Quaternary ammonium salt catalyst, application thereof and isosorbide modified polyester

A technology of modified polyester and quaternary ammonium salt, which is applied in the field of chemical preparation, can solve problems such as easy deposition of hydrolyzed products to block pipelines, inconvenient production, and reduced catalytic efficiency, so as to reduce the probability of side reactions in the system, reduce the loss of raw materials, and reduce the Effect of polycondensation reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 quaternary ammonium salt catalyst

[0039] Catalyst A Preparation

[0040] The preparation of described catalyst A can operate according to the following steps:

[0041] First, add 82.8 g of octyltrimethylammonium chloride and 200 mL of absolute ethanol into a 500 mL three-necked flask and stir evenly. 31.5gBiCl 3 with 13.1gTiCl 4 (BiCl 3 with TiCl 4 The molar ratio is about 2:1) was dissolved in 10mL of ethanol, and dropped into the three-necked flask under stirring conditions. After no gas is released, it is aged at room temperature for 12 hours. A solution of Catalyst A in ethanol was obtained by filtration.

[0042] Catalyst B preparation

[0043] Catalyst B was prepared in the same way as Catalyst A except that the BiCl 3 with SnCl 4 The molar ratio is about 1:1.

[0044] Catalyst C preparation

[0045] Catalyst C was prepared in the same way as Catalyst A except that the BiCl 3 with SnCl 4 The molar ratio is about 1:2....

Embodiment 2

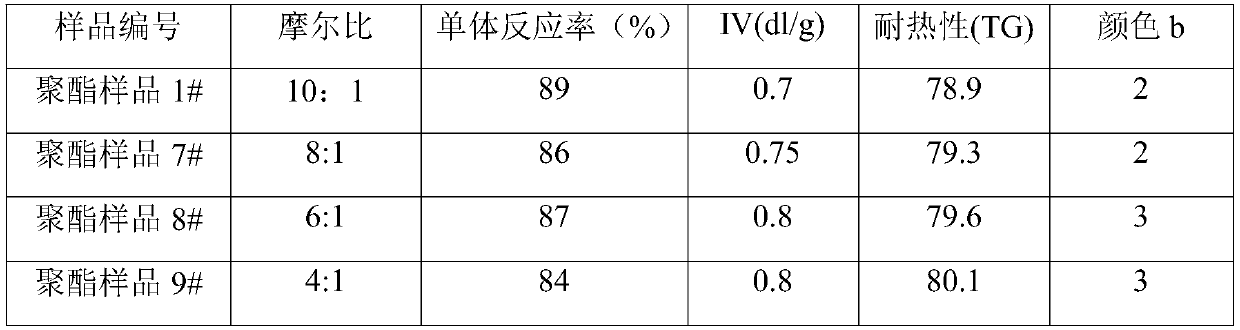

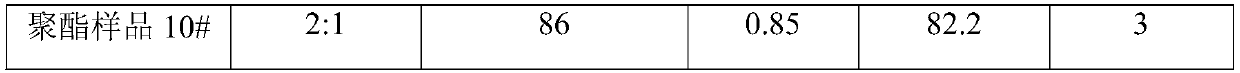

[0052] The preparation of embodiment 2 isosorbide modified polyester

[0053] Preparation of polyester sample 1#

[0054] In 1L polyester reactor, add 168.13g terephthalic acid, 67.65g ethylene glycol and 16.08g isosorbide (the molar ratio of terephthalic acid and isosorbide and ethylene glycol total molar weight 1:1.2, ethylene glycol Alcohol to isosorbide molar ratio 10:1) and 0.1mL ethanol solution of catalyst A (ie solution 1#), replaced with inert gas three times. Heat and stir under normal pressure, raise the temperature to 180°C, carry out esterification reaction, fractionate the by-product water in time, after 2 hours, quickly raise the temperature to 210°C, carry out polycondensation reaction under 5mmHg vacuum degree, and obtain isosorbide after 60 minutes The modified polyester is referred to as polyester sample 1#.

[0055] Prepare polyester samples 2#~6#, the preparation method of polyester samples 2#~6# is carried out according to the preparation method of poly...

Embodiment 3

[0057] Embodiment 3 intrinsic viscosity (IV) measurement

[0058] Dissolve polyester samples 1# to 10# in o-chlorophenol (OCP) at 150°C, respectively. The polymer concentration was adjusted to 0.12%. The measurement was performed at 35° C. in a thermostatic bath using an Ubbelohde viscometer.

[0059] The test results are shown in Table 1, Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com