Method for preparing bio-oil by liquefying biomass by high efficiency hydro-thermal method

A hydrothermal liquefaction and biomass technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of gasification, low reduction efficiency of reducing gas, low product yield, etc., and achieve coking, equipment and operation inhibition. The effect of high cost and high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

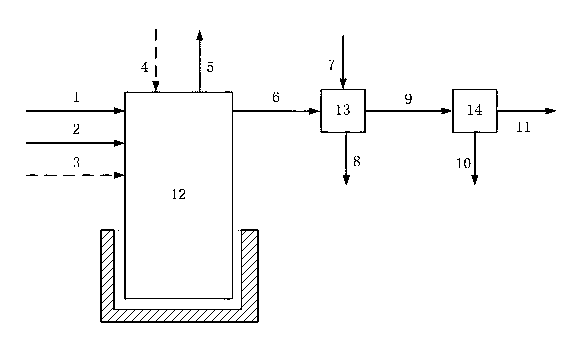

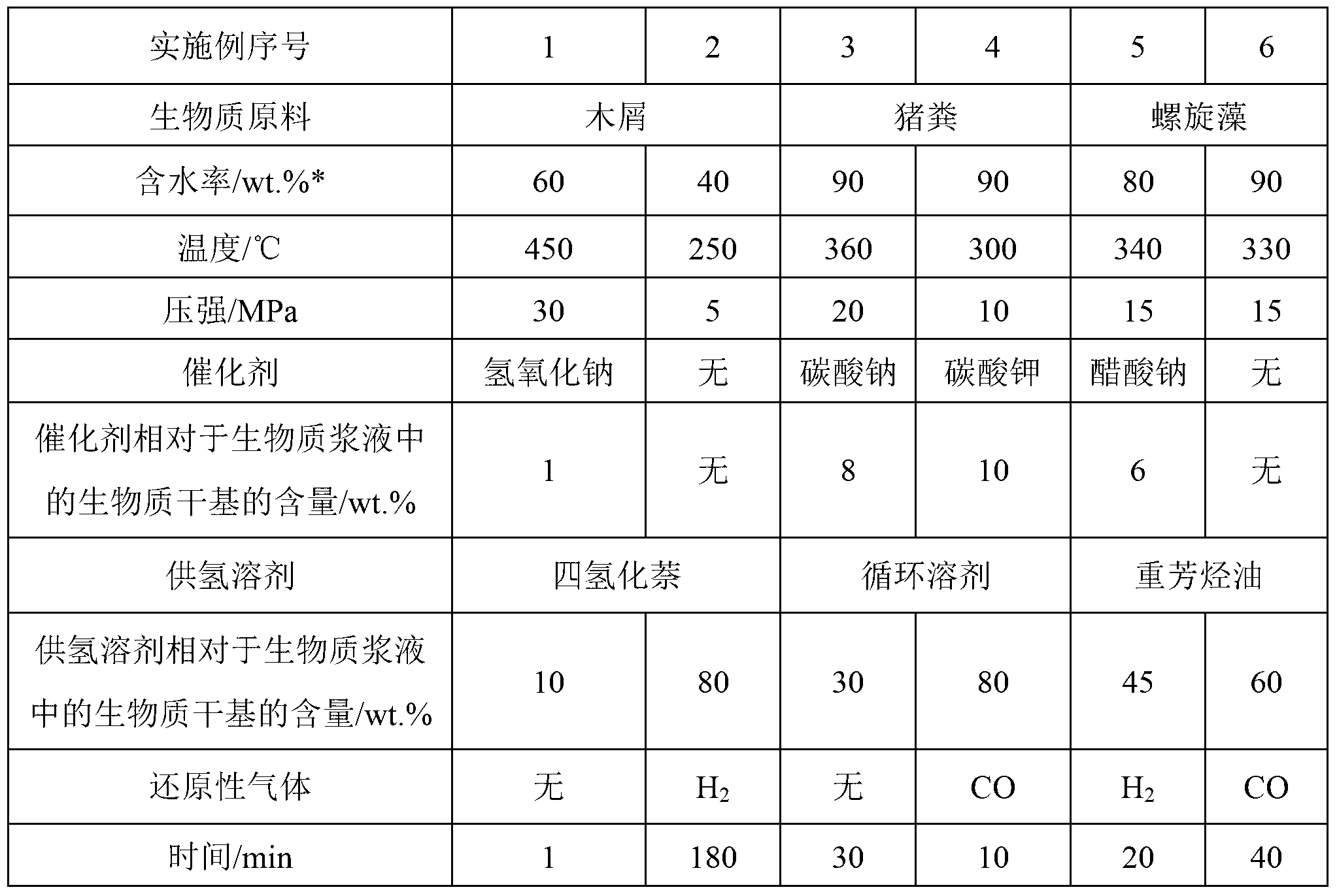

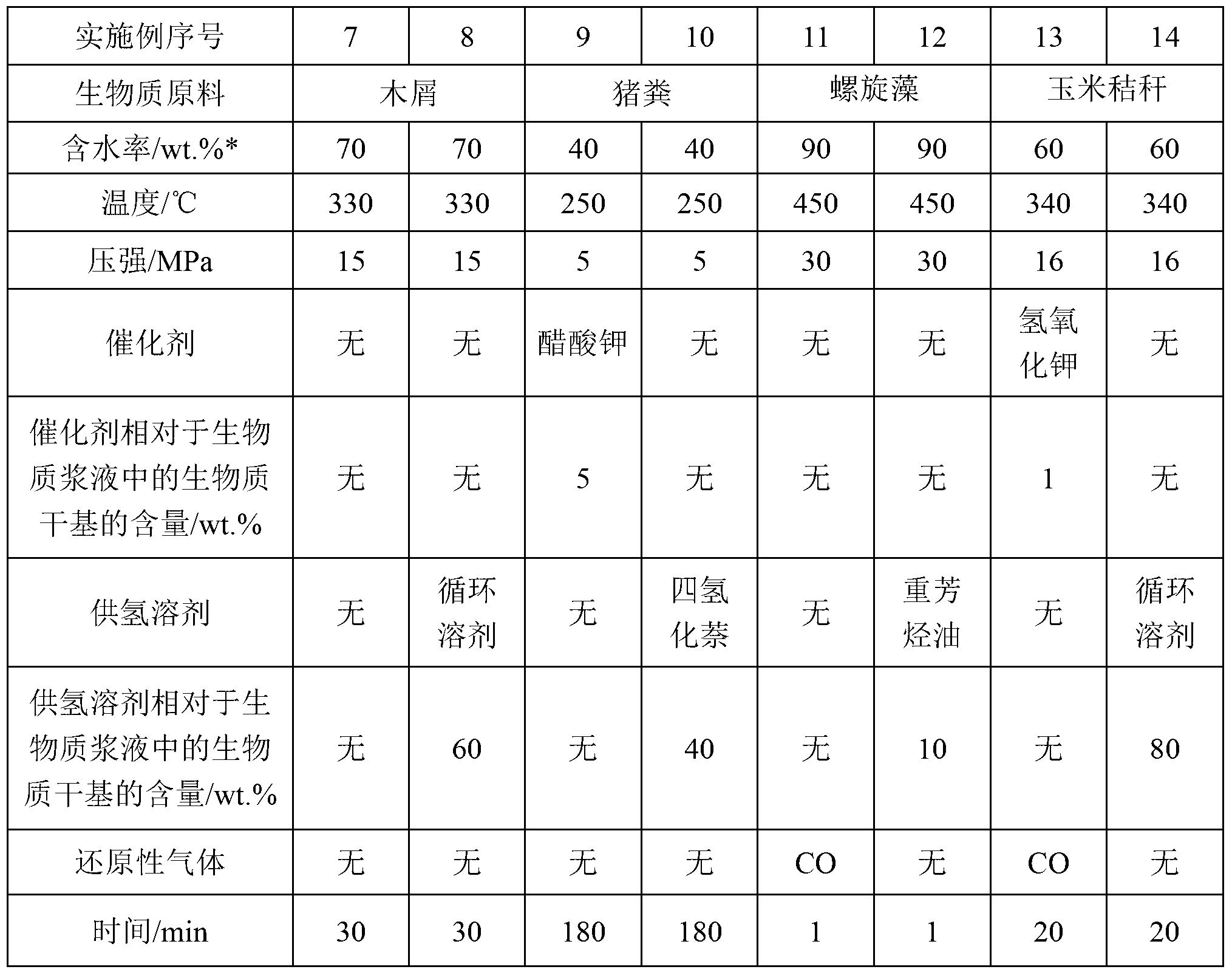

[0027] see figure 1 , In this example, sawdust (passed through a 20-mesh screen) with a moisture content (mass percentage) of 21.2% is used as biomass, and the elemental analysis of the material is shown in Table-1. A 2L high-pressure reactor is used as a liquefaction reactor, and tetralin is used as a hydrogen-donating solvent. The aromatic carbon rate is 0.6, and the boiling point is 207.6°C. Sodium hydroxide is used as a catalyst, and no reducing gas is introduced. Gas N 2 Provide initial pressure to prepare bio-oil, the specific steps are as follows:

[0028] Weigh 126.9g of wood chips, add 123.1g of water to form 250g of biomass slurry with a water content of 60%, and then mix with 10g of hydrogen-donating solvent (10% of the dry mass of biomass) and 1g of catalyst sodium hydroxide (that is, biomass 1% of the mass on a dry basis), poured into a 2L high-pressure reactor together, and introduced an inert gas N 2 (Non-reducing gas) to an initial pressure of 5MPa, the reac...

Embodiment 2

[0032] see figure 1 In this example, wood chips (passing through a 20-mesh screen) with a moisture content (mass percentage) of 21.2% are used as biomass. The elemental analysis of the material is shown in Table-1, and a 2L high-pressure reactor is used for the liquefaction reaction. device, and tetrahydronaphthalene is used as a hydrogen-donating solvent, its aromatic carbon rate is 0.6, and its boiling point is 207.6°C. No catalyst is added, and H 2 As a reducing gas and providing initial pressure to prepare bio-oil, the specific steps are as follows:

[0033] Weigh 126.9g of sawdust, add 39.8g of water to form 166.7g of biomass slurry with a water content of 40%, and then pour it into a 2L high-pressure reactor together with 80g of hydrogen-donating solvent (that is, 80% of the dry mass of biomass), Introduce reducing gas H 2 To the initial pressure of 5MPa, the reactor stirrer maintained a rotation speed of 1000r / min, and the high-pressure reactor was heated to 250°C at ...

Embodiment 3

[0036] see figure 1 In this embodiment, fresh pig manure with a water content (mass percentage) of 72.8% is used as biomass. The elemental analysis of the material is shown in Table-1. A 2L high-pressure reactor is used as a liquefaction reactor, and the distillation range is The coal hydrogenation liquefaction circulating solvent at 180-400°C is the hydrogen-donating solvent, and the aromatic carbon ratios before and after hydrogenation are 0.41 and 0.30 respectively. Sodium carbonate is used as the catalyst, and non-reducing gas N is used instead of reducing gas. 2 Provide initial pressure to prepare bio-oil, the specific steps are as follows:

[0037] Weigh 183.8g of fresh pig manure, add 316.2g of water to form 500g of biomass slurry with a moisture content of 90%, and then mix it with 15g of hydrogen-donating solvent (ie, 30% of the dry mass of biomass) and 4g of catalyst sodium carbonate (ie, 8% of the mass of the substance on a dry basis), poured into a 2L high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com