Sludge hydro-thermal treatment method for reducing heavy metal in aqueous phases

A heat treatment method and heavy metal technology, applied in water/sludge/sewage treatment, sludge treatment, water pollutants, etc., to achieve the effect of reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

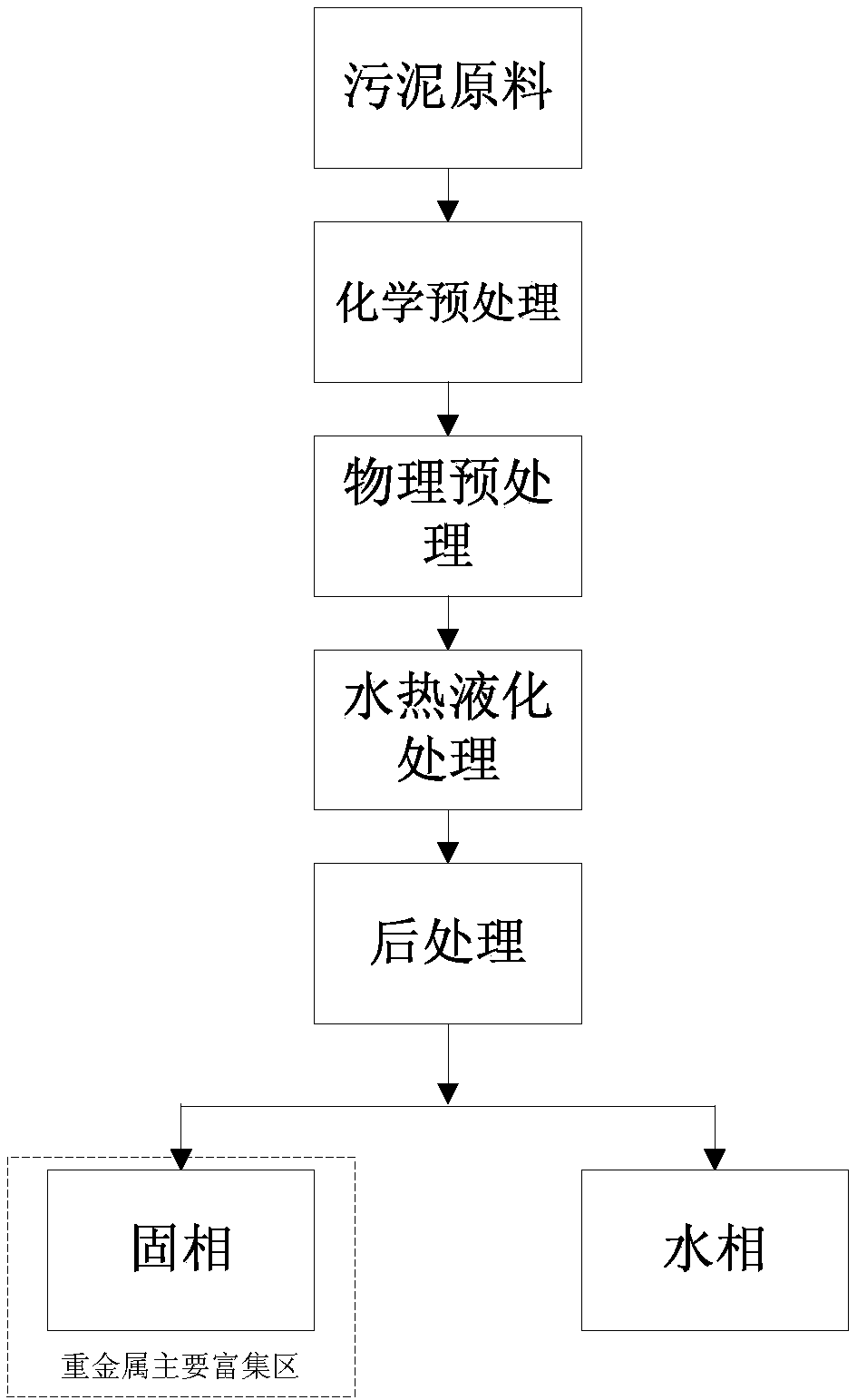

[0044] A sludge hydrothermal treatment method for reducing heavy metals in the water phase, comprising the following steps:

[0045] (1) 50g of municipal sludge raw material with a water content of 90% and 0.5g of surfactant are mixed, wherein, by mass ratio, sludge raw material dry basis:surfactant=1:0.1, surfactant is CTAC, and mixed after the sludge;

[0046] (2) The mixed sludge obtained in step (1) is stirred with a mechanical stirrer at a rate of 150 to 200 rpm for 1 hour to obtain surfactant pretreated sludge;

[0047] (3) Ultrasonic treatment is carried out to the sludge pretreated by surfactant in step (2), the ultrasonic power is 180W, the ultrasonic time is 40min, and the duty ratio is 50%, to obtain the sludge treated by surfactant-ultrasonic joint treatment ;

[0048] (4) The sludge obtained by the surfactant-ultrasonic joint treatment in step (3) is added in the intermittent high-temperature and high-pressure reactor, and the air in the reactor is replaced with...

Embodiment 2

[0055] A sludge hydrothermal treatment method for reducing heavy metals in the water phase, comprising the following steps:

[0056] (1) 50g of municipal sludge raw material with a water content of 90% and 0.5g of surfactant are mixed, wherein, by mass ratio, sludge raw material dry basis:surfactant=1:0.1, surfactant is CPAM, and mixed after the sludge;

[0057] (2) The mixed sludge obtained in step (1) is stirred with a mechanical stirrer at a rate of 150 to 200 rpm for 1 hour to obtain surfactant pretreated sludge;

[0058] (3) Ultrasonic treatment is carried out to the sludge pretreated by surfactant in step (2), the ultrasonic power is 180W, the ultrasonic time is 40min, and the duty ratio is 50%, to obtain the sludge treated by surfactant-ultrasonic joint treatment ;

[0059] (4) The sludge obtained by the surfactant-ultrasonic joint treatment in step (3) is added in the intermittent high-temperature and high-pressure reactor, and the air in the reactor is replaced with...

Embodiment 3

[0066] A sludge hydrothermal treatment method for reducing heavy metals in the water phase, comprising the following steps:

[0067] (1) 50g of municipal sludge raw material with a moisture content of 90% and 0.5g of surfactant are mixed, wherein, by mass ratio, sludge raw material dry basis:surfactant=1:0.1, surfactant is CTAB, and mixed after the sludge;

[0068] (2) The mixed sludge obtained in step (1) is stirred with a mechanical stirrer at a rate of 150 to 200 rpm for 1 hour to obtain surfactant pretreated sludge;

[0069] (3) Ultrasonic treatment is carried out to the sludge pretreated by surfactant in step (2), the ultrasonic power is 180W, the ultrasonic time is 40min, and the duty ratio is 50%, to obtain the sludge treated by surfactant-ultrasonic joint treatment ;

[0070] (4) The sludge obtained by the surfactant-ultrasonic joint treatment in step (3) is added in the intermittent high-temperature and high-pressure reactor, and the air in the reactor is replaced w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com