Separation method for solid-phase biomass hydrothermal liquefaction products

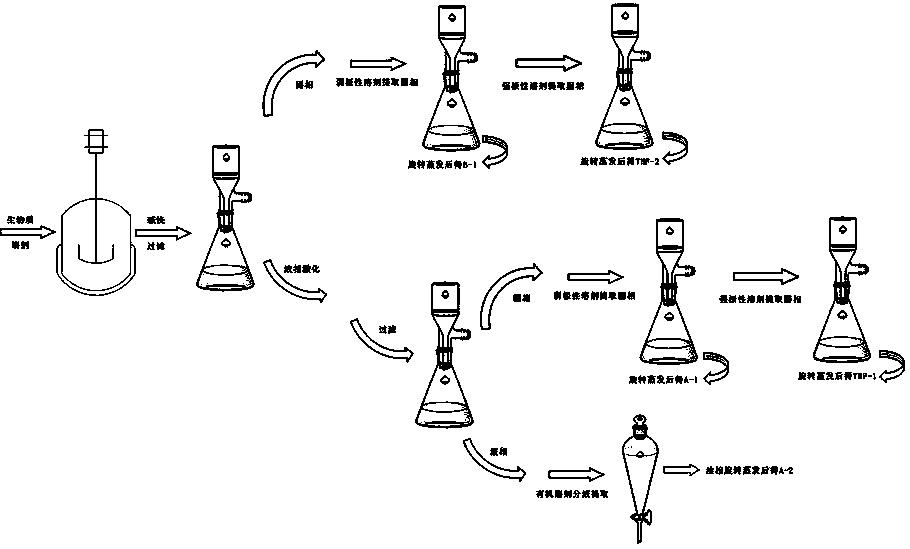

The technology of a hydrothermal liquefaction and separation method is applied in the field of biomass waste resource utilization, which can solve the problems of inability to obtain high value-added chemicals of biomass hydrothermal liquefaction products, inability to separate compounds, and high cost, thereby achieving huge economic benefits. Effectiveness and eco-efficiency, accelerated research pace, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 20.00 g of rice straw hydrothermal liquefaction solid phase product, the water content is 62.13%. Dissolve it in 100ml of 3.5 wt.% NaOH solution, put it on a magnetic stirrer and stir for 30 min, after fully reacting, separate the solid from the liquid.

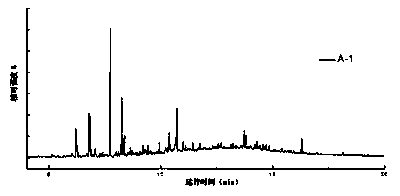

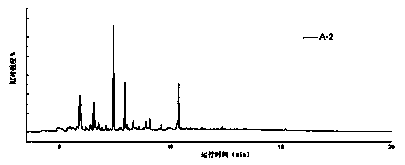

[0033] 10% HCl solution was added dropwise to the liquid phase to adjust the pH value to 2, and the solution was acidic. The solubility of phenolic substances decreased, dissolved and precipitated, and the supernatant was evaporated in an oven at 65 °C to remove water, and the insoluble matter was sodium chloride. Produce viscous precipitate, mainly phenolic compounds. The precipitate was extracted by adding 100ml of weak polar organic solvent dichloromethane, and the filtrate and residue were obtained by filtration. After the filtrate was rotary evaporated, the product A-1 was obtained. A-1 was mainly rich in phenolic compounds, and the product quality was 0.79g; the residue was further added 100ml of tetrahyd...

Embodiment 2

[0036] Weigh 20.00 g of rice straw hydrothermal liquefaction solid phase product, the water content is 62.13%. Dissolve it in 100ml of 3 wt.% NaOH solution, put it on a magnetic stirrer and stir for 30 min, after fully reacting, separate the solid from the liquid.

[0037] 10% HCl solution was added dropwise to the liquid phase to adjust the pH value to 1.5, and the solution was acidic. The solubility of phenolic substances decreased, dissolved and precipitated, and the supernatant was evaporated in an oven at 65 °C to remove water, and the insoluble matter was sodium chloride. The precipitate is thick, containing a small amount of water, mainly phenolic compounds. The precipitate was viscous, mainly phenolic compounds. The precipitate was extracted by adding 100ml weak polar organic solvent ether, and the filtrate and residue were obtained by filtration. After the filtrate was rotary evaporated, the product A-1 was obtained. A-1 was mainly rich in phenolic compounds, and th...

Embodiment 3

[0040] Weigh 20.00 g of rice straw hydrothermal liquefaction solid phase product, the water content is 62.13%. It was dissolved in 100ml of 4 wt.% NaOH solution, placed on a magnetic stirrer and stirred for 30 min, and after fully reacting, the solid and liquid were separated.

[0041] 10% HCl solution was added dropwise to the liquid phase to adjust the pH value to 1.5, and the solution was acidic. The solubility of phenolic substances decreased, dissolved and precipitated, and the supernatant was evaporated in an oven at 65 °C to remove water, and the insoluble matter was sodium chloride. The precipitate is thick, containing a small amount of water, mainly phenolic compounds. The precipitate was viscous, mainly phenolic compounds. The precipitate was extracted by adding 100ml of weak polar organic solvent ethyl acetate, and the filtrate and residue were obtained by filtration. After the filtrate was rotary evaporated, the product A-1 was obtained. A-1 was mainly rich in ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com