Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Low Odor Properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material of polypropylene in low smell and preparation method

InactiveCN1727390AGood physical and mechanical propertiesSimple preparation processMolecular sieveChemistry

A polypropene composition with low odor is proportionally prepared from polypropene, talc powder, molecular sieve (powdered silicoaluminate of alkali-metal), toughening agent poe, and thermal stabilizer.

Owner:SHANGHAI PRET COMPOSITES

Low-odour polypropylene composite

The invention relates to a low-odour polypropylene compound, the compound comprises (by weight ratio) polypropylene 55-95, talcum powder 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium oxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 3114 0.1-1.0, heat stabilizer 618 0.1-0.5, wherein the fatty acid ester compound being C25-C45 long-chain fatty acid ester, the heat stabilizer DSTP being octadecyl thiodipropionate, the heat stabilizer 3114 being 3,obtaining 5-ditert-butyl-4-hydroxy benzylphosphonate diethylate, the heat stabilizer being dioctadecyl pentaerythritol diphosphite.

Owner:SHANGHAI PRET COMPOSITES +1

Novel low odor polypropylene composite material and preparation thereof

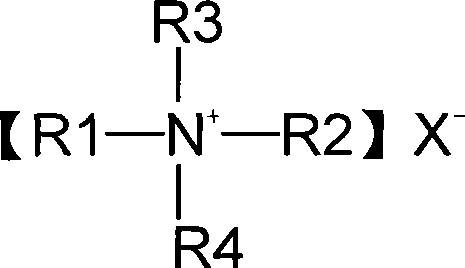

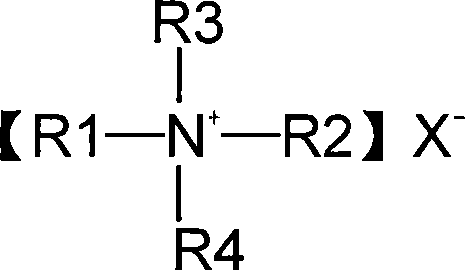

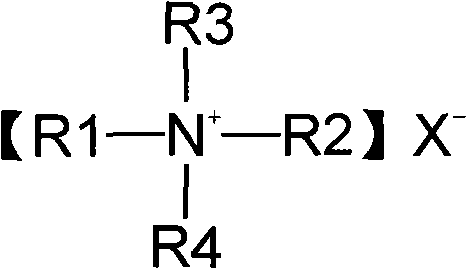

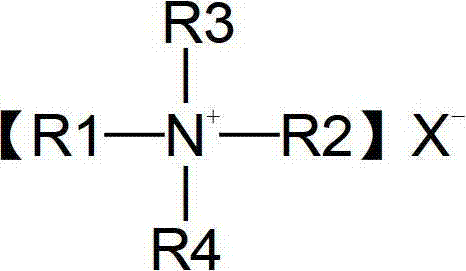

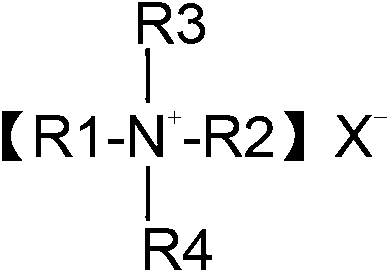

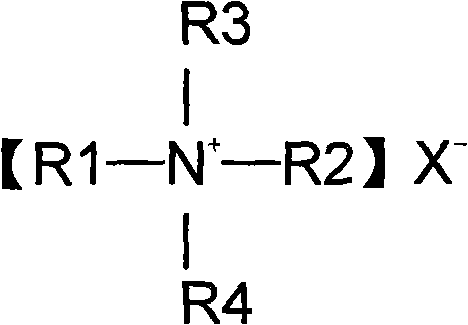

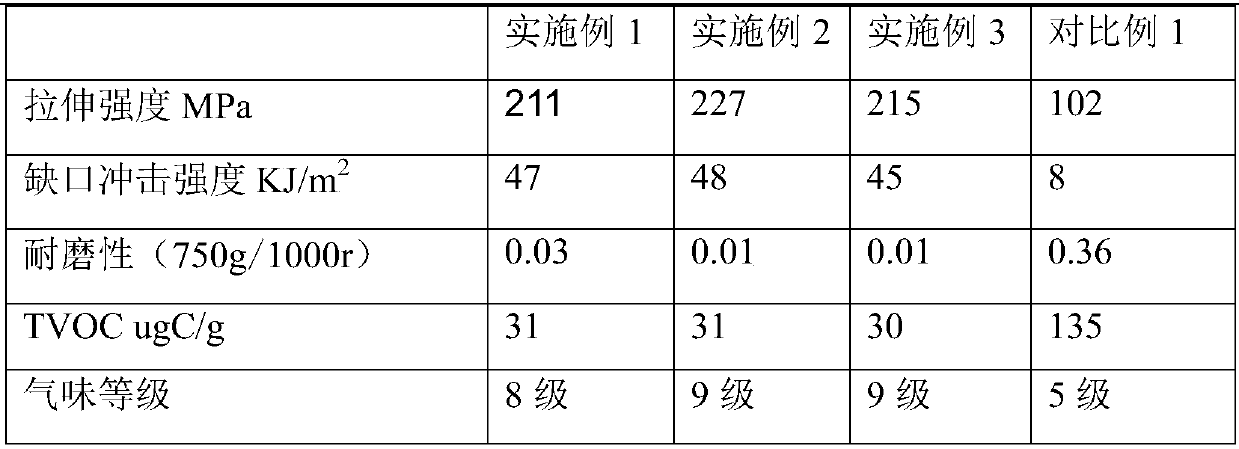

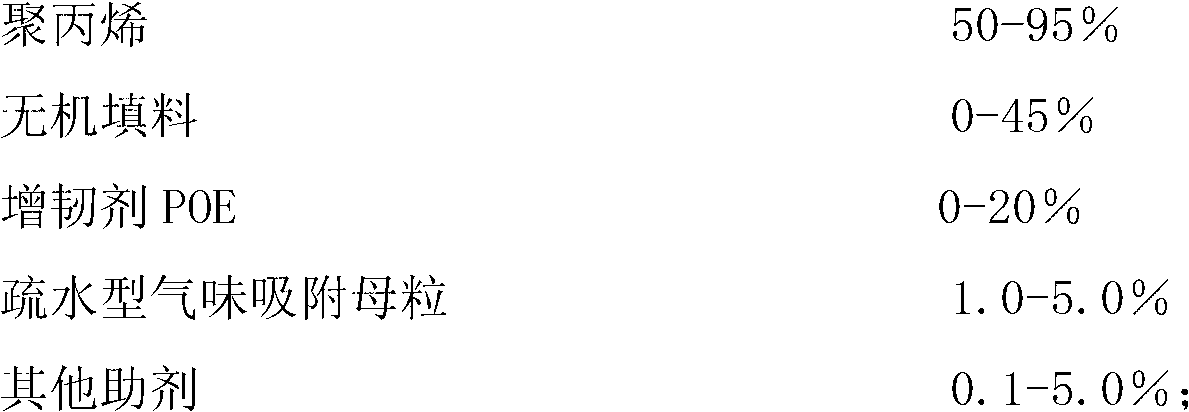

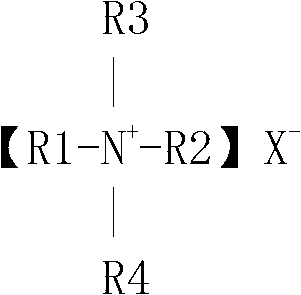

The invention relates to novel low odor polypropylene composite material and a preparation method thereof. The low odor polypropylene composite material comprises the following components by weight percentage: 50 to 95 percent of polypropylene, 0 to 45 percent of inorganic filler, 0 to 20 percent of flexibilizer POE, 1.0 to 5.0 percent of hydrophobic type odor agglomerate, and 0.1 to 5.0 percent of other additives. The preparation method comprises the following steps: firstly mixing 20 to 70 percent basal body resin and 30 to 80 percent attapulgite which is modified by a quaternary ammonium salt surfactant, and carrying out extrusion and granulation to form the high concentration hydrophobic type odor agglomerate; and then mixing the high concentration hydrophobic type odor agglomerate with the polypropylene, the inorganic filler, the flexibilizer POE and the other additives, placing the mixture in a double screw extruder, and obtaining the low odor polypropylene composite material after melted extrusion and granulation. The method is characterized in that the method can make the forming and processing of the composite material be free of any impact, and make the composite material have excellent comprehensive physical and chemical properties and a good odor characteristic.

Owner:CHONGQNG PRET NEW MATERIAL +1

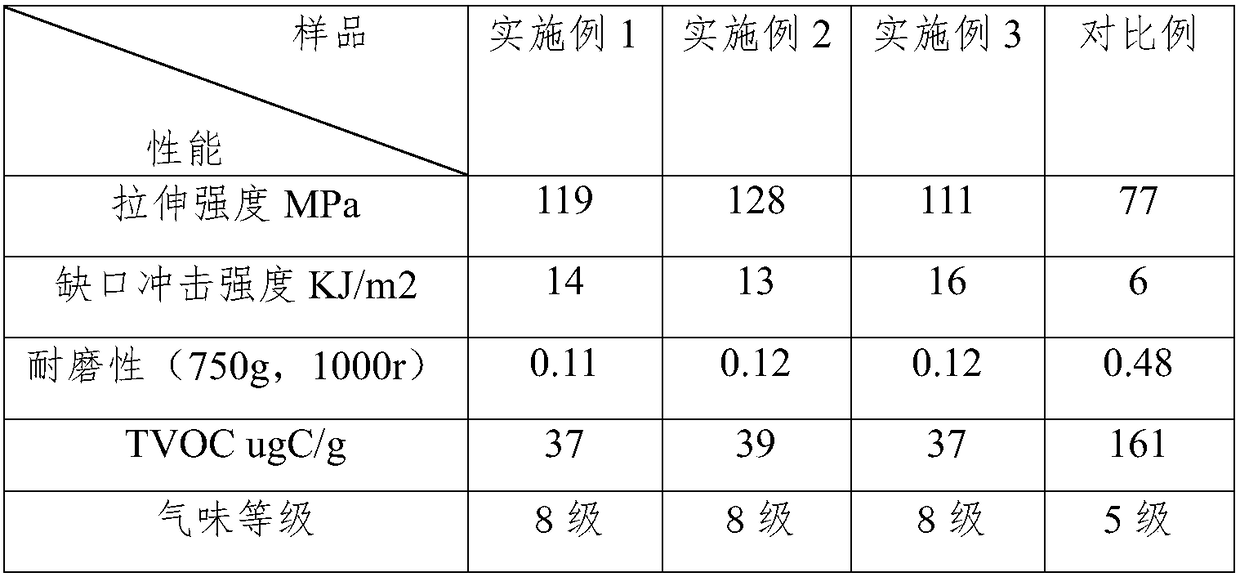

Low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and preparing method thereof

The invention relates to low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and a preparing method thereof. The material is prepared by the steps of stirring and mixing 90-98 parts of high-temperature-resistant nylon, 1-5 parts of a hydrophobic high-temperature-resistant odor-adsorption masterbatch, 1-5 parts of surface treated nano silicon carbide, 0.1-0.5 part of a solid lubricant, 0.2-1.0 part of a lubricant and 0.1-1 part of an antioxidant and then carrying out melting extrusion granulation through a twin-screw extruder. Tetraethoxysilane and a coupling agent are used for composite surface treatment of the nano silicon carbide, the dispersity of the nano silicon carbide as a wear-resisting agent in matrix resin is increased, and thus the cohesive property of the wear-resisting agent and the high-temperature-resistant nylon matrix is improved, the prepared high-temperature-resistant nylon has significant improvement in wear resistance; at the same time, with use of the hydrophobic high-temperature-resistant odor-adsorption masterbatch, the product is kept a low-odor characteristic in processing and application processes.

Owner:HEFEI GENIUS NEW MATERIALS

Method for making little odor polypropylene material using odor agglomerate

The invention relates to a method for making little odor polypropylene material using odor agglomerate, wherein the content of the flavor agglomerate is 20-70 wt% of the matrix resin, the content of flavor depressant is 30-80%, the matrix resin has good compatibility with polypropene material, which includes polypropylene or the copolymer of ethylene-octene, the liquation flow speed (230 deg C X 2.16kg) of the polypropene is 5-50g / 10min, the density of the copolymer of ethylene-octene (POE) is 0.88-0.90g / cm3, the melting index is 1-50g / 10min, the flavour depressant is physical adsorption material comprising one of molecular screen material or pore silica gel material or their combination, the molecular sieve material is a alkali metal aluminosilicate powder with sodium type crystal structure.

Owner:SHANGHAI PRET COMPOSITES

Novel low odor, low carbon emitting PC/ABS alloy material and preparation

ActiveCN101469122ADoes not affect processing performanceImprove adsorption capacityHigh concentrationAntioxidant

The invention discloses a novel low-odor low-volatilization PC / ABS (polycarbonate / acrylonitrile- butadiene-styrene copolymer) alloy material and a method for preparing the same. The PC / ABS alloy material comprises the following compositions by weight percentage: 50 to 80 percent of polycarbonate, 10 to 45 percent of ABS / PP graft, 1.0 to 5.0 percent of hydrophobic odor adsorption master particles. 0.1 to 1.0 percent of antioxidant and 0 to 0.5 percent of other additives. The preparation method comprises: firstly, 20 to 70 percent of ABS resin and 30 to 80 percent of attapulgite modified by quaternary ammonium salt type surfactant are mixed, extruded and pelletized to form high-concentration hydrophobic odor adsorption master particles; and secondly, the high-concentration hydrophobic odor adsorption master particles and the polycarbonate, the ABS / PP graft, the antioxidant and other additives are mixed, are placed in a double-screw extruder and are subjected to fusion, extrusion and pelletization. The obtained novel PC / ABS alloy material has the characteristics that the material is not influenced in molding processing at all and has excellent physical and chemical comprehensive performance and excellent odor property and the like.

Owner:CHONGQNG PRET NEW MATERIAL +2

Method for preparing little odor acrylonitrile-butadiene-styrene ternary copolymerized resin material using odor agglomerate

The invention relates to a method for preparing little odor acrylonitrile-butadiene-styrene ternary copolymerized resin material by utilizing odor agglomerate, which can effectively reduce the bad smell in ABS composite material, and is prepared from the following raw material (by weight percent), base resin 20-70, odor depressant 30-80, wherein the base resin comprises (by weight ratio) rubber 5-30%, acrylic nitrile 10-30%, phenylethene 40-70%, the odor depressant is alkali metal aluminosilicate powder, or one or combination of silica gel materials.

Owner:SHANGHAI PRET COMPOSITES

Novel low-odor and low-emission ABS resin compound and preparation method thereof

The invention discloses a low-odor and low-emission ABS resin compound which contains the following materials by weight proportion: 100 ABS, 1.0-5.0 hydrophobic odor adsorption master batch, 0.1-1.0 antioxidant and 0-5.0 other auxiliaries. The invention has the advantages that a hydrophobic odor adsorption system is adopted, so the low-odor and low-emission ABS resin compound prepared through the method can ensure the characteristic of low odor of the material, the processing of the material is not affected and the physical mechanical properties of the material are not affected.

Owner:CHONGQNG PRET NEW MATERIAL +2

Radiation curable ink jet composition and ink jet recording method

There is provided a radiation curable ink jet composition including: a monomer A that has one of a (meth)acryloyloxy group and a (meth)acryloyl group and has a cyclic structure containing one or more nitrogen atoms and one or more oxygen atoms in addition to the (meth)acryloyloxy group and the (meth)acryloyl group; and a monofunctional monomer B other than the monomer A; in which the content of the monomer A is equal to or less than 25% by mass with respect to the total mass of the composition, and in which mol average Tg of the monomer A and the monofunctional monomer B is equal to or greater than 45° C.

Owner:SEIKO EPSON CORP

Low-odour acrylonitrile-butadiene-styrene copolymer complex

ActiveCN100580022CLow Odor PropertiesExcellent physical and chemical propertiesMolecular sieveAlkali metal

Disclosed is a low-odour acrylonitrile-butadiene-styrene copolymer complex comprising the raw materials (by weight ratio) of ABS 100 and molecular sieve material 0.001-0.01, toughening agent 0-5, anti-oxidant 0.2-2.0, ultraviolet light absorbent 0-2.0, free radical quenching agent 0-2.0, pigment and lubricating agent 0-5.0, wherein the molecular sieve material being a alkali metal aluminosilicate powder of sodium type crystal structure with the chemical formula of Na86[(AlO2)86(SiO2)106]*XH2O, the toughening agent being a high colloid AB comprising rubber 50-70 wt%, acrylic nitrile 5-20 wt%, phenylethene 25-30 wt%.

Owner:CHONGQNG PRET NEW MATERIAL +2

Little odor acrylonitrile-butadiene-styrene ternary copolymerized resin material and its preparation method

The invention relates to a low-odor acrylon-butadiene-styrene copolymer resin material and its preparing process, wherein the material comprises (by weight portions) ABS100, porous silica gel material 0.5-5, toughening agent 0-5, anti-oxidant 168 0.1-1.0, anti-oxidant 245 0.1-1.0, ultraviolet absorbent 0-2.0, free radical quenching agent 0-2.0, wherein the the ABS comprises rubber 5-30 wt%, acrylic nitrile 10-30%, phenylethene 40-70%, the porous silica gel material is a silicon oxide porous powder material with a grain size greater than 200 meshes, and a micropore diameter between 20-30A. The toughening agent is a high-colloidal ABS.

Owner:CHONGQNG PRET NEW MATERIAL +2

Low odor low total carbon emanation PC/ABS alloy and preparing method thereof

The invention relates to a PC / ABS alloy material with low odor and low total carbon transpiration, ingredients (weight percentage) of which are that: 50-80 percent of polycarbonate, 10-45 percent of ABS / PP graft, 0.1-5.0 percent of odor master batch, 0.1-1.0 percent of antioxidant, 0.1-1.0 percent of lubricant and 0-5.0 percent of other addition agent. Compositions (weight percentage) of odor master batch in the method are 20-70 percent of matrix resin ABS and 30-80 percent of odor inhibitor. The preparation method thereof is that: the matrix resin and the odor inhibitor are put into a twin-screw extruder; odor master batch of high concentration is made by melting, extruding and pelleting; finally, when the PC / ABS alloy material is formed, the PC / ABS alloy material is mixed evenly with alloy material for forming. The method has the advantage that forming and processing of the composite material are not impacted and comprehensive physical and chemical properties are excellent and odor characteristic is good.

Owner:SHANGHAI PRET COMPOSITES

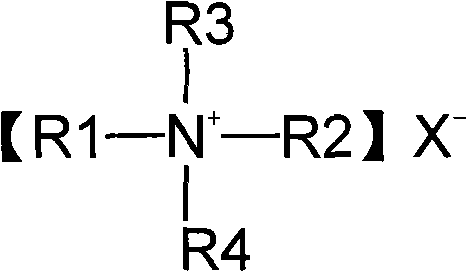

Whitened red phosphorus, low-odor and low-emission whitened red phosphorus flame retardation master batch for nylon, and preparation method of master batch

The invention discloses a low-odor and low-emission whitened red phosphorus flame retardation master batch for nylon, and a preparation method thereof. The master batch is prepared from, by weight, 50-85 parts of whitened red phosphorus, 1-5 parts of a hydrophobic odor adsorption master batch, 0.2-1.0 part of an antioxidant and 0.2-1 part of a lubricant. The red phosphorus flame retardation master batch prepared in the invention has the advantages of wide versatility, high effective components, no obvious odor and low addition amount, and the preparation method has the advantages of simplicity, breaking of color limitation, realization of the product being not limited to dark products, effective reduction of dust pollution, and improvement of the labor environment.

Owner:HEFEI GENIUS NEW MATERIALS

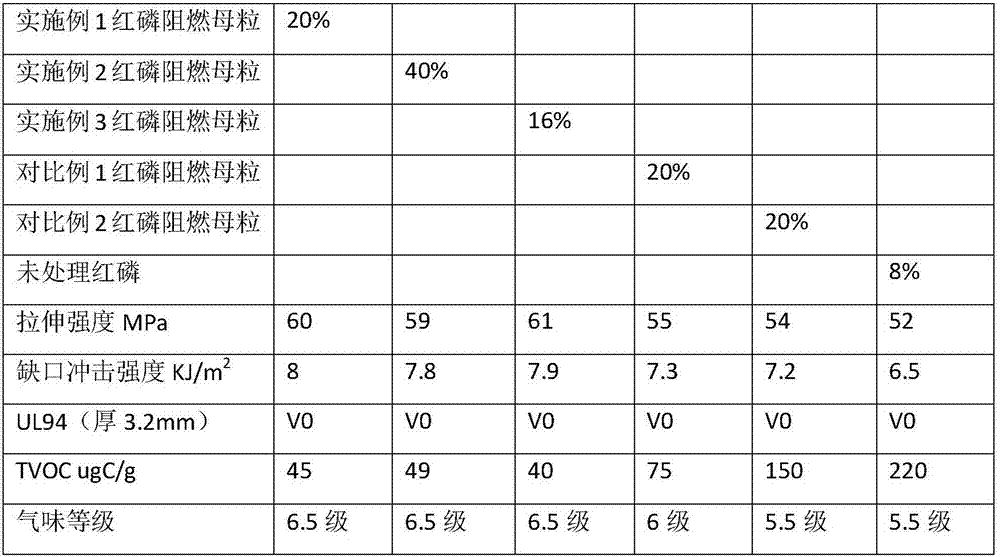

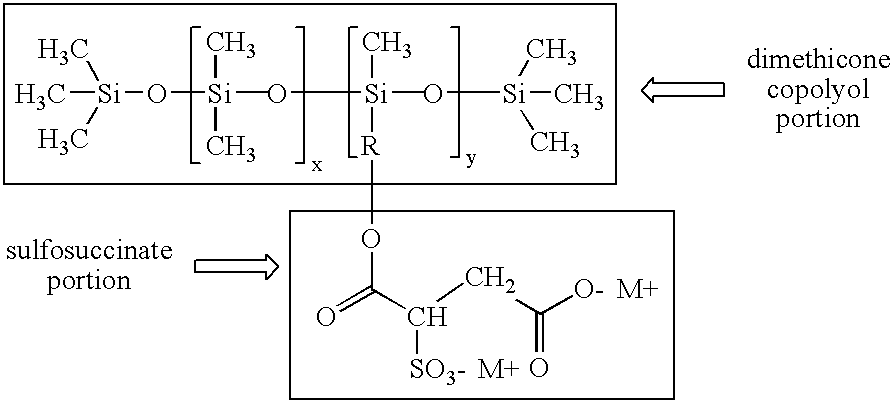

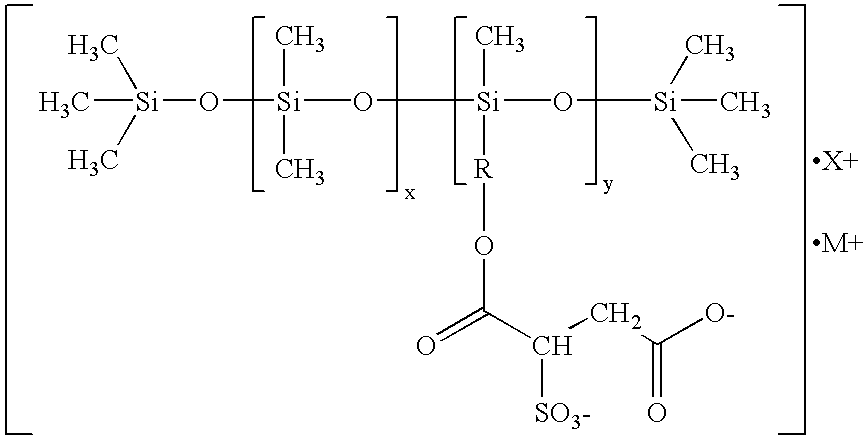

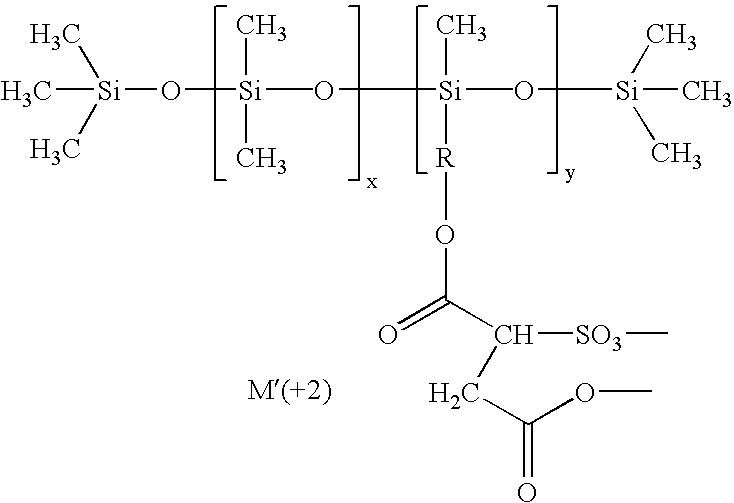

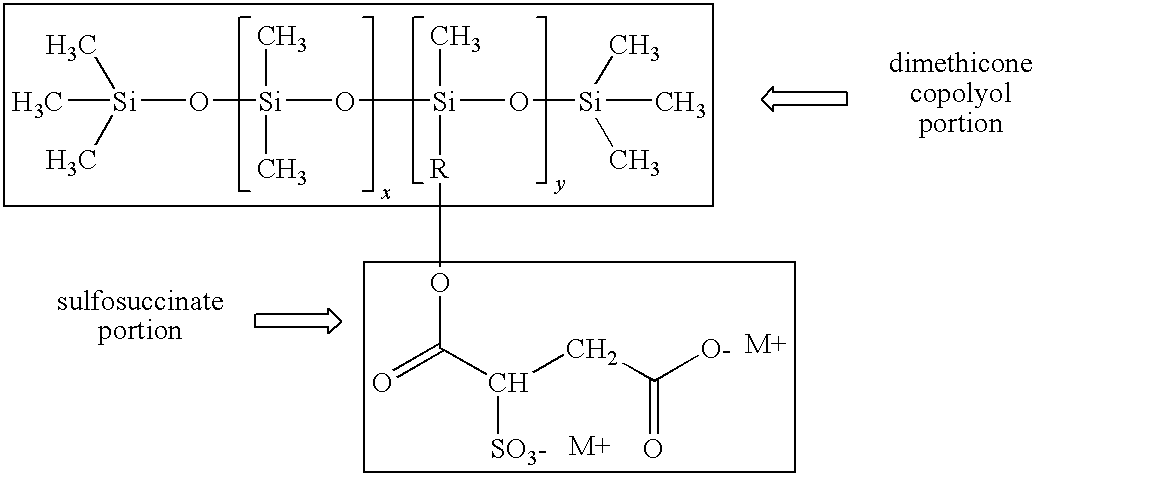

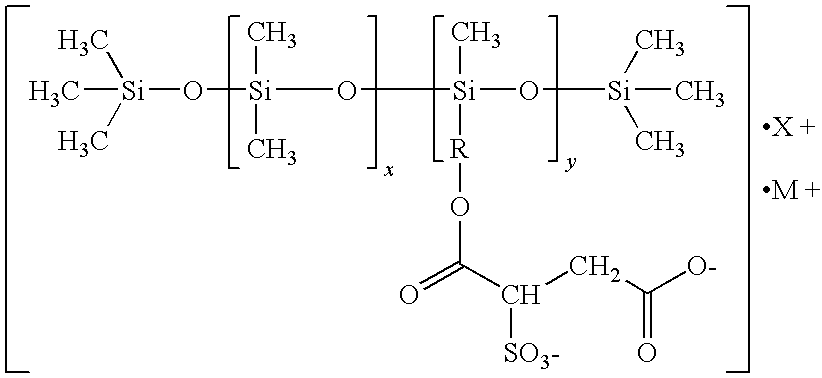

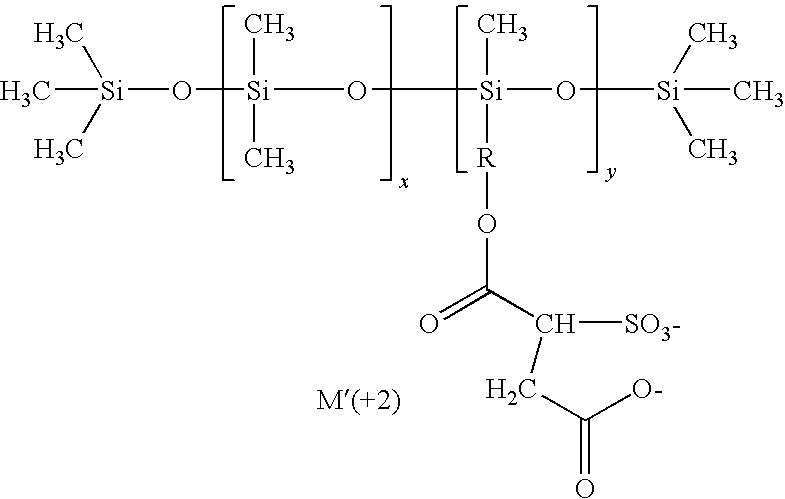

Low-odor dimethicone copolyol sulfosuccinate surfactant compositions

InactiveUS20070212319A1Exhibit to skinGood foam stabilization effectCosmetic preparationsHair cosmeticsSulfosuccinic acidDimethyl siloxane

Dimethicone copolyol sulfosuccinate surfactant compounds having low-odor characteristics are disclosed. The low-odor dimethicone copolyol sulfosuccinate is substantially free from propionaldehyde and acid-releasable precursors of propionaldehyde, thereby substantially eliminating the cosmetically undesirable odor characteristic of conventional dimethicone copolyol sulfosuccinate surfactants. The low-odor dimethicone copolyol sulfosuccinates are suitable for use as surfactants in household or personal care products and applications.

Owner:RHODIA OPERATIONS SAS

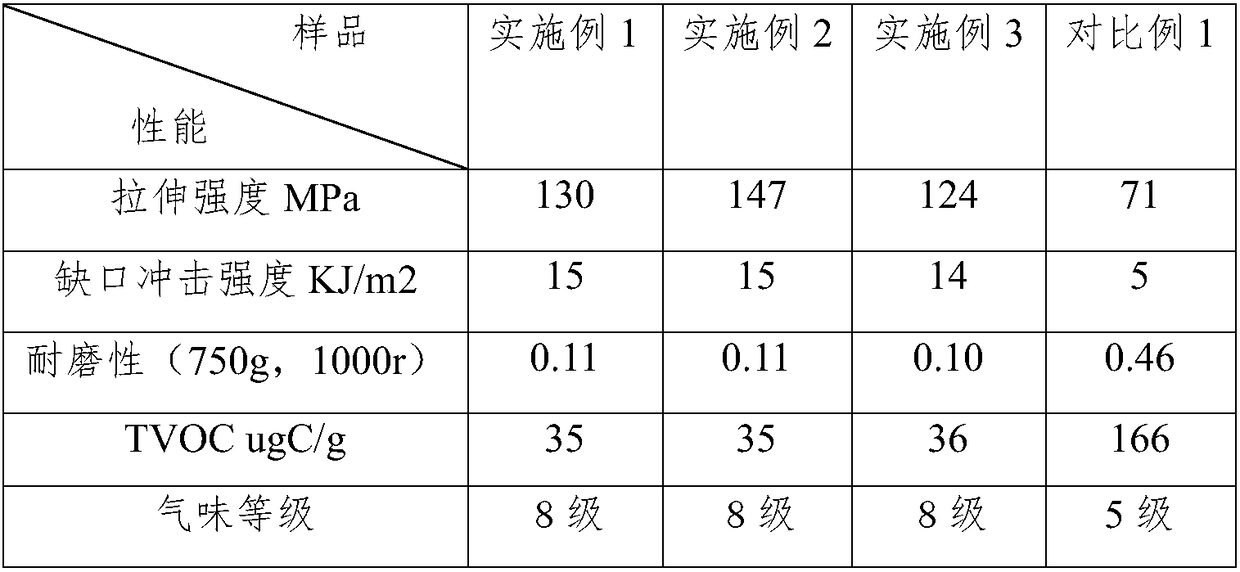

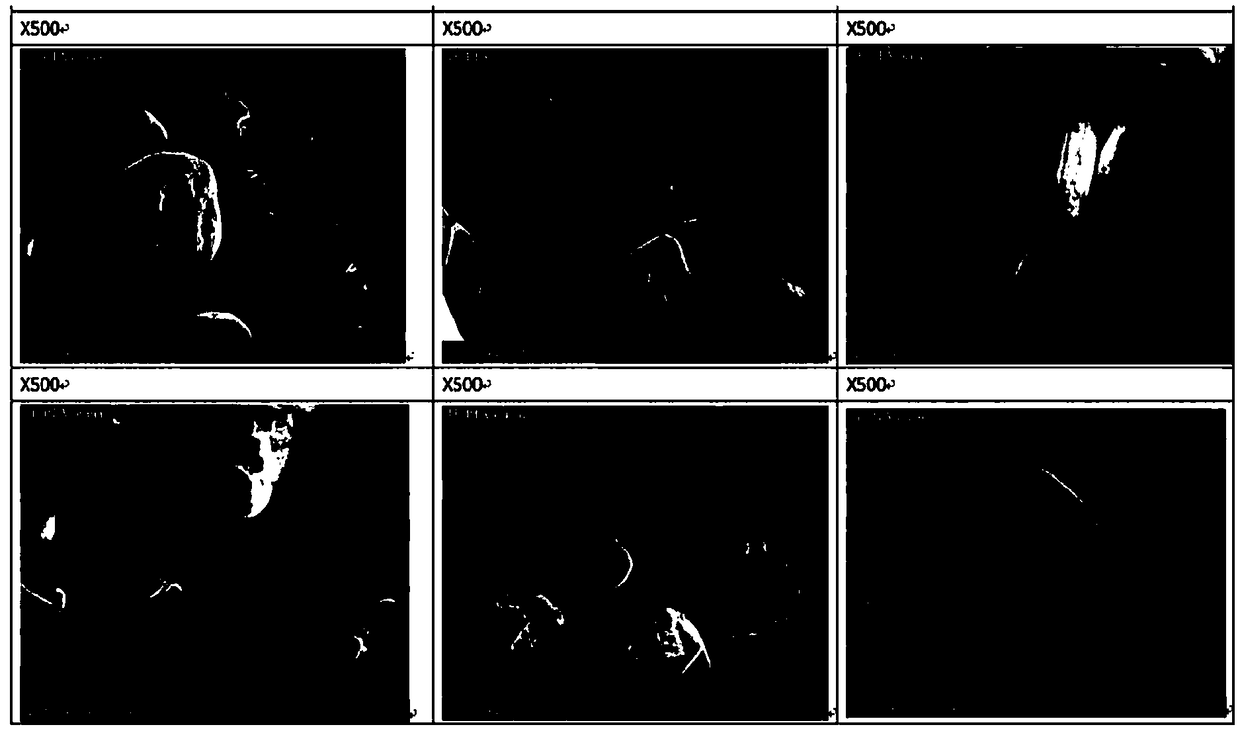

Modified nylon composition and preparation method thereof

The invention provides a modified nylon composition and a preparation method thereof, and relates to the technical field of macromolecular materials. The modified nylon composition is prepared from the following raw materials: nylon 6, nylon 66, POE grafted maleic anhydride, polytetrafluoroethylene modified glass fibers, an odor adsorption masterbatch, silicon carbide, a lubricant and an antioxidant. The modified nylon composition has the characteristics of low odor and good wear resistance. The nylon composition prepared by coordinating action of the raw materials has remarkable improvement in wear resistance and keeps excellent mechanical properties, and the forming and processing properties of the material are not affected.

Owner:HEFEI GENIUS NEW MATERIALS

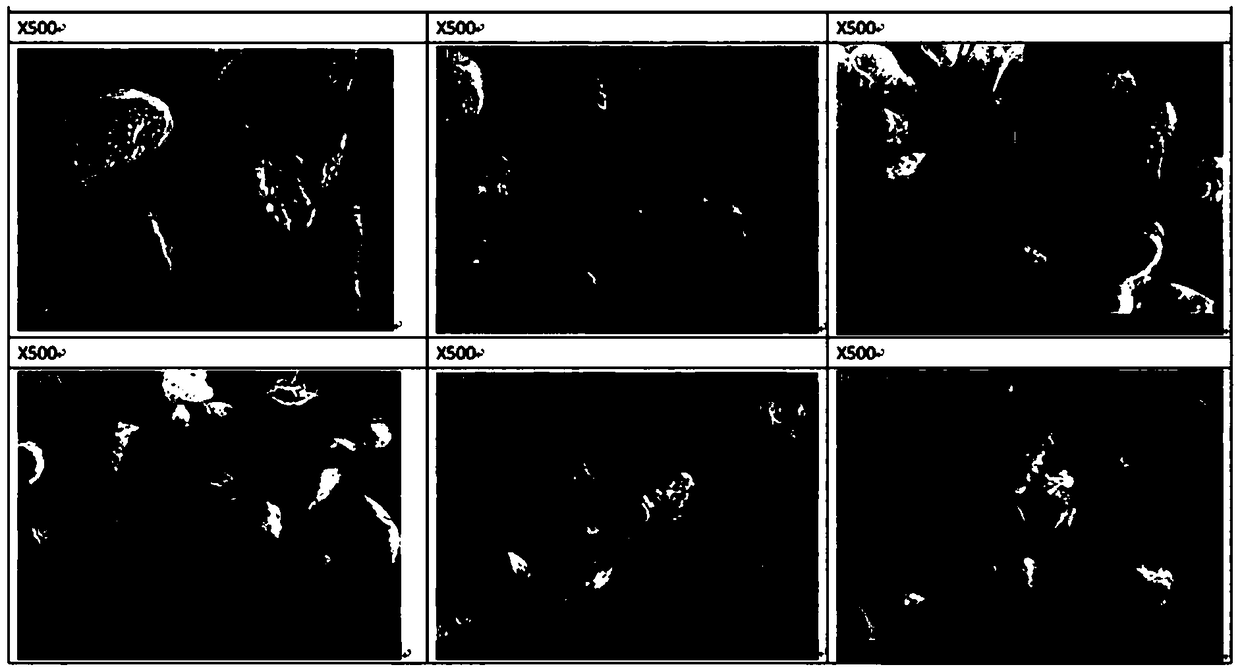

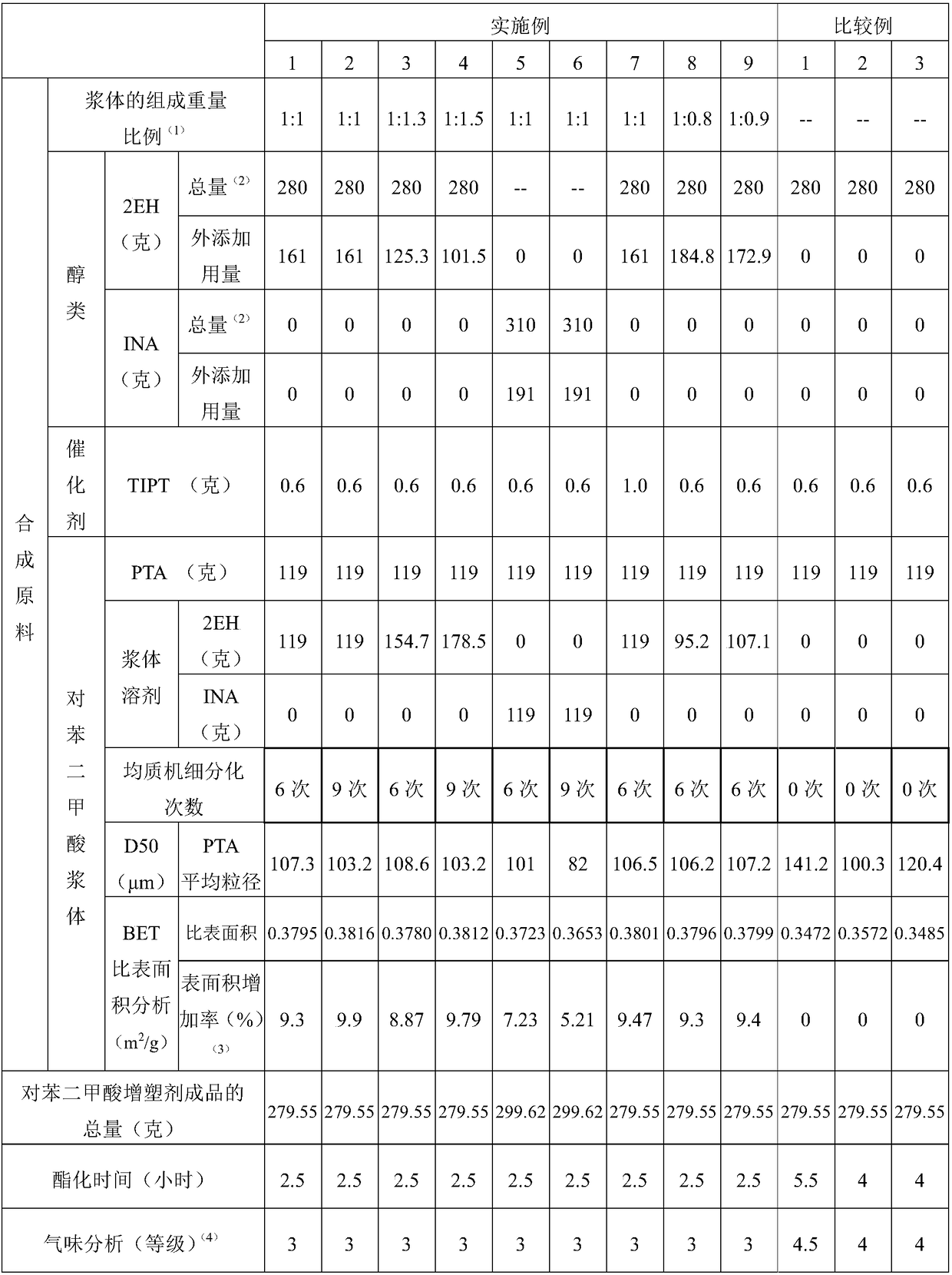

A method for improving the reaction efficiency of a terephthalate plasticizer

ActiveCN108640837AShorten the reaction time of esterificationIncrease productionOrganic compound preparationCarboxylic acid esters preparationAlcoholMetal catalyst

The invention provides a method for improving the reaction efficiency of a terephthalate plasticizer. A homogenizer is used to refine PTA in a mixture containing the PTA and C6-C10 alcohol multiple times to a grain size of 80-110 [mu]m. Esterification reaction is performed in the presence of a titanium metal catalyst. Compared with the conventional producing method, the method has the advantages that the esterification reaction time is at least shortened by more than 37.5%, the purity of a terephthalate plasticizer finished product synthesized through esterification is more than 99.5%, the physical properties such as acid value, hue, refractive index and the like all meet standards, and the product has a low odor characteristic.

Owner:NANYA PLASTICS CORP

Novel low-odor and low-emission ABS resin compound and preparation method thereof

Owner:CHONGQNG PRET NEW MATERIAL +2

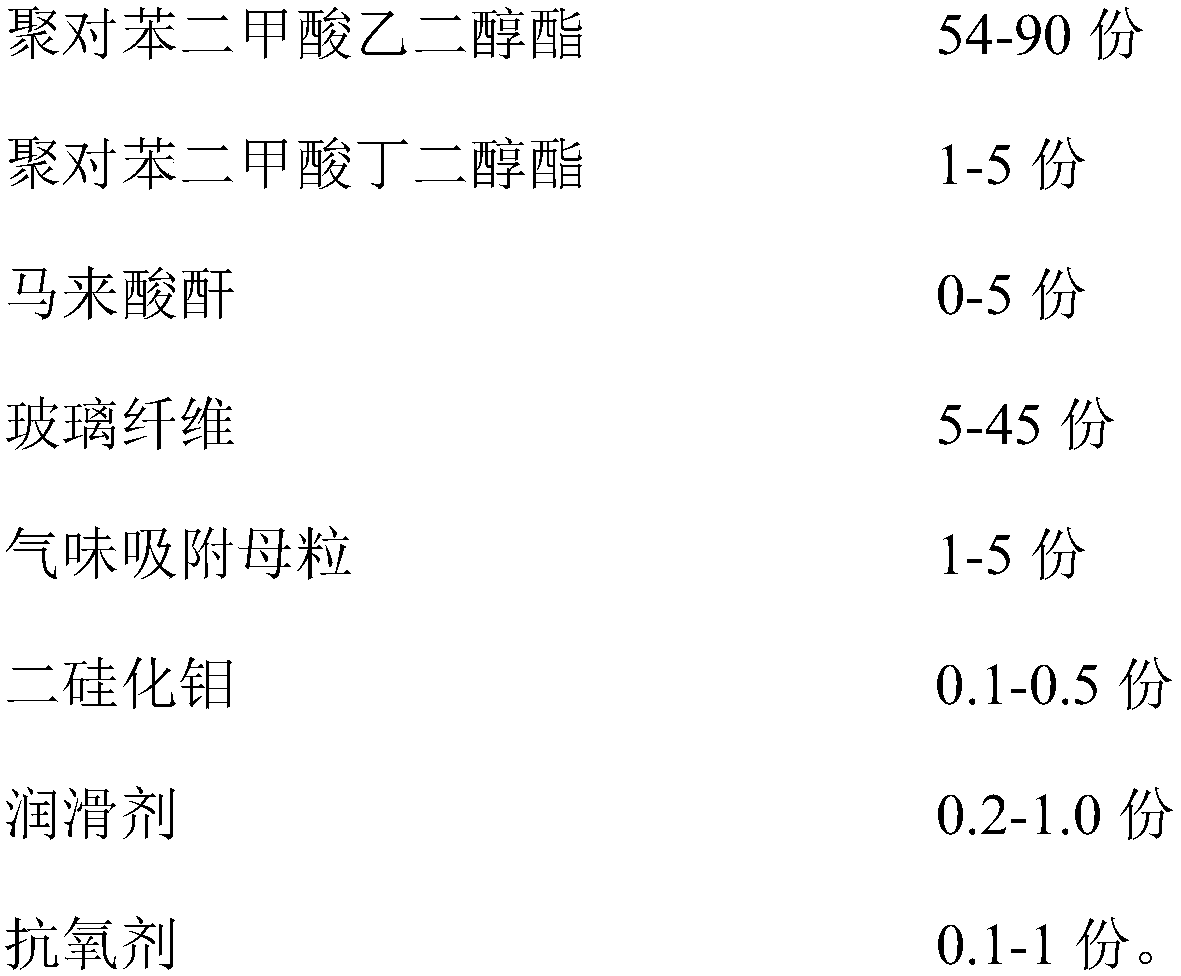

Low-odor, low-volatilization and high-wear-resistance polyethylene glycol terephthalate composition and preparation method thereof

The invention discloses a low-odor, low-volatilization and high-wear-resistance polyethylene glycol terephthalate composition and a preparation method thereof. The composition is prepared from, by weight, 54-90 parts of polyethylene glycol terephthalate, 1-5 parts of polybutylene terephthalate, 0-5 parts of maleic anhydride, 5-45 parts of glass fiber, 1-5 parts of odor adsorption masterbatch, 0.1-0.5 part of molybdenum disilicide, 0.2-1.0 part of a lubricant, and 0.1-1 part of an antioxidant. The glass fiber is subjected to immersion treatment with polyphenyltetramethylamide dispersion liquid,the dispersion of the glass fiber in a polyethylene glycol terephthalate base is greatly improved, the wear resistance of the prepared composition is significantly improved, and meanwhile the composition maintains excellent mechanical properties. The odor adsorption masterbatch is used for reducing the content of small molecules in the composition, and the content of a total volatile organic compound (TVOC) is significantly reduced; the low odor property of the composition is ensured, and the various physical and mechanical properties and the material molding processing properties are not affected.

Owner:HEFEI GENIUS NEW MATERIALS

Rubber composition, and pneumatic tire

InactiveUS20200109252A1Improve hydrophobicityAvoid odorHeavy duty tyresHeavy duty vehiclePolymer scienceAluminum silicate

A rubber composition is disclosed which includes an inorganic compound, the inorganic compound being an aluminum silicate represented by general formula (1): xAl2O3.ySiO2.zH2O in which x and y are each independently an integer, y / x≥5, and z is a positive number; and an amount of the inorganic compound being less than 15 parts by weight for 100 parts by weight of a rubber component in the rubber composition. The rubber composition of the invention can give a vulcanized rubber which can restrain an odor peculiar to tires (i.e., which has a low odor property).

Owner:TOYO TIRE & RUBBER CO LTD

Snow melting composition

InactiveUS20060261305A1Excellent effectLow odor characteristicOther chemical processesHeat-exchange elementsChemistryTripotassium citrate

The present invention provides a snow melting composition containing tripotassium citrate (a) and a non-synthetic polyhydric alcohol (b), wherein the tripotassium citrate (a) is contained in a ratio of 20 to 75 wt % and the non-synthetic polyhydric alcohol (b) is contained in a ratio of 25 to 80 wt %, with respect to the total weight of the tripotassium citrate (a) and the non-synthetic polyhydric alcohol (b). The snow melting composition of the present invention provides an excellent snow melting effect, does not corrode metals, and furthermore has low odor characteristics and thus does not adversely affect organisms living in surrounding areas.

Owner:NOF CORP

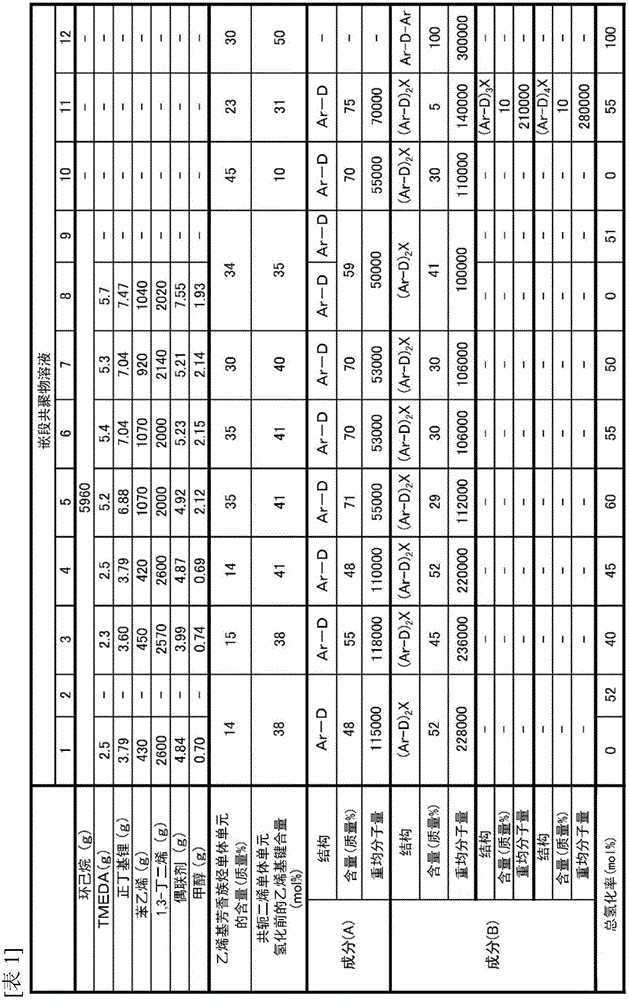

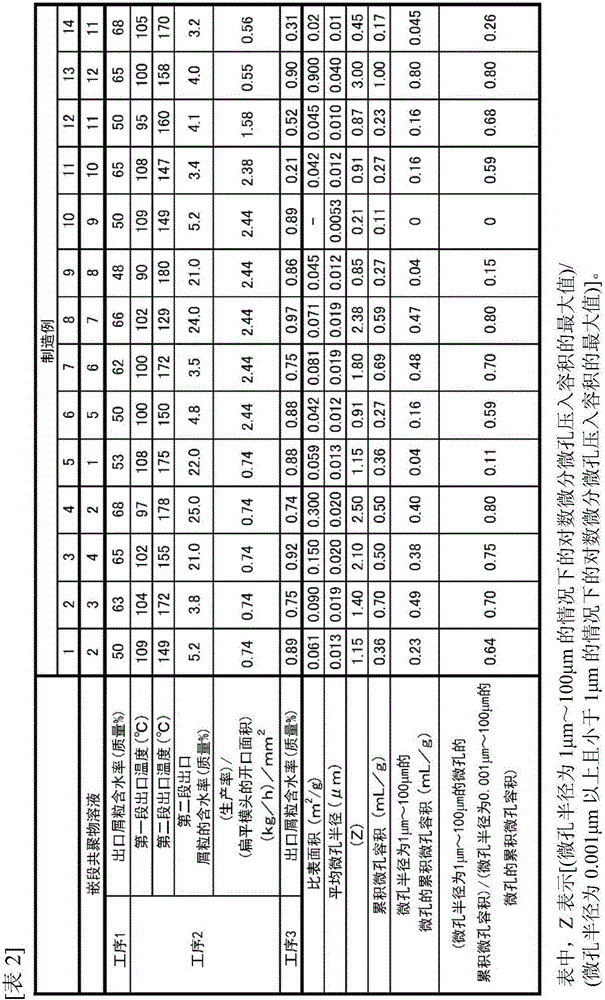

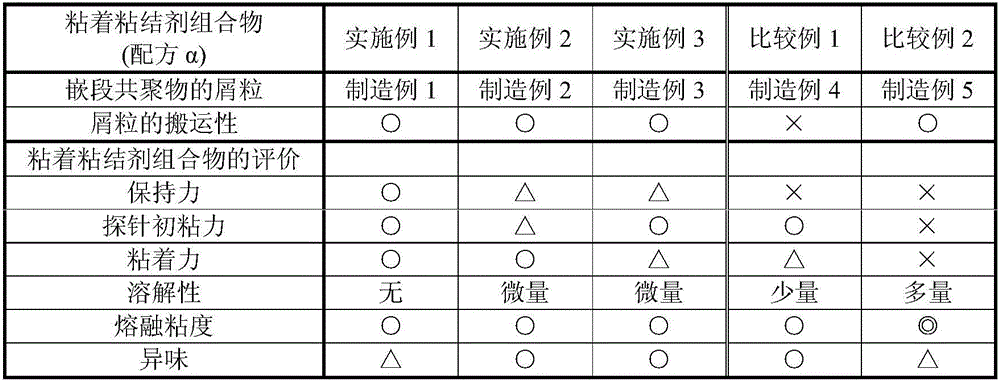

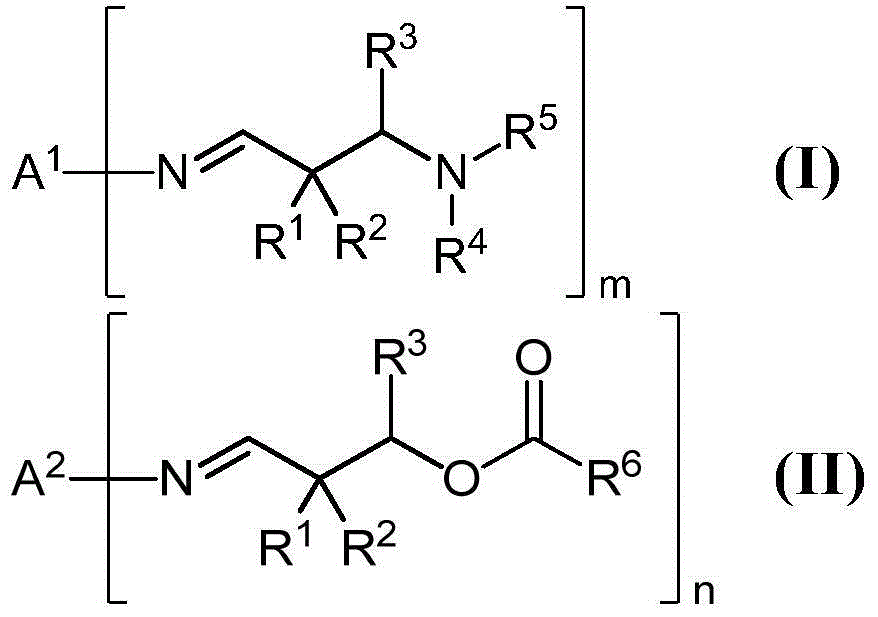

Crumb of block copolymer and adhesive composition

ActiveCN106459250AImprove the handling effectReduce solubilityAdhesive processesFilm/foil adhesivesSolubilityPolymer science

The invention provides a crumb of block copolymer and an adhesive composition. The crumb of a block copolymer has excellent transportability and is capable of forming an adhesive composition that has excellent solubility, low melt viscosity characteristics and low odor characteristics, with an excellent balance among these characteristics, in cases where the crumb of a block copolymer is used in the adhesive composition. The present invention relates to a crumb of a block copolymer, which contains a polymer block mainly composed of at least one vinyl aromatic hydrocarbon monomer unit and a polymer block mainly composed of at least one conjugated diene compound monomer unit and has a weight average molecular weight of 20,000-1,000,000, while having a specific surface area, a cumulative pore volume of pores having pore radii of 1-100 [mu]m and an average pore radius respectively within specific ranges.

Owner:ASAHI KASEI KK

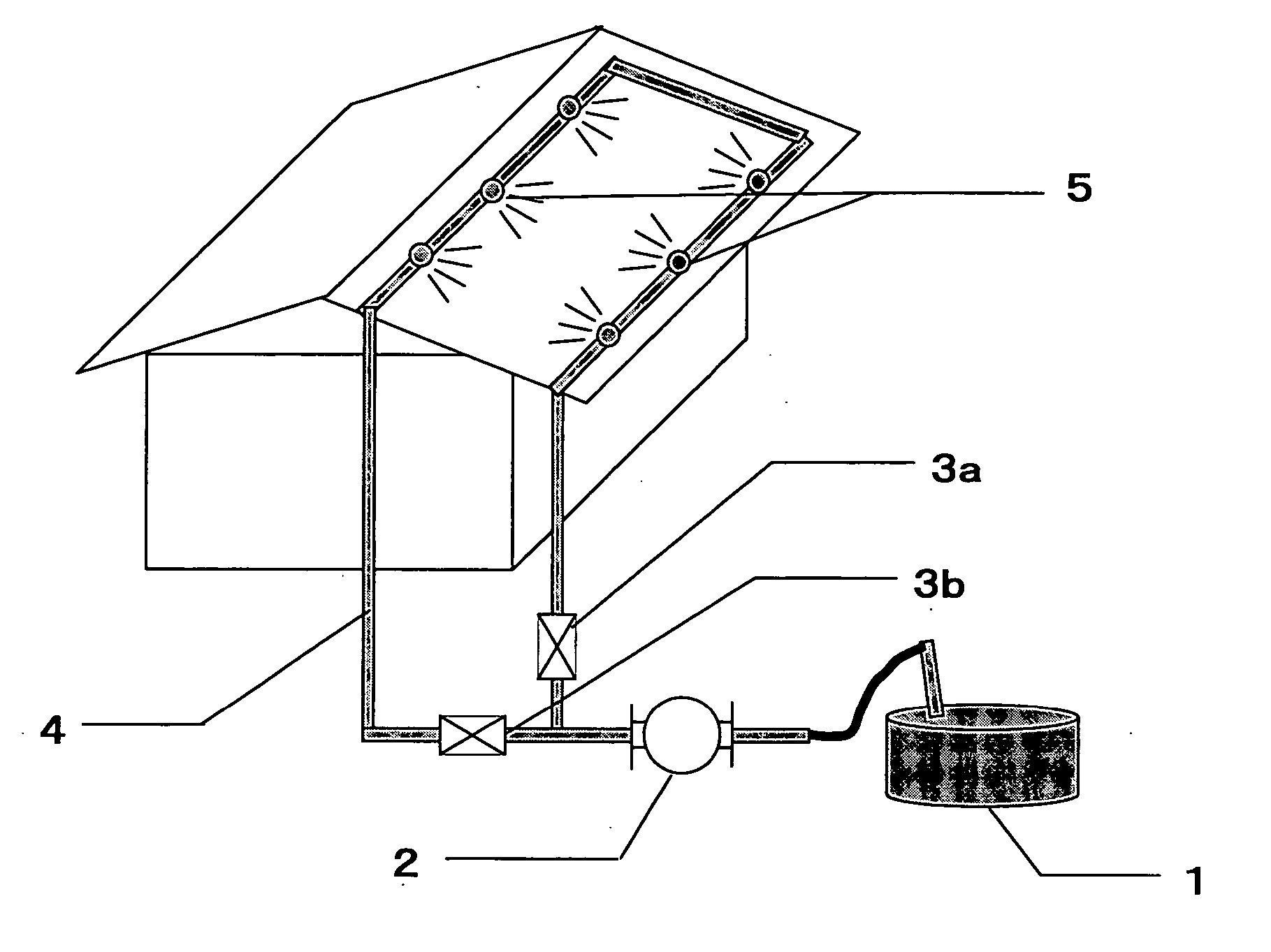

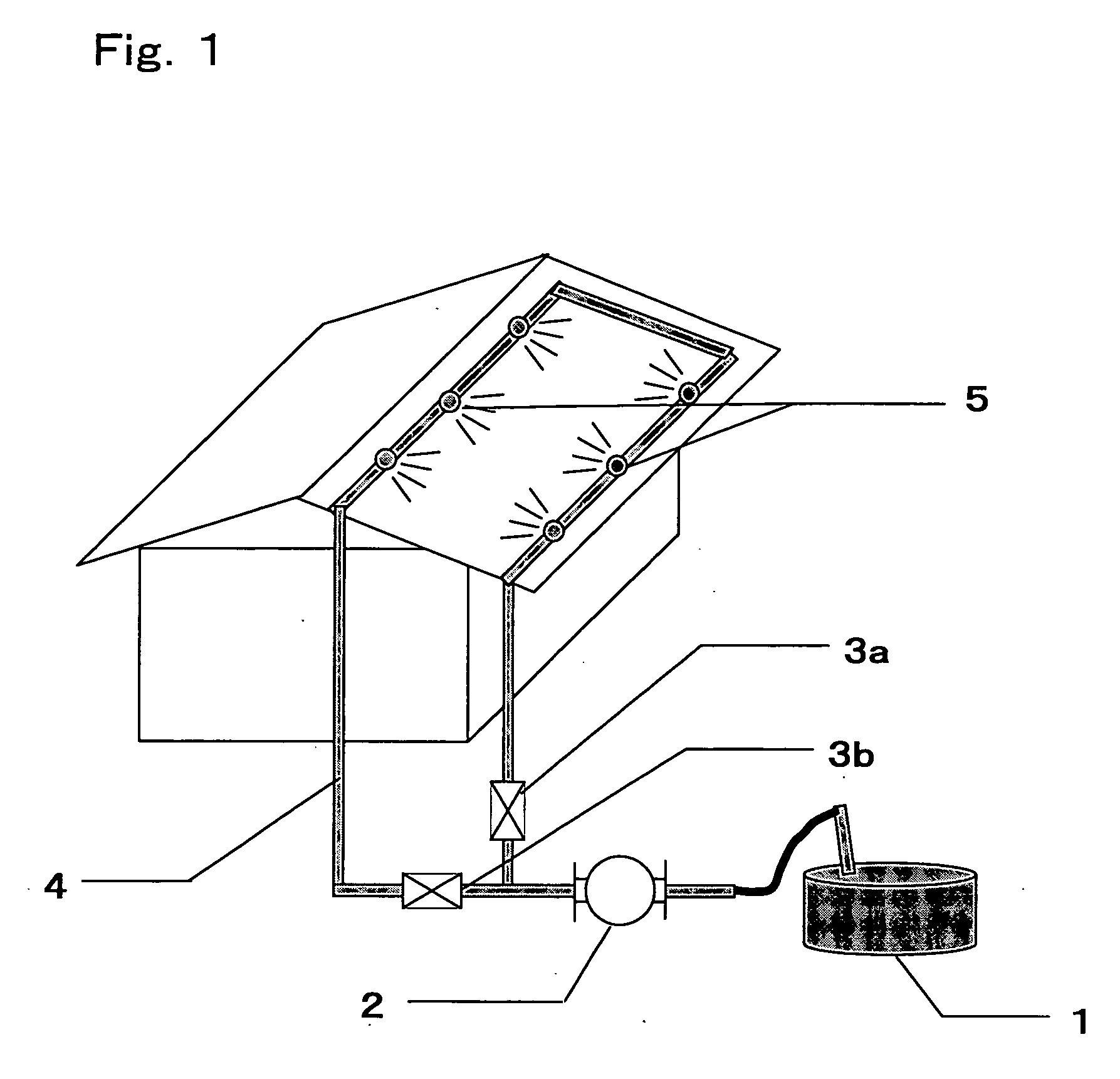

Liquid-applied waterproofing membrane for roofs comprising two different aldimines

ActiveCN104884494AGood shelf life stabilityHigh tensile strengthRoof covering using sealantsPolyurea/polyurethane coatingsPolymer scienceAldimine

The present invention describes a one-part moisture-curing liquid-applied waterproofing membrane comprising a polyurethane polymer and two different aldimines as blocked amine hardeners in a specific ratio range. The membrane has a low odour, a long shelf life stability, a low viscosity at low solvent content, a sufficiently long open time to allow hand application and cures fast to a solid elastic material. The liquid-applied waterproofing membrane is particularly suitable for roofing applications, possessing high strength, high elongation and good durability under outdoor wheathering conditions in a broad temperature range.

Owner:SIKA TECH AG

Polyformaldehyde composition and preparation method thereof

The invention provides a polyformaldehyde composition and a preparation method thereof, and relates to the technical field of high polymer materials. The polyformaldehyde composition is prepared fromthe following raw materials: polyformaldehyde, ultra-high-molecular-weight polyethylene modified glass fibers, odor-adsorption master batches, molybdenum disulfide, a lubricant and an antioxidant. Thepolyformaldehyde composition disclosed by the invention has low odor and good wear resistance and stability. Through the adoption of the matching effect of the raw materials such as the ultra-high-molecular-weight polyethylene modified glass fibers, the odor-adsorption master batches and the like, the low-odor characteristic of the polyformaldehyde composition is ensured, and the physical and mechanical properties of the polyformaldehyde composition and the moulding processability of the material are not affected at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

Low odor and emission nylon 6 composition and preparation method thereof

ActiveCN101760010BLow Odor PropertiesPhysical and mechanical properties are not affectedAntioxidantAdditive ingredient

The invention discloses low odor and distribute nylon 6 combination which comprises the following components in proportion by weight: 55 to 99% of nylon 6, 0 to 6% of polypropylene grafted with maleic anhydride, 0 to 30% of inorganic filler, 0.5 to 3.5 of hydrophobic odor adsorbent, 0.1 to 1% of antioxidant, 0 to 2% of lubricant and 0 to 3% of other accessory ingredient. The invention has the advantages that a hydrophobic odor adsorbent system is used, when the low odor characteristics of the materials are ensured by the low odor and distribute nylon 6 combinations, various physical mechanics capabilities of the materials are not influenced, and the contour machining property of the materials is not influenced.

Owner:SHANGHAI PRET COMPOSITES

Low-odor and high-wear-resistant PET composition and preparation method thereof

ActiveCN108929526AGood dispersionImprove wear resistancePolymer sciencePolyethylene terephthalate glycol

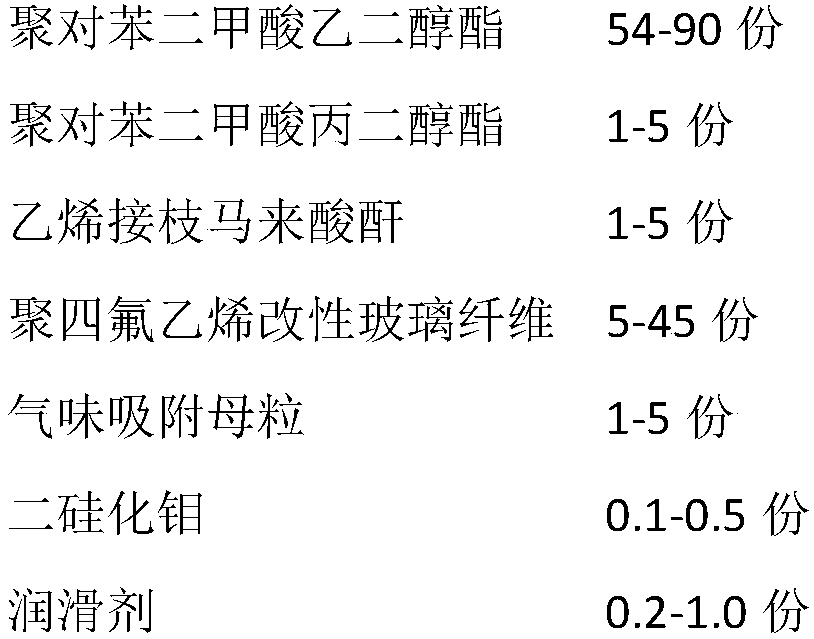

The invention provides a low-odor and high-wear-resistant PET composition and a preparation method thereof, wherein the low-odor and high-wear-resistant PET composition is prepared from the followingcomponents in parts by weight: polyethylene glycol terephthalate, polypropylene glycol terephthalate, ethylene grafted maleic anhydride, polytetrafluoroethylene modified glass fibers, an odor adsorption masterbatch, molybdenum disilicide, a lubricant and an antioxidant. The glass fibers impregnated with polytetrafluoroethylene greatly improve the dispersion in a matrix, the wear resistance of theprepared composition is improved remarkably, and excellent mechanical properties are maintained. In addition, the odor adsorption masterbatch reduces the small molecular content in the composition, and the total volatile organic compounds TVOC are reduced remarkably; moreover, while the low odor characteristics of the composition are guaranteed, the physical and mechanical properties and the forming and processing properties of the material are not affected.

Owner:HEFEI GENIUS NEW MATERIALS

Polyphenylene sulfide modified PET composition and preparation method thereof

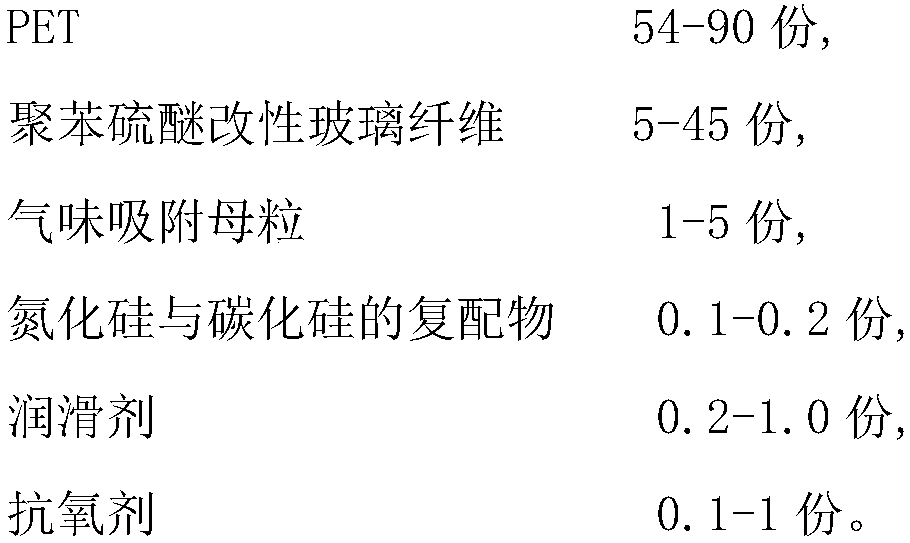

The invention discloses a polyphenylene sulfide modified PET composition and a preparation method thereof. The preparation method comprises: pouring PET, odor adsorption master batch, a silicon nitride and silicon carbide complex, a lubricant and an antioxidant into a high-speed stirrer, stirring, uniformly mixing, and adding into a double-screw extruder; and adding polyphenylene sulfide modifiedglass fiber from the glass fiber port of the extruder, carrying out melt extrusion, and granulating to obtain the polyphenylene sulfide modified PET composition. According to the invention, the glassfiber is subjected to impregnating treatment by using the special polyphenylene sulfide dispersion liquid, so that the dispersity of the glass fibers in the PET matrix is greatly improved, the wear resistance of the prepared PET is remarkably improved, and the excellent mechanical properties are maintained.

Owner:HEFEI GENIUS NEW MATERIALS

Novel low odor polypropylene composite material and preparation thereof

The invention relates to novel low odor polypropylene composite material and a preparation method thereof. The low odor polypropylene composite material comprises the following components by weight percentage: 50 to 95 percent of polypropylene, 0 to 45 percent of inorganic filler, 0 to 20 percent of flexibilizer POE, 1.0 to 5.0 percent of hydrophobic type odor agglomerate, and 0.1 to 5.0 percent of other additives. The preparation method comprises the following steps: firstly mixing 20 to 70 percent basal body resin and 30 to 80 percent attapulgite which is modified by a quaternary ammonium salt surfactant, and carrying out extrusion and granulation to form the high concentration hydrophobic type odor agglomerate; and then mixing the high concentration hydrophobic type odor agglomerate with the polypropylene, the inorganic filler, the flexibilizer POE and the other additives, placing the mixture in a double screw extruder, and obtaining the low odor polypropylene composite material after melted extrusion and granulation. The method is characterized in that the method can make the forming and processing of the composite material be free of any impact, and make the composite material have excellent comprehensive physical and chemical properties and a good odor characteristic.

Owner:CHONGQNG PRET NEW MATERIAL +1

Low-odour polypropylene composite

The invention relates to a low-odor polypropylene compound and a preparation method thereof. A low-odor polypropylene composite material incorporating a three-component stabilizer system formulated from the following raw materials in weight percent (%): polypropylene 55-95, talc 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium dioxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 31140.1-1.0, heat stabilizer 6180.1-0.5, wherein the fatty acid ester compound is carbon Long-chain fatty acid esters with carbon atoms in the chain between 25-45; the heat stabilizer DSTP is octadecyl thiodipropionate; the heat stabilizer 3114 is 3,5-di-tert-butyl-4 -Diethyl hydroxybenzyl phosphate; heat stabilizer 618 is dioctadecyl pentaerythritol bisphosphite. The invention has the characteristics of simple preparation process, low cost, excellent physical and chemical comprehensive properties, excellent odor characteristics and the like.

Owner:SHANGHAI PRET COMPOSITES +1

Low-odor and high-wear-resistance polyformaldehyde composite material and preparation method thereof

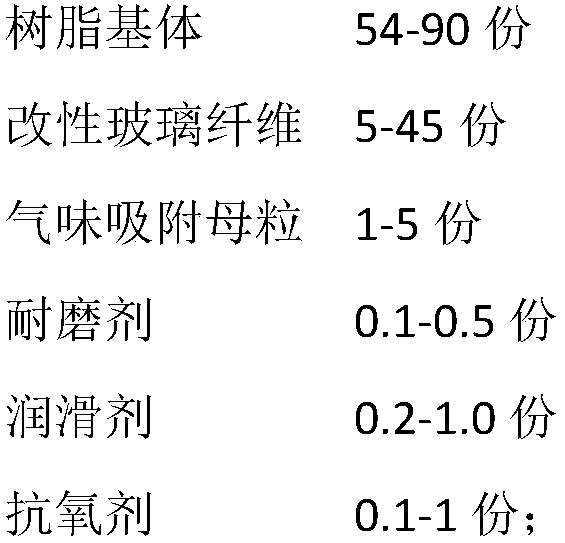

The invention discloses a low-odor and high-wear-resistance polyformaldehyde composite material, which is prepared from the following components in parts by weight: 54 to 90 parts of resin matrix, 5 to 45 parts of modified glass fiber, 1 to 5 parts of an odor adsorption master batch, 0.1 to 0.5 part of wear-resistant agent, 0.2 to 1.0 part of a lubricating agent and 0.1 to 1 part of an antioxidant; the resin matrix is a mixture composed of polyformaldehyde and PET in a weight ratio of 1: 9. According to the invention, a mixed dispersion glue solution composed of polytetrafluoroethylene and polyphenylene sulfide is used for carrying out dipping treatment on the glass fiber, and then roasting and sintering are carried out, so that the dispersity of the glass fibers in a polyformaldehyde andPET resin mixture matrix is greatly improved, the wear resistance of the prepared composite material is remarkably improved, and excellent mechanical properties are maintained. A small amount of wear-resistant agent is used for synergistically improving the wear resistance of the composite material; meanwhile, the odor adsorption master batch is used for reducing the content of formaldehyde in thecomposite material.

Owner:HEFEI GENIUS NEW MATERIALS

Low-odor dimethicone copolyol sulfosuccinate surfactant compositions

InactiveUS20090234148A1Exhibit to skinGood foam stabilization effectCosmetic preparationsSilicon organic compoundsSulfosuccinic acidPersonal Care Product

Dimethicone copolyol sulfosuccinate surfactant compounds having low-odor characteristics are disclosed. The low-odor dimethicone copolyol sulfosuccinate is substantially free from propionaldehyde and acid-releasable precursors of propionaldehyde, thereby substantially eliminating the cosmetically undesirable odor characteristic of conventional dimethicone copolyol sulfosuccinate surfactants. The low-odor dimethicone copolyol sulfosuccinates are suitable for use as surfactants in household or personal care products and applications.

Owner:RHODIA OPERATIONS SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com