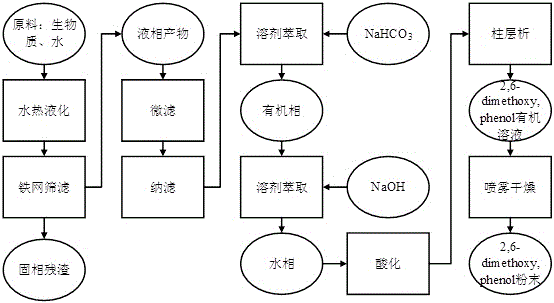

A method for separating and purifying 2,6-dimethoxyphenol from biomass hydrothermal liquefaction liquid phase product

A technology of dimethoxyphenol and hydrothermal liquefaction, which is applied in the field of separation and purification of bio-based chemicals, can solve the problems of obtaining pure industrial chemicals and complex liquid-phase products, achieving huge economic benefits and accelerating the pace of research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

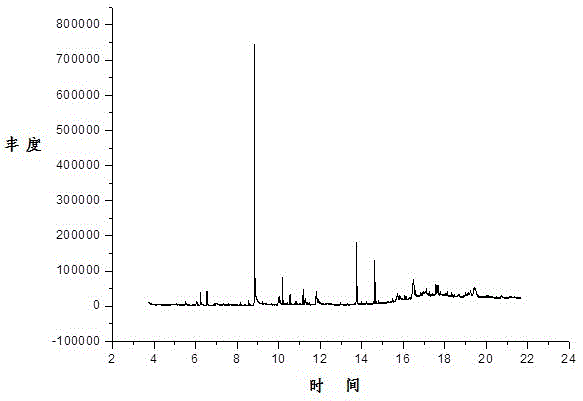

[0030] The liquid phase product produced after hydrothermal liquefaction of rice straw, the filtrate after separation by 0.1um microfiltration membrane, under the pressure of 1.0MPa and the temperature of 25°C, is filtered with a roll-type polyamide nanofiltration membrane with a molecular weight cut-off of 160Da , take the membrane filtrate and extract it with dichloromethane, mix and shake and let it stand for 1h to form a well-defined organic phase and aqueous phase. Take the organic phase from the previous step and extract it with saturated aqueous sodium bicarbonate solution, mix and shake it and let it stand for 1 hour to form a well-defined organic phase and aqueous phase. Take the organic phase from the previous step and extract it with a 3g / L aqueous sodium hydroxide solution to adjust the aqueous phase The pH of the mixture was 11, mixed and oscillated and allowed to stand for 1 hour to form a well-defined organic phase and aqueous phase. Take the aqueous phase from t...

Embodiment 2

[0032] The liquid phase product produced after hydrothermal liquefaction of Salix salix, the filtrate after separation by 0.1um microfiltration membrane, under the pressure of 1.0MPa and the temperature of 25°C, is filtered by a roll-type polyamide nanofiltration membrane with a molecular weight cut-off of 160Da Filtrate, take the membrane filtrate and extract it with benzene, mix and shake it and let it stand for 1 hour to form a layered organic phase and an aqueous phase. Take the organic phase from the previous step and extract it with a saturated aqueous solution of sodium bicarbonate, mix it and shake it and let it stand for 1 hour to form a layer Clear organic phase and aqueous phase, take the organic phase from the previous step and extract with 5g / L sodium hydroxide aqueous solution, adjust the pH of the aqueous phase to 13, mix and shake and let stand for 1h to form a distinct organic phase and aqueous phase, Take the aqueous phase from the previous step and use concen...

Embodiment 3

[0034]The liquid phase product produced after hydrothermal liquefaction of water hyacinth, the filtrate after separation by 0.1um microfiltration membrane, under the pressure of 1.0MPa and the temperature of 25°C, is filtered with a roll-type polyamide nanofiltration membrane with a molecular weight cut-off of 160Da Filtrate, take the membrane filtrate and extract it with ethyl acetate, mix and oscillate and let stand for 1h to form a well-defined organic phase and water phase, take the organic phase from the previous step and extract with saturated aqueous sodium bicarbonate solution, mix and oscillate and let stand for 1h, Form a distinct organic phase and aqueous phase, take the organic phase from the previous step and extract it with 3g / L potassium hydroxide aqueous solution, adjust the pH of the aqueous phase to 13, mix and shake and let it stand for 1h to form a distinct organic phase and aqueous phase Phase, take the aqueous phase from the previous step and adjust the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com