Water-borne environment-friendly crack lacquer and preparation method thereof

A crack paint, environmental protection technology, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of water resistance and construction performance can not meet the requirements, can not obtain the crack effect, solvent volatile substances and other problems, to achieve excellent adhesion, convenient construction Fast, fast dry time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

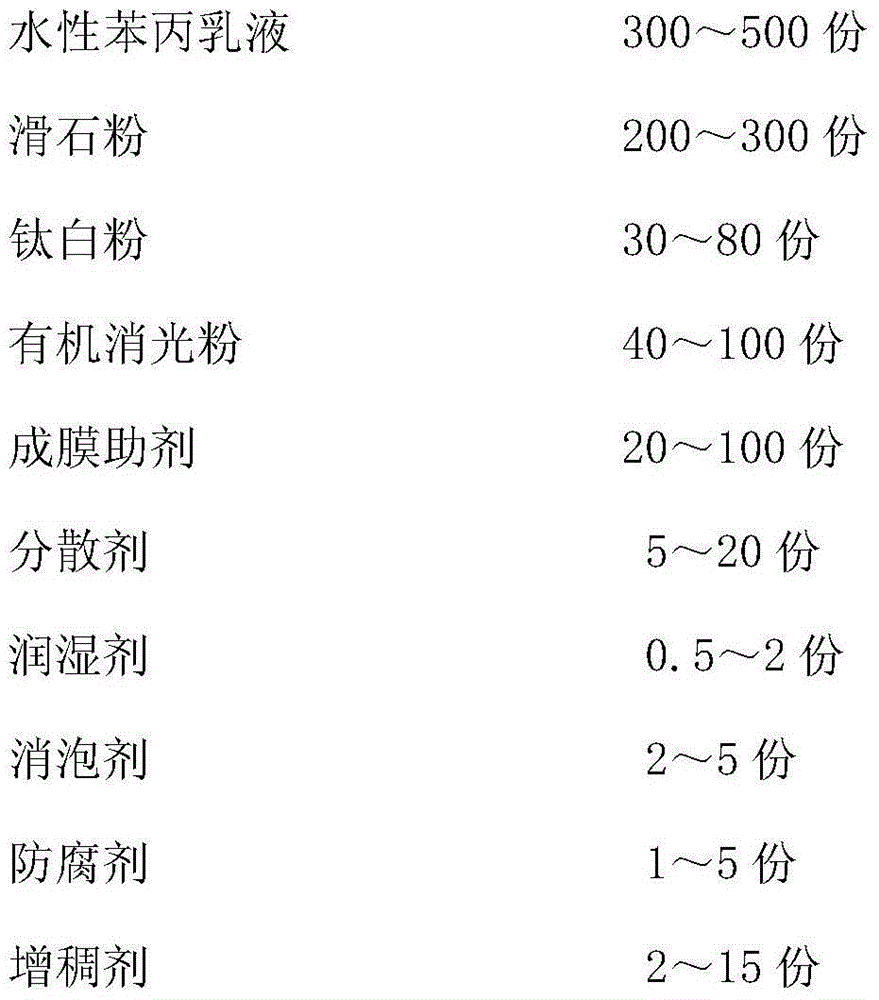

[0024] The water-based environmental protection crack paint of the present embodiment comprises: 300 parts of water-based styrene-acrylic emulsion 2455, 200 parts of talcum powder, 30 parts of titanium dioxide, 40 parts of organic matting powder M4, 10 parts of propylene glycol butyl ether, 10 parts of di Propylene glycol butyl ether, 5 parts of dispersant 462N, 0.5 parts of wetting agent CF10, 1 part of defoamer NXZ, 1 part of defoamer SN-1340, 1 part of preservative 2060, 1 part of thickener RM-8W, 1 part of thickener L117, 1 part of neutralizer OAMP-95, 100 parts of water.

[0025] The preparation method of the water-based environmental protection crack paint of the present embodiment may further comprise the steps:

[0026] (1) 90 parts by weight of water are dropped into the feeding tank, and then the water-based styrene-acrylic emulsion 2455, dispersant 462N, wetting agent CF10, defoamer NXZ, and preservative 2060 of the above parts by weight are dropped into the feeding...

Embodiment 2

[0032] The water-based environmental protection crack paint of the present embodiment comprises: 350 parts of water-based styrene-acrylic emulsion 2455, 220 parts of talcum powder, 40 parts of titanium dioxide, 50 parts of organic matting powder M4, 20 parts of propylene glycol butyl ether, 20 parts of di Propylene glycol butyl ether, 10 parts of dispersant 462N, 0.7 parts of wetting agent CF10, 1.2 parts of defoamer NXZ, 1.2 parts of defoamer SN-1340, 1.5 parts of preservative 2060, 2 parts of thickener RM-8W, 3 parts of thickener L117, 1.2 parts of neutralizer OAMP-95, 130 parts of water.

[0033] The preparation method of the water-based environmentally friendly cracked paint of this embodiment refers to Example 1, and will not be repeated here.

Embodiment 3

[0035] The water-based environmental protection crack paint of the present embodiment comprises: 380 parts of water-based styrene-acrylic emulsion 2455, 250 parts of talcum powder, 50 parts of titanium dioxide, 60 parts of organic matting powder M4, 30 parts of propylene glycol butyl ether, 30 parts of di Propylene glycol butyl ether, 16 parts of dispersant 462N, 1 part of wetting agent CF10, 1.5 parts of defoamer NXZ, 1.5 parts of defoamer SN-1340, 2 parts of preservative 2060, 4 parts of thickener RM-8W, 8 parts of thickener L117, 1.5 parts of neutralizer OAMP-95, 164.5 parts of water.

[0036] The preparation method of the water-based environmentally friendly cracked paint of this embodiment refers to Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com