product C; 4, heating the product C toobtain a product D; and 5, imidizing the product D by adopting low-temperature microwave radiation at 60-100 DEG C to obtain the finished film. The method can realize the low-temperature complete imidization of the polyimide film only by a low-temperature microwave radiation technology on the premise of not changing or even improving the mechanical and thermal properties of the polyimide film inorder to obtain the polyimide film having excellent performances. The method has the characteristics of facilitation of large-scale production, and ensuring of the performances of the polyimide film.

Owner:HARBIN ENG UNIV

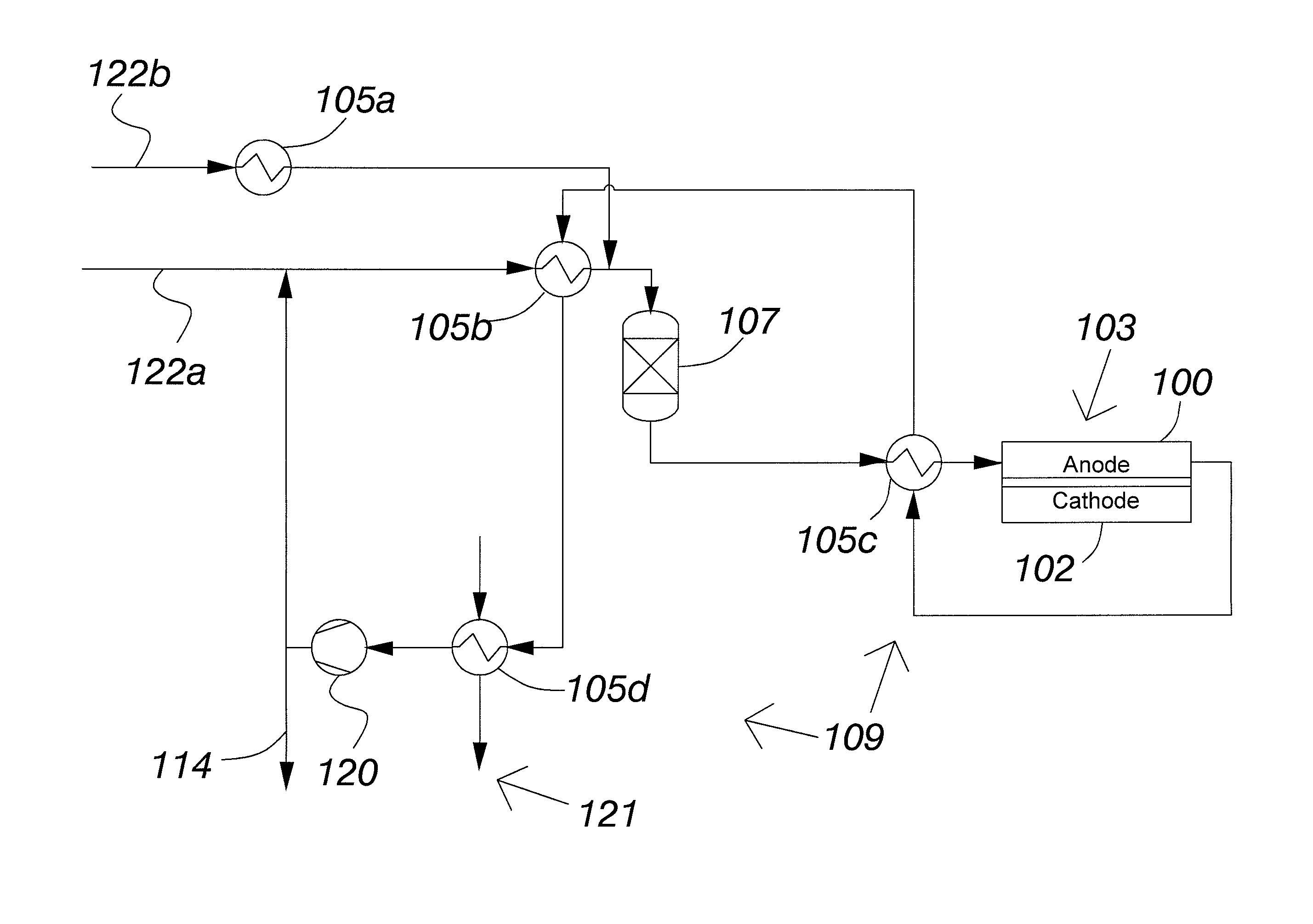

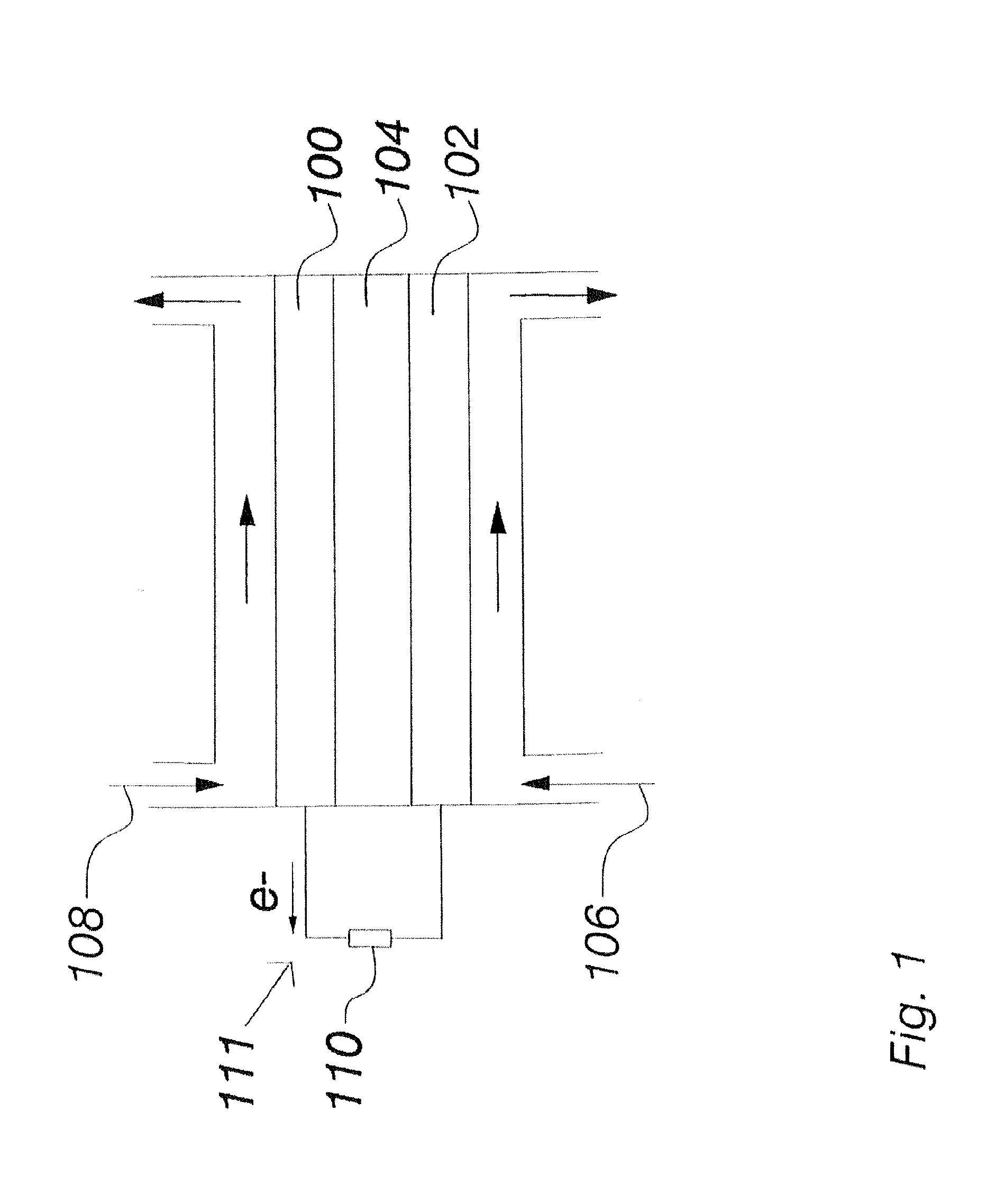

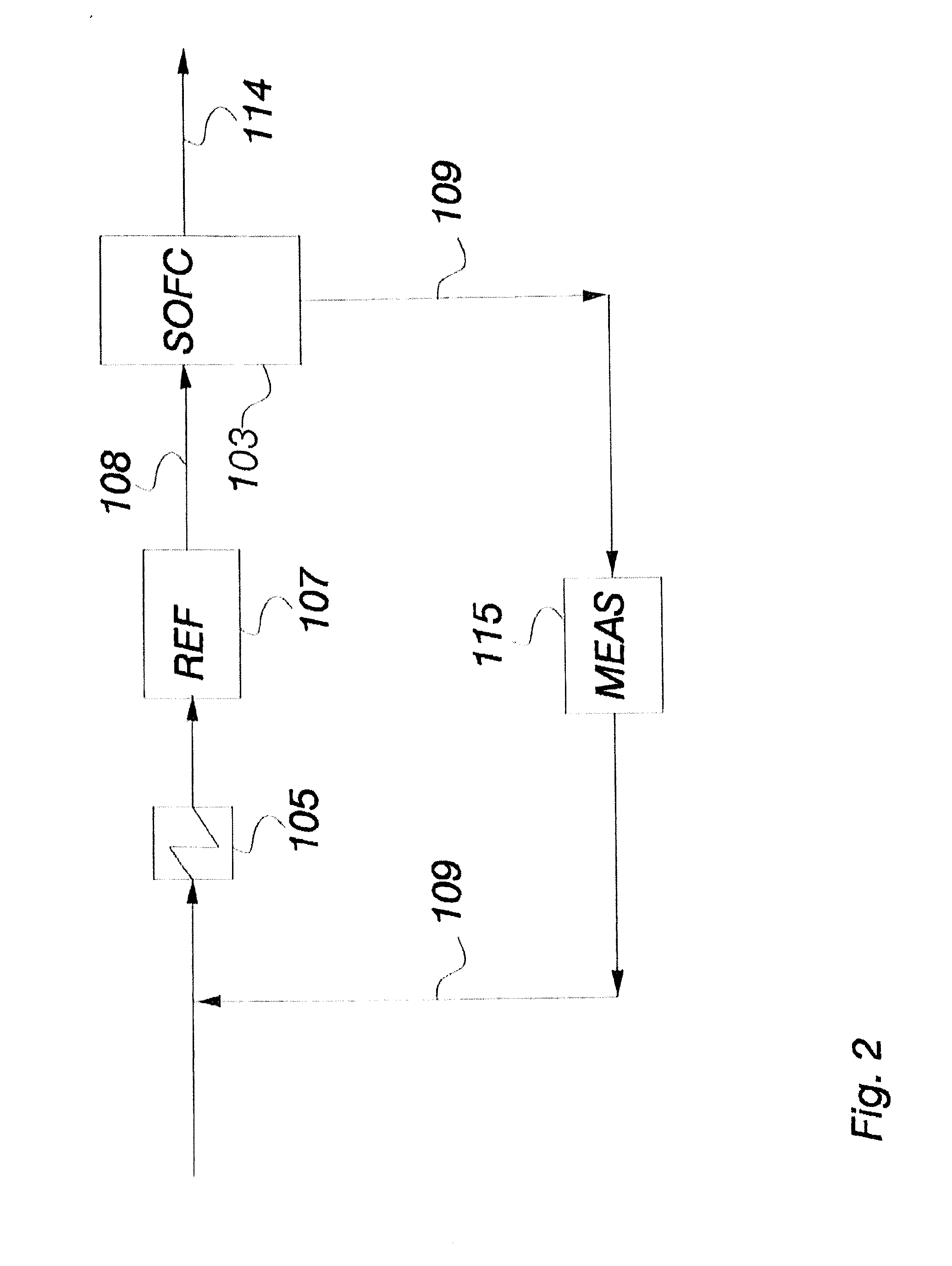

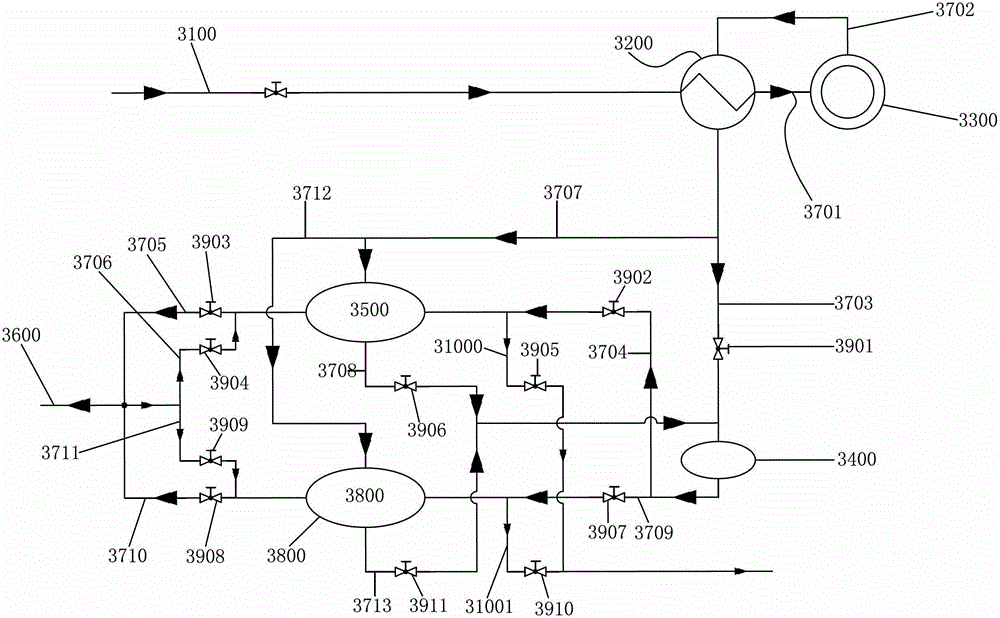

Method and arrangement for utilizing recirculation for high temperature fuel cell system

InactiveUS20150147665A1Lower temperature conditionsReduce the amount of solutionFuel cell heat exchangeSolid electrolyte fuel cellsFuel cellsPartial oxidation

An arrangement utilizing recirculation for high temperature fuel cell system, each fuel cell including an anode side, a cathode side, and an electrolyte between the anode side and the cathode side, wherein the fuel cell system can perform anode side recirculation flow of reactants. The arrangement can accomplish a recycle ratio of 70% or more for the recirculation flow, feed to the recirculation a feed-in flow, which can include substantially high oxygen content, the feed-in flow being 30% or less of entire flow, perform heat exchanging to provide substantially reduced low temperature conditions in the recirculation flow, perform catalytic partial oxidation in the recirculation flow to produce a substantially high amount of hydrogen for the recirculation flow in fuel cell system start-up or shutdown situations, and exhaust 30% or less of the entire flow from the anode side recirculation.

Owner:CONVION OY

Method for synthesizing artificial bone from carboxylic apatite of coral

InactiveCN1462638APromote healingHigh compressive strengthPhosphorus compoundsProsthesisPorosityApatite

An artificial coral hydroxy apatitis (CHA) bone for medical purpose is prepared from coral through hydrothermal reaction in the diammonium hydrogen phosphate plus hydrothermal liquid system under high-temp and high-pressure condition to convert the CaCO3 of coral to Ca5(PO4)3(OH) which is just the artificial bone. Its advantages are high compression strength, high porosity (24.86-65.71%), no toxic by-effect and good biologic compatibility.

Owner:SUN YAT SEN UNIV

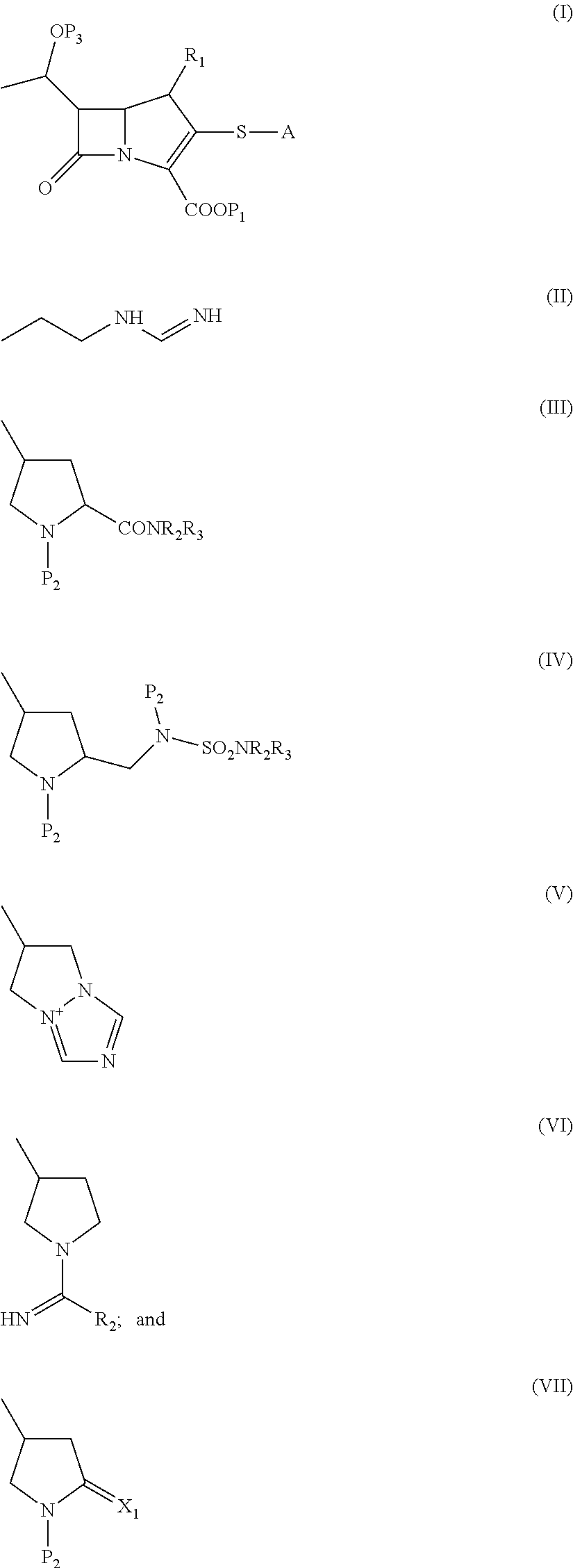

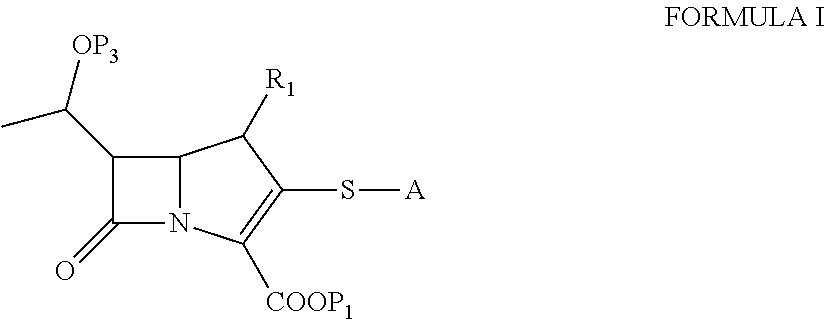

Process for the preparation of carbapenem compounds

InactiveUS20110224426A1Reduce necessityMinimize formationOrganic active ingredientsOrganic chemistryArylHydrogen

The present invention relates to a process for the preparation of carbapenem compound of Formula (I), wherein P1 is hydrogen or a carboxyl protecting group, P3 is hydrogen or a hydroxyl protecting group, R1 is C1-3 alkyl, and A is selected from a group consisting of a) Formula (II), b) Formula (III), c) Formula (IV), d) Formula (V), e) Formula (VI), f) Formula (VII), wherein P2 is hydrogen or an amino protecting group, R2 and R3 may be same or different and are hydrogen, C1-5 alkyl, optionally substituted aryl, or optionally substituted heteroaryl, and X1 is O or S, or its stereoisomers, or salts thereof.

Owner:RANBAXY LAB LTD

Anti-scale water cooling bearing bush

InactiveCN108825666AReduce the temperatureAchieve anti-scaling functionBearing coolingCooling effectEngineering

The invention relates to an anti-scale water cooling bearing bush. The anti-scale water cooling bearing bush comprises an upper bearing bush and a lower bearing bush fixedly connected; multiple watercooling through holes are formed in the lower bearing bush; water cooling pipes are mounted in all the water cooling through holes; the water cooling pipes comprise water cooling outer pipes whose outer walls are contacted with the inner walls of the water cooling through holes and whose two ends extend out of the water cooling through holes, and water cooling inner pipes arranged in the water cooling outer pipes and whose two ends extend out of the water cooling outer pipes; sealing bodies are arranged between the inner walls of the two ends of the water cooling outer pipes and the outer walls of the water cooling inner pipes, so that the water cooling outer pipes and the water cooling inner pipes are tightly sealed to form first runners; water inlet pipes are arranged on the side walls of one ends of the water cooling outer pipes, and water outlet pipes are arranged on the side walls of the other ends; and second runners are formed in the water cooling inner pipes. Through design ofsleeves on cooling water paths, the overall temperature of cooling water is lowered, the temperature condition of separation of metal salt is weakened, the scaling prevention of the water cooling pipes is realized, and the cooling effect of the bearing bush is guaranteed.

Owner:EMEISHAN JIANNAN HYDROPOWER EQUIP MFG CO LTD

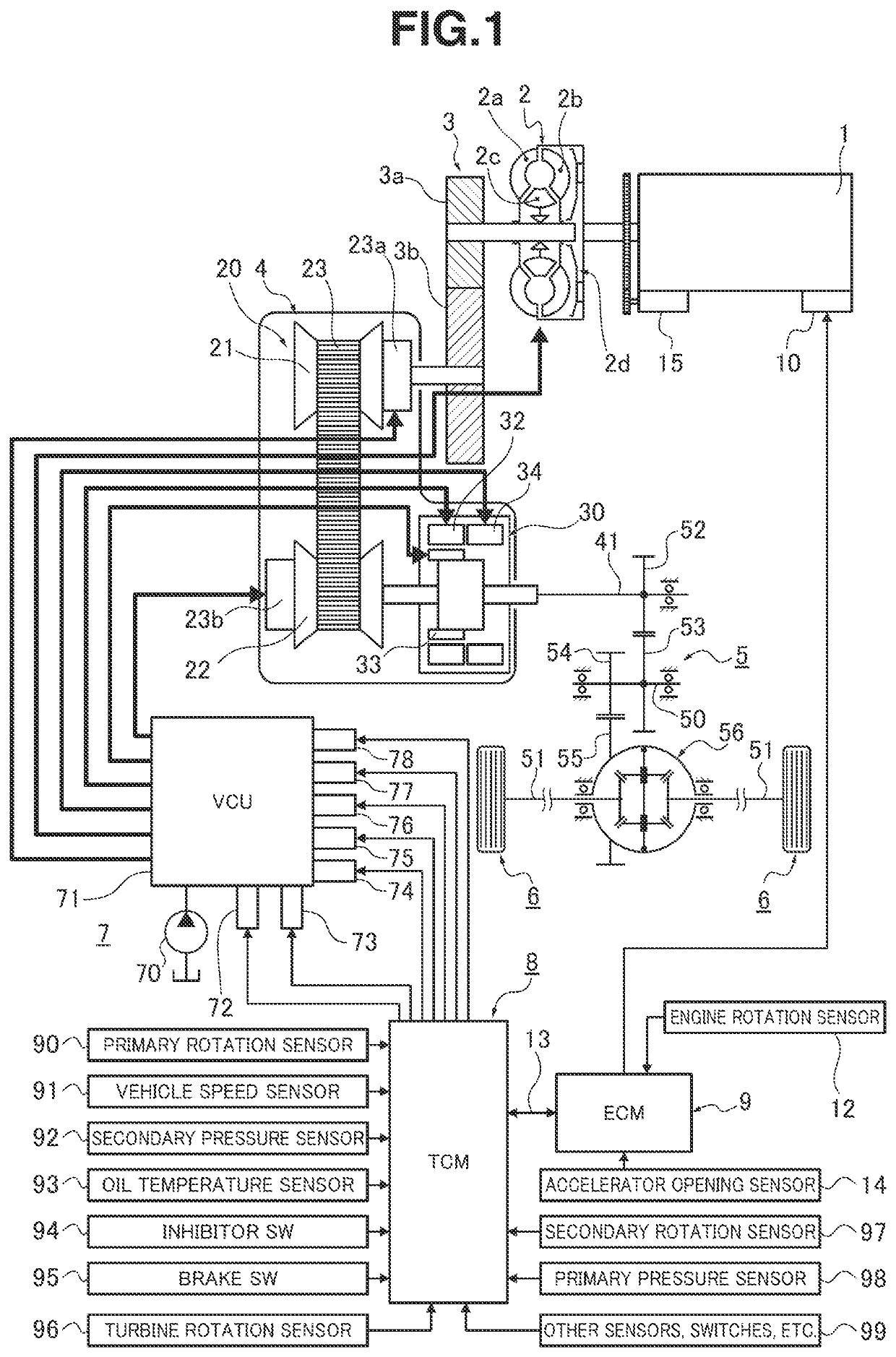

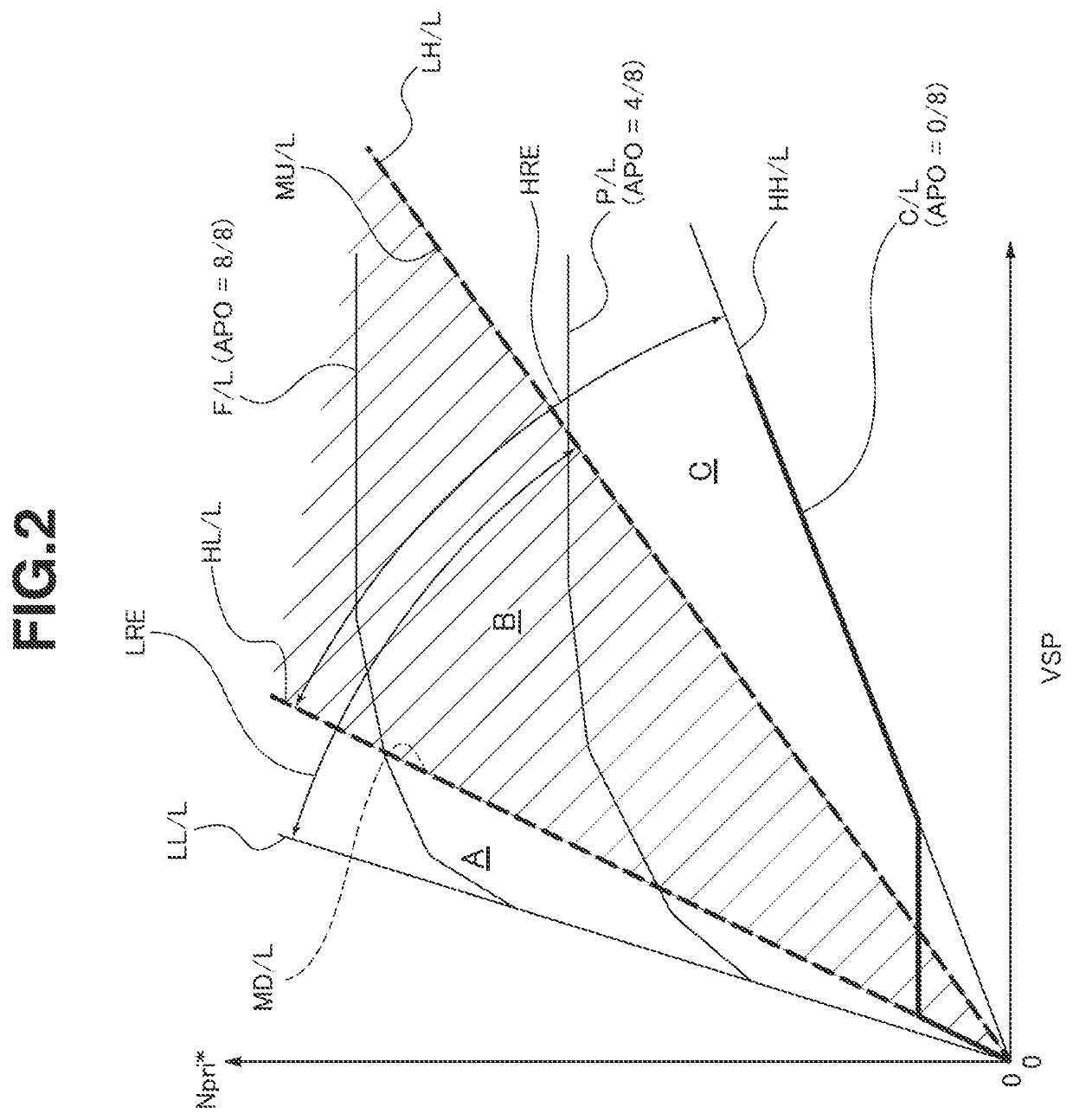

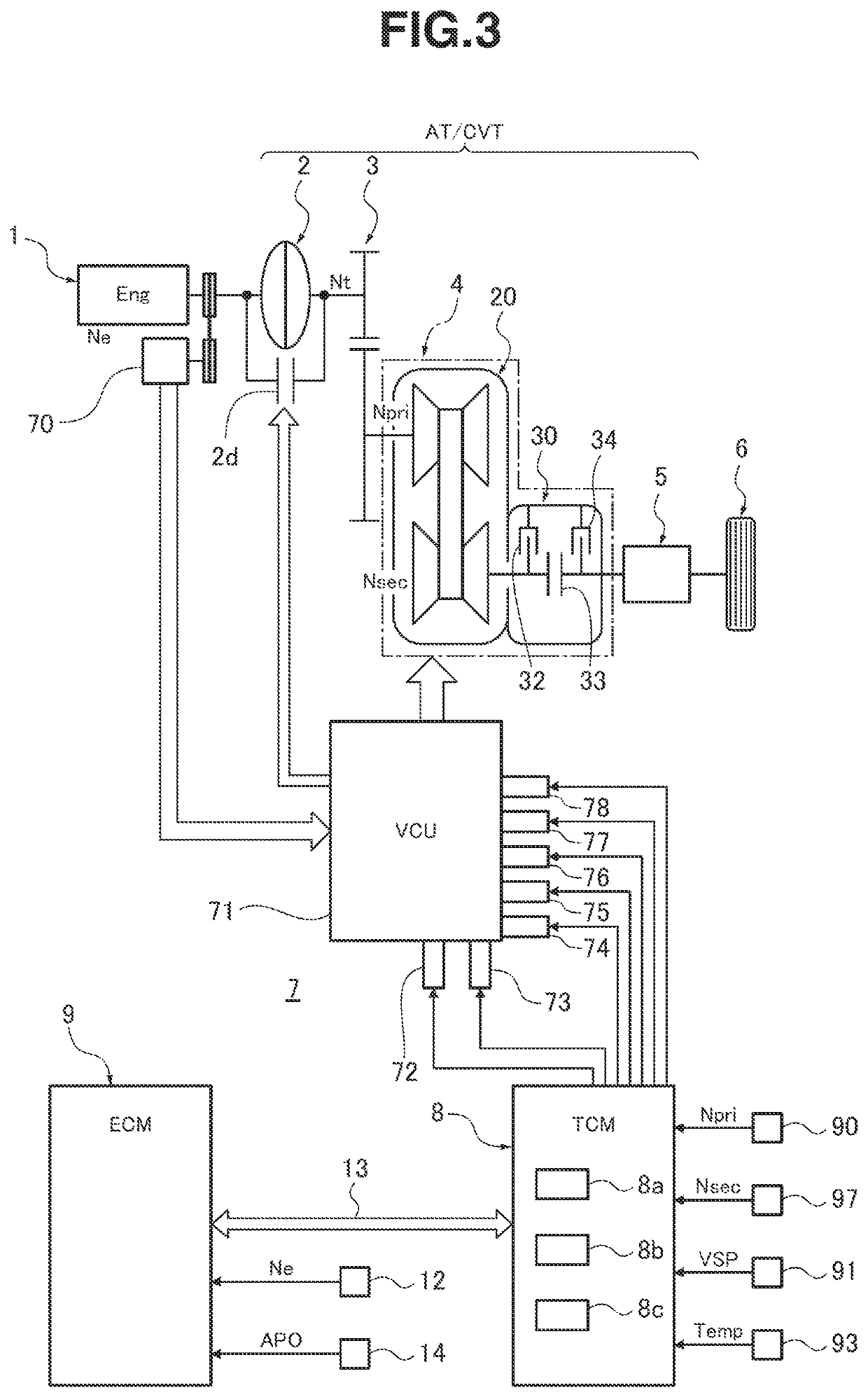

Control device for automatic transmission

ActiveUS20210237733A1Reduce stepsSuppression temperatureGearingGearing controlAutomatic transmissionControl system

A control device for an automatic transmission includes: a failure diagnosis section for diagnosing whether or not a failure has occurred in a shift control system of the automatic transmission; a fail-safe control section for fixing the automatic transmission into a predetermined gear position in response to confirmation of the failure of the shift control system of the automatic transmission; and an oil temperature rise regulation torque reduction control section for outputting a torque reduction request to suppress torque of a vehicle driving source, based on temperature of transmission operating oil of the automatic transmission, and outputting the torque reduction request in response to satisfaction of an oil temperature condition that is set lower in oil temperature when the automatic transmission is fixed in a first gear position by the fail-safe control section than when the automatic transmission is not fixed in the first gear position.

Owner:JATCO LTD

Conductive filler

ActiveUS7686982B2Damage to componentLow costConductive materialPrinted circuit aspectsChemical compositionConductive polymer

Disclosed is a conductive filler which can be fusion-bonded under lower temperature conditions (with the peak temperature of not less than 181° C.) than the reflow heat treatment conditions for an Sn-37Pb eutectic solder. This conductive filler is applicable to heat-resistant uses similar to those of the Sn-37Pb eutectic solder. The conductive filler is a mixture of first metal particles composed of an alloy having a chemical composition including 25-40% by mass of Ag, 2-8% by mass of Bi, 5-15% by mass of Cu, 2-8% by mass of In and 29-66% by mass of Sn, and second metal particles composed of an alloy having a chemical composition including 5-20% by mass of Ag, 10-20% by mass of Bi, 1-15% by mass of Cu and 50-80% by mass of Sn. In the mixture, 20-10,000 parts by mass of the second metal particles are contained per 100 parts by mass of the first metal particles.

Owner:KOKI

A method for joint production of potassium sulfate and calcium chloride dihydrate

ActiveCN105329920BMove quicklyLower energy requirementsCalcium/strontium/barium chloridesSulfate/bisulfate preparationCalcium hydroxidePotassium sulfate

The invention relates to a method for joint production of potassium sulphate and calcium chloride dihydrate. The method comprises the steps of 1, adding potassium chloride and sulfuric acid to a first reactor, and introducing superheated steam to the first reactor to generate potassium sulphate and vapor containing hydrogen chloride through reaction; 2, introducing the vapor containing hydrogen chloride to a second reactor to generate calcium chloride dihydrate and superheated steam through reaction with calcium oxide or calcium hydroxide, and circulating the superheated steam to the step 1. By the adoption of the method, high energy consumption during production of potassium sulphate and calcium chloride dihydrate is avoided, the byproduct hydrogen chloride is well utilized, and environment pollution is basically avoided.

Owner:LONGYAN ZIYUN CHEM TECH

A kind of naphthyl ligand MOF activated carbon composite catalyst and its preparation method and application

ActiveCN111905828BReduce vacuumLower temperature conditionsOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsActivated carbonPtru catalyst

The invention provides a naphthyl ligand MOF composite activated carbon catalyst and its method for preparing high-purity lactide from L-lactic acid. The MOF organometallic skeleton activated carbon composite catalyst is used to catalyze the polymerization of L-lactic acid, and the metal element is used as the active The component uses 2,3,6,7-tetraformyl imidazolyl-α-naphthoic acid as the MOF catalyst ligand and activated carbon as the carrier. The catalyst raw material is cheap, has high thermal stability, has certain acid resistance, is not easy to decompose under low pressure, has a simple preparation method, is easy to industrialize, and has good catalytic activity. The application of the catalyst in the lactide synthesis process can significantly reduce the process The required vacuum degree increases the yield of lactide, which is conducive to reducing its process cost, and has certain potential in industrial application.

Owner:WANHUA CHEM GRP CO LTD

Productive process for Rufloxaxin Hydrochloride raw material

The production process of raw material medicine of rufluoxin hydrochloride is an improvement on oil technological process, and is aimed at overcome defects of old technological process whose production yield is low, cost is high and by-product can pollute environment. It mainly improves second step and sixth step of old technological process, in second step, in the reaction container the ethyl alcohol, water ammonium chloride are added, iron powder is added while stirring, the dilute hydrochloric acid is slowly added, heated to reflux state, B is dropped in slowly, pH value is retained to 5-6, reacted for 1 hr, then TLC is ued to test reaction end point; and in sixth step, in reaction container the F, boron trifluoride etherate and acetone are added, heated to 58-63 deg.C and reflux reaction is made for 3-3.5 hr. Said invention can reduce production cost and raise product yield.

Owner:WUHAN BINHU DOUBLE CRANE PHARMA

Preparation method and application of ZnO/TiO2 composite powder

ActiveCN102618109BEasy to operateLower temperature conditionsAntifouling/underwater paintsPaints with biocidesAdhesion forceLacquer

The invention discloses a preparation method and application of ZnO / TiO2 composite powder. The preparation method comprises the following steps: dissolving soluble a zinc salt, a surfactant and butyl titanate in alcohol, and mixing to obtain a raw material liquid; adding a strong base aqueous solution to the raw material liquid under the stirring condition to obtain a mixed liquid; and reacting the mixed liquid at 120-180 DEG C for 8-16h, washing and drying to obtain the ZnO / TiO2 composite powder. The preparation method is relatively low in temperature conditions, good in controllability, simple in preparation and strong in operability, is favorable to industrialized popularization and production, and has wide application prospects. The obtained ZnO / TiO2 composite powder is complete in crystallization, small in original granularity, uniform in distribution and low in agglomeration, and is particularly suitable to be used as an additive for an automobile paint to be applied to the automobile paint, so that the automobile finish coat has the advantages of being plump in lacquer film, level and bright, strong in adhesion force, high in hardness, good in light retention rate, excellent in natural solarization performance and the like.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

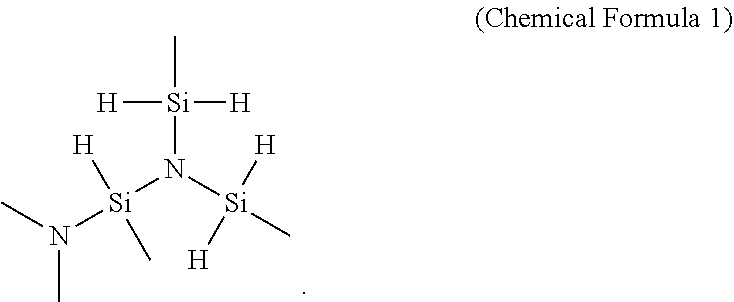

Composition for depositing silicon-containing thin film and method for producing silicon-containing thin film using the same

ActiveUS11390635B2Increase relative volatilityImprove thermal stabilityGroup 4/14 element organic compoundsSilicon compoundsThin membraneDisplay device

Provided are a composition for depositing a silicon-containing thin film, containing a trisilylamine compound and a method for producing a silicon-containing thin film using the same, and more particularly, a composition for depositing a silicon-containing thin film, containing a trisilylamine compound which is capable of forming a silicon-containing thin film at a very high deposition rate at a low temperature to be usable as a precursor of a silicon-containing thin film and an encapsulant of a display, and a method for producing a silicon-containing thin film by using the same.

Owner:DNF

Hydrogel composition for facial mask comprising water-soluble polyurethane

ActiveCN105456056BIncrease elasticityImprove ventilationCosmetic preparationsToilet preparationsPolyolCosmetic component

The present invention relates to a hydrogel composition and, more specifically, to a hydrogel composition having improved elasticity and air permeability by including water-soluble polyurethane. Based on the total weight of the hydrogel composition, the hydrogel composition comprises 0.01 to 5.0 wt% of water-soluble polyurethane; 0.4 to 5.0 wt% of a natural polymer gelating agent; 1.0 to 60.0 wt% of a functional cosmetic component for imparting a skin beautifying function; 0.1 to 1.0 wt% of an electrolyte; 10.0 to 30.0 wt% of polyalcohol as a plasticizer; a preserving agent; and a solvent including other water. The hydrogel composition of the present invention is a cosmetic mask distributed after being pre-produced in a face shape or patch shape. The hydrogel composition has improved elasticity so as to be excellently adhered on the skin without an additional adhesive component, and the shape thereof can be maintained for a long time. Air permeability is improved, so that a useful component for skin can be easily transferred to the skin without concern over skin irritation.

Owner:株式会社伊思韩佛

A mesoporous catalyst with hydrothermal stability, preparation method and method for preparing bio-oil by catalyzing hydrothermal liquefaction of microalgae

ActiveCN105536849BOvercoming and mitigating pollution problemsReduce energy consumptionMolecular sieve catalystsLiquid carbonaceous fuelsMolecular sieveThermal stability

The invention discloses a mesoporous catalyst with hydro-thermal stability. The catalyst is prepared by subjecting a mixture containing a dual-template, an active metal salt and a silicon source to one-step hydrothermal crystallization under a sealed condition so as to introduce the metal to a mesoporous molecular sieve SBA-15, wherein the active metal is one or more of Pt, Pd, Zr, Ru, Ni, Co and Mo. The invention also discloses a method of catalyzing microalgae hydrothermal liquefaction with a mesoporous catalyst material with hydro-thermal stability to prepare bio-oil. The method includes introducing the prepared mesoporous catalyst material with hydro-thermal stability into a process of preparing the bio-oil through the microalgae hydrothermal liquefaction. After the bio-oil prepared by liquefaction is separated and purified, the liquefaction product mainly comprises furfural and furfural derivatives.

Owner:TSINGHUA UNIV

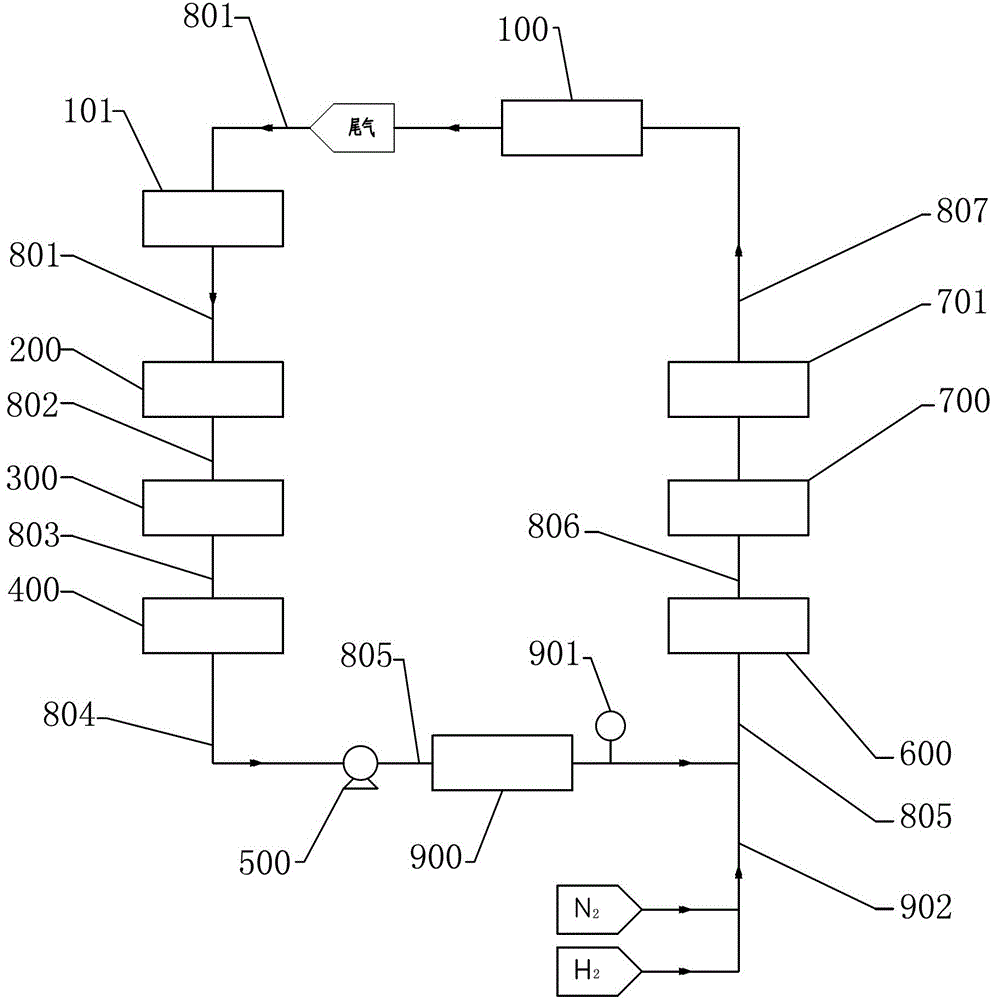

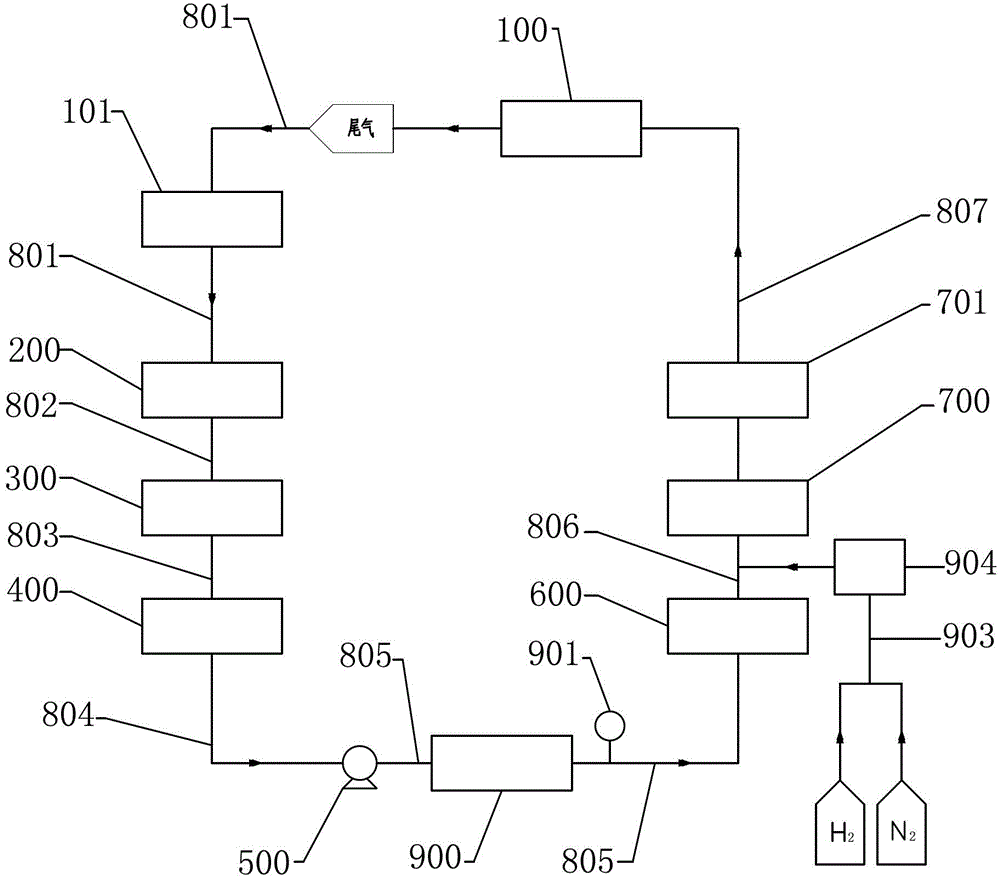

Device and method for preparing high-purity ammonia by regeneration of ammonia-contained tail gas of electronic industry

ActiveCN102942194BReduce storage costsReduced Possibility of ContaminationChemical industryHydrogen productionDecompositionElectronic industry

Owner:HUNAN HIEND PRODUCTS CO LTD

Method for synthesizing artificial bone from carboxylic apatite of coral

InactiveCN1235645CPromote healingHigh compressive strengthPhosphorus compoundsProsthesisPorosityApatite

An artificial coral hydroxy apatitis (CHA) bone for medical purpose is prepared from coral through hydrothermal reaction in the diammonium hydrogen phosphate plus hydrothermal liquid system under high-temp and high-pressure condition to convert the CaCO3 of coral to Ca5(PO4)3(OH) which is just the artificial bone. Its advantages are high compression strength, high porosity (24.86-65.71%), no toxic by-effect and good biologic compatibility.

Owner:SUN YAT SEN UNIV

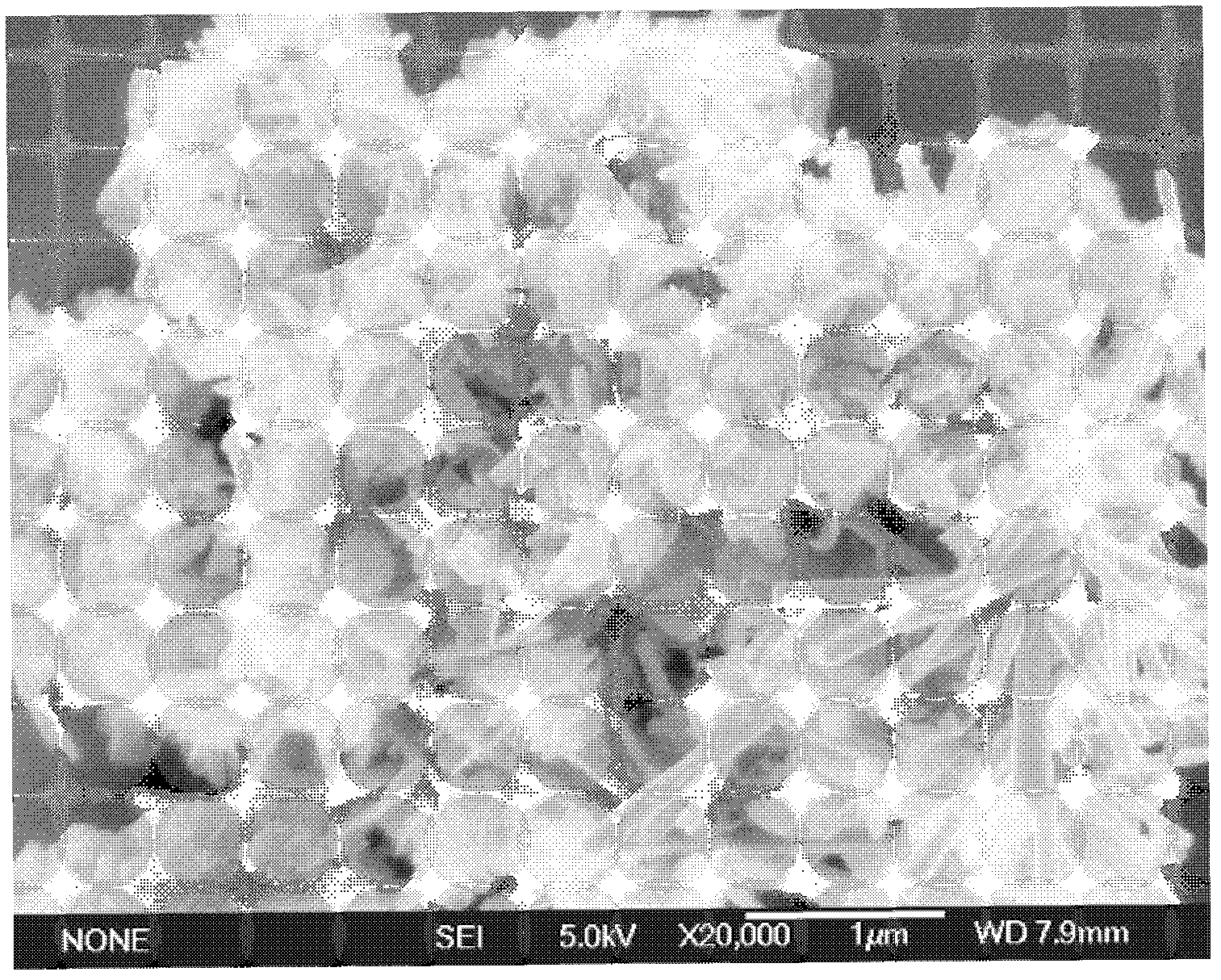

Method for preparing nanometer SiC reinforced aluminum base composite material

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com