Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157 results about "Hydrothermal liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

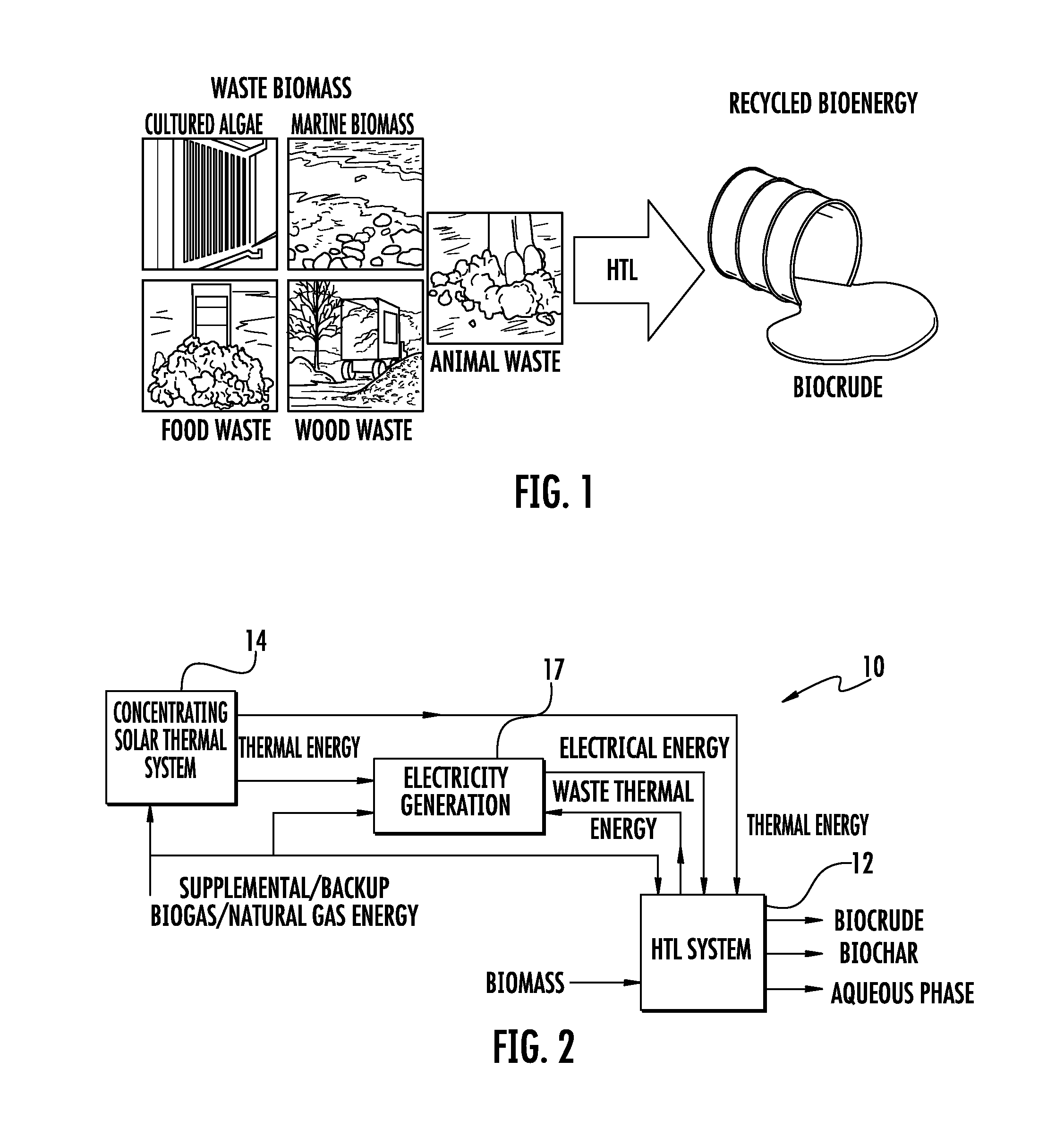

Hydrothermal liquefaction (HTL) is a thermal depolymerization process used to convert wet biomass into crude-like oil -sometimes referred to as bio-oil or biocrude- under moderate temperature and high pressure. The crude-like oil (or bio-oil) has high energy density with a lower heating value of 33.8-36.9 MJ/kg and 5-20 wt% oxygen and renewable chemicals.

Method for producing fuel oil by biomass hydrothermal liquefaction

InactiveCN101805629AImprove conversion ratePotential for industrial applicationsLiquid hydrocarbon mixture productionMass ratioReaction temperature

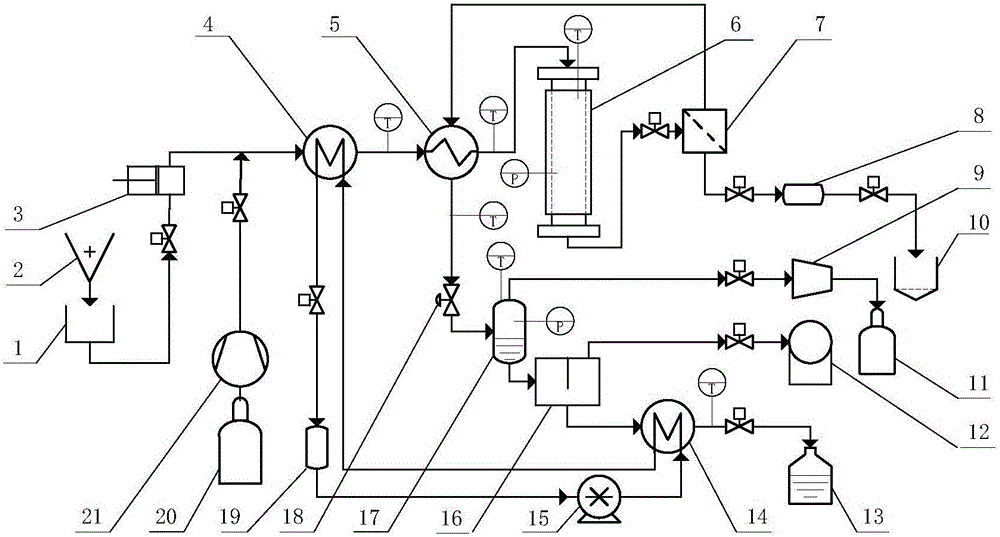

The invention discloses a method for producing fuel oil by biomass hydrothermal liquefaction. The method is characterized by comprising the following steps: fully mixing a biomass raw material and solvent water (or adding catalyst water solution) to prepare seriflux, wherein a mass ratio of a catalyst to the raw material is 1:10 to 1:50, and the mass ratio of the raw material to water is 1:2 to 1:8; performing a reaction in a slurry bed reactor under a reducing atmosphere; controlling a liquefaction reaction temperature between 300 and 450 DEG C, a reaction pressure between 5 and 30 MPa and reaction time between 5 and 40 minutes; after the reaction, separating a product to obtain the fuel oil, solid residue, water, gas and the like. The method has the advantages of achieving complete biomass conversion, high oil product productivity, obtaining an oil product with a heat value equal to that of standard oil, relieving dependence on fossil energy, contributing to environment protection, lowering production cost and achieving good social and economic benefits.

Owner:EAST CHINA UNIV OF SCI & TECH

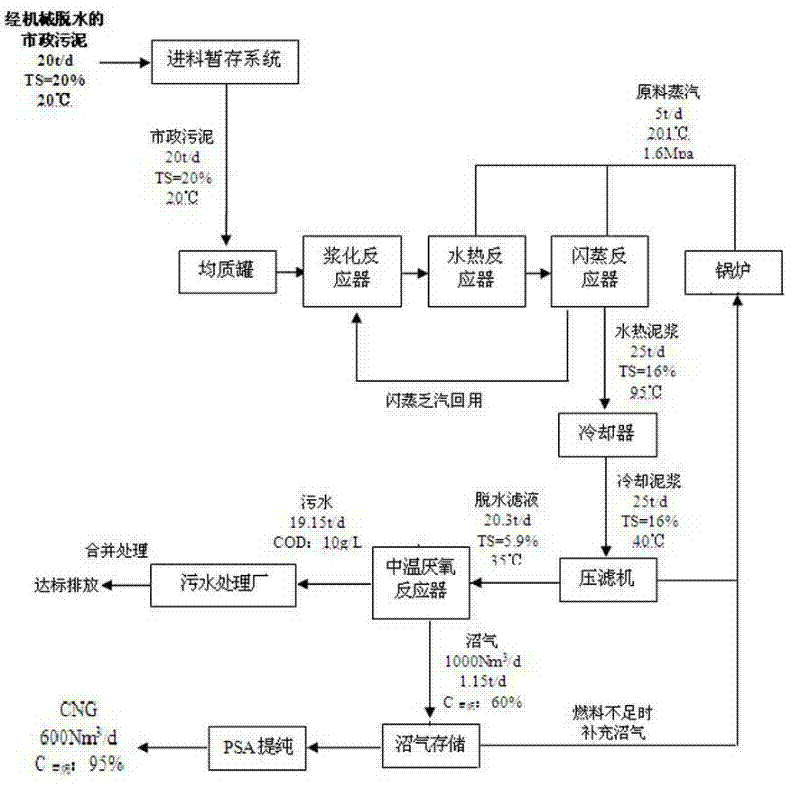

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

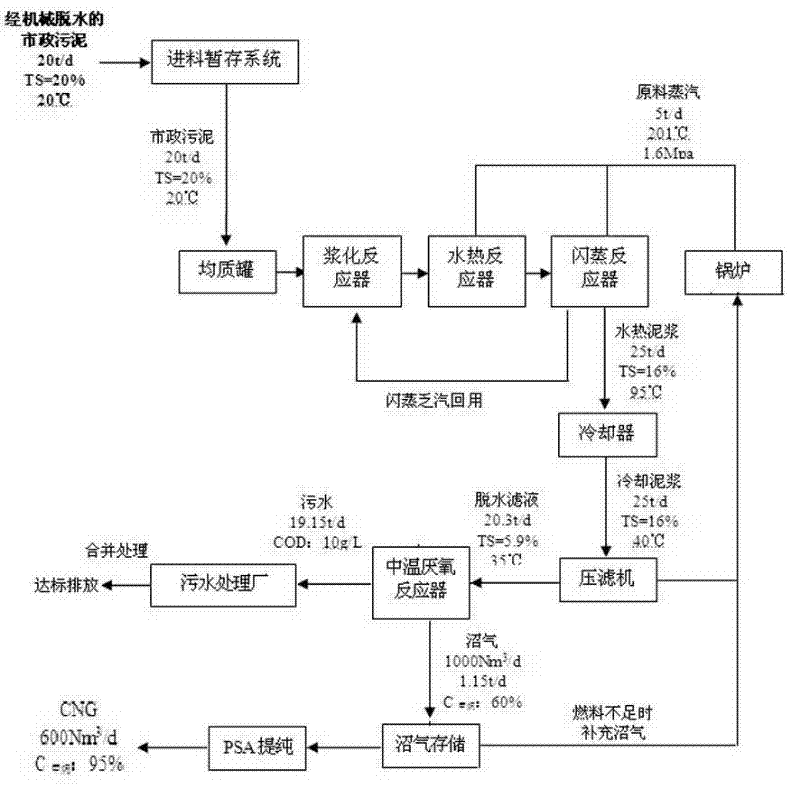

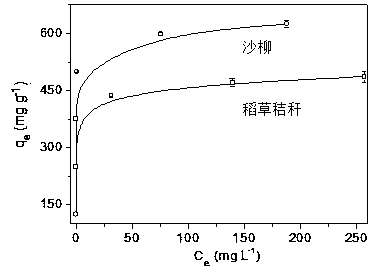

Separating and upgrading method of bio-oil by column chromatography

InactiveCN102899069AAccelerate the pace of research on high value-added utilizationGreat potentialSolid sorbent liquid separationHydrocarbon oils refiningDistillationOrganosolv

The invention belongs to the technical field of environment and new energy, and relates to a separating and upgrading method of bio-oil by column chromatography. The bio-oil refers to a viscous oily substance generated by hydrothermal liquefaction and pyrolysis and other processes of biomass raw materials such as enteromorpha, microalgae, straw, salix psammophila, tobacco stems, corn cobs, wood chips and water hyacinth, and the bio-oil passes through a chromatography column by taking silica gel or aluminum oxide and the like as a carrier, and is respectively subjected to gradient elution with different organic solvents so as to respectively obtain different components such as organic acids, ketones, esters and phenols; and after being pooled and concentrated, the different compounds are separated by chromatography columns with different natures to obtain a bio-oil component with relatively higher purity, therefore the separation of a complex bio-oil mixing system is realized, and the development of biomass industry is greatly promoted. Compared with the traditional distillation separation, solvent extraction and other methods, the separation method has the advantages of low energy consumption, mild conditions, simple technological process, high separation efficiency, recycling and reuse of eluent, environmental friendliness and the like.

Owner:FUDAN UNIV

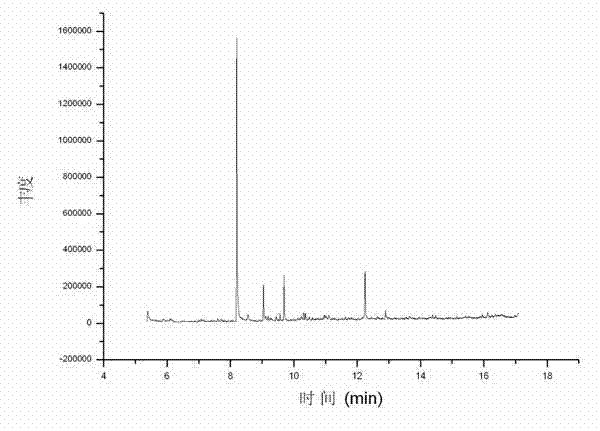

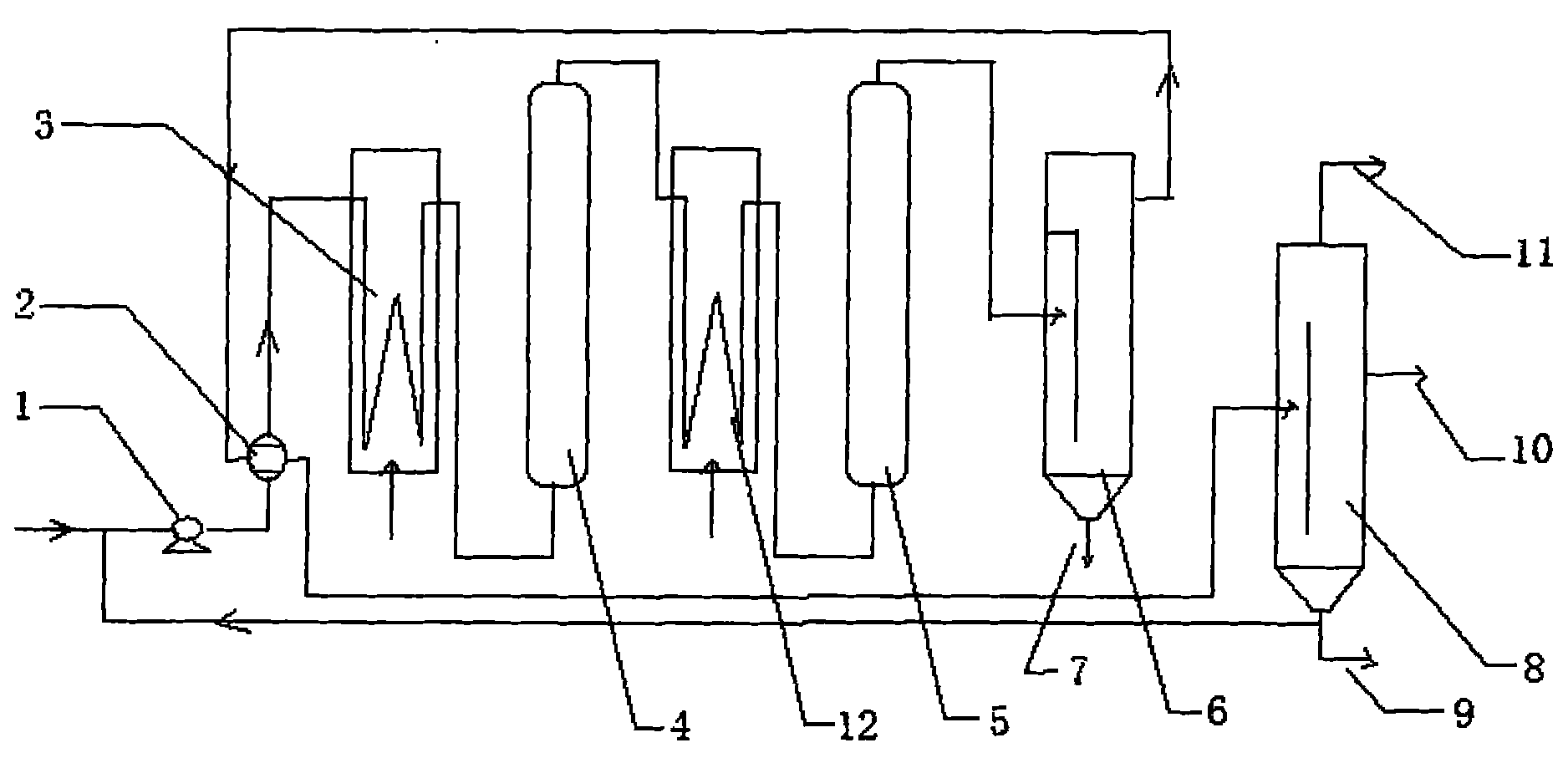

Microalgae high-pressure continuous tower-type liquefying process

InactiveCN102071038AHigh reaction conversion rateHigh recovery rateLiquid hydrocarbon mixture productionGas phaseSnow melting

The invention provides a microalgae high-pressure continuous tower-type liquefying process, which comprises the following steps of: pressurizing microalgae-containing suspension by using a high-pressure pump, making the suspension flow through a heat exchanger to exchange heat with liquefied liquid, heating to be between 180 and 250 DEG C according to a certain heating curve by using a heating furnace, and preserving heat in a gelatinizing tower for certain time to make solid biomass changed into flowable slurry; quickly heating gelatinized liquid to be between 270 and 350 DEG C at a certain heating rate by using a secondary heating furnace, and adding into a liquefying tower for hydrothermal liquefying to prepare a liquid fuel; separating coke slurry from a hydrothermal liquefying product by using a high-pressure settling tank, discharging the coke slurry from a coke slurry outlet, and making liquefied gas liquid pass through the top of the high-pressure settling tank, exchange heat with the microalgae suspension through the heat exchanger and flow into a three-phase separator; separating the liquefied gas liquid into a water phase, an oil phase and a gas phase in the three-phase separator, circulating and discharging the water phase by connecting the water phase with the high-pressure pump and a discharging port from the lower part of the three-phase separator, concentrating to prepare a foliar fertilizer, biological gasoline or a snow-melting agent and the like, discharging the oil phase from a biological oil outlet in the middle of the three-phase separator to obtain a product, and discharging the gas phase from a tail gas outlet on the top of the three-phase separator to serve as a fuel; and discharging the solid-phase coke slurry to serve as an activated carbon material or a fuel.

Owner:田原宇

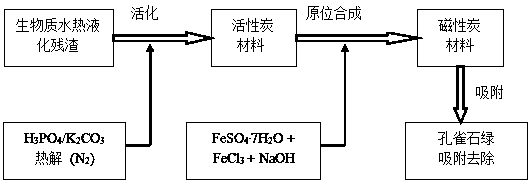

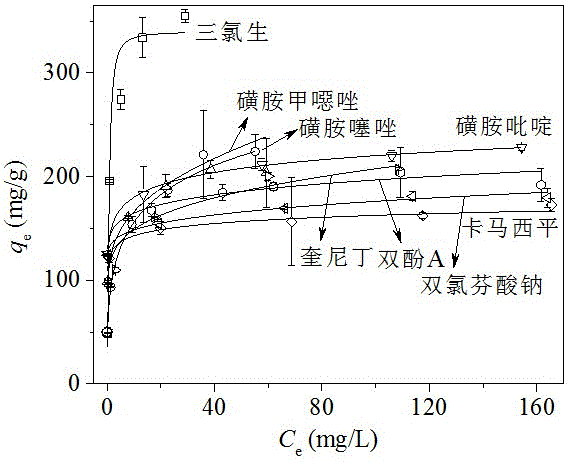

Activation method and application of biomass liquefaction residue

InactiveCN103406095ASimple preparation processLow costOther chemical processesWater/sewage treatment by magnetic/electric fieldsActivated carbonMagnetic carbon

The invention belongs to the technical fields of environmental protection and comprehensive utilization of resources, and particularly relates to a biomass liquefaction residue activation method for recycling a biomass hydrothermal liquefaction residue and application of the biomass liquefaction residue. The specific process comprises the following steps: (1) activating a biomass liquefaction residue with acid or alkali to generate activated carbon particles; (2) performing in-situ synthesis on the activated carbon particles to generate magnetic particles, wherein the magnetic carbon material has high specific surface area, high pore volume and high magnetic intensity, and can be magnetically separated from a water solution; and (3) removing organic dye pollutants in wastewater with the magnetic carbon material. The invention has important promotion action on development of the biomass industry. The preparation method has the advantages of low energy consumption, environment friendliness, mild conditions, simple process, high adsorption capacity for dye organic pollutants, no secondary pollution and the like.

Owner:FUDAN UNIV

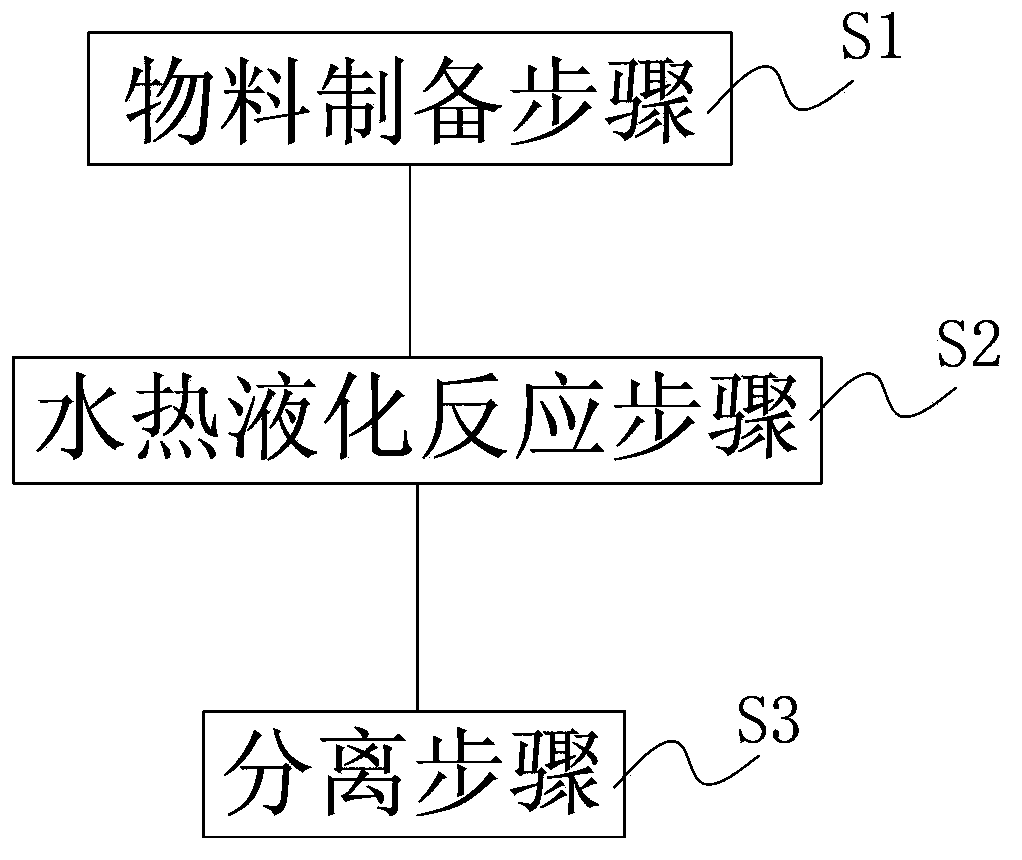

Method and system for preparing biological oil by antibiotic bacteria residue

ActiveCN104109550AHarmlessAchieve reductionLiquid hydrocarbon mixture productionMaterials preparationAntibiotic Y

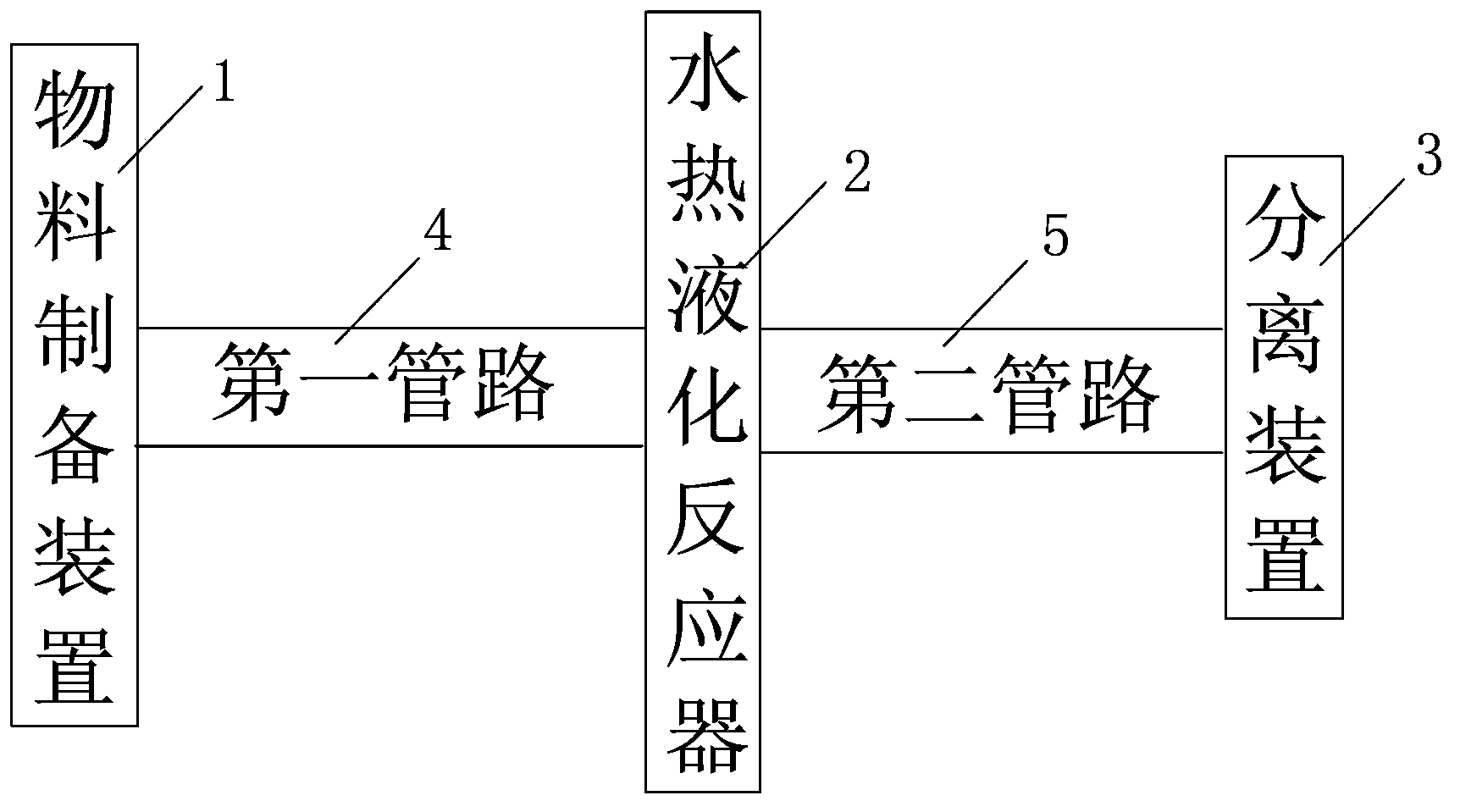

A method and a system for preparing biological oil by an antibiotic bacteria residue are provided. Hydrothermal liquefaction of the antibiotic bacteria residue is adopted to produce the biological oil, and the method comprises the steps: material preparation comprising the steps of evenly mixing and stirring the antibiotic bacteria residue with the water content of 70%-95% and a catalyst in proportion into a slurry material; a hydrothermal liquefaction reaction comprising the steps of sending the slurry material into a hydrothermal liquefaction reactor, carrying out the hydrothermal liquefaction reaction, allowing organic matters in the slurry material to be converted into the biological oil, and removing residual antibiotics in the slurry material; and separation comprising the steps of separating the product after the hydrothermal liquefaction reaction to obtain the biological oil. The system comprises a material preparation device, the hydrothermal liquefaction reactor and a separation device. The method and the system are simple, feasible, economic and effective, can directly treat the wet antibiotic bacteria residue, and are high in treatment efficiency, good in environmental protection effect and energy saving effect, and suitable for concentrated mass treatment of the antibiotic bacteria residue.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

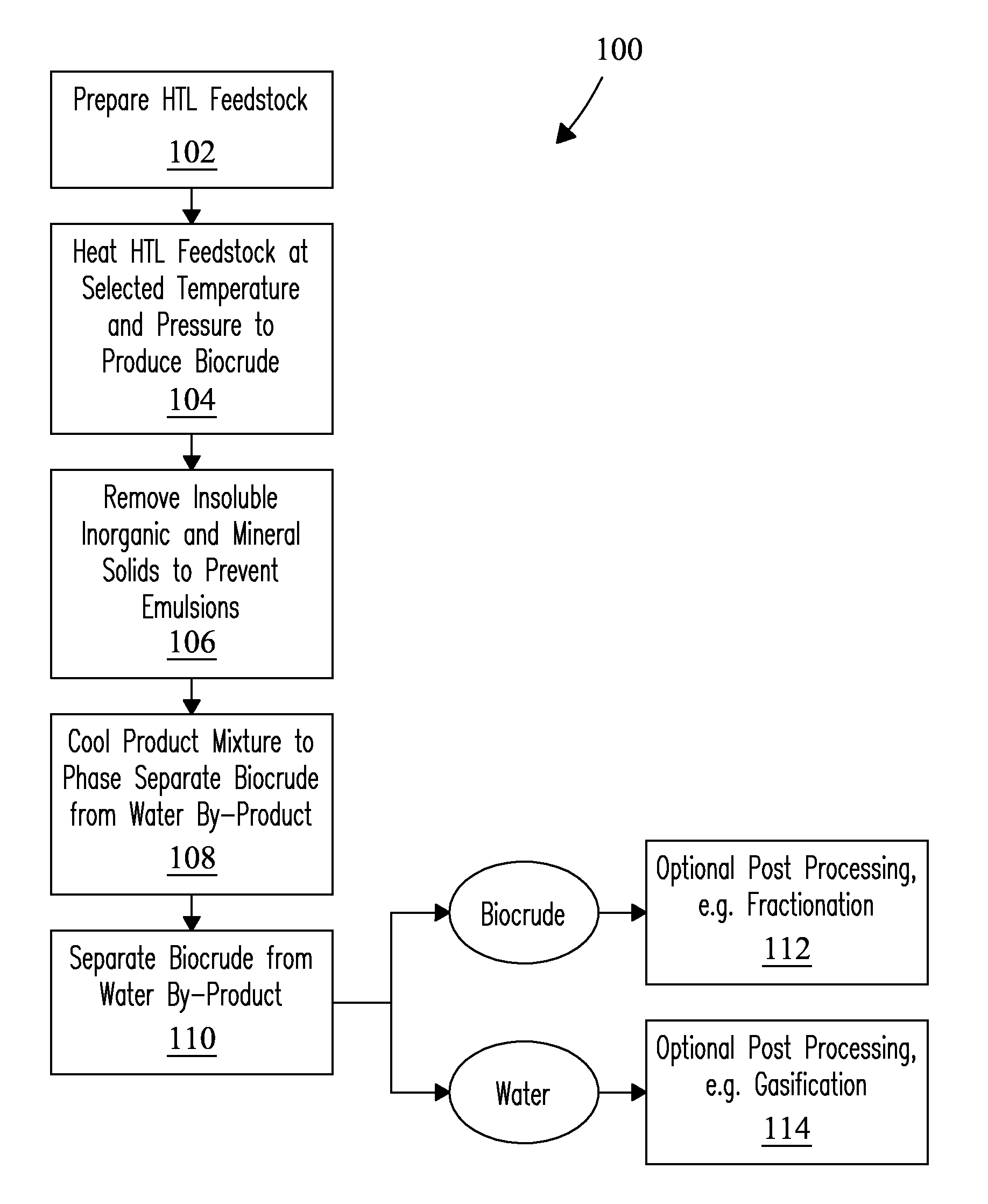

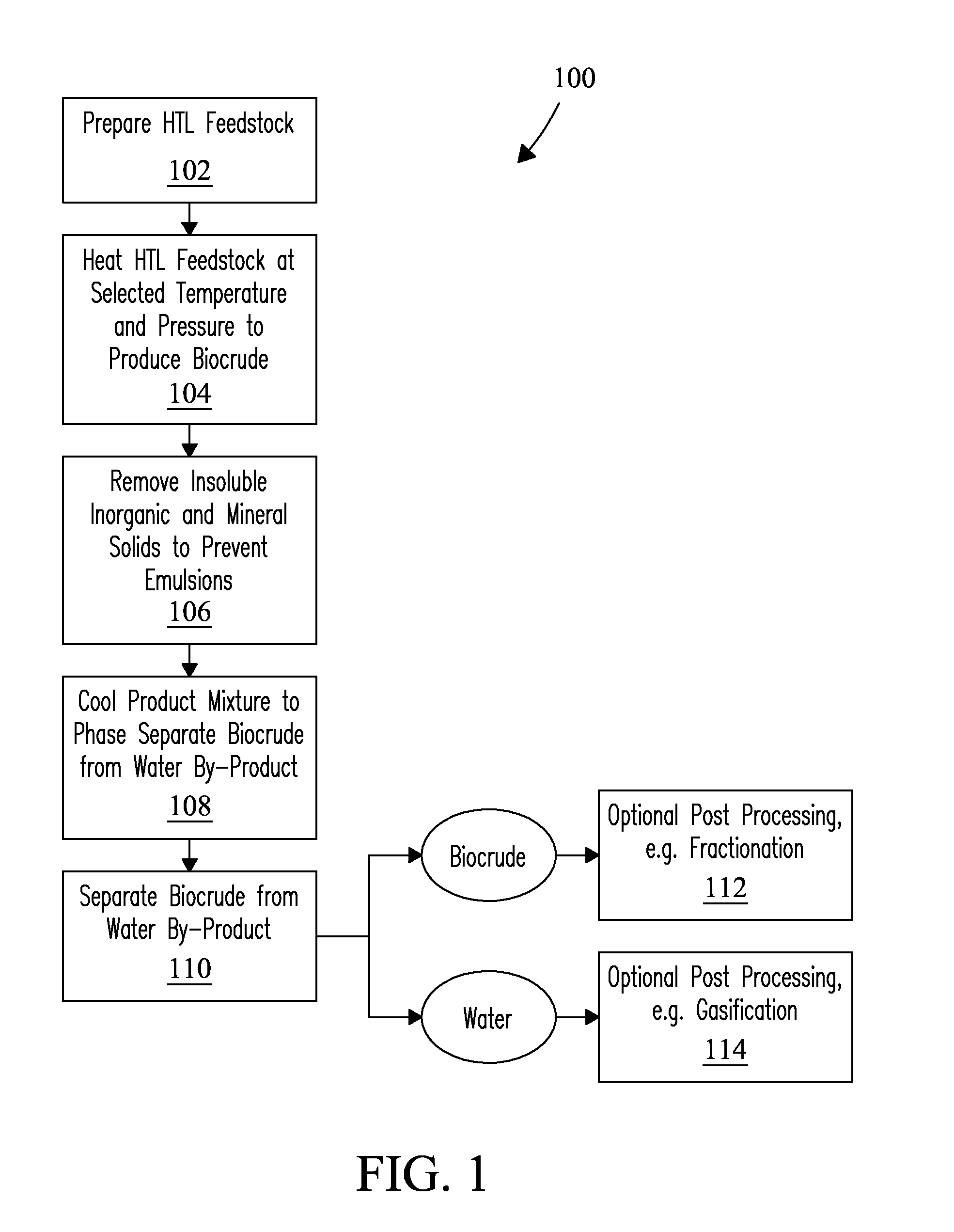

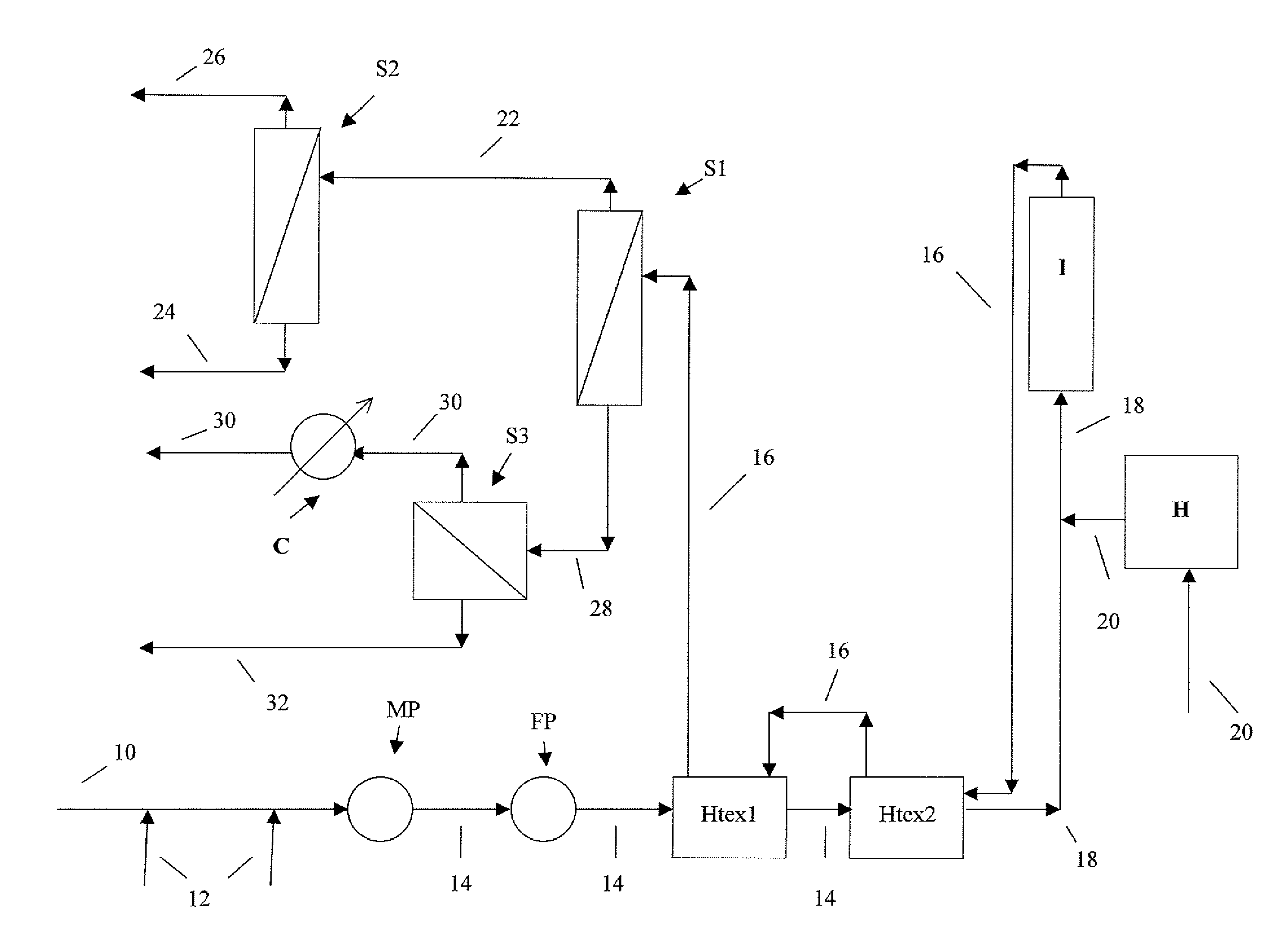

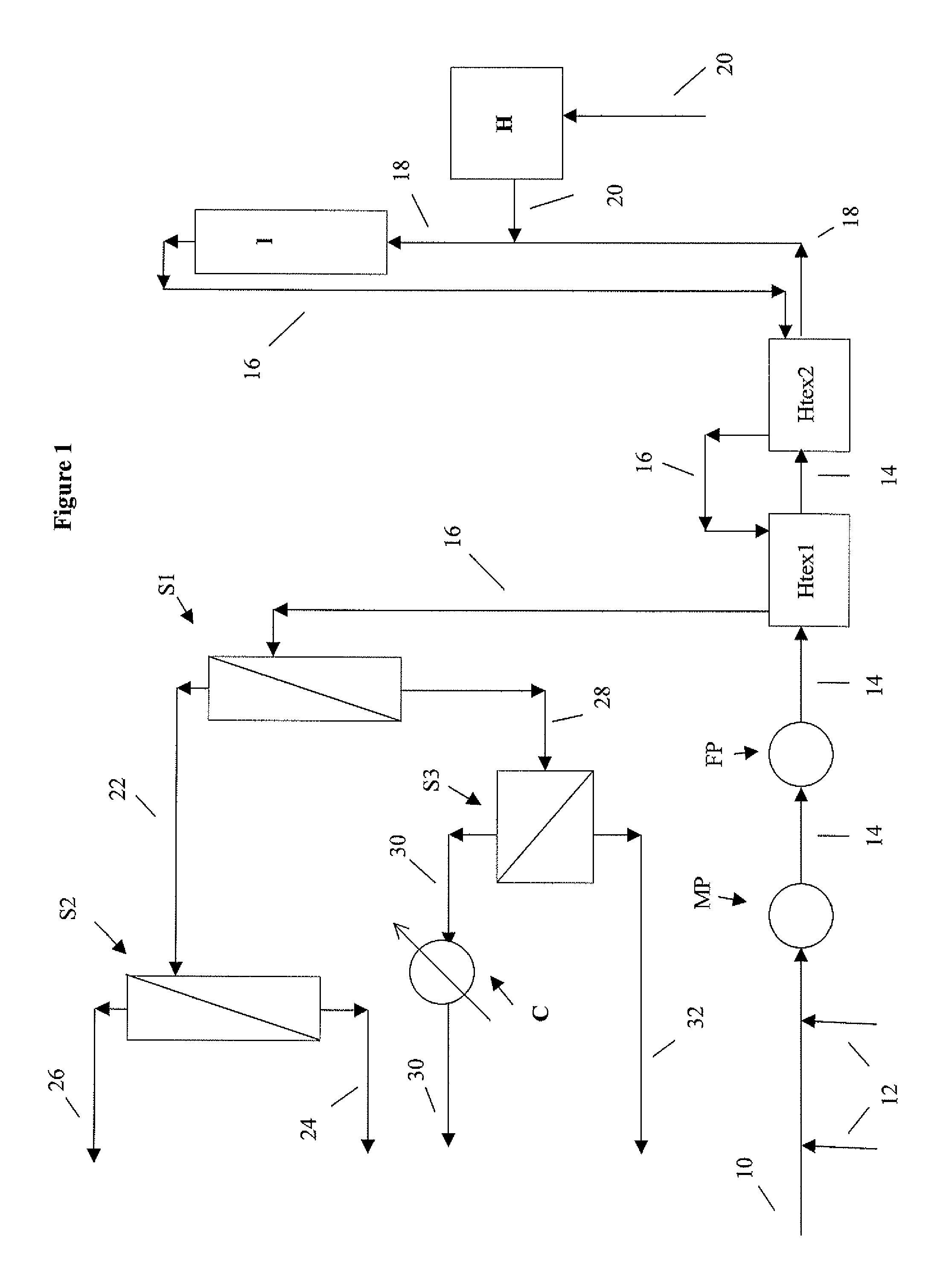

System and process for efficient separation of biocrudes and water in a hydrothermal liquefaction system

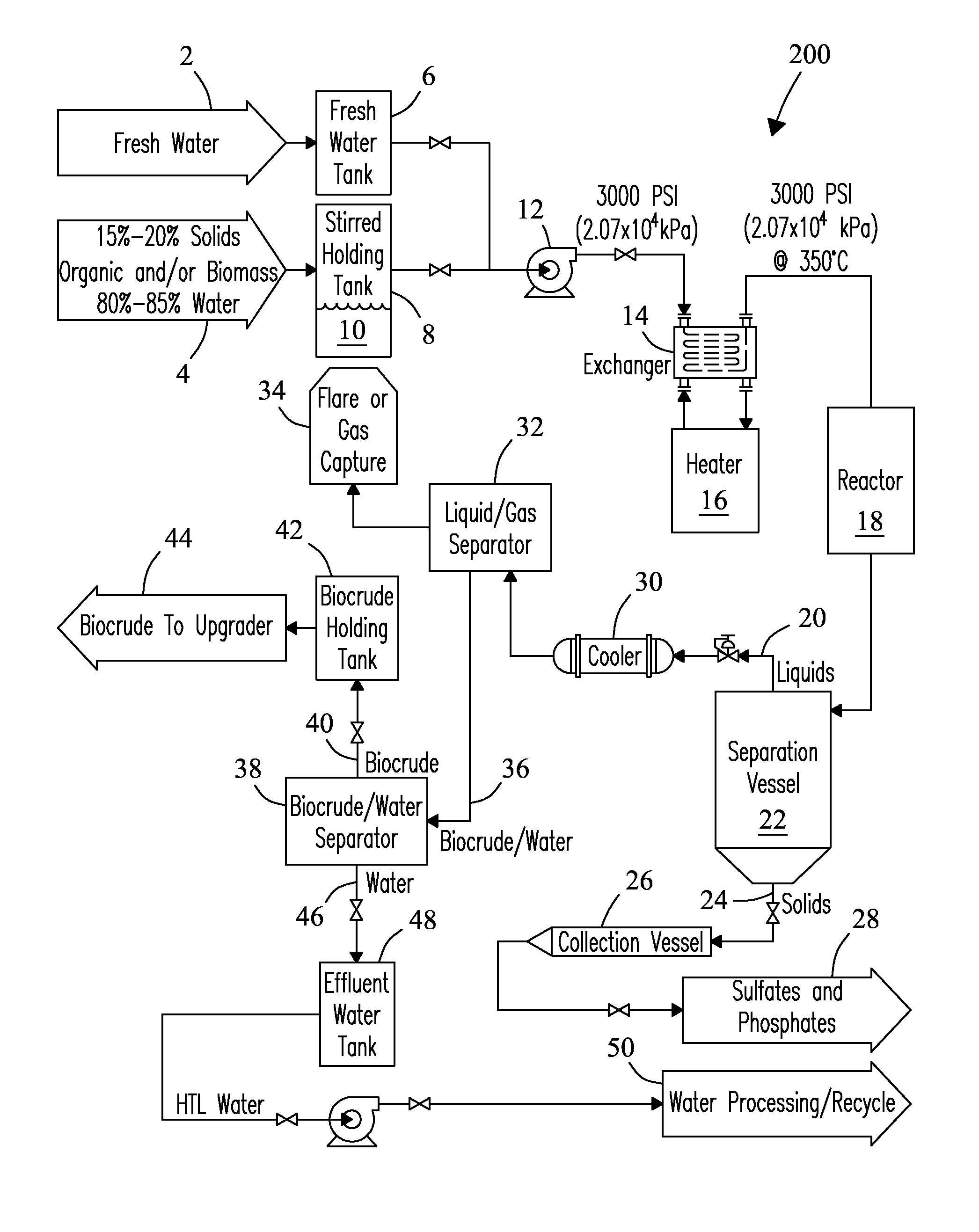

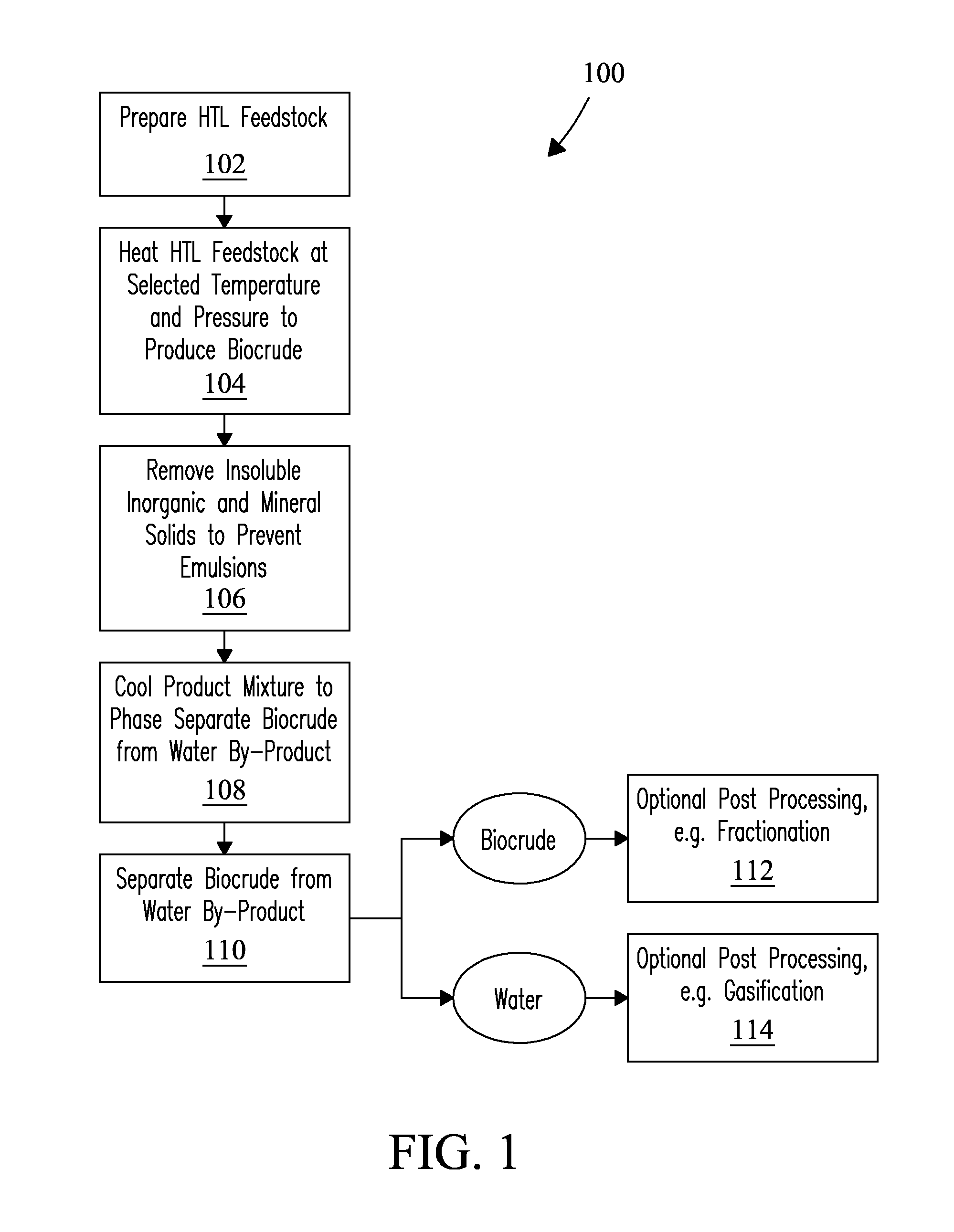

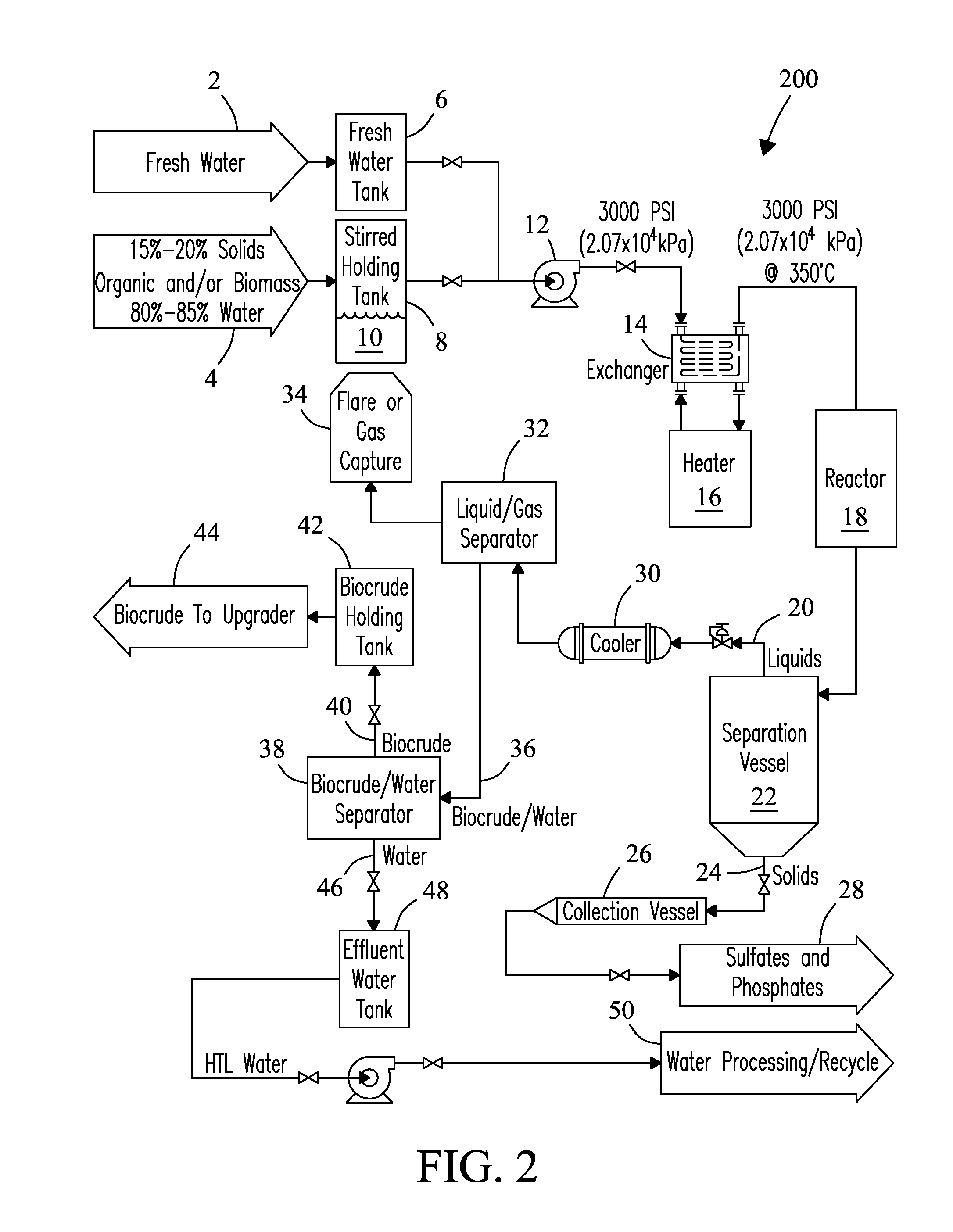

ActiveUS20150126758A1Efficient separationAvoid separationFatty oils/acids recovery from wasteDewatering/demulsification with mechanical meansEmulsionInorganic compound

A system and process are described for clean separation of biocrudes and water by-products from hydrothermal liquefaction (HTL) product mixtures of organic and biomass-containing feedstocks at elevated temperatures and pressures. Inorganic compound solids are removed prior to separation of biocrude and water by-product fractions to minimize formation of emulsions that impede separation. Separation may be performed at higher temperatures that reduce heat loss and need to cool product mixtures to ambient. The present invention thus achieves separation efficiencies not achieved in conventional HTL processing.

Owner:BATTELLE MEMORIAL INST +1

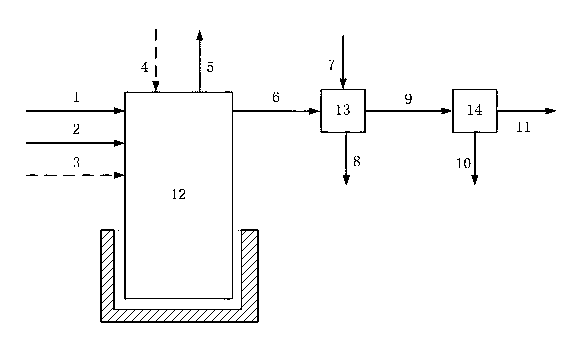

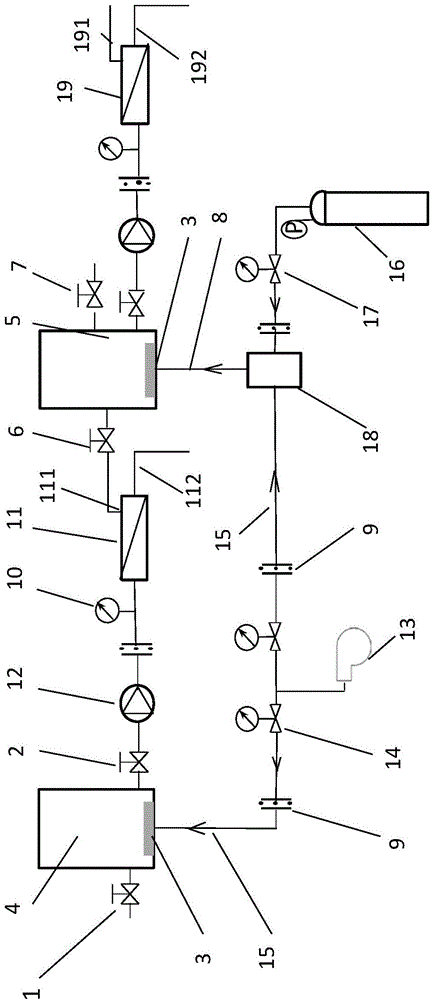

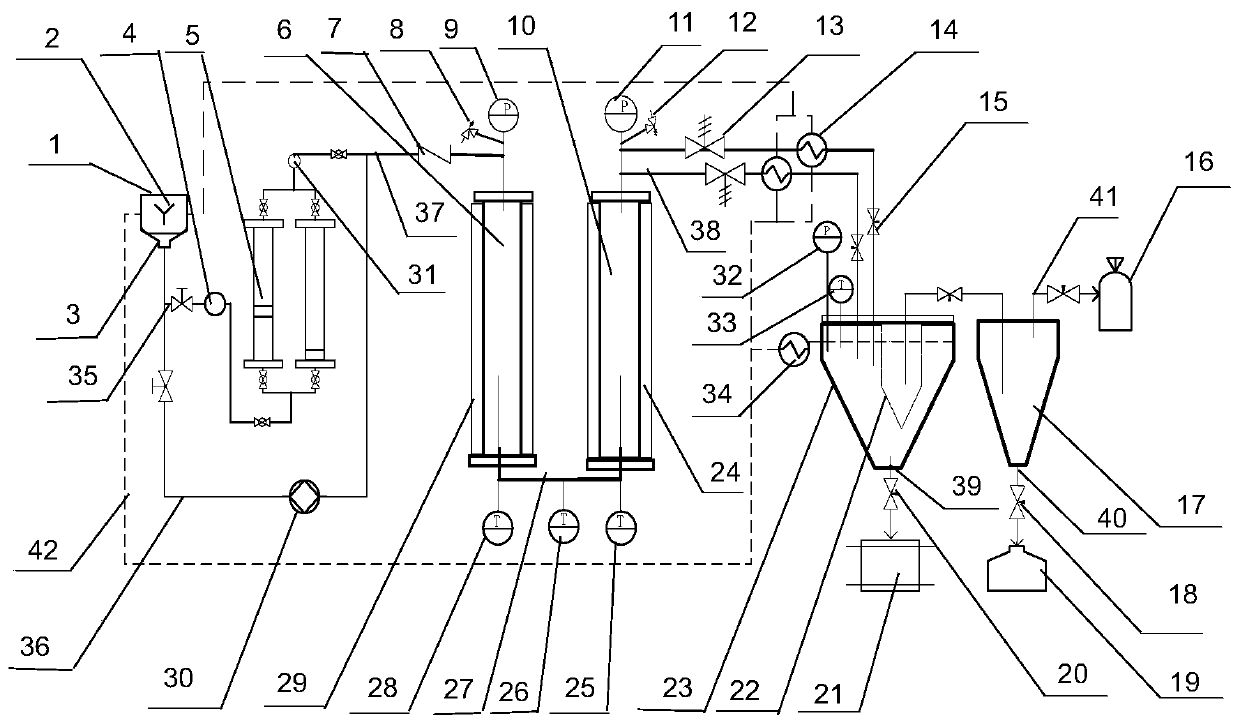

Continuous reaction system for preparing bio-oil through microalgae hydrothermal liquidization and method thereof

ActiveCN106118705AReduce energy consumptionContinuous separationLiquid hydrocarbon mixture productionHydrocarbon oils treatmentVapor–liquid separatorOrganic solvent

The invention provides a continuous reaction system for preparing bio-oil through microalgae hydrothermal liquidization and a method thereof. According to the invention, a two-stage preheater is set so that waste heat after liquidization can be fully used, and integral energy consumption of the reaction system is reduced. The system can continuously realize the separating of the liquidized products with high efficiency through combined effect of a solid-liquid separator, a gas-liquid separator and a centrifuge, and an extra organic solvent for separating the bio-oil is not required. Compared with the other hydrothermal liquidization systems, the system provided by the invention has the advantages of low operation cost, complete separation of the products, and good system continuity, and can be widely used for preparing bio-oil through microalgae hydrothermal liquidization.

Owner:XI AN JIAOTONG UNIV

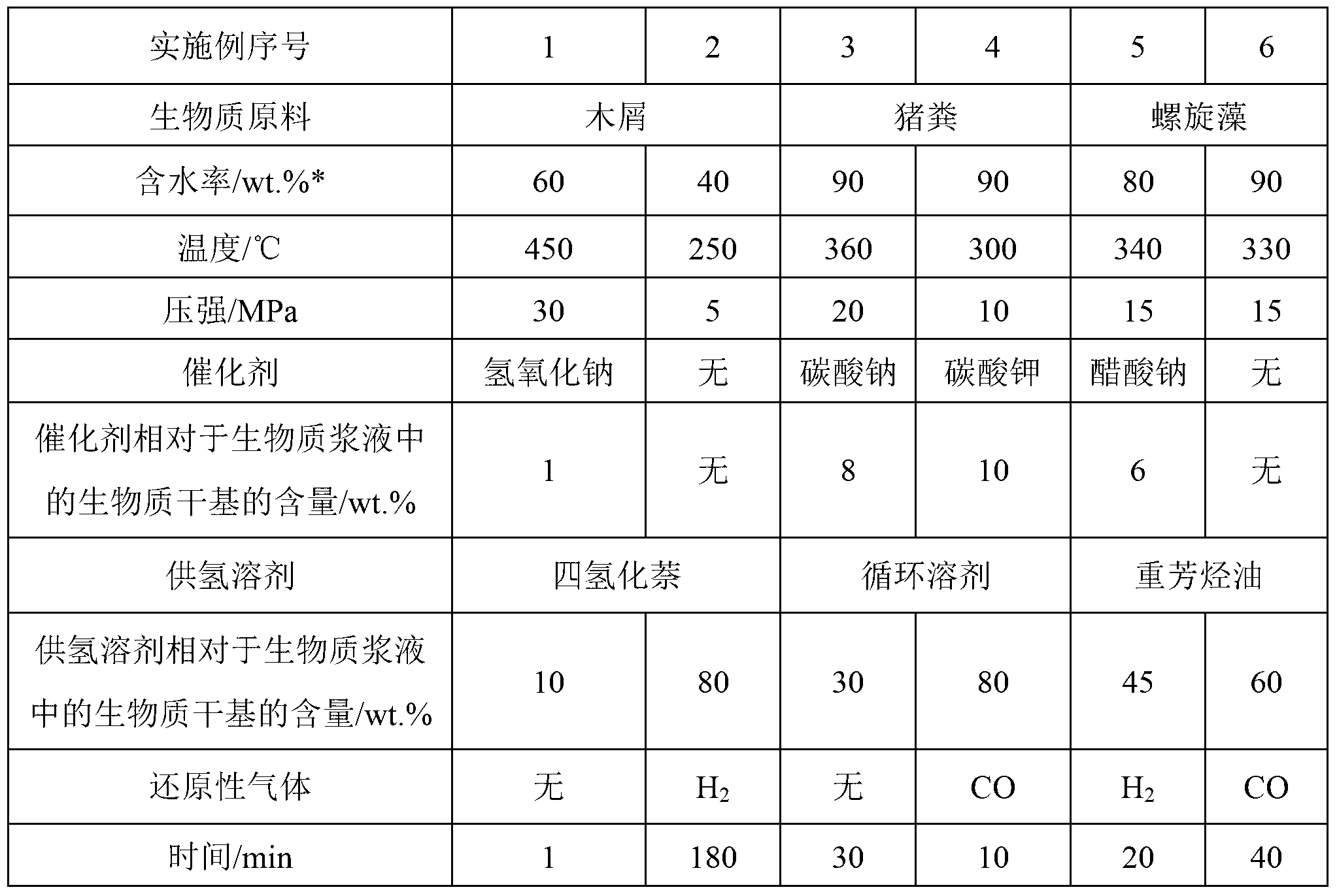

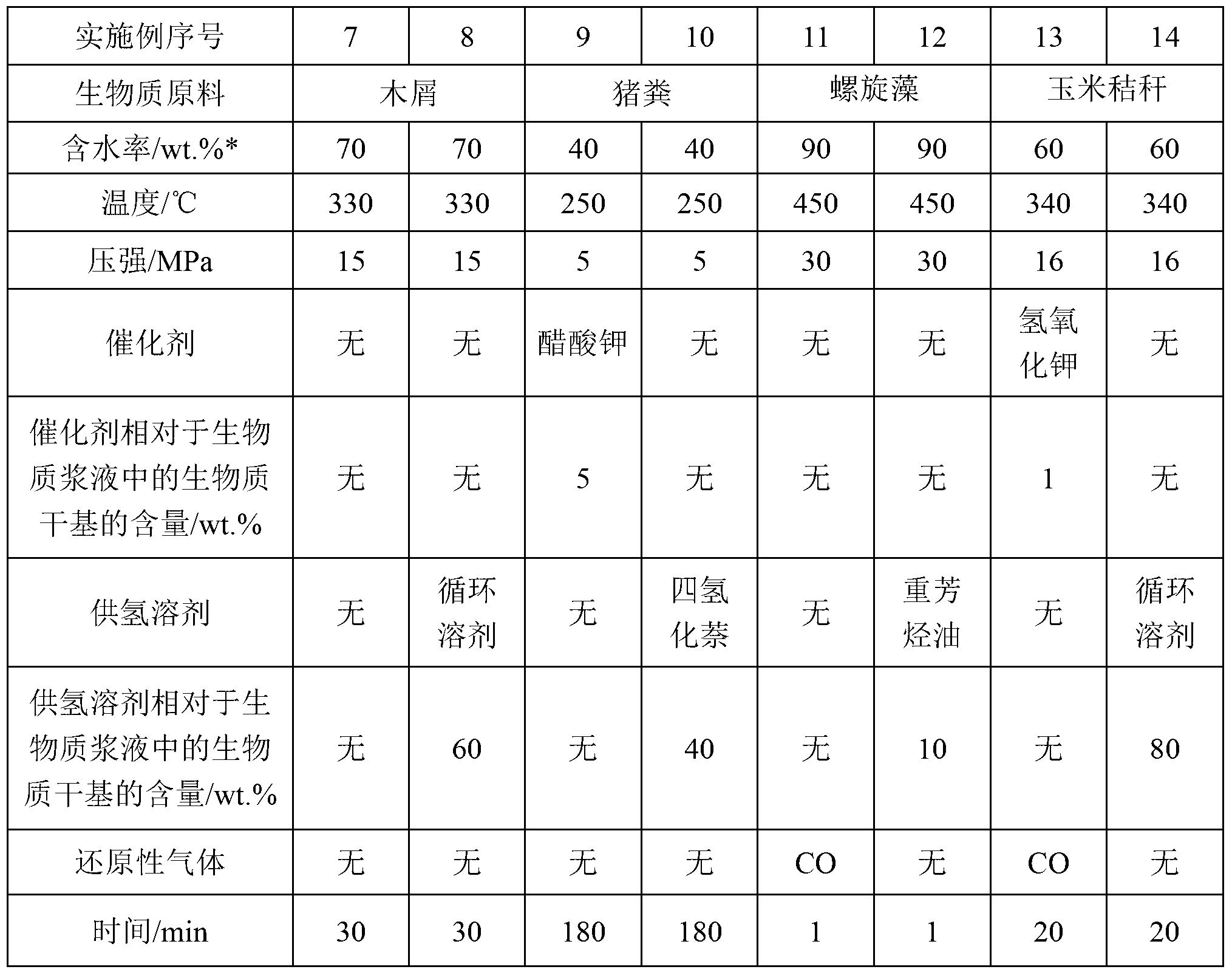

Method for preparing bio-oil by liquefying biomass by high efficiency hydro-thermal method

InactiveCN103265967AHigh yieldIncrease equipment costLiquid hydrocarbon mixture productionSlurryOil phase

The invention discloses a method for preparing bio-oil by liquefying biomass by a high efficiency hydro-thermal method, comprising the following steps of: (a) sending a biomass slurry with 40-90% of water content and a hydrogen-donor solvent into a liquefaction reactor, and reacting for 1-180min at 250-450 DEG C and under total pressure intensity of 5-30MPa, to generate a liquid-solid mixed slurry and gases; and (b) separating an oil phase from the liquid-solid mixed slurry, to obtain the bio-oil contain a hydrogen-poor solvent. The method introduces the hydrogen-donor solvent into a traditional 'CO / H2O / alkali metal catalyst' line, to obtain a new 'hydrogen-donor solvent / H2O' line, is especially suitable for biomass with high water content, and can still obtain a high oil-production rate under a condition without a catalyst and / or a reducing gas.

Owner:ZHEJIANG UNIV

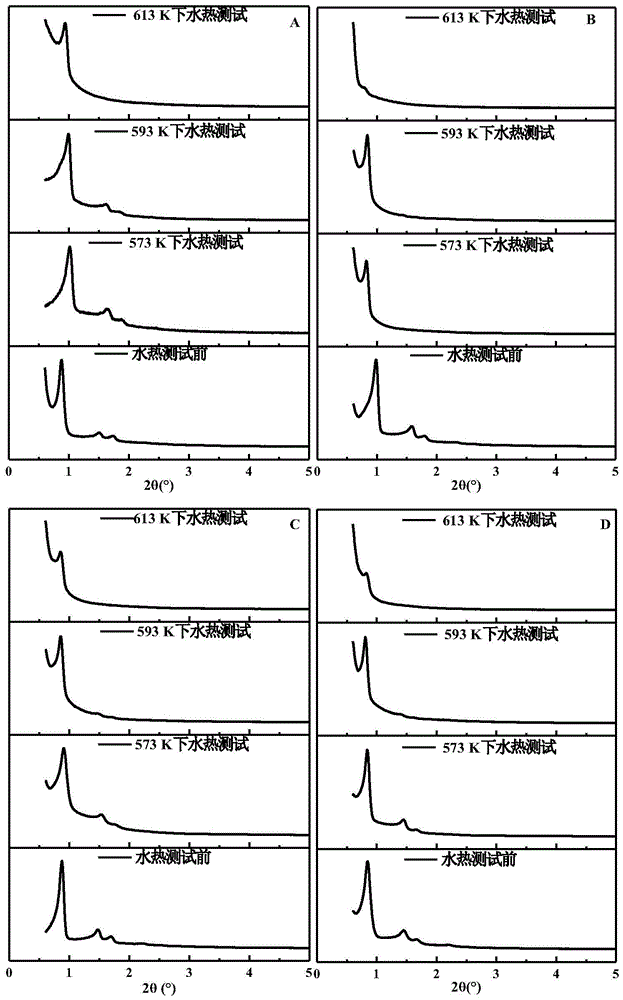

A mesoporous catalyst with hydro-thermal stability, a preparing method thereof and a method of catalyzing microalgae hydrothermal liquefaction with the catalyst to prepare bio-oil

ActiveCN105536849AOvercoming and mitigating pollution problemsReduce energy consumptionMolecular sieve catalystsLiquid carbonaceous fuelsMolecular sieveThermal stability

The invention discloses a mesoporous catalyst with hydro-thermal stability. The catalyst is prepared by subjecting a mixture containing a dual-template, an active metal salt and a silicon source to one-step hydrothermal crystallization under a sealed condition so as to introduce the metal to a mesoporous molecular sieve SBA-15, wherein the active metal is one or more of Pt, Pd, Zr, Ru, Ni, Co and Mo. The invention also discloses a method of catalyzing microalgae hydrothermal liquefaction with a mesoporous catalyst material with hydro-thermal stability to prepare bio-oil. The method includes introducing the prepared mesoporous catalyst material with hydro-thermal stability into a process of preparing the bio-oil through the microalgae hydrothermal liquefaction. After the bio-oil prepared by liquefaction is separated and purified, the liquefaction product mainly comprises furfural and furfural derivatives.

Owner:TSINGHUA UNIV

Method for producing fuel oil from biomass through hydro-thermal liquefaction

InactiveCN108165290AImprove conversion ratePotential for industrial applicationsLiquid hydrocarbon mixture productionHydrocarbon oils treatmentMass ratioReaction temperature

The invention discloses a method for producing fuel oil from biomass through hydro-thermal liquefaction. The method is characterized by comprising the following steps: fully mixing a biomass raw material with the solvent water (or further with an aqueous solution of a catalyst) to form slurry, wherein a mass ratio of the catalyst to the raw material is in a range of 1: 10 to 1: 50, and a mass ratio of the catalyst to water is in a range of 1: 2 to 1: 8; carrying out a reaction in a slurry bed reactor in a reducing atmosphere, wherein a liquefaction reaction temperature is controlled to be 300to 450 DEG C, a reaction pressure is controlled to be 5 to 30 MPa, and reaction time is controlled to be 5 to 40 min; and after completion of the reaction, carrying out separation on a product so as to obtain fuel oil, solid residues, water, gas, etc. According to the invention, the conversion of biomass is thorough; the yield of an oil product is high; the calorific value of the prepared oil product is equivalent to the calorific value of standard oil; and the method can alleviate dependence on fossil energy, is beneficial for environmental protection and low in production cost, and has goodsocial and economic benefits.

Owner:西宁晶海科教化玻仪器有限公司

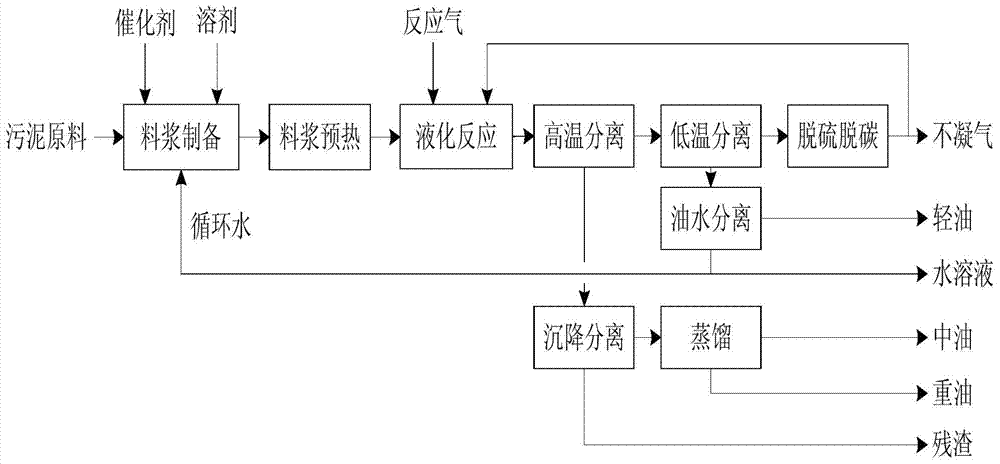

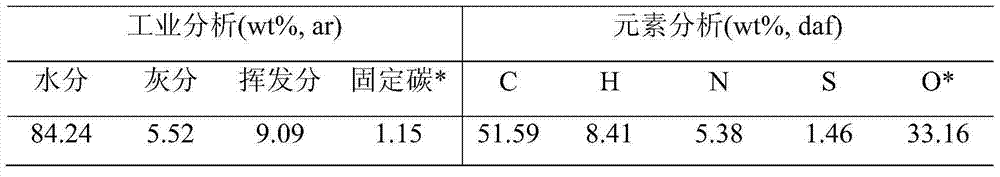

Processing method for preparing liquid fuel by performing sludge liquefaction

InactiveCN103614168AQuality improvementImprove the conversion rate of hydrogenation catalytic liquefactionSludge treatmentLiquid carbonaceous fuelsSludgeGas phase

The invention discloses a processing method for preparing a liquid fuel by performing sludge liquefaction. The processing method comprises the following steps: 1, mixing a sludge raw material, a recycling solvent and a catalyst in proportion at a certain temperature so as to obtain a slurry; 2, after preheating the slurry, and mixing the slurry and reaction gas to generate a liquefaction reaction; 3, performing gas-liquid separation on a liquefied product, and separating a gas phase by using an oil-water separator to obtain light oil, gas and a water phase, performing desulfurization and decarbonization on the gas phase to obtain noncondensable gas, performing settling separation on a liquid phase to obtain an oil phase and residues, and distilling the oil phase to obtain medium oil and heavy oil; 4, pressurizing partial noncondensable gas to return the partial noncondensable gas into a reactor so as to participate in a liquefaction reaction; 5, returning partial water phase to the slurry preparation step. According to the processing method, the sludge raw material without drying treatment is directly subjected to a hydrothermal liquefaction reaction under the atmosphere of CO or synthesis gas, not only can a lot of water in the raw material be consumed, but also the quality of the liquefaction product is improved, so that high-quality oil and other products are obtained. By adopting the processing method, the organic substances in the sludge are efficiently transferred, and the processing method has good environment and social benefit.

Owner:EAST CHINA UNIV OF SCI & TECH +1

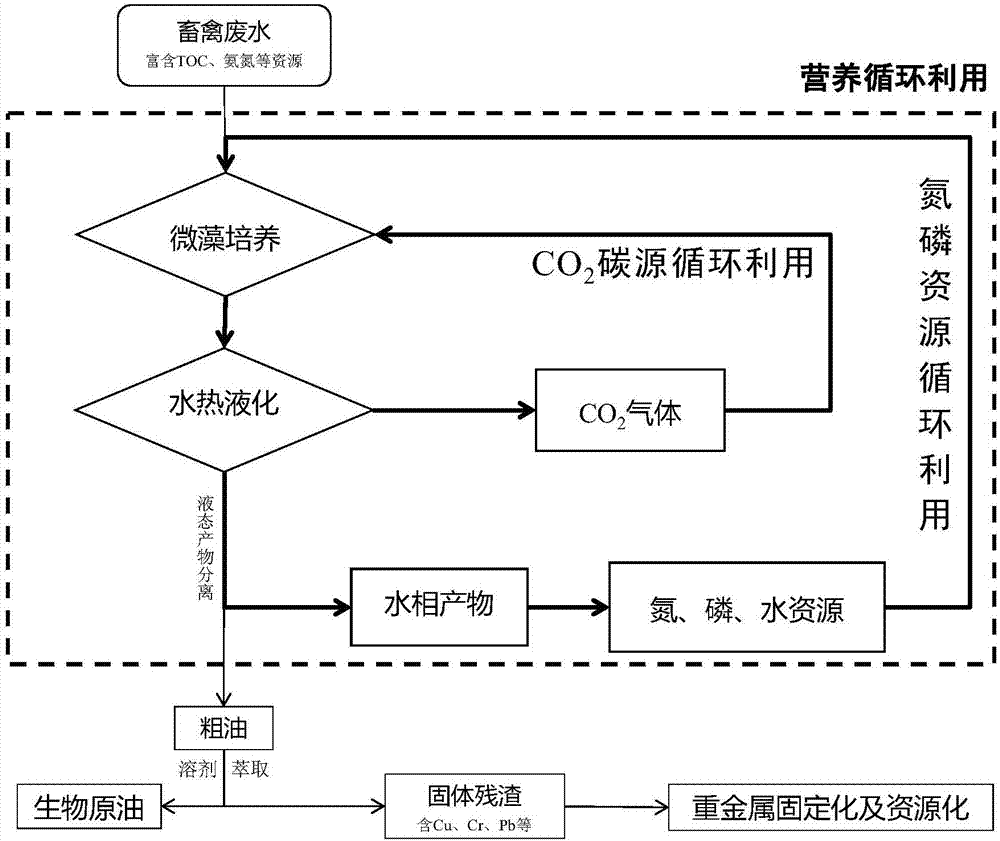

Method for livestock wastewater environment value-added utilization

ActiveCN107151055AAchieve recyclingAvoid pollutionSpecific water treatment objectivesWater contaminantsLiquid productNew energy

The invention belongs to the technical fields of environmental protection and new energy and particularly relates to a microalgae culture and hydrothermal liquefaction based livestock wastewater value-added utilization method which comprises the following steps: 1) performing flocculating settling and filtering on livestock wastewater, placing a diluted solution in a microalgae culture pool, and inoculating domesticated microalgae to the solution; 2) performing microalgae culture; 3) performing hydrothermal liquefaction; and 4) performing liquid product separation, filtering and separating a liquid mixture product to obtain crude oil and a water-phase product, hydrothermal liquefaction wastewater is circularly used by being introduced into the microalgae culture pool in the step 2) serving as a nutrient solution for supplementing nutrient substance, such as nitrogen, phosphorus and the like; wherein the hydrothermal liquefaction wastewater is introduced into the microalgae culture pool to be mixed with the livestock wastewater, and regulating the concentrations of water quality total nitrogen TN and water quality total phosphorus TP in the microalgae culture pool to 200-1000mg / L and 20-500mg / L respectively, and repeating the steps 2)-4). According to the method, nutrient elements such as nitrogen, phosphorus and the like in the livestock wastewater can be supplemented again through the hydrothermal liquefaction wastewater so as to be recycled for 3-10 times.

Owner:CHINA AGRI UNIV

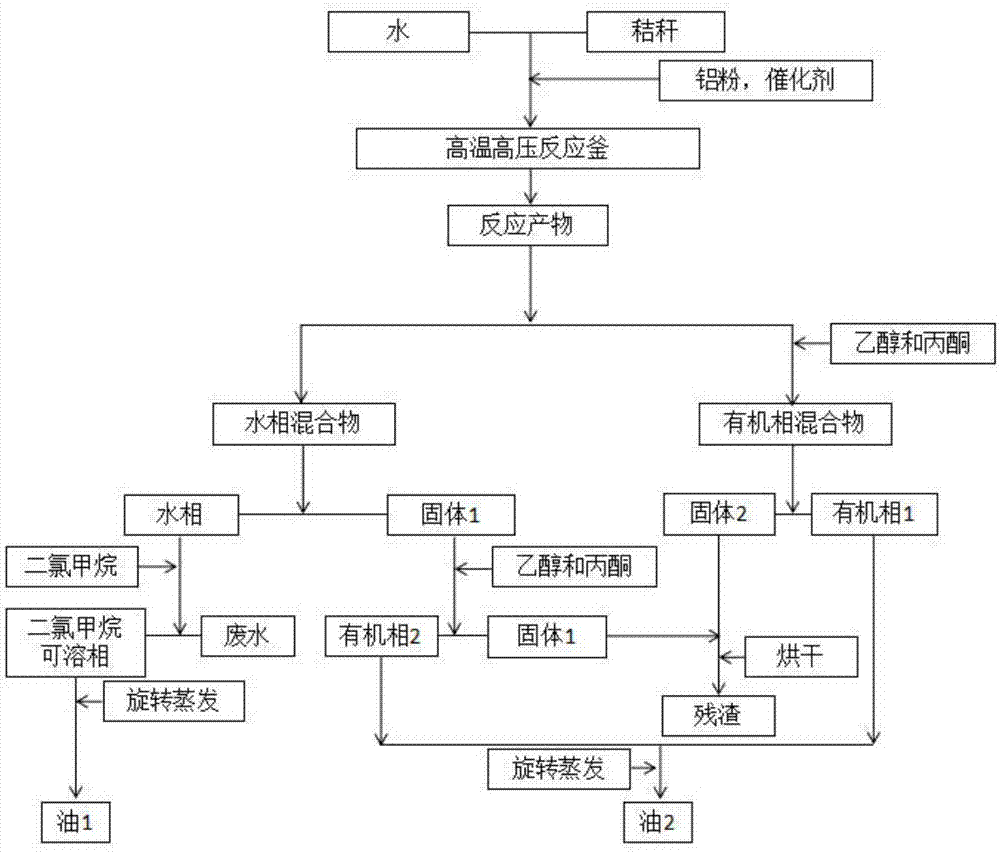

Biomass in-situ hydrogen supply liquefaction oil preparation method

ActiveCN107163973ALow oxygenImprove qualityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentNew energyOil quality

The invention relates to a novel biomass hydrothermal liquefaction bio-oil preparation method. An aluminum-water hydrogen producing reaction is used as a hydrogen supply source to be cooperated with corn stalk catalytic liquefaction for preparing bio-oil; the bio-oil quality can be improved; the method belongs to the technical field of environment protection and new energy sources. The aluminum-water hydrogen producing reaction is used as the hydrogen supply source to be cooperated with corn stalk catalytic liquefaction for preparing bio-oil; the aluminum water reaction hydrogen production and the biomass hydrothermal liquefaction are performed at the same time; the in-situ hydrogen supply modification refining is performed in the biomass liquefaction process; the bio-oil oxygen content can be effectively reduced; the thermal value is improved; the goal of improving the bio-oil quality is achieved.

Owner:SHENYANG AEROSPACE UNIVERSITY

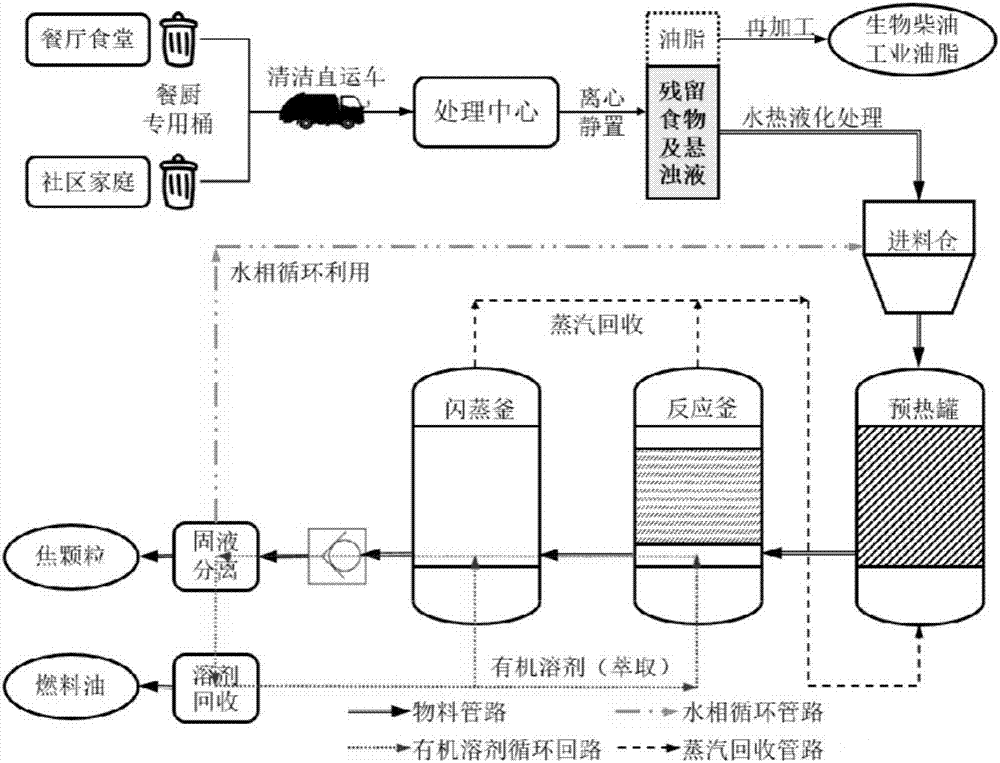

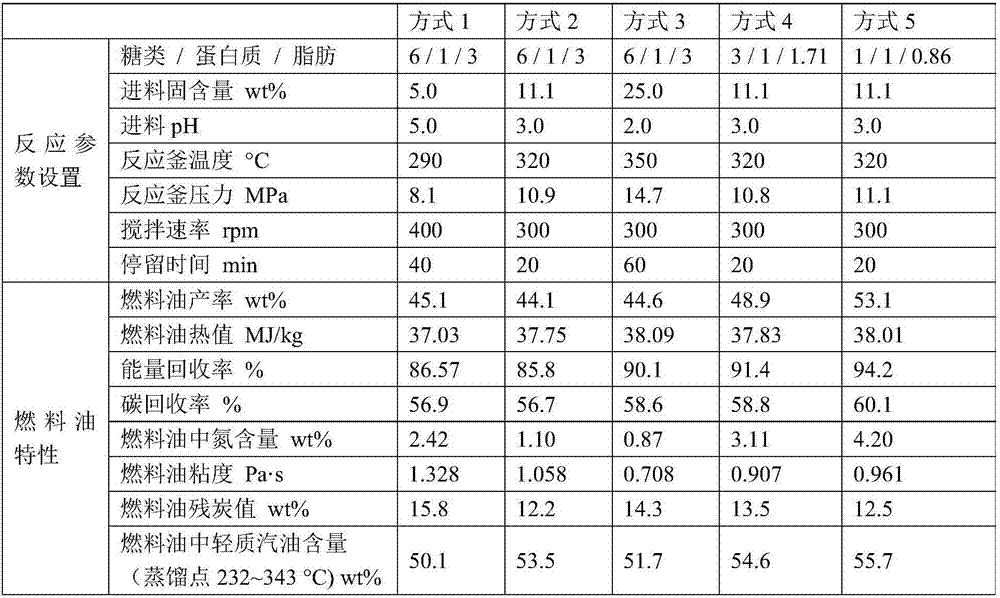

Method for preparing fuel oil by hydrothermally liquefying kitchen waste

ActiveCN107159679AHarmlessAchieve reductionFatty oils/acids recovery from wasteTransportation and packagingOil and greaseAlkane

The invention discloses a method for preparing fuel oil by hydrothermally liquefying kitchen waste, which can realize fast and efficiency resource utilization of the kitchen waste. After the kitchen waste is collected, inorganic impurity in the kitchen waste is separated, and the residue is used as raw materials; the separated raw materials are subjected to centrifuging and standing processing, grease on the upper layer is separated as biodiesel or industrial grease raw materials, massive residue food in the lower layer and swill turbid liquid are fed into a hydrothermal reaction kettle, a temperature in the reaction kettle is controlled within 290-350 DEG C, a self pressure range is 8-15MPa, stirring and standing under a hydrothermal condition for 20-60min are performed, a relief valve is opened, and discharged high temperature steam preheats charged materials and is recycled. After pressure relief, an organic solvent (mixed alkanes) is added to extract product oil adhered to the bottom and wall surface of the reaction kettle. The method for preparing fuel oil by hydrothermally liquefying kitchen waste can realize resource utilization of the high water content kitchen waste, and organic waste with an extremely low heat value is subjected to hydrothermal liquefying to prepare the fuel oil with a high heat value and high additional value.

Owner:ZHEJIANG UNIV

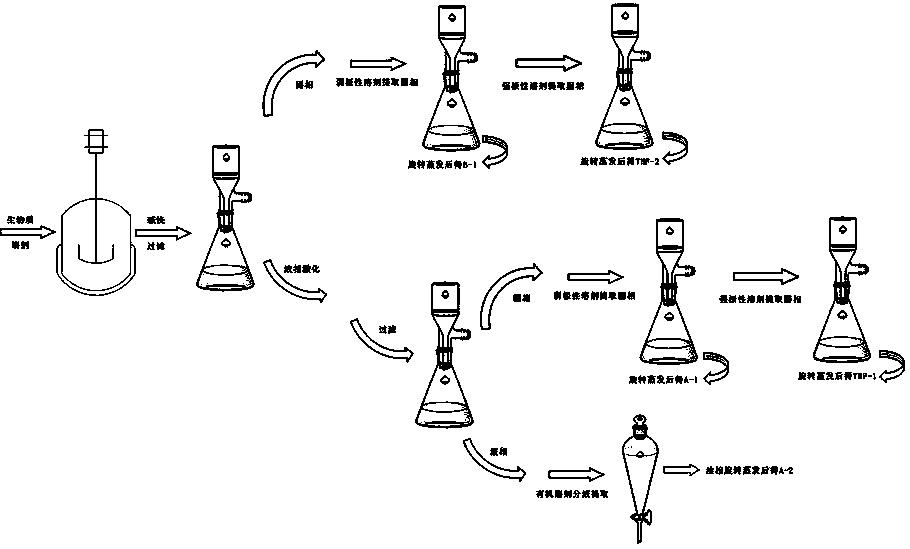

Separation method for solid-phase biomass hydrothermal liquefaction products

ActiveCN103755506AAccelerate the pace of researchThe separation method is simpleOrganic compounds purification/separation/stabilisationFuranFatty acid

The invention belongs to the field of resource utilization of biomass waste, and particularly relates to a separation method for solid-phase biomass hydrothermal liquefaction products. The solid-phase biomass hydrothermal liquefaction products refer to solid-phase products (comprising oil-phase products and solid residues) obtained by the hydrothermal liquefaction reaction of biomasses, wherein the biomasses comprise enteromorpha, microalgae, rice straws, salix psammophila, tobacco stems, corncobs, sawdust, water hyacinths and the like. According to the method, the solid-phase biomass hydrothermal liquefaction products are mainly used as raw materials, a separation scheme of performing alkali washing and acidification and sequentially and stepwise extracting products by using organic solvents with different polarities is adopted, and the obtained products are analyzed, so that phenol, fatty acid, furan and cyclopentenone compounds can be separated in a way of combining multi-stage solution pH regulation and multi-stage stepwise extraction with the organic solvents with different polarities; the separation method is simple and convenient, environment-friendly, less in pollution, low in cost and favorable for industrial production, and the solvents can be recycled.

Owner:FUDAN UNIV

Method for reclaiming nutrient elements in hydrothermal liquidation waste water and equipment for using nutrient elements

ActiveCN104926022ATake advantage ofFully degradedBioreactor/fermenter combinationsBiological substance pretreatmentsChemical oxygen demandFiltration membrane

The invention provides a method for reclaiming and using nutrient elements in hydrothermal liquidation waste water. The method comprises the following steps that (1) the waste water which is generated by making biological crude oil by a hydrothermal liquidation method is diluted by water until the concentration of COD (chemical oxygen demand) is 18,000 to 20,000mg / L; (2) a photosynthetic bacterium is inoculated into the waste water to culture; (3) after being cultured for 11 to 13 days, the waste water is separated by an ultra-filtration membrane; (4) microalgae are inoculated in the separated water, at daytime, CO2 and air-mixed gas are filled into the water to continuously culture for 6 to 8 days. The method of combining the photosynthetic bacterium and the microalgae to reclaim the nutrient elements in the hydrothermal liquidation waste water and reclaim a water resource is provided for the first time, the current gap of treating the hydrothermal liquidation waste water is solved, organics, nitrogen and phosphorus in the waste water can be degraded and reclaimed, biomass materials can also be produced to be applied to hydrothermal liquidation to produce crude oil, meanwhile, the reclaimed water can serve as the dilution water for the primary hydrothermal liquidation waste water, and the functions of protecting environment, reclaiming the organics and the water resource, and producing biomasses are realized.

Owner:CHINA AGRI UNIV

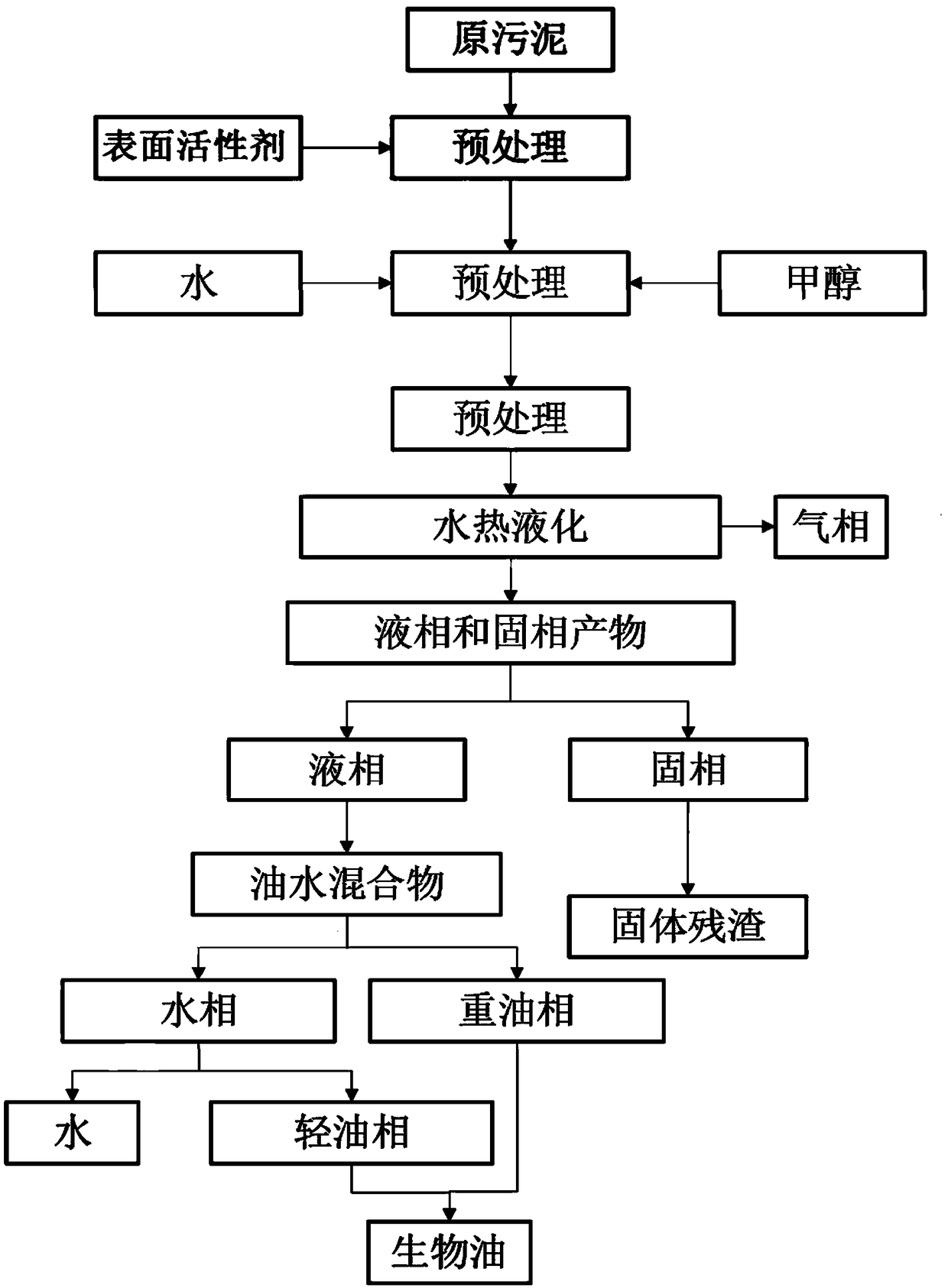

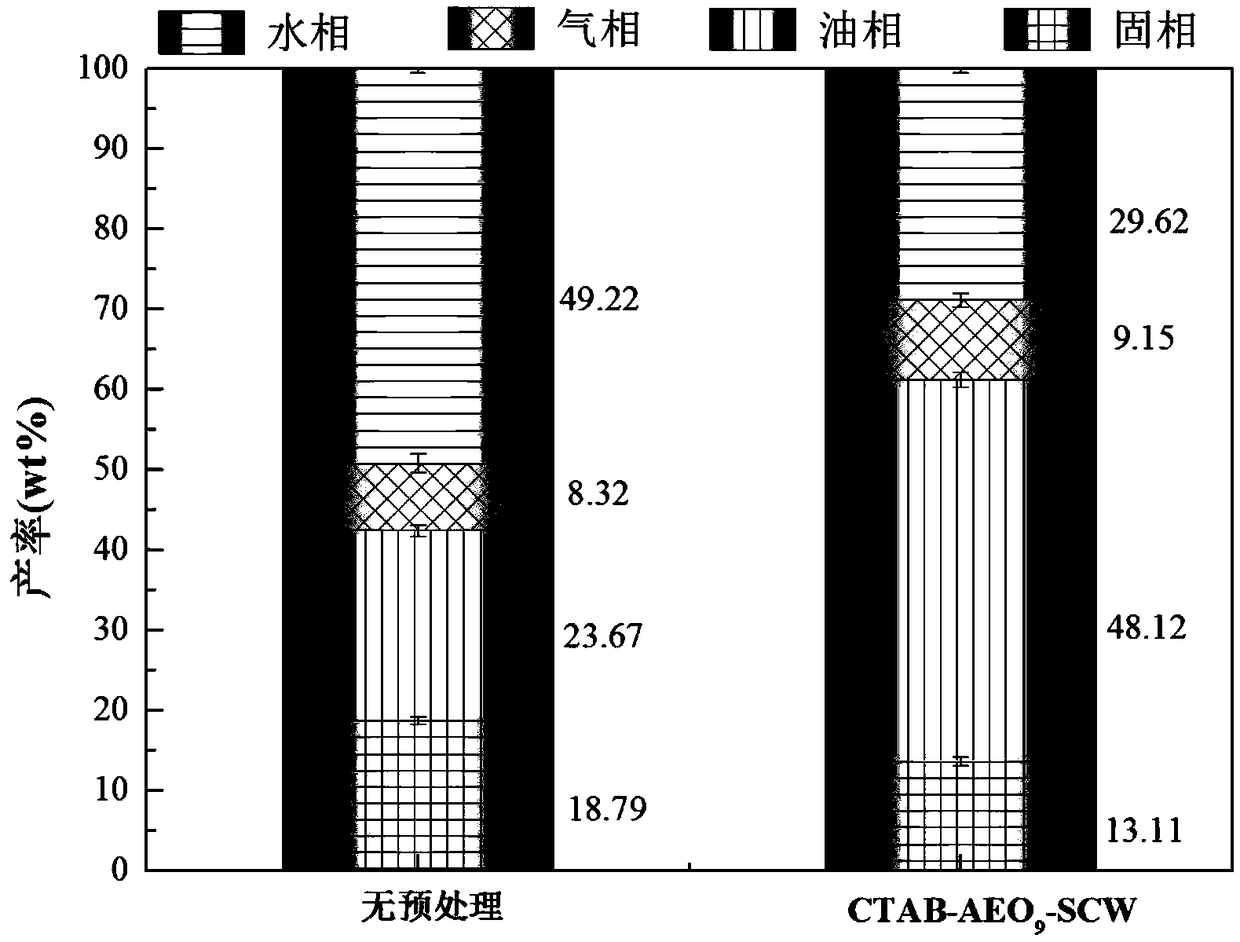

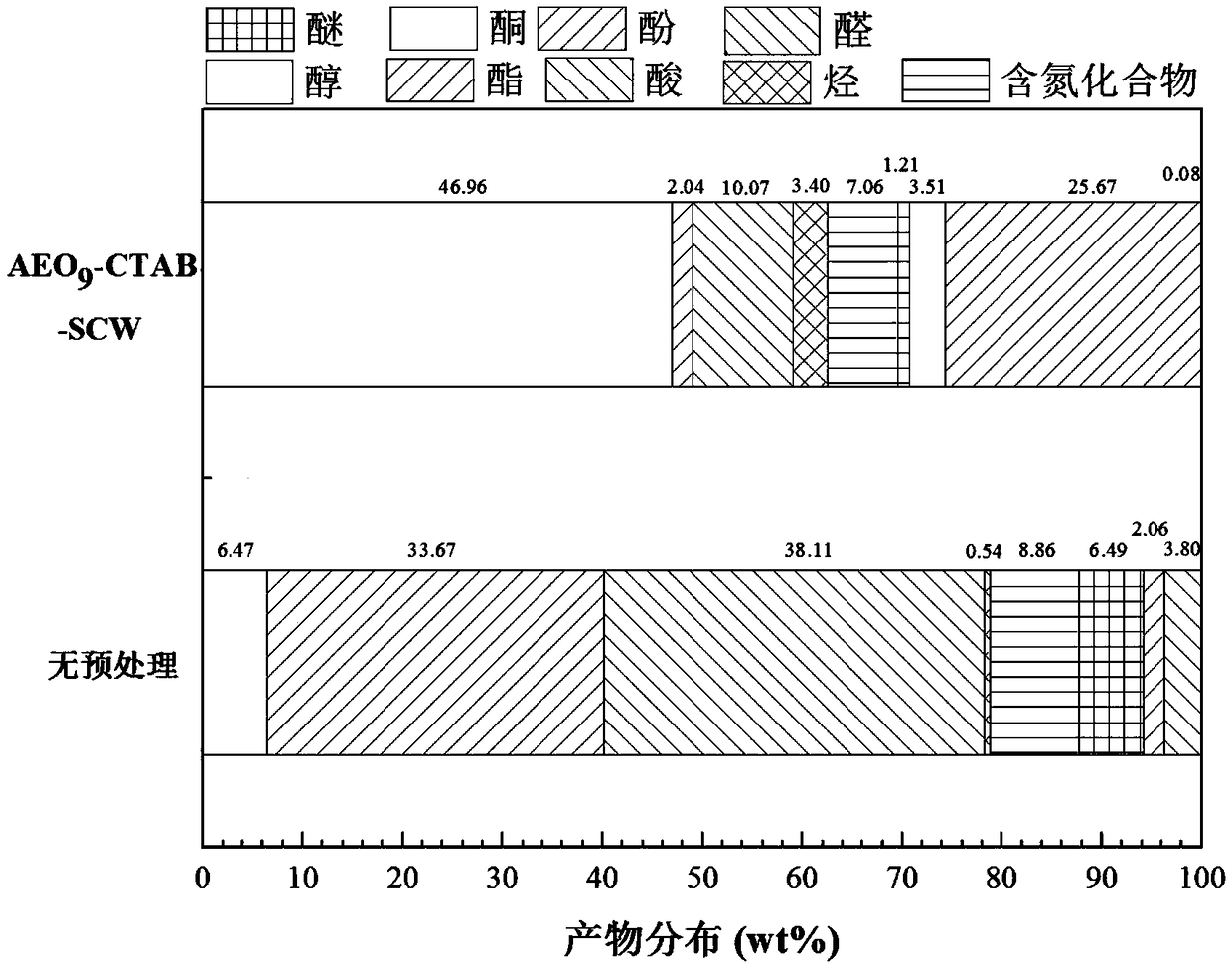

Method of preparing bio-oil through raw material pretreatment and hydrothermal liquefaction

InactiveCN108659876ASource not requiredReduce consumptionWater contaminantsLiquid hydrocarbon mixture productionBound waterSludge

The invention belongs to the technical field of environmental protection and new energy and relates to a novel method of improving quality of biological fuel produced by a biomass hydrothermal liquefaction method, in particular to a method of preparing bio-oil through raw material pretreatment and hydrothermal liquefaction. In order to solve the problems of lower bio-oil productivity and too complicated oil ingredients of the existing sludge hydrothermal liquefaction method, the novel method of preparing biological fuel through chemical pretreatment-hydrothermal liquefaction is developed according to a removal effect of two-step pretreatment of CTAB, AEO9 and subcritical water on bound water in sludge and a modification effect of a methanol cosolvent on the bio-oil.

Owner:SHENYANG AEROSPACE UNIVERSITY

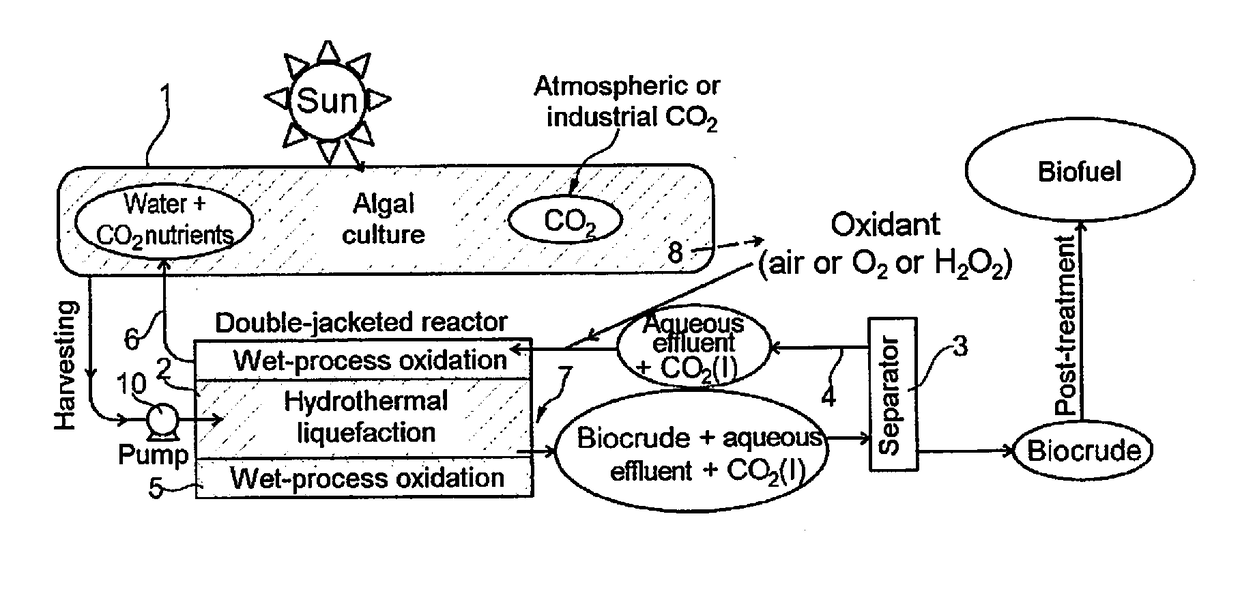

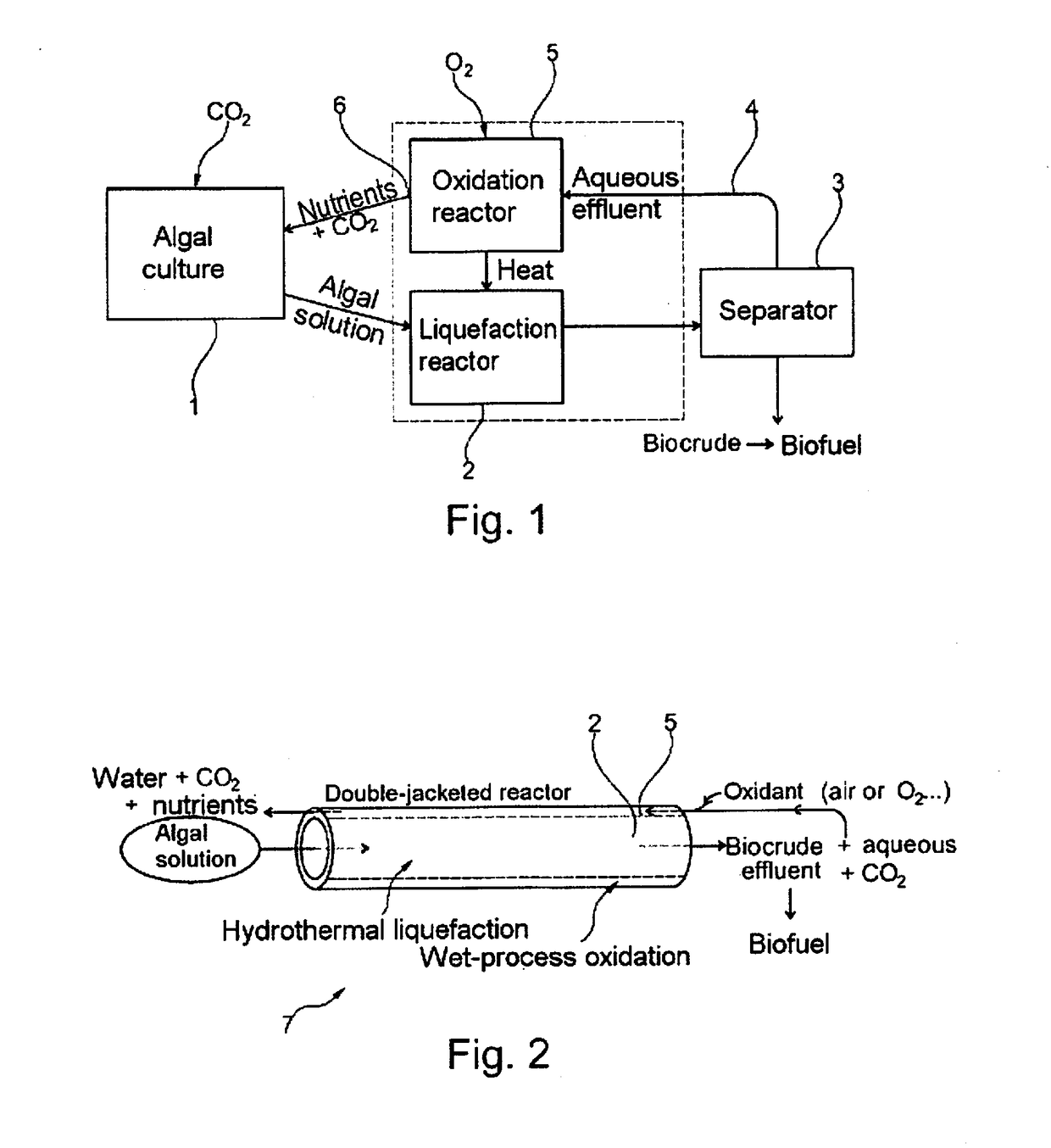

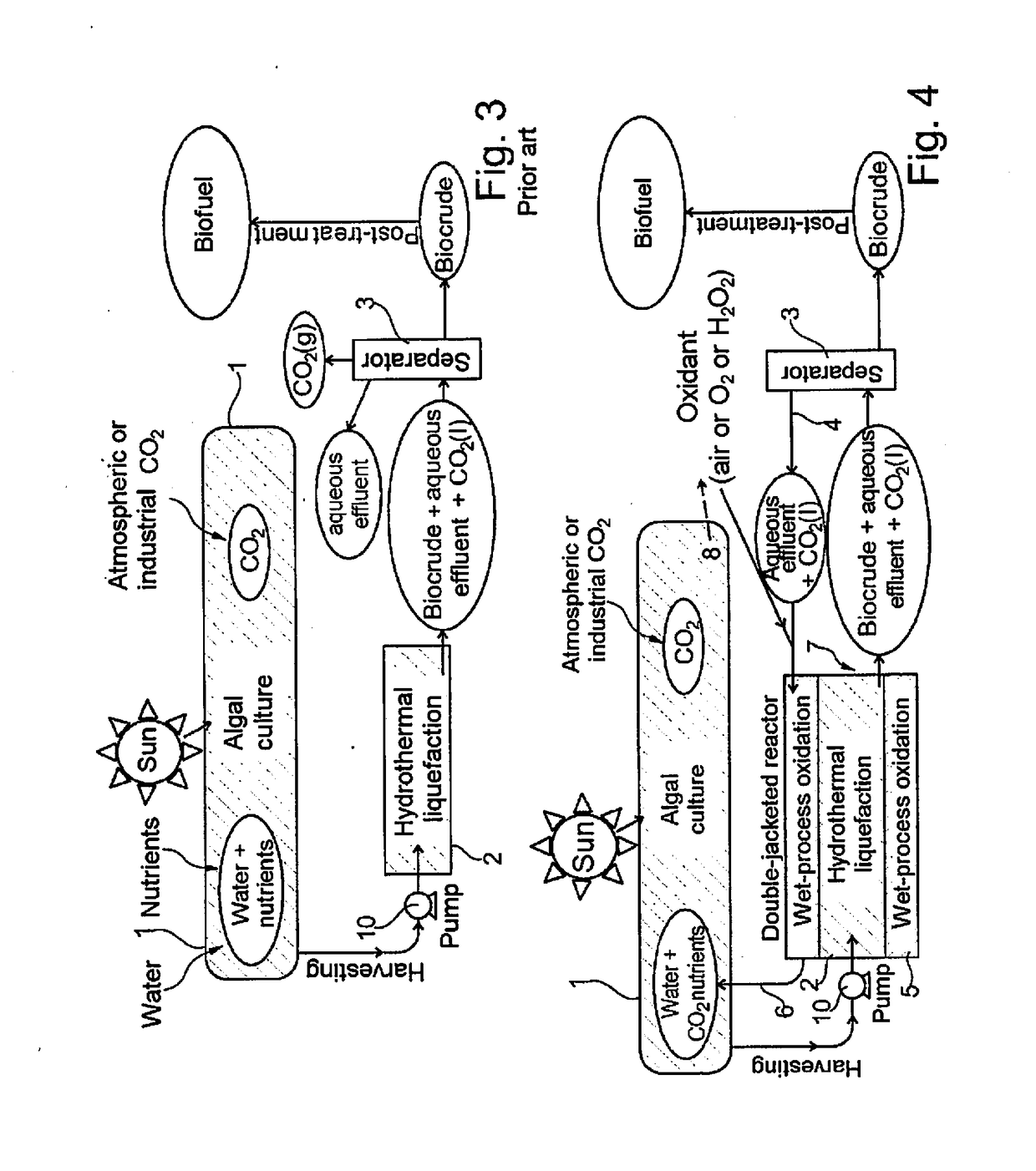

Method for converting algal biomass into a gas or into biocrude by hydrothermal gasification or hydrothermal liquefaction, respectively

ActiveUS20170342327A1Efficient conversionWaste based fuelGasification processes detailsProduct gasHydrothermal liquefaction

The invention relates to methods for converting algal biomass into a gas or into biocrude comprising (a) gasification or hydrothermal liquefaction of an algal biomass in at least one first reactor, (b) separation of the gas or biocrude produced thereby from the aqueous effluents and the CO2 produced, at the outlet of the first reactor, (c) recovery of the aqueous effluents, and (d) oxidation of the aqueous effluents in at least one second reactor. Continuous processes for culture of algal biomass and conversion of the algal biomass cultivated into a gas or into a biocrude are also disclosed.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

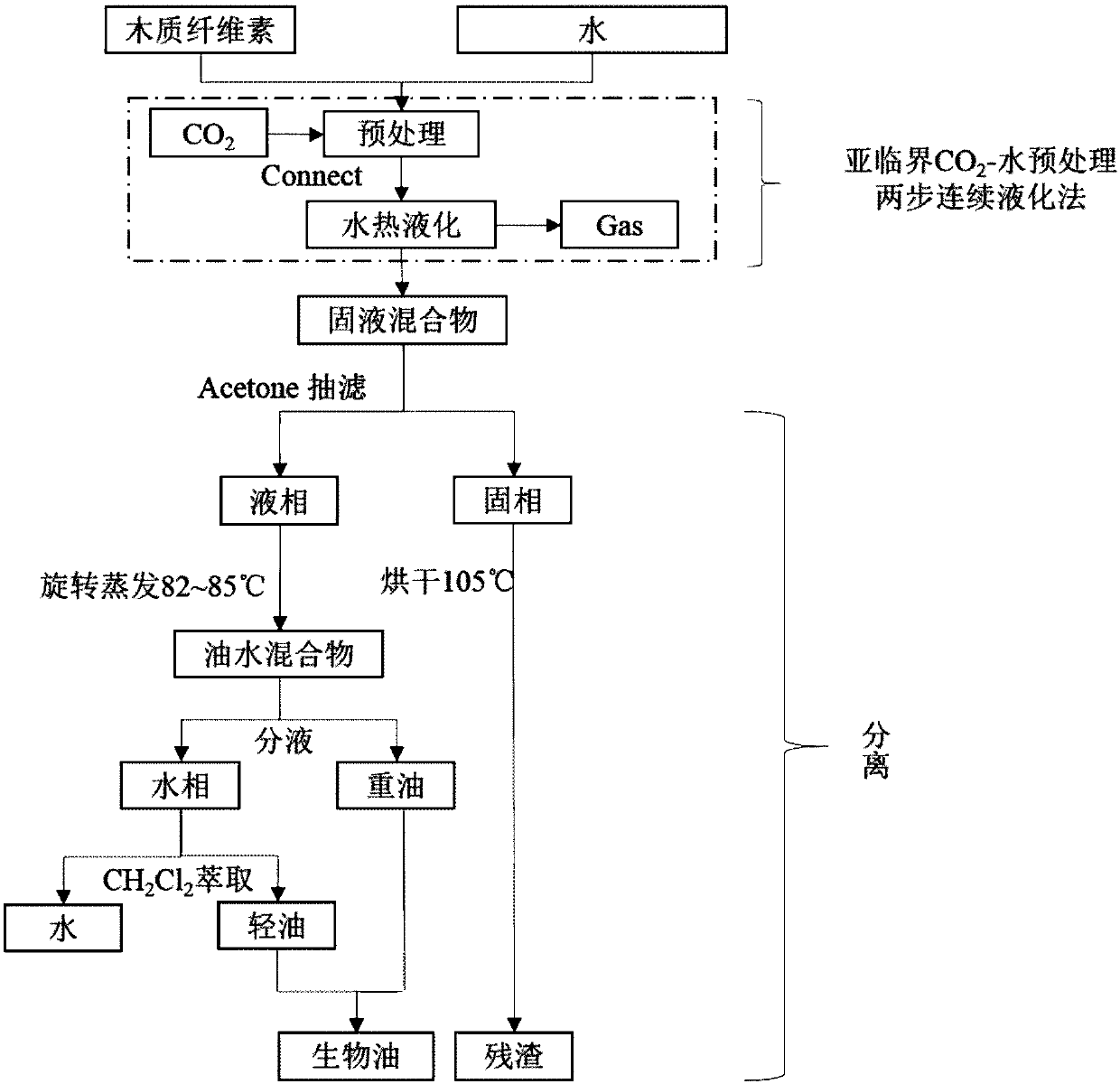

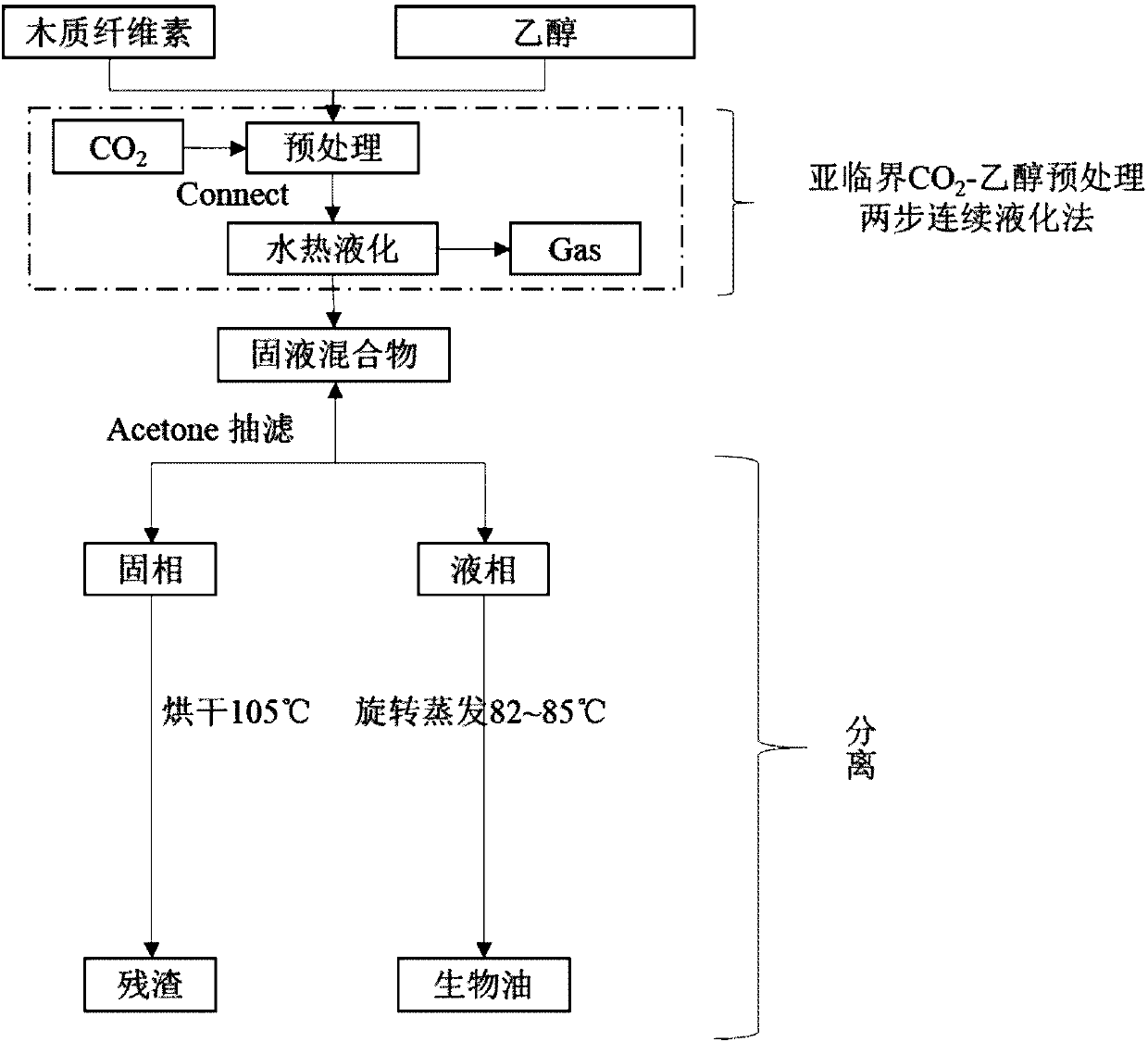

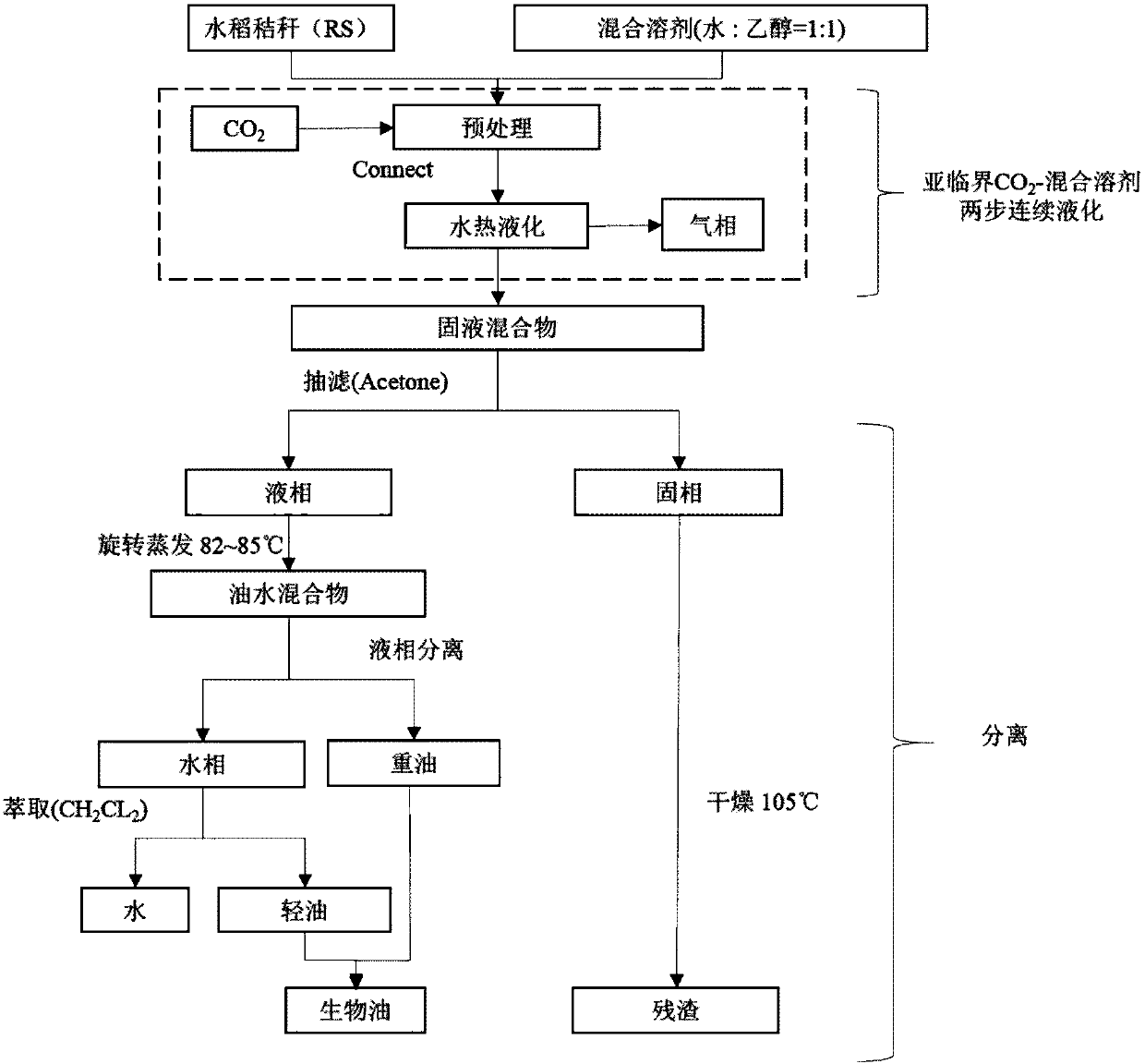

Method for preparing bio-oil by performing two-step grading hydrothermal liquification on lignocellulose under CO2 atmosphere

ActiveCN107858170AImprove conversion rateHigh yieldLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHeat stabilityChemical products

The invention belongs to the technical field of green renewable energy of bio-oil prepared by biomass, and in particular relates to a method for preparing bio-oil by performing two-step grading hydrothermal liquification on lignocellulose under CO2 atmosphere. The invention provides a method for preparing bio-oil and chemical products with high additional value by performing high-temperature and high-pressure liquification on lignocelluloses biomass in an intermittent reaction kettle. According to the method, gas generated based on liquification reaction is CO2 mainly, the defect that supercritical CO2 fluid cannot be directly extracted to prepare the bio-oil is overcome, the CO2 and the solvent form an acidic thermal solvent by a mode of externally supplying the CO2 to achieve the pretreatment coupling effect, the integrated liquification process is divided into a plurality of stages based on different heat stability of three components, such as cellulose, hemicellulose and lignin, ofthe lignocelluloses, the conversion rate and the yield of the bio-oil are further increased, the generation quantity of residues and gases are reduced, and directional regulation and control of the biomass liquification process are realized.

Owner:SHENYANG AEROSPACE UNIVERSITY

System and process for efficient separation of biocrudes and water in a hydrothermal liquefaction system

ActiveUS9404063B2Efficient separationLow viscosityDewatering/demulsification with mechanical meansFatty-oils/fats refiningEmulsionInorganic compound

A system and process are described for clean separation of biocrudes and water by-products from hydrothermal liquefaction (HTL) product mixtures of organic and biomass-containing feedstocks at elevated temperatures and pressures. Inorganic compound solids are removed prior to separation of biocrude and water by-product fractions to minimize formation of emulsions that impede separation. Separation may be performed at higher temperatures that reduce heat loss and need to cool product mixtures to ambient. The present invention thus achieves separation efficiencies not achieved in conventional HTL processing.

Owner:BATTELLE MEMORIAL INST +1

Two-step production method for microalgae bio-oil

ActiveCN105001971AReduce nitrogen contentReduce the cost of quality improvementPeptide preparation methodsFatty-oils/fats productionHydrogenNitrogen

Relating to the technical field of microalgae bio-oil extraction, the invention discloses a two-step production method for microalgal bio-oil to solve the problem of high quality improvement cost caused by large nitrogen content of microalgae bio-oil. The method includes: firstly extracting protein contained in microalgae cells of a microalgae raw material to obtain a protein water solution and microalgae residue; then separating the protein precipitate from the protein water solution to obtain protein and a water phase; then adjusting the solid content of the microalgae residue with the water phase to obtain a microalgae residue suspension; and then taking the microalgae residue suspension as the raw material, and utilizing hydrothermal liquefaction method to produce microalgae bio-oil. Compared with conventional hydrothermal liquefaction methods, the microalgae bio-oil obtained by the method has a nitrogen content reduced by 40%, thus greatly saving the dosage of hydrogen during subsequent microalgae bio-oil quality improvement, reducing catalyst intoxicating phenomenon in the quality improvement process, and also realizing secondary utilization of the water phase at the same time. The two-step production method for microalgal bio-oil provided by the invention is used for extraction of microalgae bio-oil.

Owner:ENN SCI & TECH DEV

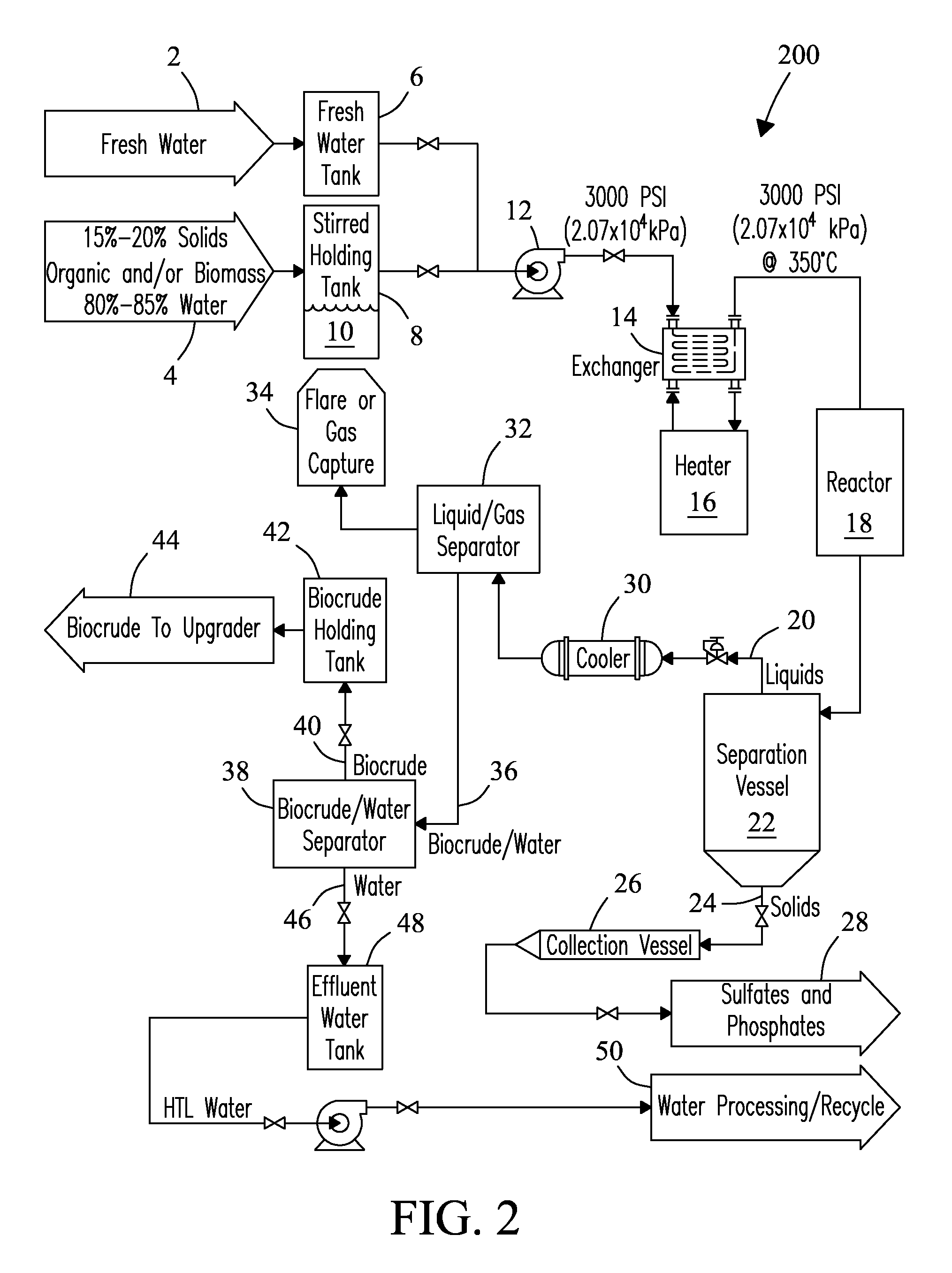

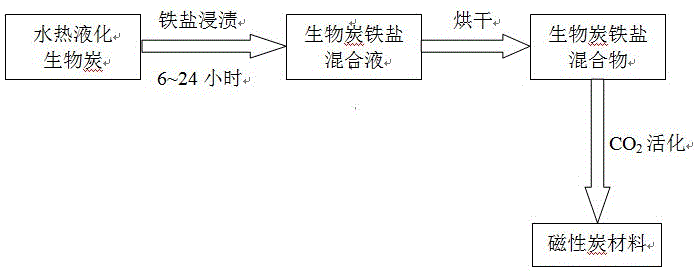

Method for preparing magnetic carbon material by activating hydrothermal liquified biochar through CO2 and application of method

InactiveCN105854799AHigh porosityAvoid wastingOther chemical processesAlkali metal oxides/hydroxidesMagnetic carbonEnvironmental engineering

The invention relates to a method for preparing magnetic carbon material by activating hydrothermal liquified biochar through CO2 and application of the method, belonging to the field of environment protection and resource utilization of solid wastes. The method comprises the following steps: 1, impregnating hydrothermal charcoal and ferric salt, and drying in the air; 2, performing pyrolysis on the dried material in a tubular atmosphere furnace in a CO2 atmosphere, taking out the material, washing the material with water, and drying the material to obtain a magnetic charcoal material; and 3, removing organic pollutants from a water body by the magnetic charcoal material. The method is simple, the cost is low, and magnetic charcoal has good magnetism and is easy to separate and free of secondary pollution. The method can be used for effectively reducing the content of CO2 in the atmosphere and alleviating the greenhouse effect, and provides an effective utilization way for waste hydrothermal liquified biochar.

Owner:FUDAN UNIV

Integrated recycling system for co-hydrothermal preparation of oil with sludge and microalgae and culture of microalgae with waste liquid

InactiveCN110194981ARealize added valueOvercome the difficulty of purification standardsBiofuelsSolid fuelsLiquid wasteSocial benefits

The invention discloses an integrated recycling system for co-hydrothermal preparation of oil with sludge and microalgae and culture of microalgae with waste liquid. The system comprises a microalgaeculture device and a hydrothermal liquefaction reactor. The cultured microalgae are adopted as the raw material and are compounded with sludge in proportion, then the mixture is input into the hydrothermal liquefaction reactor, the liquid phase in the pyrolysis product of the hydrothermal liquefaction reactor is input into the microalgae culture device and mixed with sewage in proportion, then themixture is used as the microalgae culture raw material, thus purifying sewage and avoiding the discharge of carbon, nitrogen and phosphorus elements in the liquid phase. The system provided by the invention has high economic, environmental and social benefits, is effectively applicable to treatment of urban sludge treatment with growing industry and can produce considerable economic and environmental benefits.

Owner:JIANGSU UNIV

Continuous type catalytic upgrading reaction system for microalgae liquefied oil

ActiveCN106987263AEfficient separationAchieve recyclingLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesVapor–liquid separatorOil phase

The invention provides a continuous type catalytic upgrading reaction system for microalgae liquefied oil. The continuous type catalytic upgrading reaction system for microalgae liquefied oil comprises a hydrothermal liquefaction reaction unit, a hydrothermal liquefaction separation unit, a catalytic upgrading reaction unit, a catalytic upgrading separation unit and an oil storage tank, wherein the hydrothermal liquefaction reaction unit is connected with the hydrothermal liquefaction separation unit; the hydrothermal liquefaction separation unit is connected with the catalytic upgrading reaction unit; the catalytic upgrading reaction unit is connected with the catalytic upgrading separation unit; the catalytic upgrading separation unit is connected with the oil storage tank; the catalytic upgrading separating unit comprises a gas-liquid separator and an upgrading centrifugal machine; a feeding opening of the gas-liquid separator is connected with the catalytic upgrading reaction unit; a liquid phase discharging opening of the gas-liquid separator is connected with a feeding opening of the upgrading centrifugal machine; an oil phase discharging opening of the upgrading centrifugal machine is connected with the oil storage tank; and the hydrothermal liquefaction separation unit comprises a liquefaction centrifugal machine. The continuous type catalytic upgrading reaction system for the microalgae liquefied oil can run efficiently and continuously.

Owner:XI AN JIAOTONG UNIV

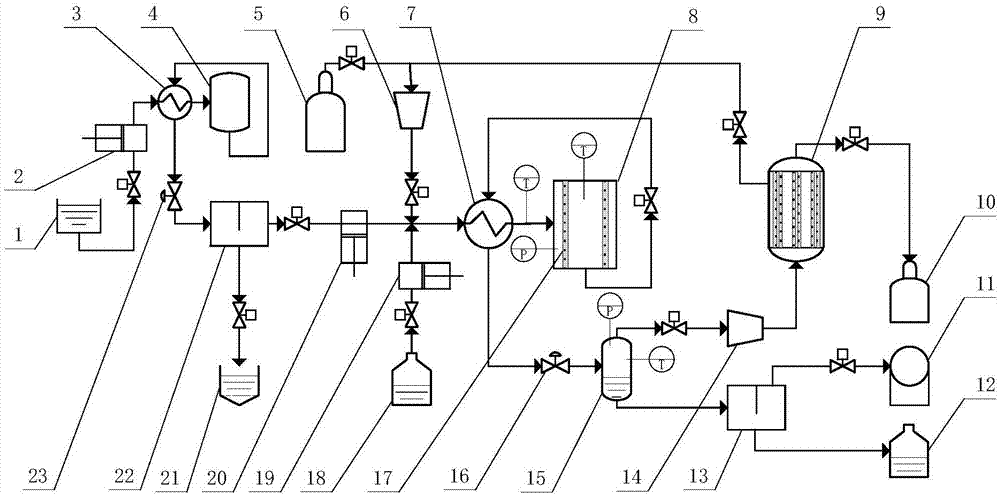

Device and method for preparing biological crude oil through biomass continuous hydrothermal liquefaction

ActiveCN110368885ALow costImprove universalityFatty-oils/fats refiningLiquid hydrocarbon mixture productionHydraulic cylinderHigh pressure

The invention belongs to the field of biomass energy utilization, and particularly relates to a device and method for preparing biological crude oil through biomass continuous hydrothermal liquefaction. The device comprises a dual hydraulic cylinder feeding system (5), a material stirring tank (2), a pre-heating reactor (6), a hydrothermal liquefaction reactor (10), a product collecting kettle (23), a back pressure valve (15), a filter (22), a gas, liquid and oil separator (17), a circulating water pipeline (42) and a control element. The feeding system of the device adopts a mode of a dual hydraulic cylinder system and a high-pressure pump combined, the generality of raw materials and the pumping efficiency can be improved, and the cost of the feeding system is lowered. According to the method, the product separation effect is good, the experiment safety is improved, products can be efficiently and continuously separated, and additional use of an organic reagent is not needed; and theseparation device is simple in structure and low cost, and can be widely applied to continuous separation of the biomass hydrothermal liquefaction products.

Owner:CHINA AGRI UNIV

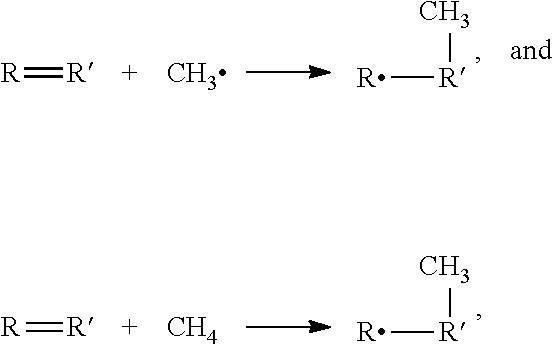

Hydrothermal Conversion of Biomass to Hydrocarbon Products

The conversion of biomass to hydrocarbon products such as transportation fuels, kerosene, diesel oil, fuel oil, chemical and refinery plant feeds. The instant process uses a hydrocarbon, oxygenated hydrocarbon, or synthesis gas co-feed and hot pressurized water to convert the biomass in a manner commonly referred to as hydrothermal liquefaction.

Owner:MILLER GARY PEYTON

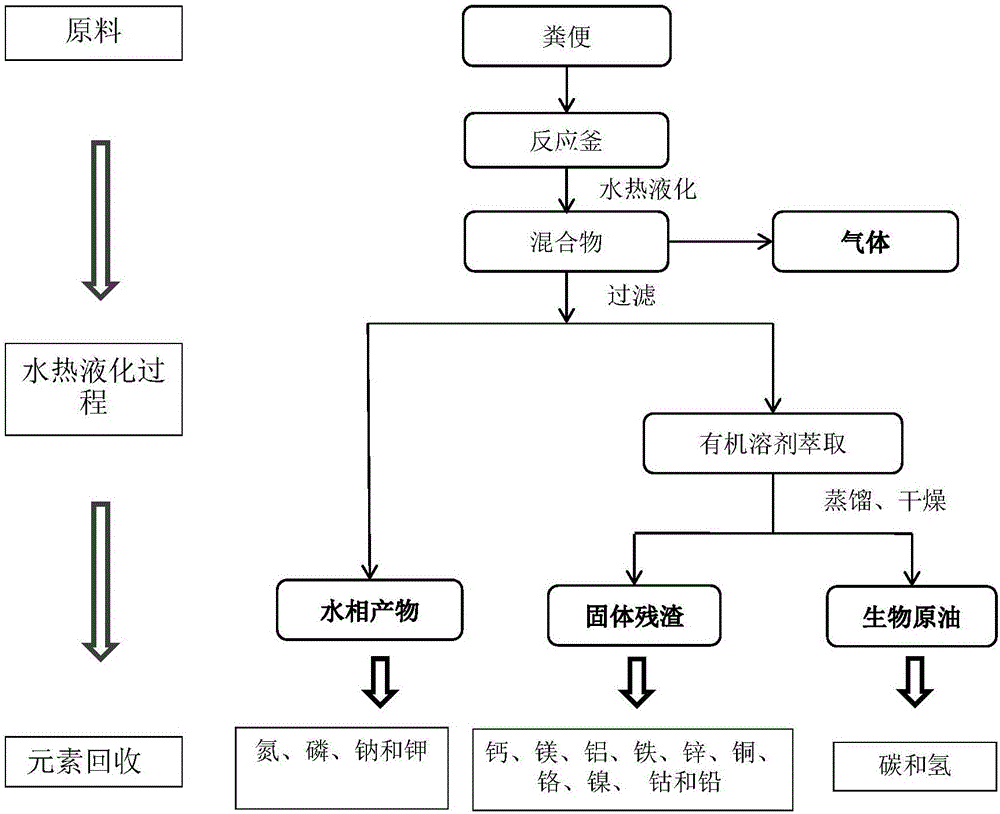

Heat-treatment recycling method for excrement

InactiveCN106673389ARealize harmless treatmentAvoid pollutionSludge treatment by pyrolysisHydrogenOrganic solvent

The invention discloses a heat-treatment recycling method for excrement. The method comprises steps as follows: the excrement is added to a reaction kettle, treated by applying initial pressure and heated, and a residual mixture is collected, extracted with an organic solvent, filtered, distillated and dried. According to the heat-treatment recycling method for excrement, harmless treatment of the excrement and recycling of resources are realized with a hydrothermal liquefying method. C, H, N, P and metal elements including Ca, Mg, Al, Fe, Zn, Cu, Cr, Ni, Co and Pb are recycled while harmless treatment of waste biomass is realized. The excrement can be further recycled while safety and sanitation management of the excrement is realized.

Owner:CHINA AGRI UNIV

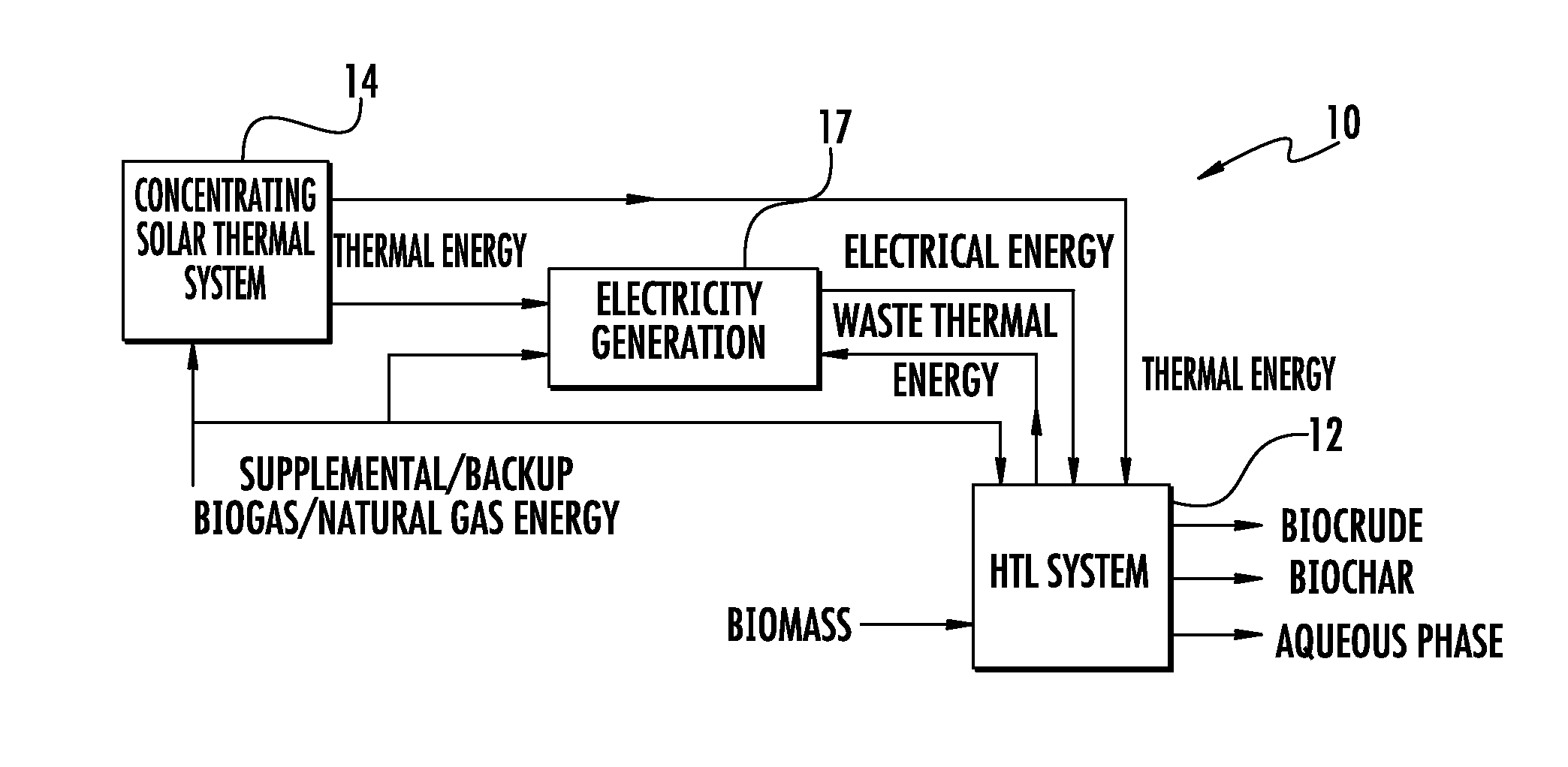

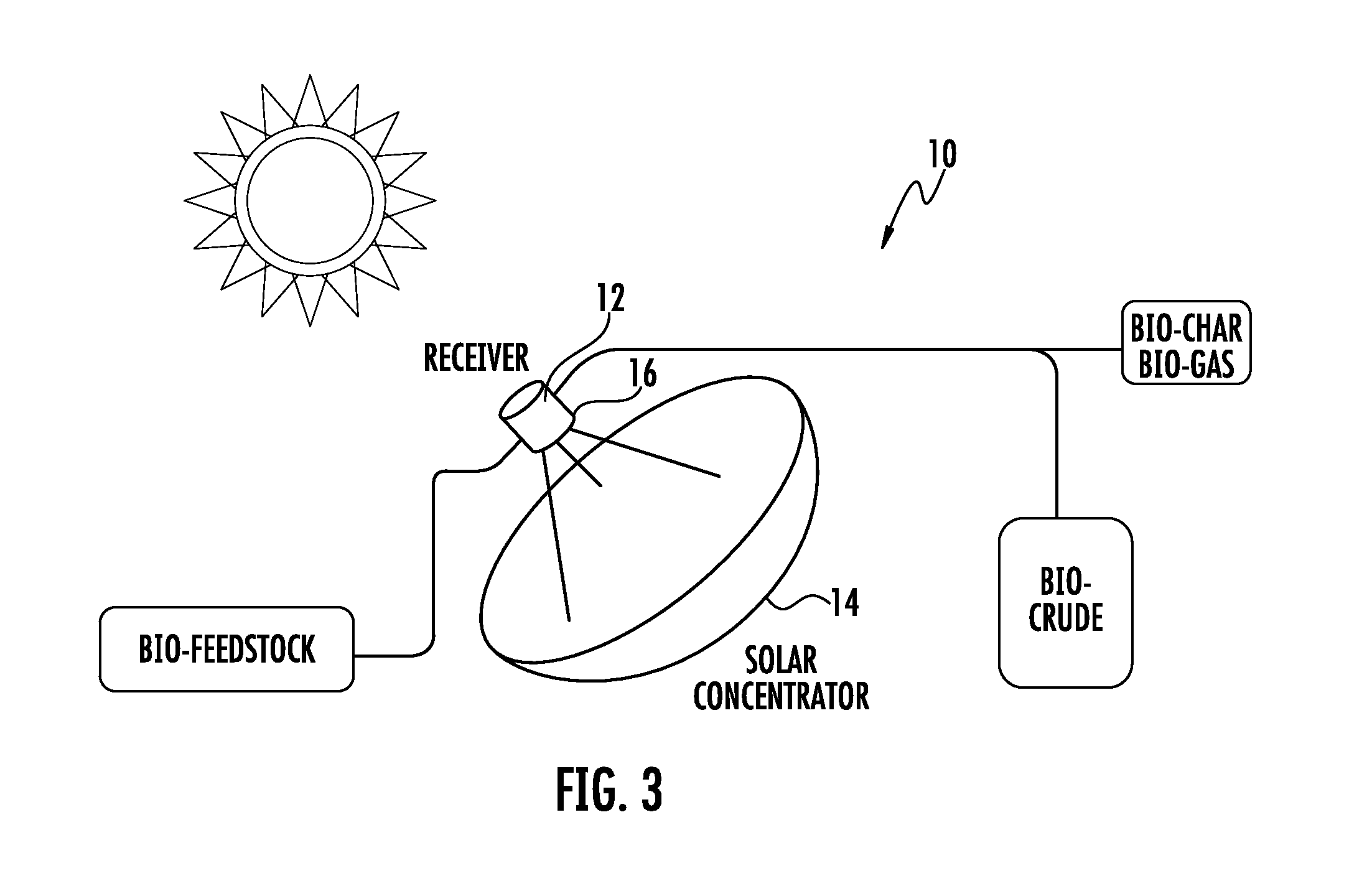

Systems and methods for converting biomass to biocrude via hydrothermal liquefaction

ActiveUS20150099275A1Sufficient thermal energyBioreactor/fermenter combinationsSolar heating energyThermal energyHigh energy beam

Systems and processes of providing novel thermal energy sources for hydrothermal liquefaction (HTL) reactors are described herein. According to various implementations, the systems and processes use concentrated solar thermal energy from a focused high-energy beam to provide sufficient energy for driving the HTL biomass-to-biocrude process. In addition, other implementations convert biowaste, such as municipal biosolids and grease and food waste, to biocrude using anaerobic digesters, and a portion of the biogas generated by the digesters is used to produce the thermal and / or electrical energy used in the HTL reactor for the biomass-to-biocrude process. Furthermore, alternative implementations may include a hybrid system that uses biogas and solar radiation to provide sufficient thermal energy for the HTL reactor.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Method for preparing liquid fuel by performing hydrothermal liquefaction on sandy shrubs

ActiveCN101955787AReduce direct combustionImprove eco-efficiencyLiquid hydrocarbon mixture productionSoil scienceOrganosolv

The invention belongs to the technical field of new energy and in particular relates to a method for preparing liquid fuel by performing hydrothermal liquefaction on sandy shrubs. The method comprises the following steps of: pretreating the collected sandy shrubs and then pouring the pretreated sandy shrubs into a high-pressure reaction kettle to form a mixed solution in a certain solid-liquid ratio; introducing inert gases with a certain pressure into the reaction kettle; stirring the mixture and heating the mixture to 200 to 450 DEG C; keeping the temperature for 5 to 120 minutes and then cooling the mixture to room temperature; collecting the reaction mixture; extracting the mixture by using an organic solvent; and separating and filtering organic phase to remove the organic solvent toobtain bio-oil. The method is suitable for various sandy shrubs. Large-area sandy shrubs are planted in the northwest area of China and need to be cut at set intervals to generate a large number of waste branches, and the waste branches can be converted into the liquid fuel by the method of the invention, so that huge economic, social and ecological benefits are produced.

Owner:FUDAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com