Treatment method and device for solid waste

A technology of solid waste and treatment method, applied in the field of high-efficiency resource utilization of solid waste, can solve the problems of increasing treatment costs, difficulty in landfill site selection, and limitation of incineration treatment methods, and achieves great social and economic benefits, Achieve efficient resource utilization and alleviate the effect of fossil energy shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

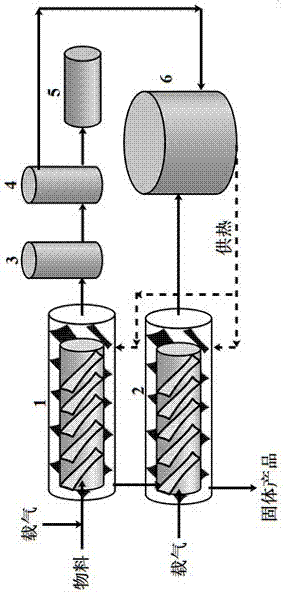

Image

Examples

Embodiment 1

[0033] Catalyst preparation: Classify carbon nanotubes according to size and pore size to obtain graded carbon sources as hard templates; then dissolve 1.0 g sodium metaaluminate in 2 mL deionized water, add organic structure-directing agent tetraethyl hydroxide Ammonium, and then under the premise of controlling the silicon-aluminum ratio (1:10), add tetraethyl silicate, stir well and form a gel, transfer it to a high-temperature and high-pressure reactor with a polytetrafluoroethylene liner, and place Crystallization was carried out in a drying oven at 120 °C for 48 h. Afterwards, the reaction solution was transferred into an aqueous solution containing graded inorganic carbon materials, stirred for 5 h, and continued to crystallize for 48 h. After the crystallization is completed, the solid is separated by centrifugation, filtered by suction, washed, dried, and calcined at 600°C to obtain a multi-stage molecular sieve. A high-efficiency catalyst, Ni-ZSM-5, is obtained by l...

Embodiment 2

[0036] Catalyst preparation: Classify carbon nanofibers according to size and pore size, and obtain graded carbon sources as hard templates; then dissolve 1.0 g of sodium metaaluminate in 2 mL of deionized water, add organic structure-directing agent tetraethyl base ammonium hydroxide, and then under the premise of controlling the silicon-aluminum ratio (1:20), add tetraethyl silicate, stir well and form a gel, and transfer it to a high-temperature and high-pressure reactor with a polytetrafluoroethylene liner , placed in a drying oven at 120 °C for 48 h to crystallize. Afterwards, the reaction solution was transferred into an aqueous solution containing graded inorganic carbon materials, stirred for 5 h, and continued to crystallize for 48 h. After the crystallization is completed, the solid is separated by centrifugation, filtered by suction, washed, dried, and calcined at 600°C to obtain a multi-stage molecular sieve. A high-efficiency catalyst, Au-ZSM-5, was obtained by l...

Embodiment 3

[0039] Catalyst preparation: Classify carbon nanotubes according to size and pore size, etc., to obtain graded carbon sources as hard templates; then dissolve 1.0 g of sodium metaaluminate in 2 mL of deionized water, add organic structure-directing agent tetraethyl base ammonium hydroxide, and then under the premise of controlling the silicon-aluminum ratio (1:20), add tetraethyl silicate, stir well and form a gel, and transfer it to a high-temperature and high-pressure reactor with a polytetrafluoroethylene liner , placed in a drying oven at 120 °C for 48 h to crystallize. Afterwards, the reaction solution was transferred into an aqueous solution containing graded inorganic carbon materials, stirred for 5 h, and continued to crystallize for 48 h. After the crystallization is completed, the solid is separated by centrifugation, filtered by suction, washed, dried, and calcined at 600°C to obtain a multi-stage molecular sieve. A high-efficiency catalyst, Co-ZSM-5, was obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com