Novel low odor polypropylene composite material and preparation thereof

A technology for composite materials and polypropylene, which is applied in the field of preparation of polypropylene composite materials, hydrophobic odor-absorbing masterbatches, and polypropylene composite materials. It can solve problems such as complex molding and processing techniques, and achieve low preparation costs and simple processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In the following, the present invention will be further described in detail with reference to the embodiments:

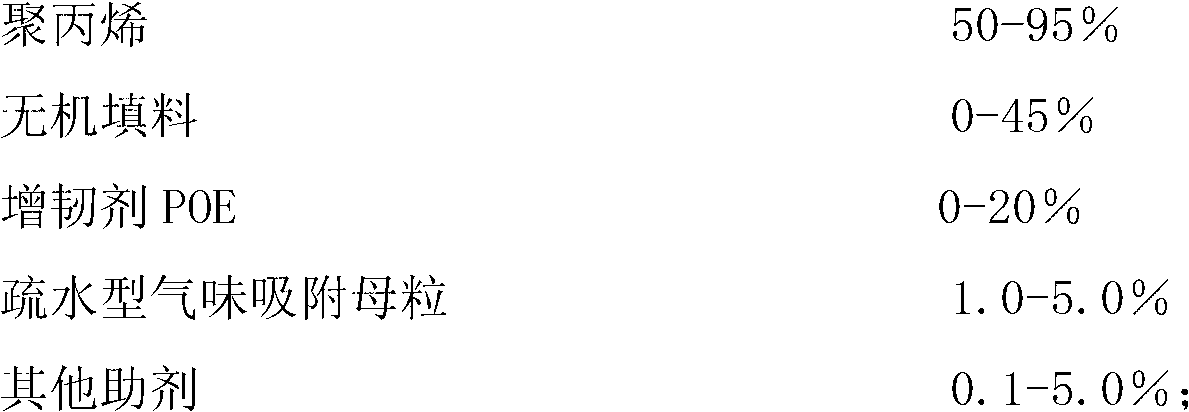

[0060] In the composite material formulations of the examples and comparative examples, polypropylene is highly crystalline homo-polypropylene and block co-polypropylene with different fluidity, and the amount is 50-95%. Among them, the common comonomer of block co-polypropylene is ethylene, and its content is in the range of 4-10mol%. The melt flow rate of polypropylene (230℃×2.16kg) is 5-50g / 10min, more commonly 5 -30g / 10min, the crystallinity of high crystalline polypropylene is more than 70%, and the isotacticity is more than 99%; the particle size range of the talc powder is 1-10 microns; the toughening agent POE is an ethylene- The copolymer of octene has a density of 0.88-0.90g / cm3 and a melt index of 1-50g / 10min; the attapulgite clay is produced by Jiangsu Xuyi attapulgite clay company, with a purity of 80%, a fineness of 300 mesh, and The amount of cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com