Method of preparing bio-oil through raw material pretreatment and hydrothermal liquefaction

A hydrothermal liquefaction and combined preparation technology, which is applied in the fields of environmental protection and new energy, can solve the problems of complex oil composition and low bio-oil yield, and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

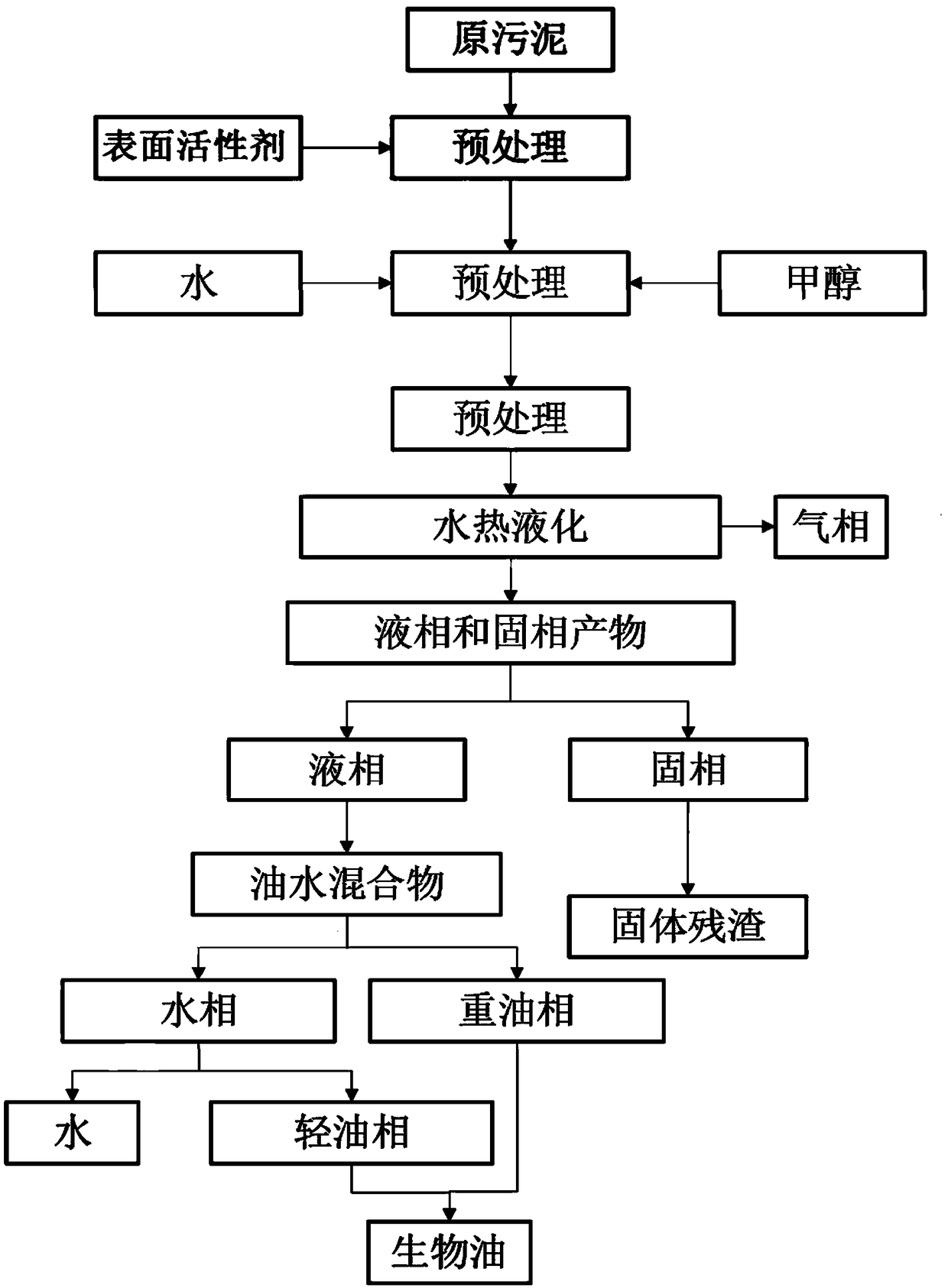

Method used

Image

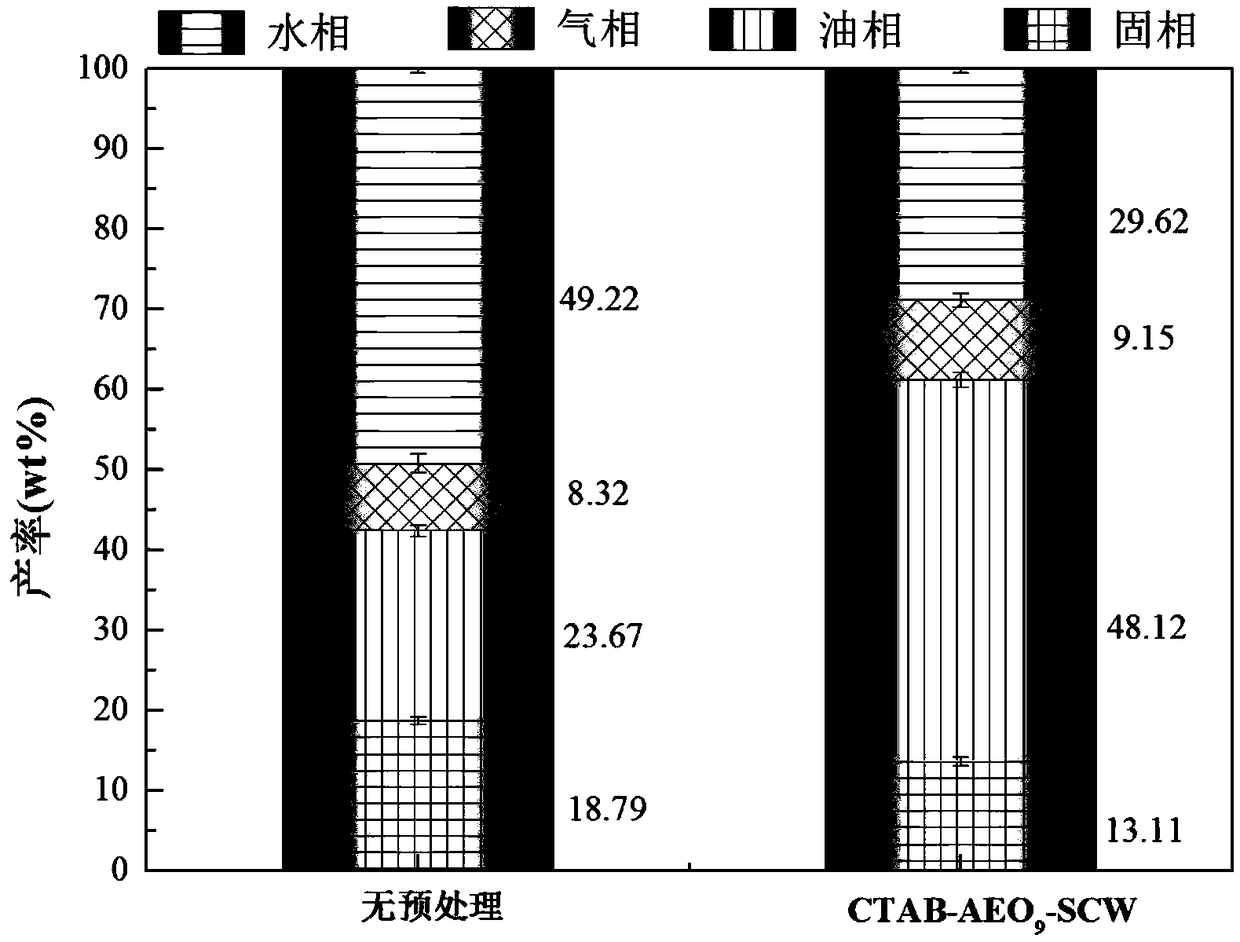

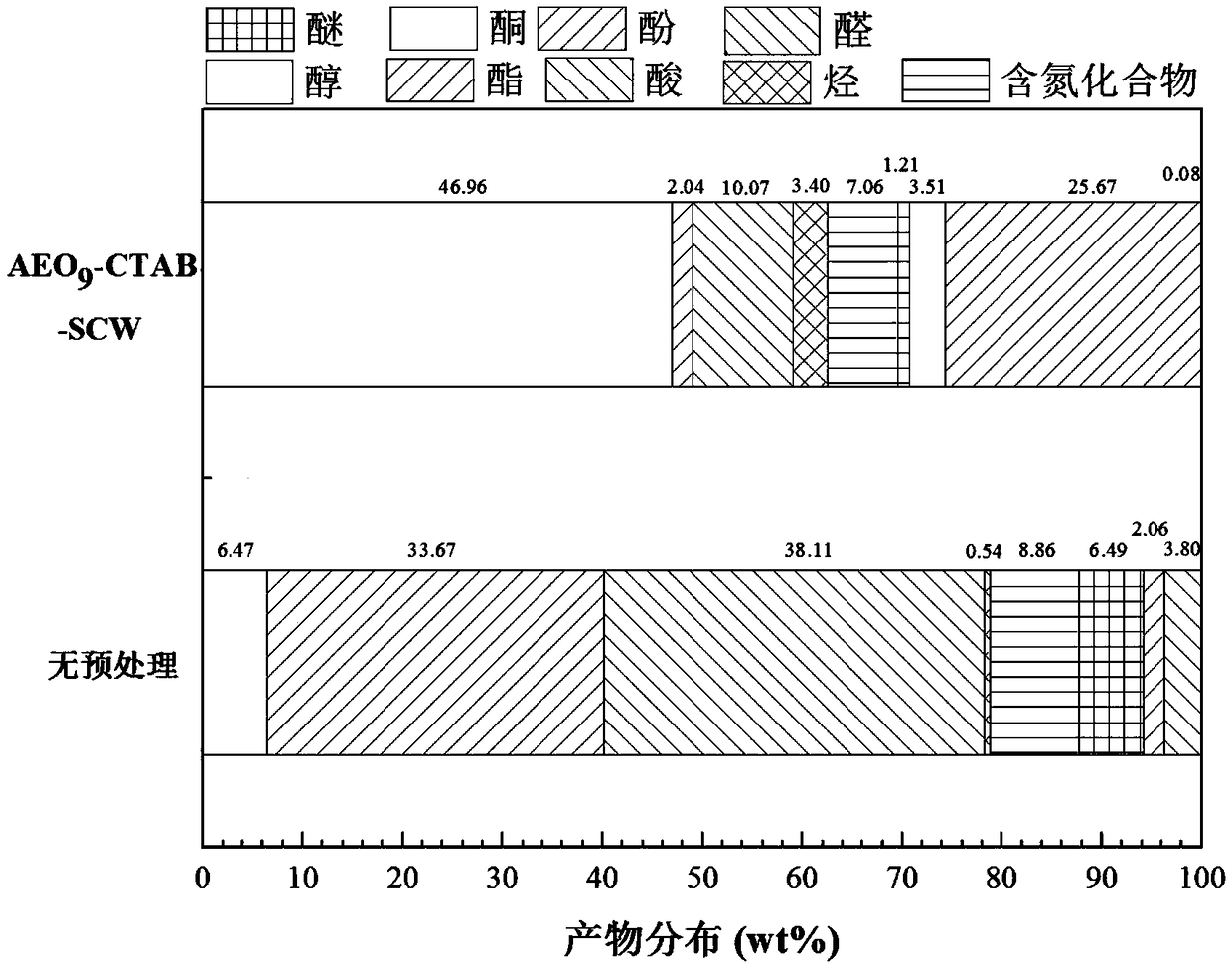

Examples

Embodiment 1

[0038] (1) Mix 50 g of municipal sludge with a moisture content of 85% and 0.75 g of surfactant, wherein: the dry basis sludge raw material: the mass ratio of surfactant = 1:0.1, and the surfactant is CTAB: AEO 9 =3:7, to obtain uniformly mixed sludge;

[0039] (2) Stir the sludge homogeneously mixed in step (1) with a mechanical agitator at a rate of 200r / min for 1h to obtain sludge pretreated by surfactant;

[0040] (3) Mix 50.75g of sludge pretreated with surfactant, 150ml of deionized water, and 75ml of methanol in step (2) to make a slurry, wherein: dry basis of sludge pretreated with surfactant: solvent The mass ratio of = 1:10, the volume ratio of solvent:cosolvent: 1:0.5;

[0041] (4) Add the slurry obtained in step (3) into the intermittent high-temperature and high-pressure reaction kettle, replace the air in the kettle with high-alcohol nitrogen after sealing the reaction, and heat the kettle body at 10°C / min to 180°C for 15 minutes;

[0042] (5) Continue to heat ...

Embodiment 2

[0050] (1) Mix 50g of municipal sludge with a moisture content of 85% and 1.125g of surfactant, wherein: dry basis sludge raw material: mass ratio of surfactant = 1:0.15, surfactant is CTAB: AEO 9 =3:7, to obtain uniformly mixed sludge;

[0051] (2) Stir the sludge homogeneously mixed in step (1) with a mechanical agitator at a rate of 200r / min for 1h to obtain sludge pretreated by surfactant;

[0052] (3) Mix 51.125g of sludge pretreated with surfactant, 150ml of deionized water, and 75ml of methanol in step (2) to make a slurry, wherein: dry basis of sludge pretreated with surfactant: solvent The mass ratio of = 1:10, the volume ratio of solvent:cosolvent: 1:0.5;

[0053] (4) Add the slurry obtained in step (3) into a batch-type high-temperature and high-pressure reaction kettle, replace the air in the kettle with high-alcohol nitrogen after sealing the reaction, and heat the kettle body at 10°C / min to 190°C for 20 minutes;

[0054] (5) Continue to heat the reactor to 340°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com