A method for improving the reaction efficiency of a terephthalate plasticizer

A technology of terephthalate and terephthalic acid, applied in the field of terephthalate plasticizer, can solve the problems of long reaction time, side reactions, increased production process, etc., and shorten the esterification reaction time , low odor characteristics, the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

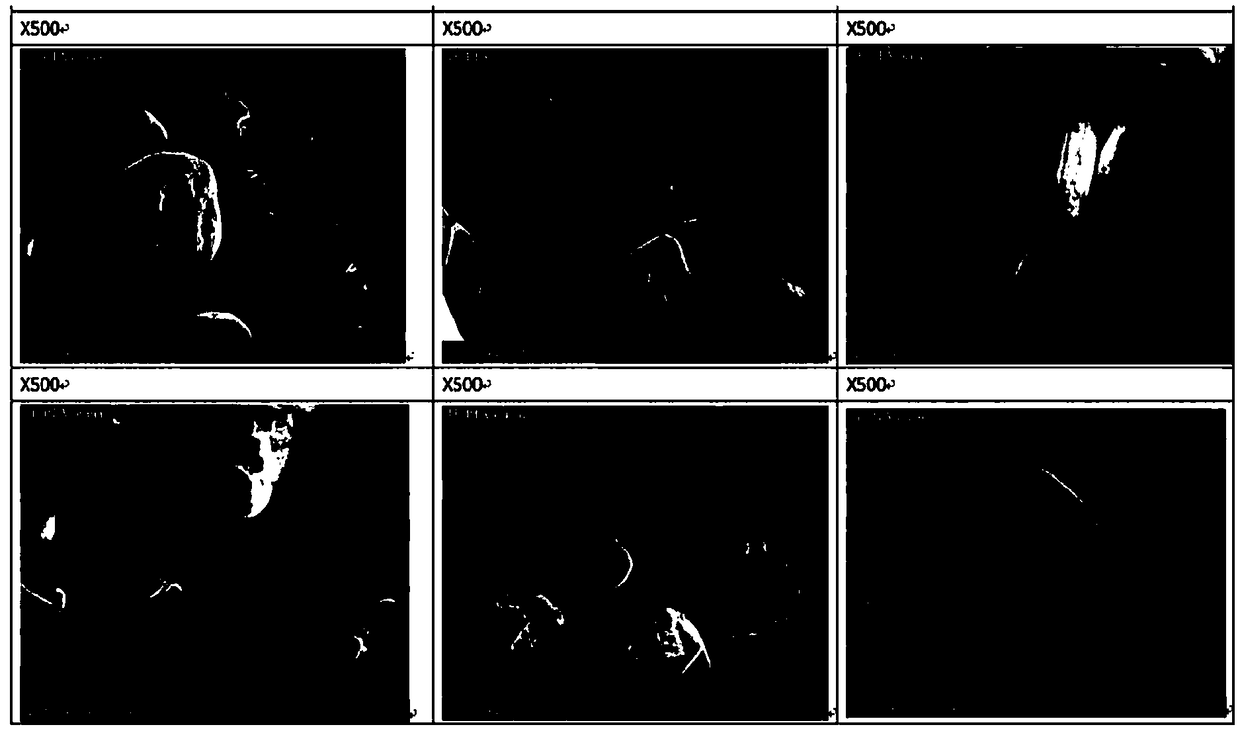

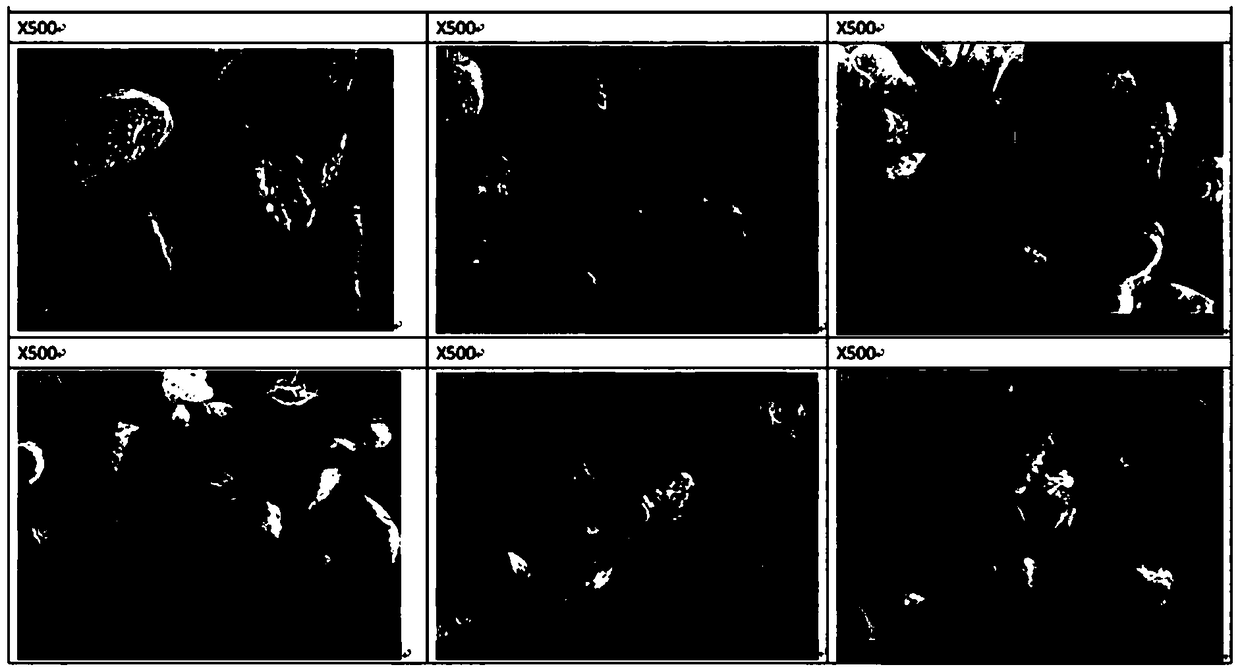

Image

Examples

Embodiment 1

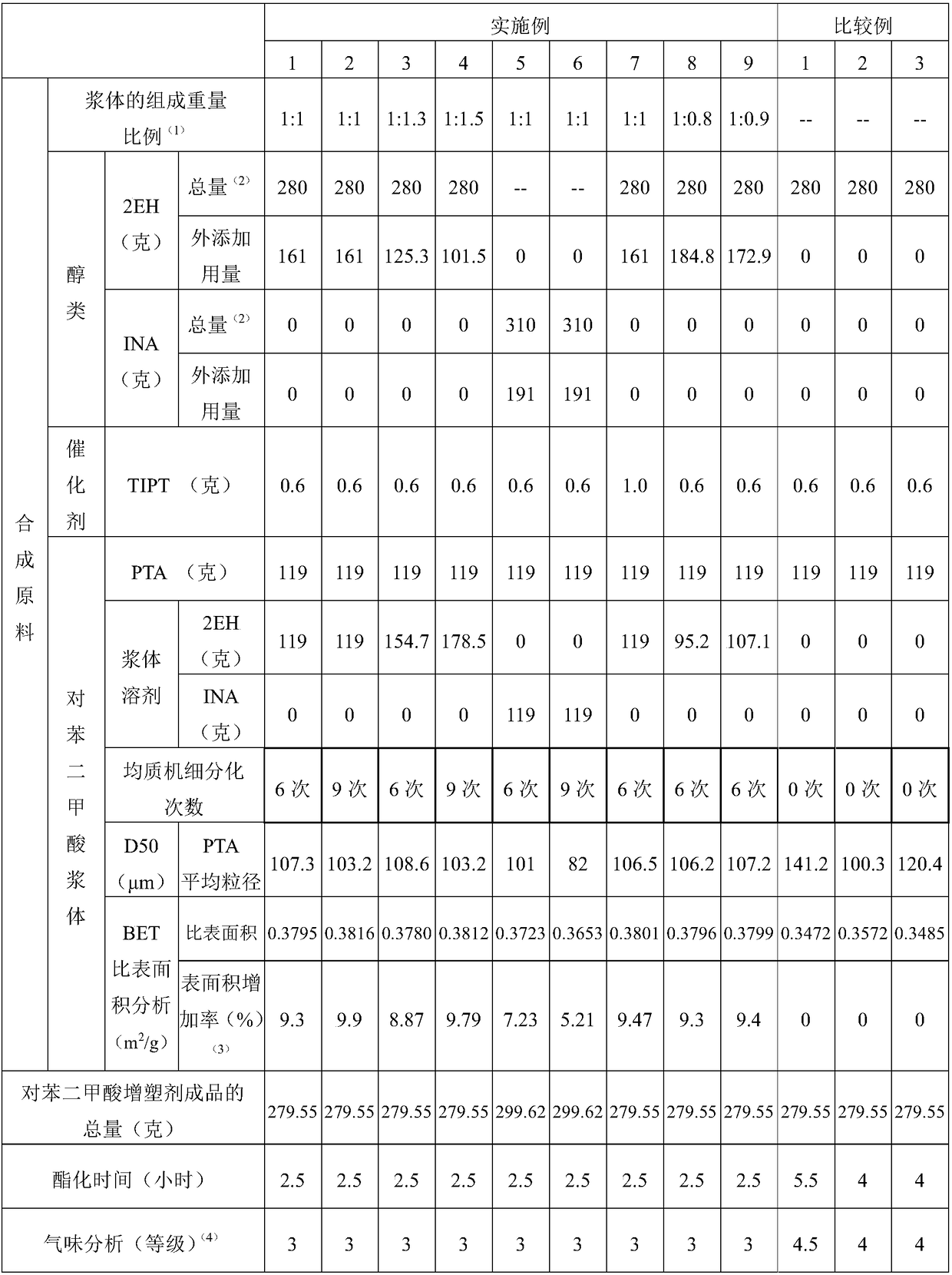

[0029] As in the formula in Table 1, first use a homogenizer to subdivide the terephthalic acid (PTA) composition, (1) get 119 grams of terephthalic acid (PTA), and 119 grams of slurry solvent 2-ethylhexyl After the alcohol (2EH) is mixed, the homogenizer (specification: 3000-6000rpm, frequency: 50-60Hz) is subdivided and treated 6 times to form a PTA slurry with an average particle size of PTA in the slurry of 107.3 μm. After taking out, (2) take another 161 grams of 2EH as the slurry solvent added outside, and clean the PTA slurry residue left by the homogenizer. Get 0.6 grams of TIPT (tetraisopropyl titanate) as a catalyst, mix (1) and (2) slurries and feed them into a four-necked flask simultaneously with the catalyst, and the reaction temperature is changed from 180 to 180 ℃ is gradually raised to 225 ℃, and the reaction time is 2.5 hours, including: after reacting for 1.5 hours at a reaction pressure of 1013 millibars (mbar), and then reacting for 1 hour at a reaction pr...

Embodiment 2

[0031] Formulation composition as in Table 1, the same as in Example 1, except that the PTA / 2EH slurry was treated 9 times with a homogenizer to form a slurry with an average particle size of PTA of 103.2 μm. The results are shown in Table 1.

Embodiment 3

[0033] The formula composition shown in Table 1 is the same as that of Example 1, except that the composition ratio of PTA / 2EH slurry is 1:1.3. The average particle size of PTA in the PTA slurry is 108.6 μm. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com