Spraying and wind leaking stoppage polyurethane combined polyether for coal mine as well as preparation and use methods thereof

A technology combining polyether and plugging air, applied in mining equipment, shaft equipment, earth-moving drilling, etc., can solve the problems of micro-toxic, strong irritating odor, bulky protective equipment, etc., and achieve high and low surface resistance of foam. GWP, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

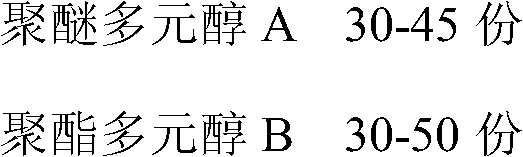

[0022] Preparation of spray-type combined polyether: Firstly, HFC-365mfc and HFC-245fa are airtightly transported to the foaming agent premixing tank according to the mass ratio of 3:7, and circulated by a circulating pump to form a uniform and stable liquid, which is used as a mixed foaming agent . According to the proportions in Table 1, the raw materials were put into the reaction kettle, and stirred at room temperature for 1 hour to obtain the combined polyether.

[0023] Table 1

[0024] YD-401P

Embodiment 2

[0026] Preparation of spray-coating combined polyether: First, HFC-365mfc and HFC-245fa are airtightly transported to the foaming agent premixing tank according to the mass ratio of 5:5, and circulated by a circulating pump to form a uniform and stable liquid, which is used as a mixed foaming agent . According to the proportions in Table 2, the raw materials were put into the reaction kettle, and stirred at room temperature for 1 hour to obtain the combined polyether.

[0027] Table 2

[0028] YD-401P

Embodiment 3

[0030] Preparation of spray-coating combined polyether: First, HFC-365mfc and HFC-245fa are airtightly transported to the foaming agent premixing tank according to the mass ratio of 7:3, and circulated and mixed by a circulating pump to form a uniform and stable liquid, which is used as a mixed foaming agent . According to the proportions in Table 3, the raw materials were put into the reaction kettle, and stirred at room temperature for 1 hour to obtain the composite polyether.

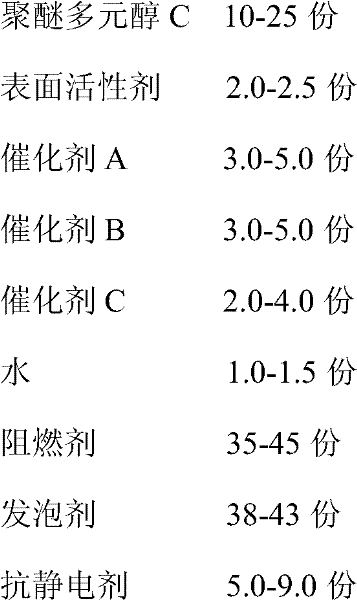

[0031] table 3

[0032] YD-401P

30

CF-6255

50

NT-403

20

LK221

0.0

LK443

2.5

h 2 o

1.3

PT303

3.0

PT304

5.0

PT306

2.0

TEP

17.5

DEEP

17.5

HFC-365mfc / HFC-245fa

40

LQ-01

5

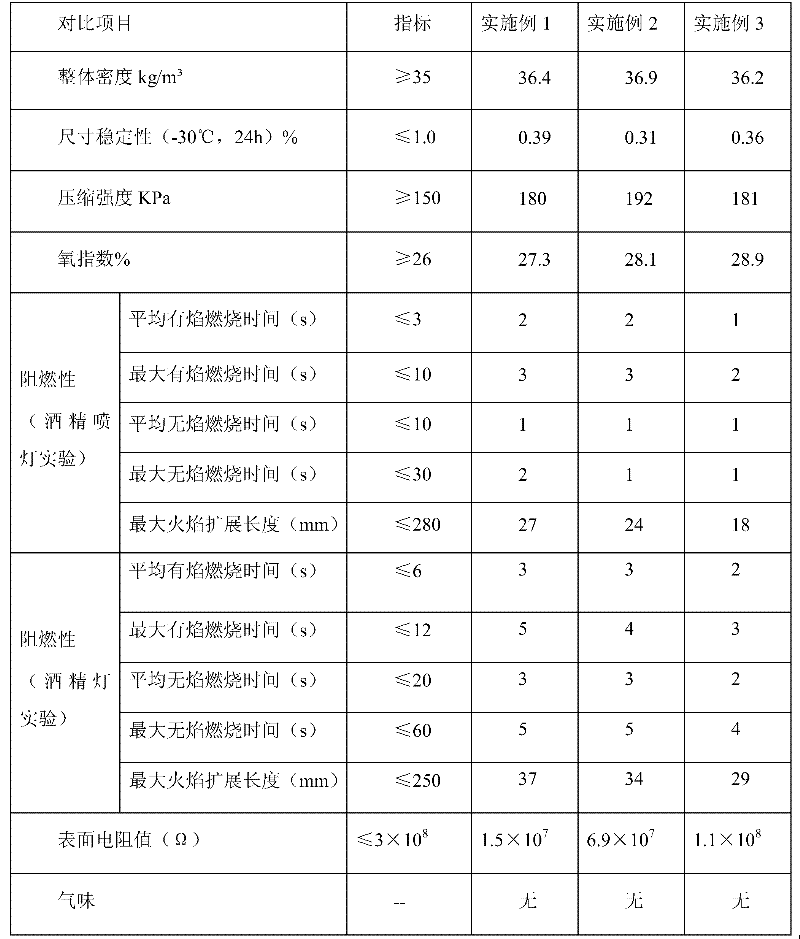

[0033] Polyurethane foam prepared from the sprayed polyurethane combination polyether obtained in the above examples: the combination polyether obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com