A Multi-stage Membrane Separation and Series Process for Graded Utilization of Biomass Hydrothermal Liquefaction Liquid Phase Products

A technology for hydrothermal liquefaction and membrane separation, applied in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve problems such as shortage, and achieve the effect of development promotion, huge economic benefits, improvement effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

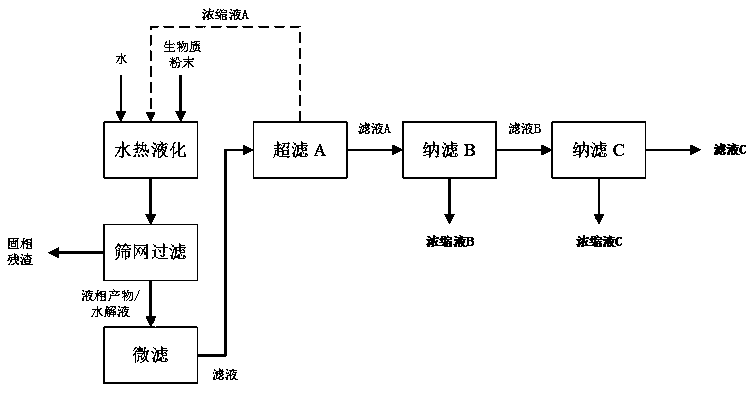

Method used

Image

Examples

Embodiment 1

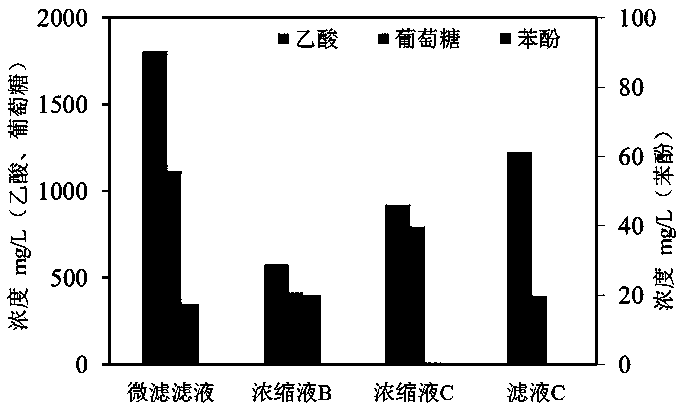

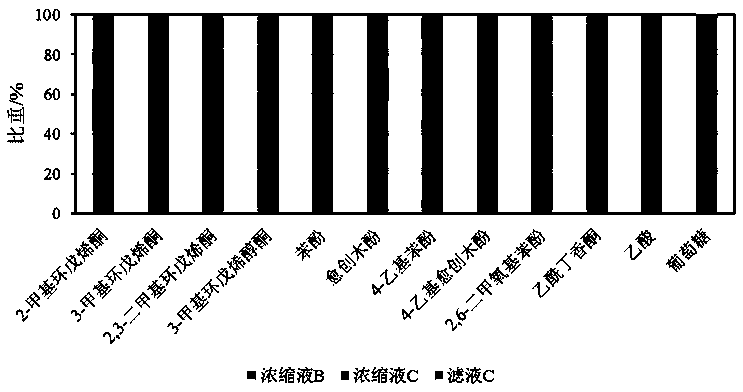

[0032] The liquid phase product produced after hydrothermal liquefaction of rice straw, the filtrate after separation by 0.45um microfiltration membrane, is filtered with roll-type ultrafiltration membrane A with a molecular weight cut-off of 1000Da under the pressure of 0.2MPa and temperature of 30°C. The volume ratio of the filtrate to the concentrated liquid is 5:1, collect and store the concentrated liquid A at low temperature; take the filtrate A as a roll-type nanofiltration membrane B with a molecular weight cut-off of 360Da, and filter it under the pressure of 0.8 MPa and at a temperature of 40°C. The volume to concentrate volume ratio is 4:1, collect and store the concentrate B at low temperature; take the filtrate B as roll-type nanofiltration membrane C with a molecular weight cut-off of 150Da, and filter it under the pressure of 2.5MPa and the temperature of 40°C, the volume of the filtrate The volume ratio to the concentrate is 3:1, collect and store the concentrat...

Embodiment 2

[0035]The liquid phase product produced after hydrothermal liquefaction of rice straw, the filtrate after separation by 0.45um microfiltration membrane, is filtered with roll-type ultrafiltration membrane A with a molecular weight cut-off of 10000Da under the pressure of 0.2MPa and temperature of 30°C. The volume ratio of the filtrate to the concentrated liquid is 5:1, collect and store the concentrated liquid A at low temperature; take the filtrate A as a roll-type nanofiltration membrane B with a molecular weight cut-off of 360Da, filter it under 0.5 MPa pressure and a temperature of 40°C, and the filtrate The volume to concentrate volume ratio is 4:1, collect and store the concentrate B at low temperature; take the filtrate B as roll-type nanofiltration membrane C with a molecular weight cut-off of 150Da, and filter it under the pressure of 2.5MPa and the temperature of 40°C, the volume of the filtrate The volume ratio to the concentrate is 3:1, collect and store the concent...

Embodiment 3

[0038] The liquid phase product produced after hydrothermal liquefaction of rice straw, the filtrate after separation by 0.45um microfiltration membrane, is filtered with roll-type ultrafiltration membrane A with a molecular weight cut-off of 20000Da under the pressure of 0.2MPa and temperature of 30°C. The volume ratio of the filtrate to the concentrated liquid is 5:1, collect and store the concentrated liquid A at low temperature; take the filtrate A as a roll-type nanofiltration membrane B with a molecular weight cut-off of 360Da, and filter it under a pressure of 1.0MPa and a temperature of 40°C. The volume to concentrate volume ratio is 4:1, collect and store the concentrate B at low temperature; take the filtrate B as roll-type nanofiltration membrane C with a molecular weight cut-off of 150Da, and filter it under the pressure of 2.5MPa and the temperature of 40°C, the volume of the filtrate The volume ratio to the concentrate is 3:1, collect and store the concentrate C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com