Composite adsorbent for biogas desulfurization and decarburization as well as preparation method and application of the composite adsorbent

A biogas desulfurization and composite technology, which is applied in chemical instruments and methods, gas fuels, and other chemical processes, can solve the problems of natural gas purification reaching the pipeline transmission standard, adding traditional treatment technologies, and poor membrane performance stability, etc., to achieve extended Lifespan, full use of resources, and reduced reunion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The simulated biogas containing 40% carbon dioxide volume fraction, 3% hydrogen sulfide volume fraction, and the rest is methane is used for desulfurization and decarbonization reaction. Fly ash, calcium carbide slag, steel slag and waste cement with particle diameters ranging from 90 to 300 microns are selected. Irregular particles are used as the carrier of the composite adsorbent, iron oxide is selected as the auxiliary agent, and the mass ratio of iron oxide to the solid waste carrier of different types of alkaline oxides is 15:100. The iron oxide is dissolved in nitric acid to prepare a ferric nitrate solution , Then mix the ferric nitrate solution into a 10wt% salt solution, place the salt solution and the carrier in a closed device, with a valve between the two to control the flow rate of the salt solution; use a vacuum pump to reduce the pressure of the salt solution and carrier mixed system to 2kPa , Keep for 5h for negative pressure degassing. Open the valve un...

Embodiment 2

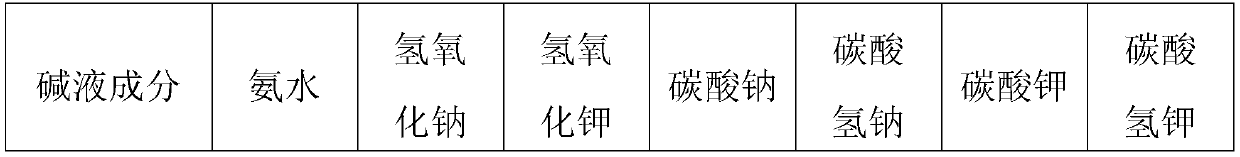

[0040] Fly ash is used as a composite adsorbent carrier, and potassium oxide, sodium oxide, iron oxide, calcium oxide, copper oxide, zinc oxide, and cerium oxide are respectively used as auxiliary components. Other conditions are the same as in Example 1. From the experimental results in Table 2, it can be seen that iron oxide and cerium oxide have the best effect. The removal rate of carbon dioxide is 88% and hydrogen sulfide is 89%. This is because potassium oxide and sodium oxide are more alkaline. , The removal rate of carbon dioxide is high, but the desulfurization activity is low; iron oxide and cerium oxide are moderately alkaline, and the desulfurization activity is high. Considering the cost of catalyst preparation, iron oxide is preferred.

[0041] Table 2 Desulfurization and decarbonization effects of composite adsorbents with different oxide additives

[0042]

Embodiment 3

[0044] Fly ash is used as the carrier of the composite adsorbent, iron oxide is used as the auxiliary agent, and the mass ratio of the auxiliary agent to the carrier is (1 to 5): 20 for preparation. Other conditions are the same as in Example 1. From the experimental results in Table 4, it can be seen that the composite adsorbent prepared when the mass ratio of auxiliary agent to carrier is 3:20 has the best effect. The carbon dioxide removal rate is 88%, and the hydrogen sulfide is 89%. In the system, the carrier mainly plays the role of removing carbon dioxide, and the auxiliary agent mainly plays the role of removing hydrogen sulfide. The desulfurization and decarbonization reaction can achieve high efficiency under the condition of the relatively moderate mass ratio of the auxiliary agent to the carrier.

[0045] Table 3 Desulfurization and decarbonization effects of composite adsorbents prepared by mass ratios of different additives and carriers

[0046] The mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com