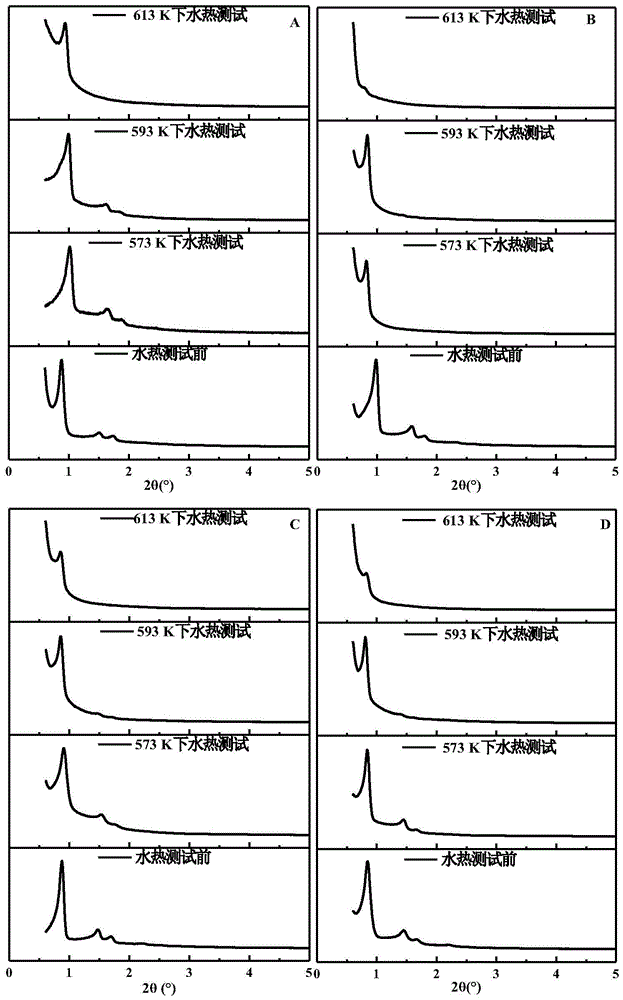

A mesoporous catalyst with hydro-thermal stability, a preparing method thereof and a method of catalyzing microalgae hydrothermal liquefaction with the catalyst to prepare bio-oil

A hydrothermal stability and hydrothermal liquefaction technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of destroying the framework structure of mesoporous molecular sieves, and achieve a simple, safe and reliable process. , the effect of improving the conversion rate and the yield of bio-oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] According to the solid-liquid ratio of 1:10, weigh 4g microalgae sample and 40mL water into the reactor, the amount of catalyst added is 5% of the microalgae, the mesoporous catalyst is Ni-SBA-15, and the liquefaction temperature is 260°C The pressure is 8.45MPa; the reaction time is 20min, the liquefaction rate of microalgae is 78.8%, the oil production rate is 25.6%, the relative content of furfural and its derivatives in the bio-oil is 57.61%, and the relative content of hexadecanoic acid is 11.25%, and the content of cyclopentanone is 3.20%.

Embodiment 2

[0051] According to the solid-liquid ratio of 1:10, weigh 4g microalgae sample and 40mL water into the reactor, the amount of catalyst added is 10% of the microalgae, the mesoporous catalyst is Co-SBA-15, and the liquefaction temperature is 320°C The pressure is 14.52MPa; the reaction time is 45min, the liquefaction rate of microalgae is 85.12%, the oil production rate is 42.15%, the relative content of furfural and its derivatives in bio-oil is 70.76%, and the relative content of hexadecanoic acid is 8.21%, and the content of cyclopentanone is 1.24%.

Embodiment 3

[0053] According to the solid-liquid ratio of 1:10, weigh 4g microalgae sample and 40mL water into the reactor, the amount of catalyst added is 1% of the microalgae, the mesoporous catalyst is Pd-SBA-15, and the liquefaction temperature is 320°C The pressure is 11.27MPa; the reaction time is 30min, the liquefaction rate of microalgae is 75.9%, the oil production rate is 29.6%, the relative content of furfural and its derivatives in bio-oil is 51.29%, and the relative content of hexadecanoic acid is 18.25%, and the content of cyclopentanone is 4.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com