Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "TVOC reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly flame retardant low-odor modified polypropylene and preparation method and application of modified polypropylene

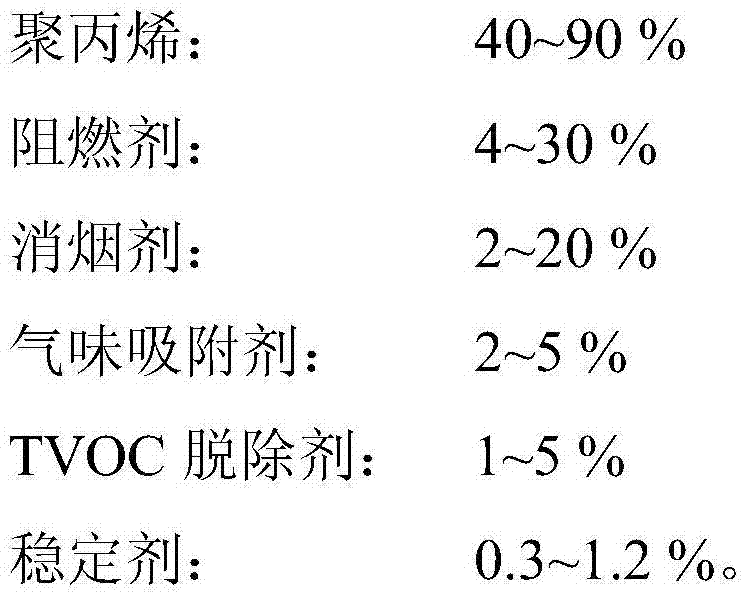

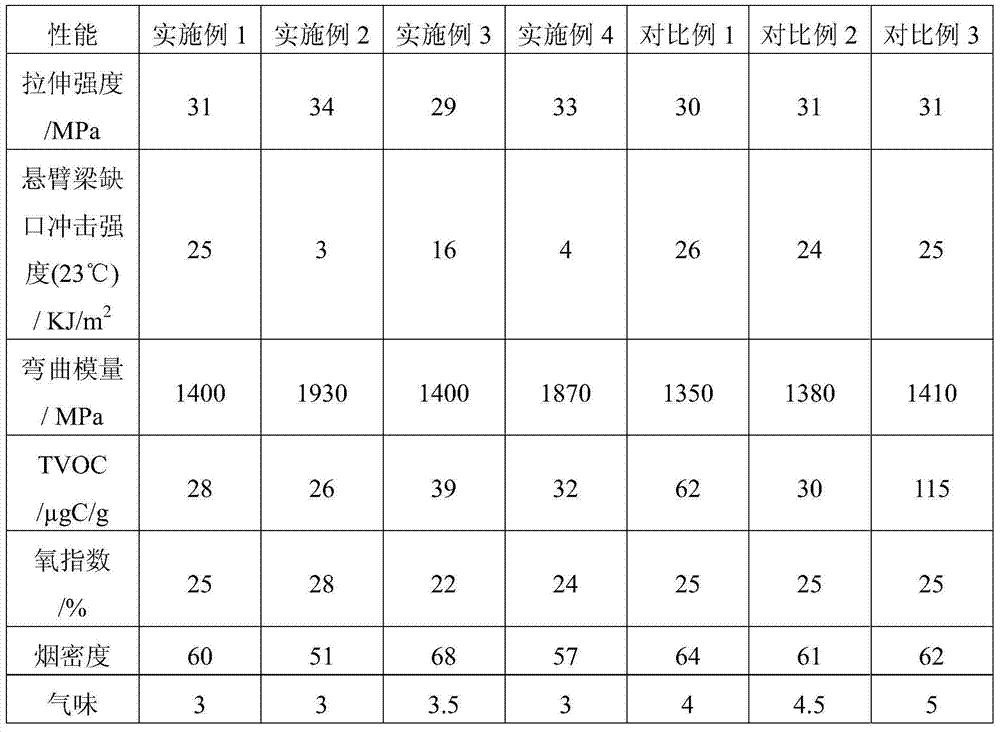

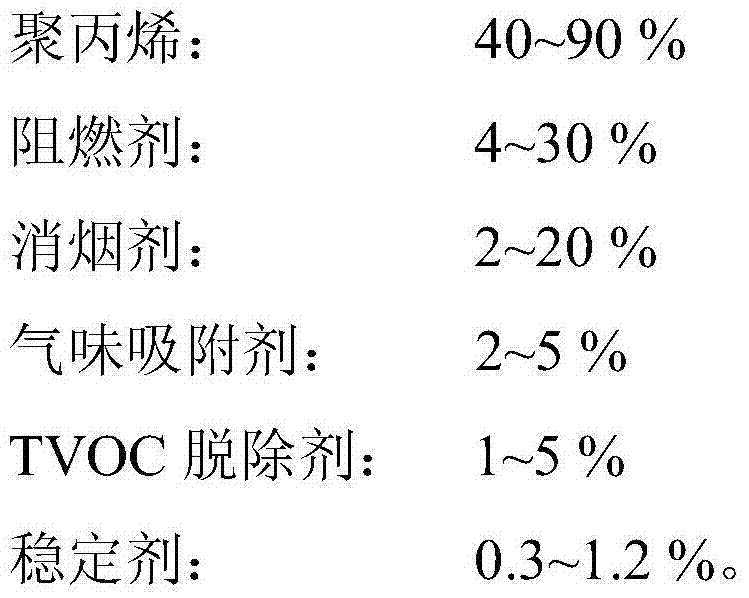

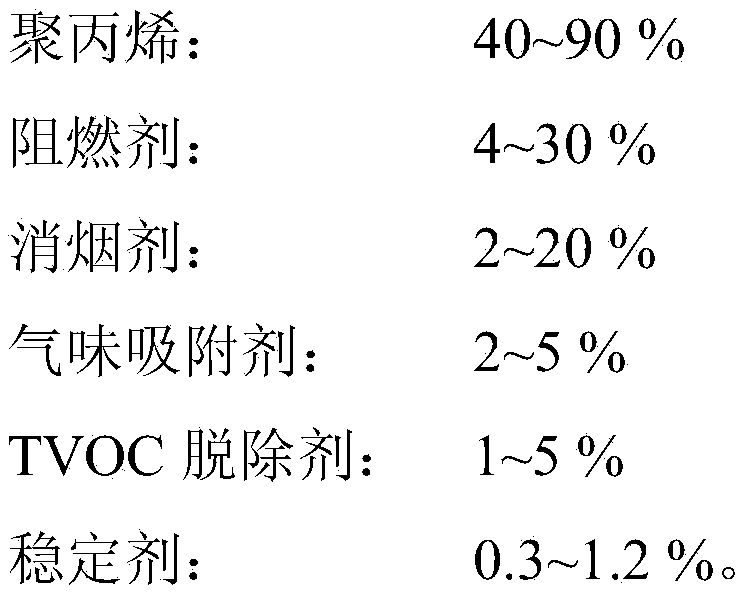

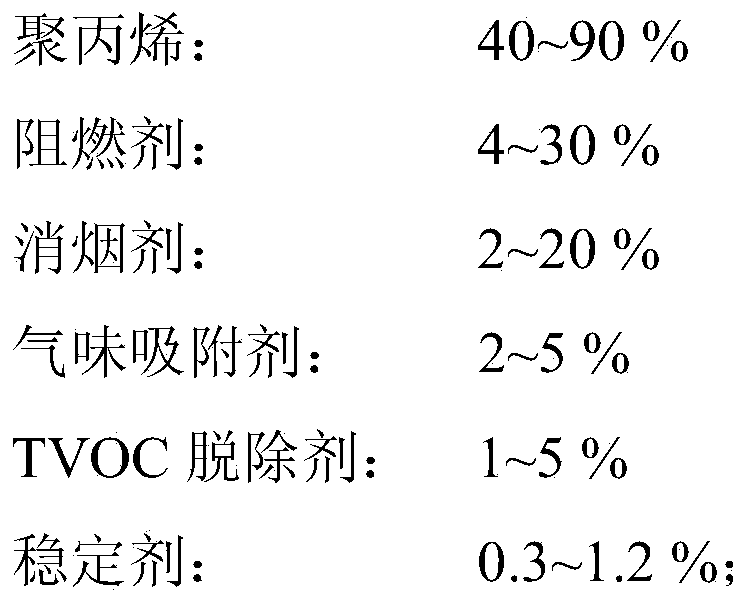

ActiveCN103756135ALow smoke densityImprove mechanical propertiesSimple Organic CompoundsPolymer science

The invention belongs to the technical field of polypropylene materials, and discloses environment-friendly flame retardant low-odor modified polypropylene and a preparation method and application of modified polypropylene in inner decoration of a school bus. The environment-friendly flame retardant low-odor modified polypropylene comprises the following components by weight percent: 40-90% of polypropylene, 4-30% of a flame retardant, 2-20% of an antismoke agent, 2-5% of an odor adsorbent, 1-5% of a TVOC (Total Volatile Organic Compound) remover and 0.3-1.2% of a stabilizer. According to polypropylene provided by the invention, the effect of excellent mechanical property, good flame retardant effect and low smoke density is realized by selecting a special low-odor nitrogen and phosphorus halogen-free flame retardant and metal hydroxide as the antismoke agent. The odor adsorbent and the TVOC remover are added to effectively remove TVOC and other small molecular matters, so that the modified polypropylene which satisfies the demand on excellent mechanical property, good flame retardant effect, low smoke density, low odor and low TVOC is prepared, and the modified polypropylene can be suitable for inner decoration of the school bus.

Owner:TIANJIN KINGFA NEW MATERIAL +1

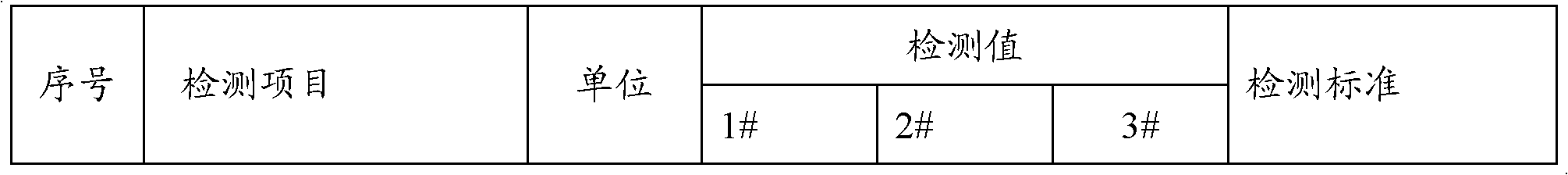

Raw bamboo fiber and polypropylene staple fiber composite molding interior panel and preparation process thereof

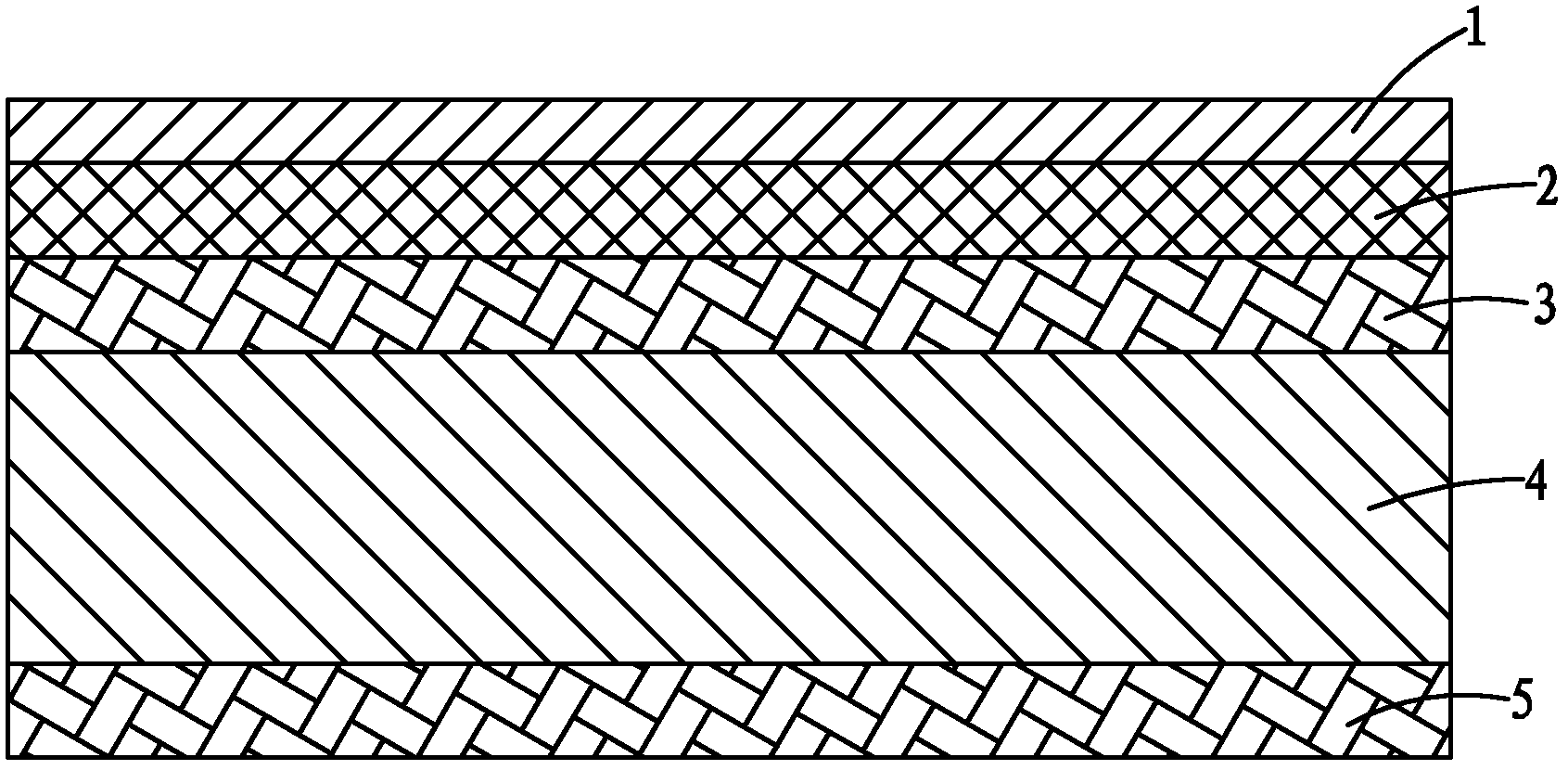

InactiveCN102582140AHigh tensile strengthImprove bending strengthLaminationLamination apparatusFiberSurface layer

The invention provides a raw bamboo fiber and polypropylene staple fiber composite molding interior panel and a preparation process thereof. The interior panel has a surface layer of a decorative fabric, a second layer of a hot melt adhesive film, a third layer of a first non-woven fabric, a fourth layer of a raw bamboo fiber and polypropylene staple fiber mixed needled felt and a fifth layer of a second non-woven fabric, wherein the raw bamboo fiber and polypropylene staple fiber mixed needled felt comprises the following components in percentage by weight: 53 to 56 percent of raw bamboo fiber and 44 to 47 percent of polypropylene staple fiber. The composite molding interior panel has excellent comprehensive performance and is high in environment friendliness.

Owner:福建建州竹业科技开发有限公司

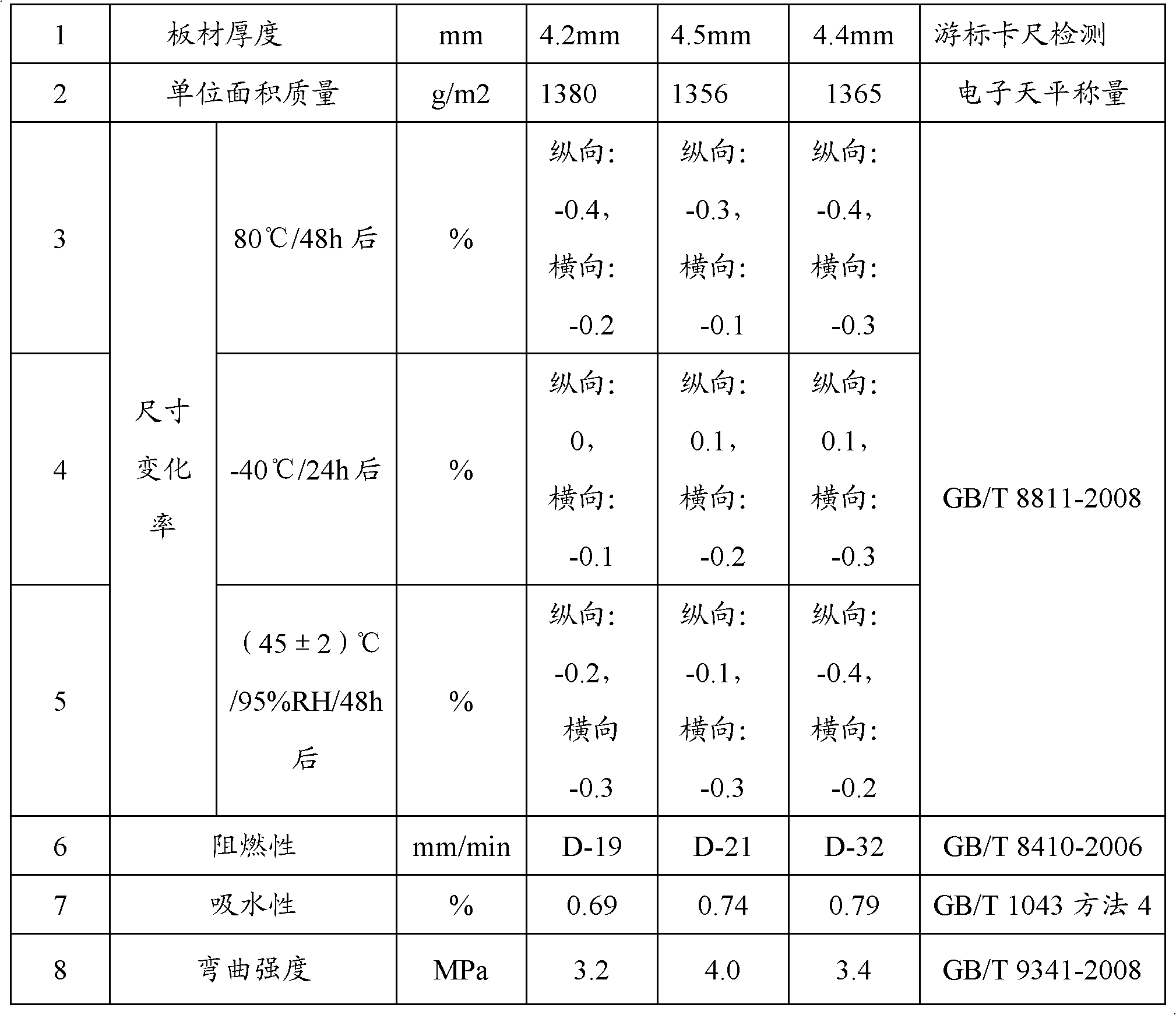

Odor-free and low-TVOC polyurethane sealant for automotive trims, and preparation method and application thereof

ActiveCN106753181ASmall smellNo smellNon-macromolecular adhesive additivesOther chemical processesPlasticizerAntioxidant

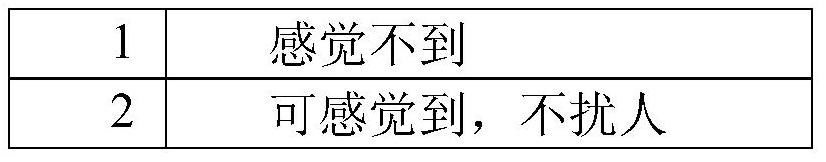

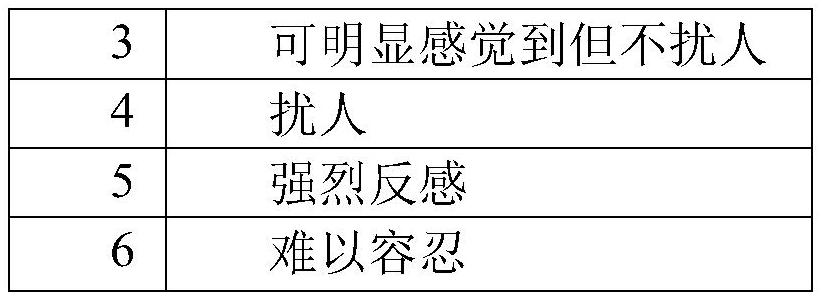

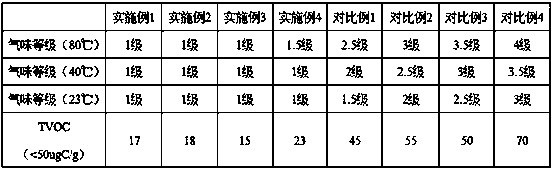

The invention relates to an odor-free and low-TVOC polyurethane sealant for automotive trims, and a preparation method and an application thereof. The polyurethane sealant is prepared from the following components in mass percents: 20-40% of polyurethane prepolymer, 15-40% of environmentally friendly plasticizer, 5-25% of carbon black, 25-60% of white reinforcing filler, 0.2-2% of curing accelerator, 0.2-2% of dehydration stabilizer, 0.2-2% of deodorant, 0-2% of adhesion promoter, 0-30% of thixotropic agent, 0-2% of light stabilizer and 0-2% of antioxidant. Compared with the traditional polyurethane sealant, the polyurethane sealant provided by the invention emits no odor when being used in a long-term closed high temperature (80 DEG C) environment, and the odor rating is 1 level, so the polyurethane sealant has the advantages of being odor-free, low in TVOC and harmless to human body and environment, satisfies the air quality evaluation guidance requirements of passenger cars, and is suitable for sealing and joint filling of automotive trims.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

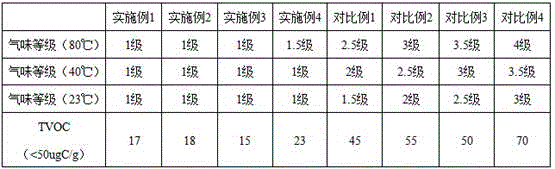

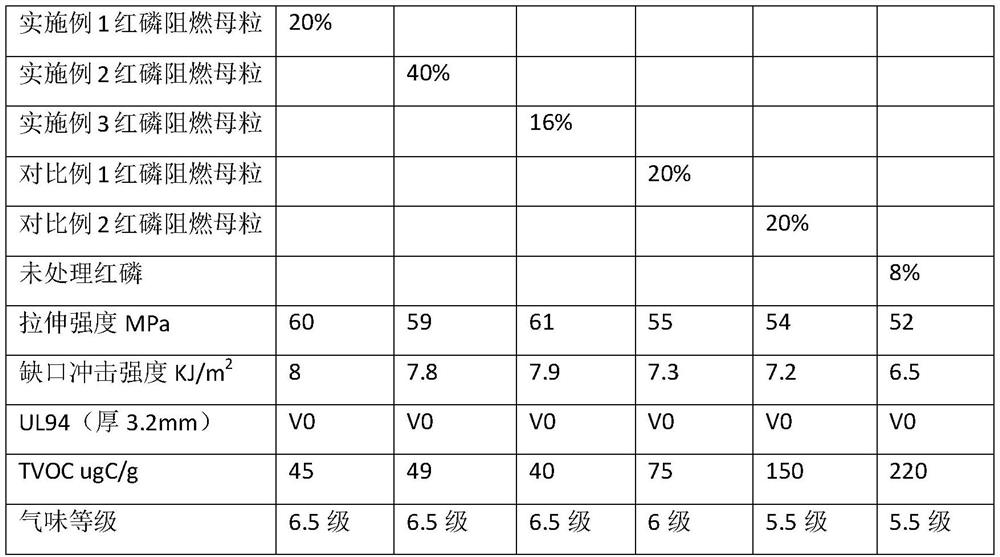

Whitened red phosphorus, low-odor and low-emission whitened red phosphorus flame retardation master batch for nylon, and preparation method of master batch

The invention discloses a low-odor and low-emission whitened red phosphorus flame retardation master batch for nylon, and a preparation method thereof. The master batch is prepared from, by weight, 50-85 parts of whitened red phosphorus, 1-5 parts of a hydrophobic odor adsorption master batch, 0.2-1.0 part of an antioxidant and 0.2-1 part of a lubricant. The red phosphorus flame retardation master batch prepared in the invention has the advantages of wide versatility, high effective components, no obvious odor and low addition amount, and the preparation method has the advantages of simplicity, breaking of color limitation, realization of the product being not limited to dark products, effective reduction of dust pollution, and improvement of the labor environment.

Owner:HEFEI GENIUS NEW MATERIALS

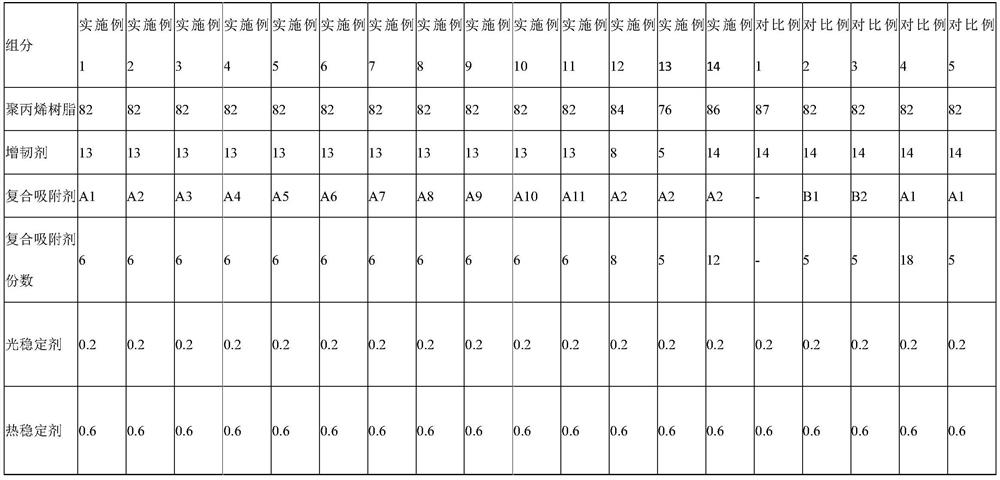

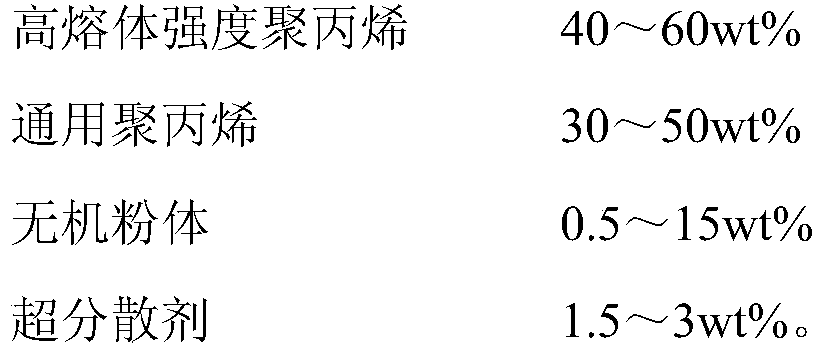

Low-odor polypropylene composition as well as preparation method and application thereof

The invention discloses a low-odor polypropylene composition as well as a preparation method and an application thereof, polypropylene resin is used as a matrix, a composite adsorbent is added, and the composite adsorbent has an acid absorption effect, can inhibit degradation reaction of the polypropylene resin in the processing process, and has a relatively strong adsorption effect on various volatile components; along with the increase of the service time, small odor molecules cannot be gradually separated out, so that the obtained polypropylene composition has the characteristics of low odor and low TVOC, the mechanical property of the material cannot be influenced, in addition, the preparation method provided by the invention is simple and feasible, and the low-odor polypropylene composition provided by the invention can be used for preparing the automotive upholstery, the prepared product has the characteristics of low odor and low TVOC, and meets the odor standard of an automotive interior trim part material.

Owner:KINGFA SCI & TECH CO LTD

Process for production of wood based materials from lignocellulose

ActiveUS9895824B2Reduced responseLow VOC emissionFibreboardNatural cellulose pulp/paperCelluloseActivated carbon

A process for production of wood-base materials from lignocellulosic comminution product is disclosed. The wood-base materials are treated with at least one additive in the course of their production to reduce or diminish the emission of volatile organic compounds (VOCs) and, optionally, very volatile organic compounds (VVOCs), in particular terpenes and acids. The treatment is effected with one additive, being a porous carbon, like activated carbon. In another aspect, the present application is directed to the use of porous carbon, in particular, activated carbon, to reduce or diminish the emission of VOC, and optionally, VVOC, to reduce or diminish the emission of terpene and acids and aldehydes. Also, wood-base materials which are obtainable with the process or wood-based materials produced by using the additives mentioned above and which have reduced emission of VOCs, in particular terpenes and acids but also aldehydes are disclosed.

Owner:KRONOTEC

Method for reducing the emissions of volatile organic compounds from wooden materials and wooden material

ActiveUS20150298346A1Low VOC emissionEmission limit being loweredFibreboardNatural cellulose pulp/paperActivated carbonCellulose

A process for production of wood-base materials from lignocellulosic comminution product is disclosed. The wood-base materials are treated with at least one additive in the course of their production to reduce or diminish the emission of volatile organic compounds (VOCs) and, optionally, very volatile organic compounds (VVOCs), in particular terpenes and acids. The treatment is effected with one additive, being a porous carbon, like activated carbon. In another aspect, the present application is directed to the use of porous carbon, in particular, activated carbon, to reduce or diminish the emission of VOC, and optionally, VVOC, to reduce or diminish the emission of terpene and acids and aldehydes. Also, wood-base materials which are obtainable with the process or wood-based materials produced by using the additives mentioned above and which have reduced emission of VOCs, in particular terpenes and acids but also aldehydes are disclosed.

Owner:KRONOTEC

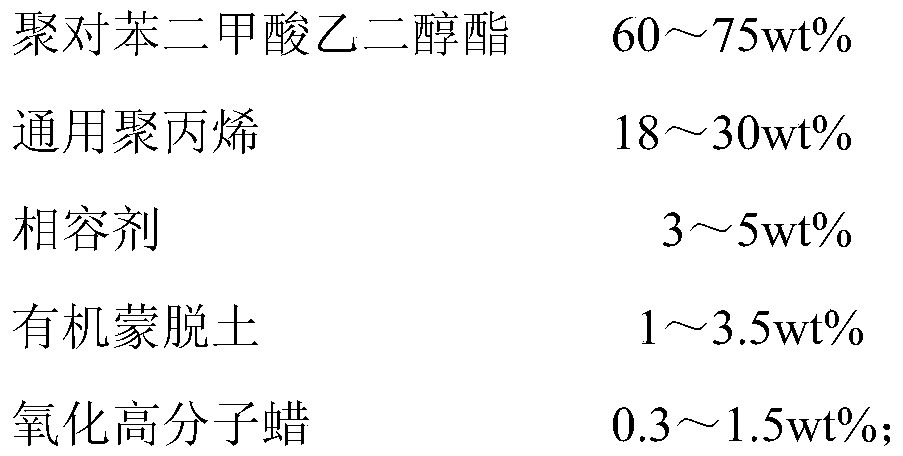

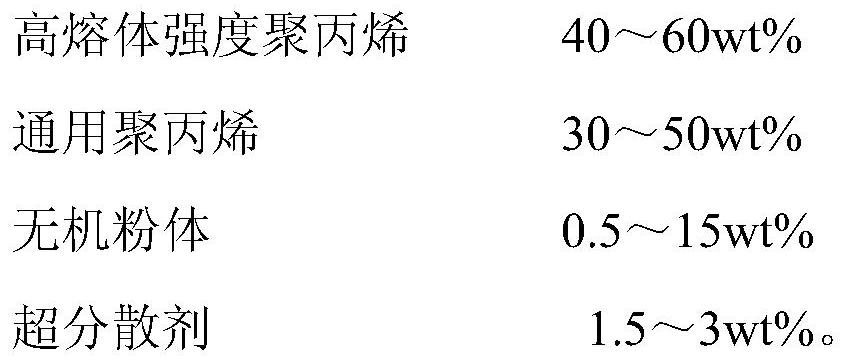

Foamed polypropylene composite sheet and preparation method thereof

ActiveCN110549707AHigh foaming ratioReduce and avoid collapseSynthetic resin layered productsCoatingsPolyesterPolyolefin

The invention discloses a foamed polypropylene composite sheet and a preparation method thereof. The foamed polypropylene composite sheet comprises a toughening layer, a reinforcing layer and a core layer sequentially from outside to inside, wherein the toughening layer comprises crosslinked foamed polypropylene with the surface composited with a thermoplastic elastomer or polyvinyl chloride, thereinforcing layer comprises a polyester / polyolefin / organic montmorillonite compound, the core layer comprises a foamed composite material with the foaming ratio being 2-5 times, the thickness of the composite sheet is 4-6 mm, and the bending modulus of the composite sheet is 1100-1400 MPa. According to the foamed polypropylene composite sheet, in the increasing process of the foaming ratio, the high bending strength is still maintained, due to the fact that high specific-surface and high surface activity inorganic particles are added into the composite sheet, the product has certain adsorptioncapacity for harmful gas, the purpose of reducing release of VOC is achieved, and the foamed polypropylene composite sheet is suitable for being used and promoted.

Owner:合肥森烨轻质塑料科技有限责任公司

Polyformaldehyde composition and preparation method thereof

The invention provides a polyformaldehyde composition and a preparation method thereof, and relates to the technical field of high polymer materials. The polyformaldehyde composition is prepared fromthe following raw materials: polyformaldehyde, ultra-high-molecular-weight polyethylene modified glass fibers, odor-adsorption master batches, molybdenum disulfide, a lubricant and an antioxidant. Thepolyformaldehyde composition disclosed by the invention has low odor and good wear resistance and stability. Through the adoption of the matching effect of the raw materials such as the ultra-high-molecular-weight polyethylene modified glass fibers, the odor-adsorption master batches and the like, the low-odor characteristic of the polyformaldehyde composition is ensured, and the physical and mechanical properties of the polyformaldehyde composition and the moulding processability of the material are not affected at the same time.

Owner:HEFEI GENIUS NEW MATERIALS

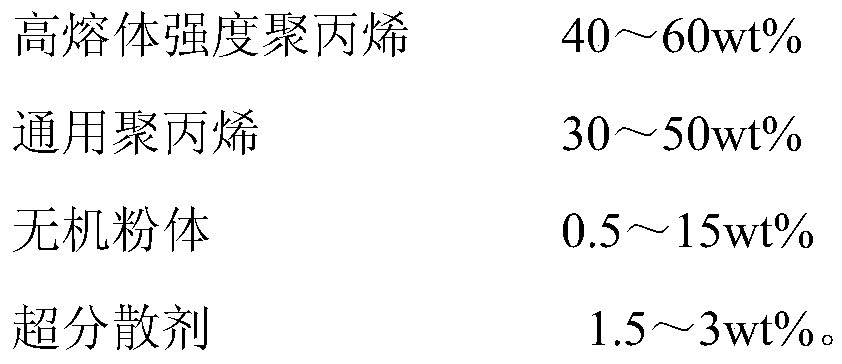

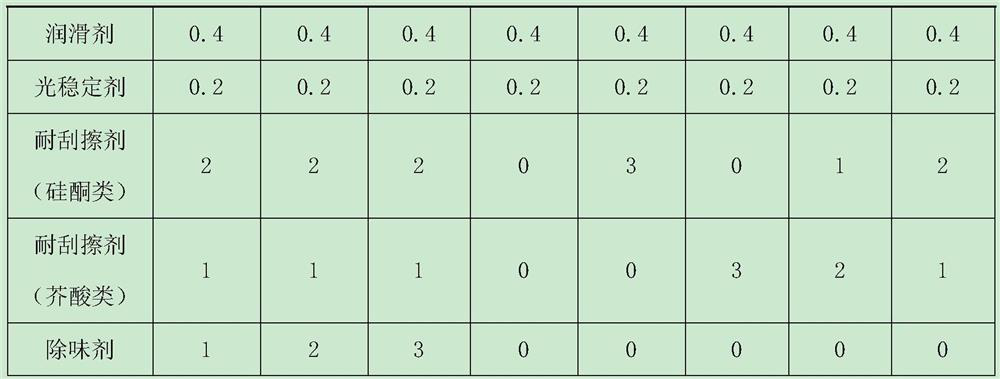

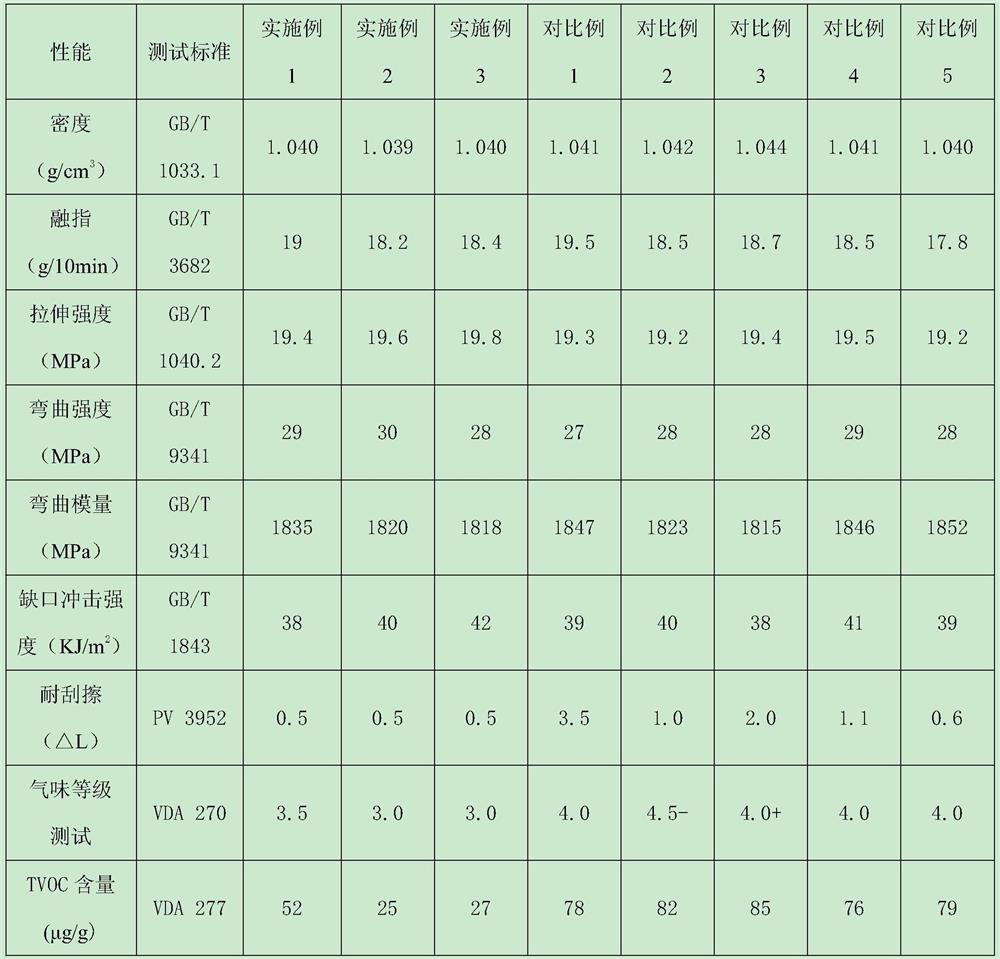

Low-odor, low-VOC and scratch-resistant polypropylene interior material for vehicle and preparation method of polypropylene interior material

The invention discloses a low-odor, low-VOC and scratch-resistant polypropylene interior material for vehicles and a preparation method of the polypropylene interior material. The low-odor low-VOC scratch-resistant polypropylene interior material for the vehicle comprises the following components: 63 to 66% of polypropylene, 18 to 22% of talcum powder, 8 to 12% of a flexibilizer, 0.3 to 0.5% of an antioxidant, 0.3 to 0.5% of a lubricant, 0.1 to 0.3% of a light stabilizer, 1 to 3% of a deodorant and 1 to 3% of a scratch-resistant agent. The pore diameter of the deodorant is 10 [mu] m and 50 [mu] m; and the scratch-resistant agent is formed by compounding silicone and erucyl amide according to a weight ratio of 1: 2-2: 1. By adopting the deodorant containing the microporous water-containing structure, the odor grade and VOC content of the material can be effectively reduced, so that the odor grade standard of automotive trim materials of various main engine plants is less than or equal to 3.0, and the VOC content standard is met.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

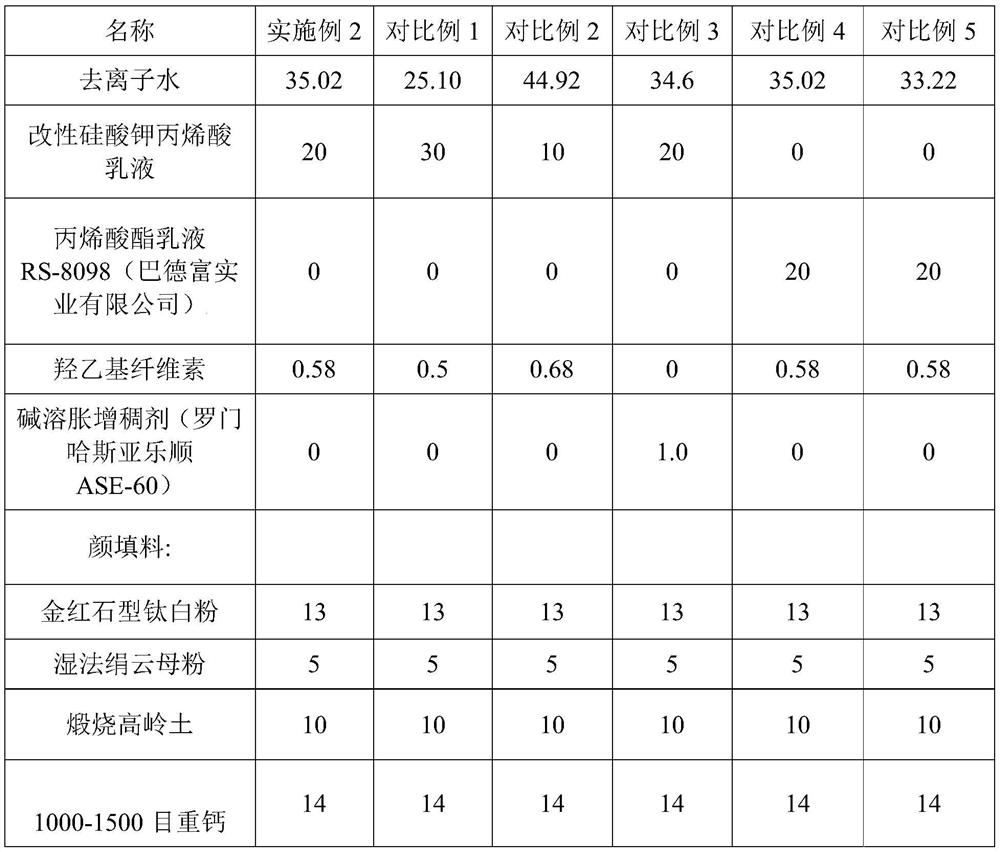

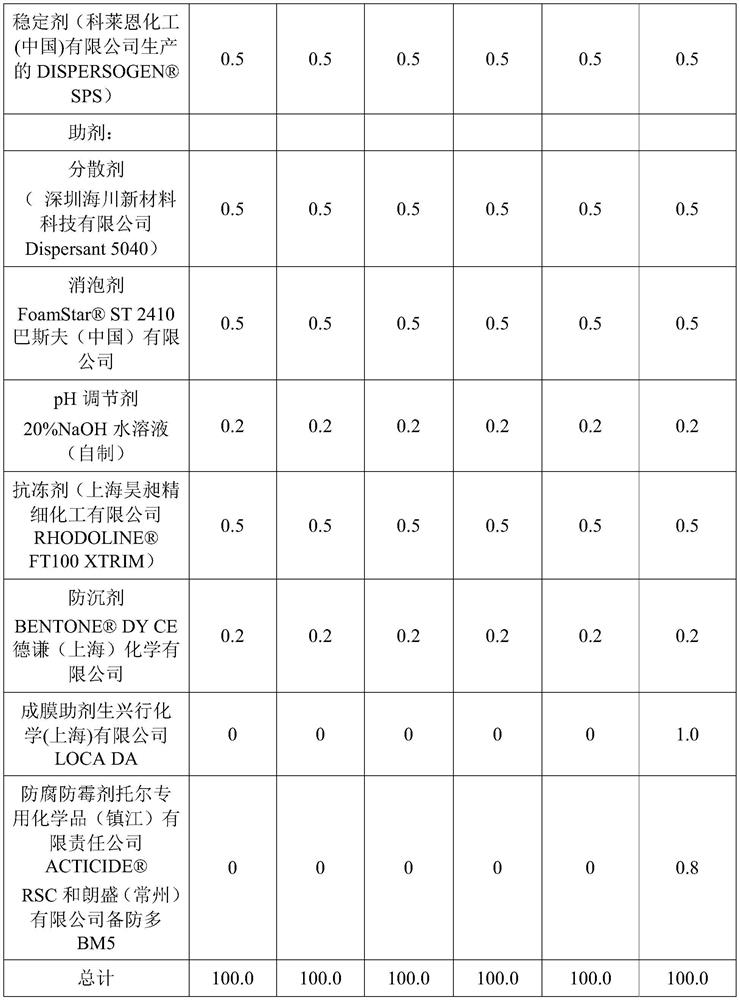

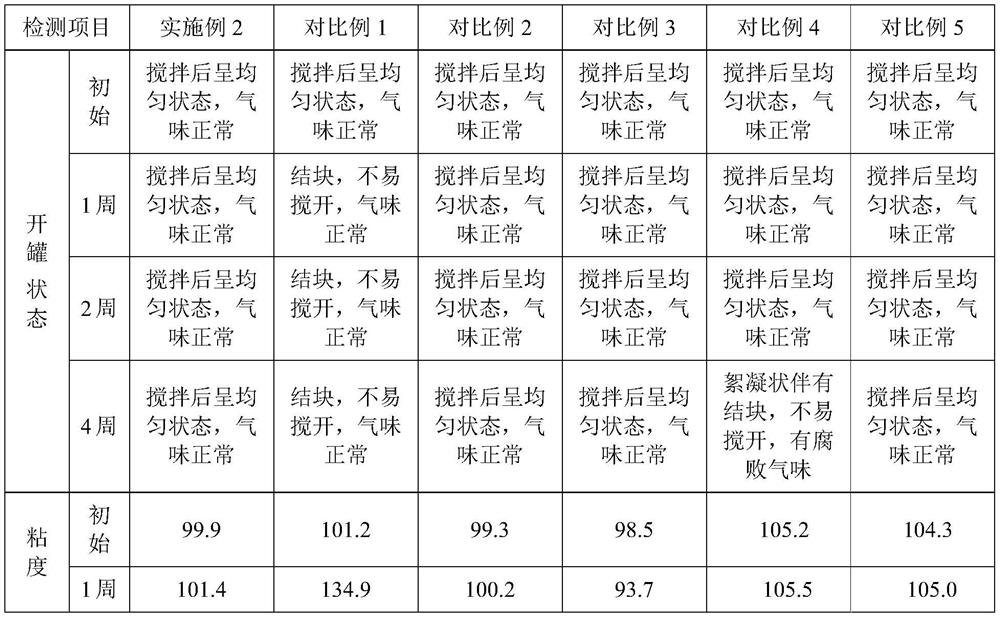

Modified potassium silicate styrene-acrylic emulsion and preparation method thereof as well as preservative-free and solvent-free water-based polymer material and preparation method thereof

The invention belongs to the field of water-based polymer materials, and particularly relates to a modified potassium silicate styrene-acrylic emulsion and a preparation method thereof as well as a preservative-free and solvent-free water-based polymer material and a preparation method thereof. The modified potassium silicate styrene-acrylic emulsion comprises methyl methacrylate, butyl acrylate, styrene, sodium bicarbonate, potassium persulfate, an emulsifier, a silane coupling agent, quaternary ammonium salt containing unsaturated double bonds, organic silicon modified potassium silicate, protective glue and water. The preservative-free solvent-free water-based polymer material provided by the invention is not added with preservatives and organic solvents, has extremely low VOC (Volatile Organic Compounds), SVOC (Soluble Volatile Organic Compounds) and TVOC (Total Volatile Organic Compounds), does not detect free formaldehyde, and has the characteristics of excellent alkali burnout resistance, alkali burnout resistance, storage stability and the like.

Owner:德爱威(中国)有限公司

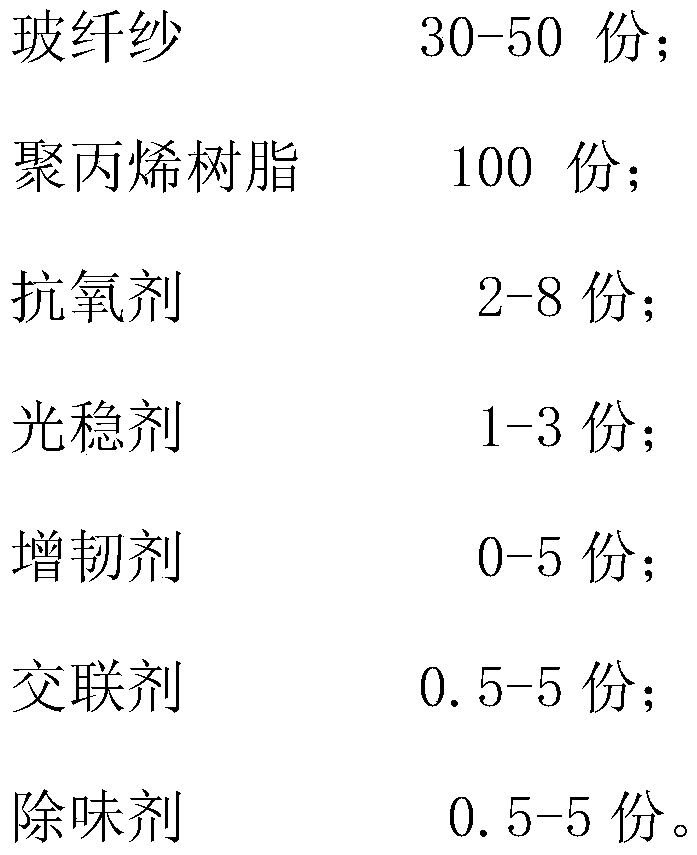

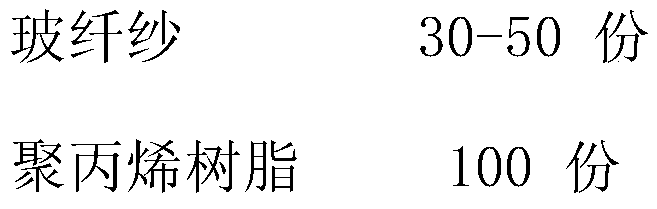

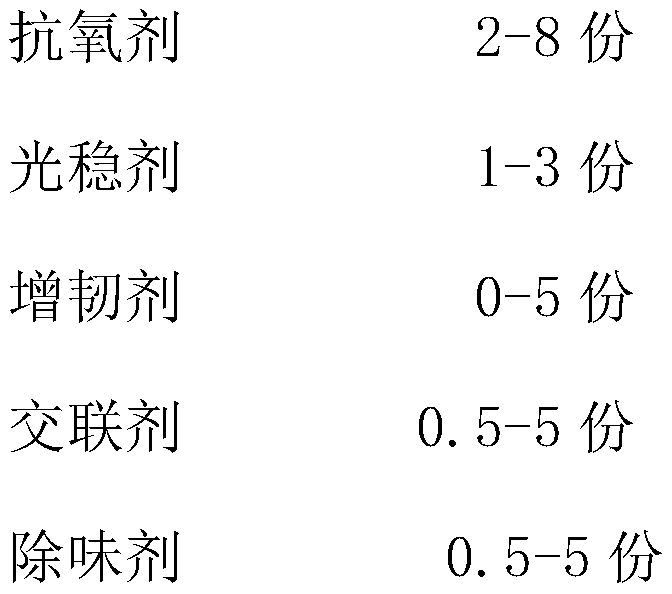

Low-TVOC (total volatile organic compound) long glass fiber reinforced polypropylene material for automotive trim and preparation method of material

The invention relates to a low-TVOC (total volatile organic compound) long glass fiber reinforced polypropylene material for an automotive trim and a preparation method of the material. The material comprises, by weight, 30-50 parts of glass fiber yarns, 100 parts of polypropylene resin, 2-8 parts of antioxidants, 1-3 parts of light stabilizers, 0-5 parts of flexibilizers, 0.5-5 parts of crosslinking agents and 0.5-5 parts of adsorbents. The long glass fiber reinforced polypropylene material has the characteristic of low TVOC, is simple in process and meets the requirements of practical production. The requirements of broad consumers for continuous improvement of in-car air quality are further met, and development of green environment-friendly materials in automobile industries in China ismore effectively pushed.

Owner:ZHEJIANG PRET NEW MATERIALS +5

A kind of environmentally friendly flame-retardant low-odor modified polypropylene and its preparation method and application

The invention belongs to the technical field of polypropylene materials, and discloses environment-friendly flame retardant low-odor modified polypropylene and a preparation method and application of modified polypropylene in inner decoration of a school bus. The environment-friendly flame retardant low-odor modified polypropylene comprises the following components by weight percent: 40-90% of polypropylene, 4-30% of a flame retardant, 2-20% of an antismoke agent, 2-5% of an odor adsorbent, 1-5% of a TVOC (Total Volatile Organic Compound) remover and 0.3-1.2% of a stabilizer. According to polypropylene provided by the invention, the effect of excellent mechanical property, good flame retardant effect and low smoke density is realized by selecting a special low-odor nitrogen and phosphorus halogen-free flame retardant and metal hydroxide as the antismoke agent. The odor adsorbent and the TVOC remover are added to effectively remove TVOC and other small molecular matters, so that the modified polypropylene which satisfies the demand on excellent mechanical property, good flame retardant effect, low smoke density, low odor and low TVOC is prepared, and the modified polypropylene can be suitable for inner decoration of the school bus.

Owner:TIANJIN KINGFA NEW MATERIAL +1

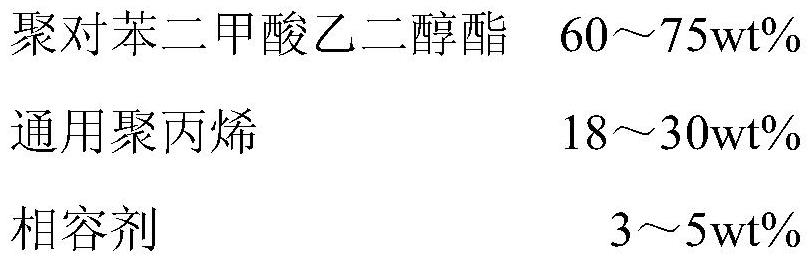

Polyester resin for toner, method for producing same, and toner

There are provided a polyester resin for toner which has a sufficiently low TVOC, can be produced with high productivity, and can produce toner having excellent durability; and toner containing the polyester resin for toner. The polyester resin for toner has a TVOC of 380 ppm or less and includes a component derived from ethylene glycol, a hydrocarbon group having 12 carbon atoms or more, and a titanium element.

Owner:MITSUBISHI CHEM CORP

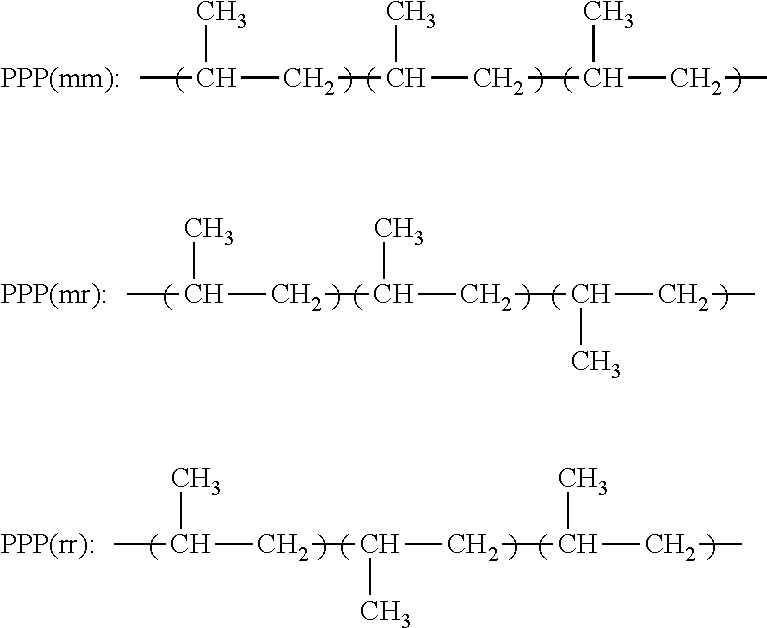

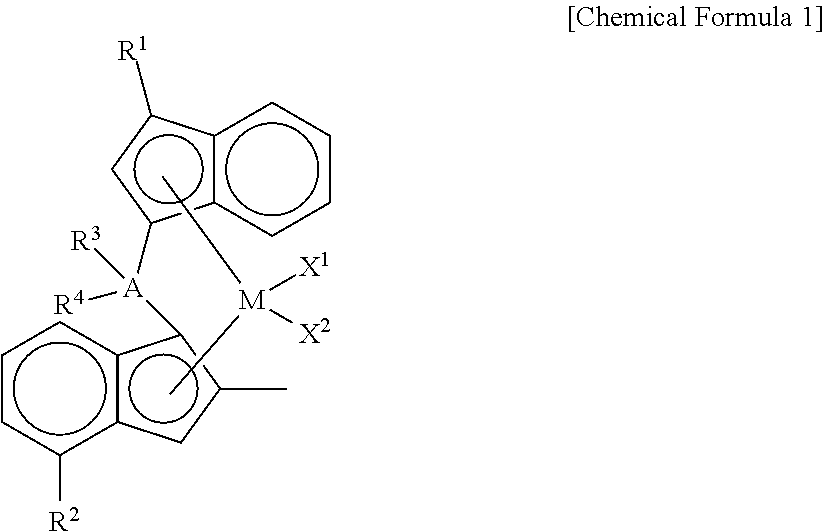

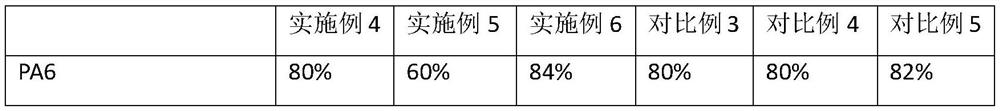

Resin Composition for Bi-Component Fiber

ActiveUS20210040294A1Low residual stress rateImprove tactical performanceConjugated synthetic polymer artificial filamentsPolymer scienceNonwoven fabric

The present invention provides a resin composition for core-sheath type bi-component fiber that not only maintains excellent softness, but also improves tensile strength, when preparing non-woven fabric, particularly spunbond non-woven fabric.

Owner:LG CHEM LTD

A kind of foamed polypropylene composite sheet and preparation method thereof

ActiveCN110549707BHigh foaming ratioUniform cell structureSynthetic resin layered productsCoatingsPolyesterElastomer

The invention discloses a foamed polypropylene composite sheet and a preparation method thereof. The sheet sequentially comprises from the outside to the inside: a toughening layer, including a cross-linked foamed polypropylene composited with a thermoplastic elastomer or polyvinyl chloride on the surface. Propylene; reinforcement layer, including polyester / polyolefin / organic montmorillonite composite; core layer, including foam composite material with a foaming ratio of 2 to 5 times; the thickness of the composite sheet is 4 to 6mm, and the bending The modulus is 1100~1400MPa. The foamed polypropylene composite sheet provided by the present invention still maintains high bending strength during the process of increasing the expansion ratio, and due to the addition of inorganic particles with high specific surface area and high surface activity in the composite sheet, the product It has a certain adsorption capacity for harmful gases, realizes the purpose of reducing VOC release, and is suitable for popularization and use.

Owner:合肥森烨轻质塑料科技有限责任公司

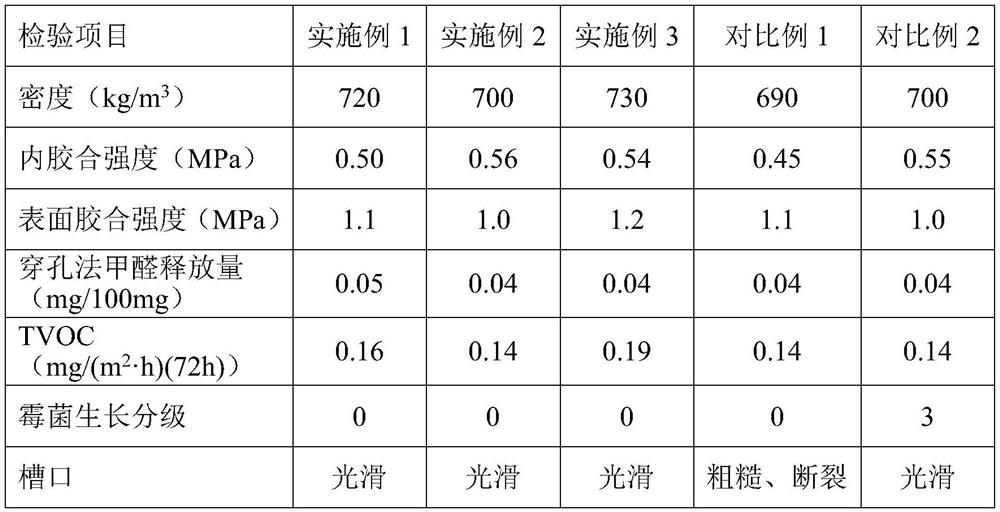

A kind of formaldehyde-free antibacterial bamboo straw composite substrate and preparation method thereof

ActiveCN112388795BReduce TVOC contentImprove antibacterial propertiesNon-macromolecular adhesive additivesWood working apparatusAdhesiveComposite substrate

Owner:BEIJING FORESTRY UNIVERSITY

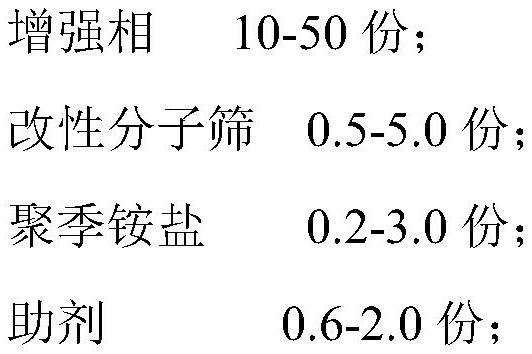

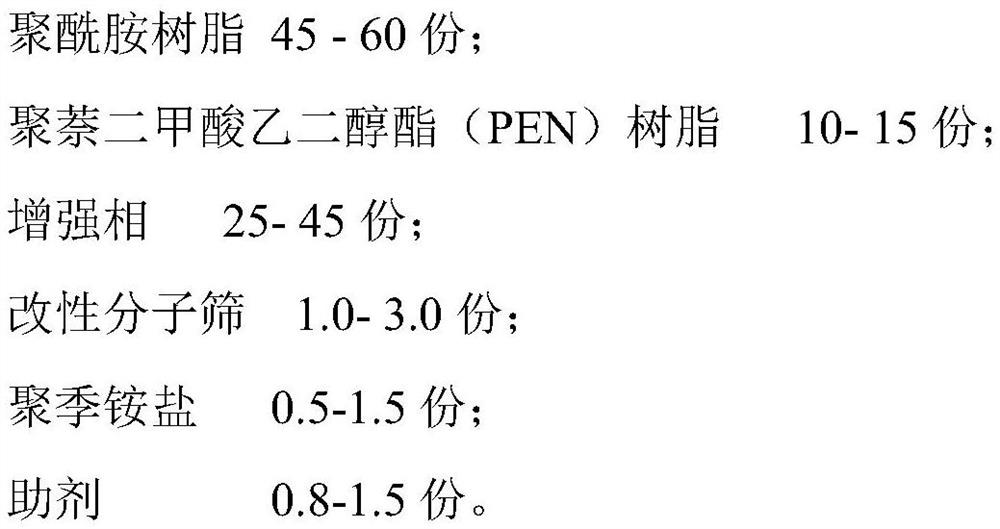

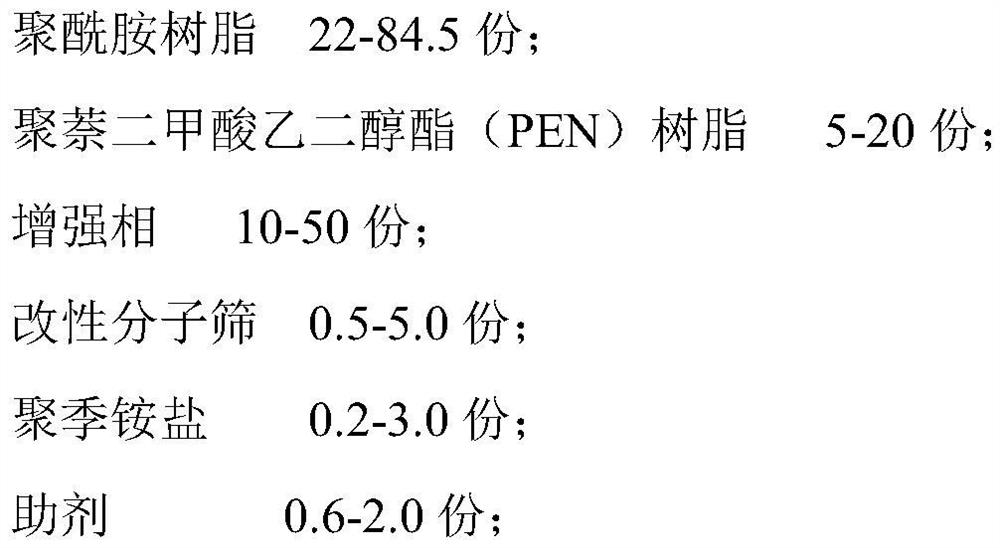

Polyamide composition as well as preparation method and application thereof

The invention provides a polyamide composition as well as a preparation method and application thereof. The polyamide composition comprises the following components: polyamide resin, polyethylene naphthalate (PEN) resin, a reinforcing phase, a modified molecular sieve, polyquaternium and an auxiliary agent, the modified molecular sieve is a gold bromide modified molecular sieve. According to the polyamide composition, the PA is blended with the PEN resin, and the gold bromide modified molecular sieve and the polyquaternium are added, so that the ion barrier property and the gas barrier property of the polyamide composition can be improved, the volatility of small molecular substances in the composition is reduced, the small molecular substances are not easy to desorb, the precipitation of impurities is effectively reduced, and the service life of the composition is prolonged. In addition, by adding the polyquaternium, impurity ions such as sulfate ions in a resin system are fully reacted, and ion precipitation is reduced. The polyamide composition disclosed by the invention has the advantages of low impurity, low ion precipitation and low TVOC (Total Volatile Organic Compound).

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

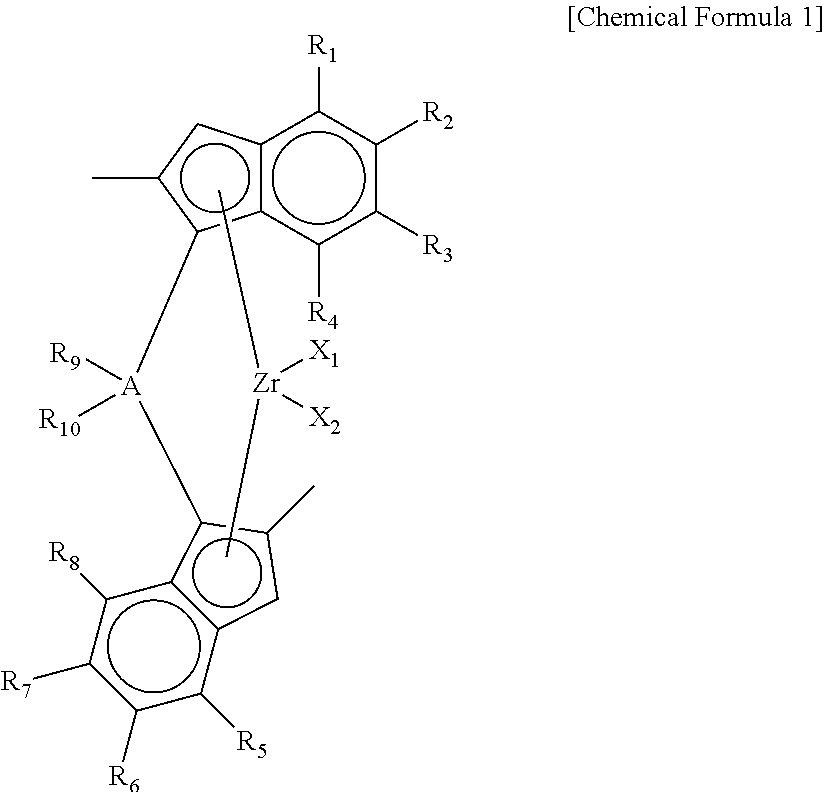

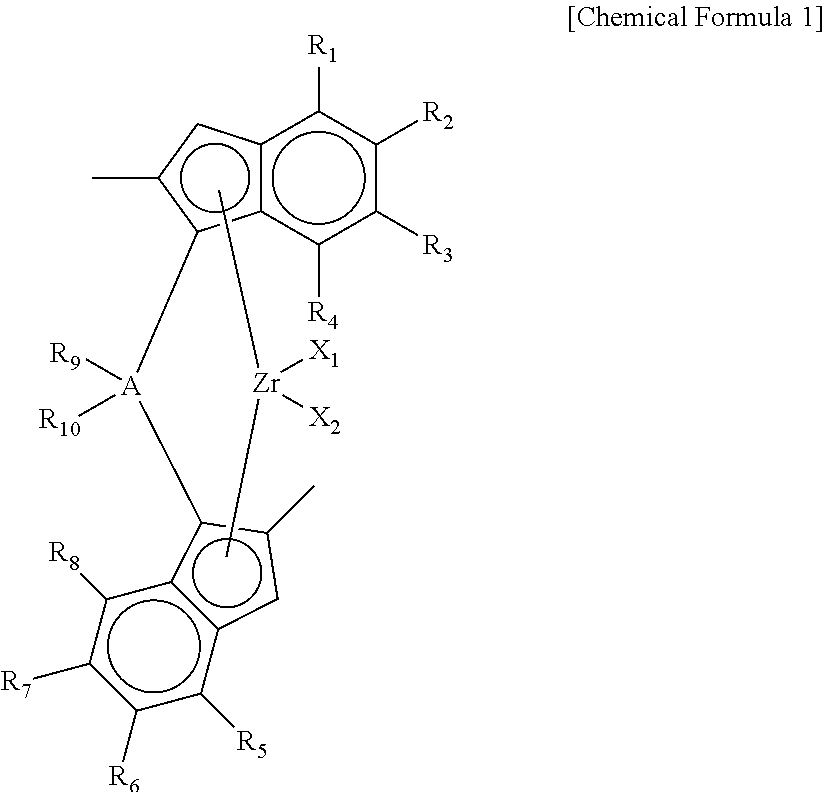

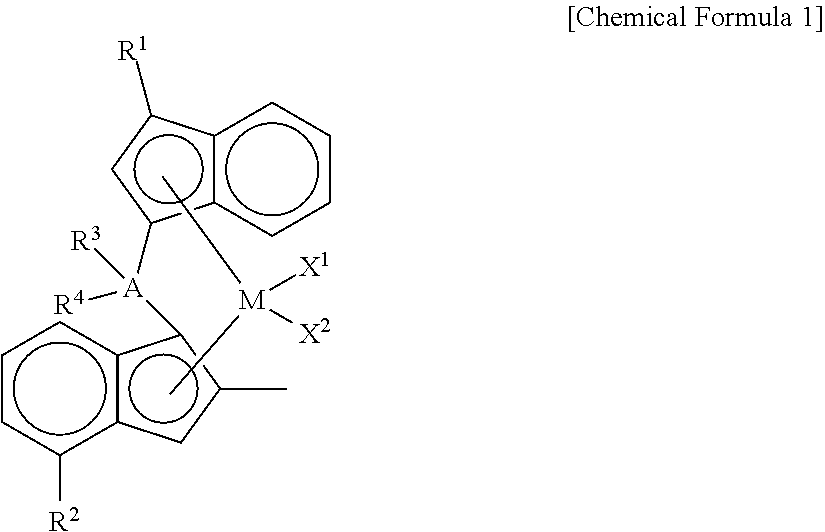

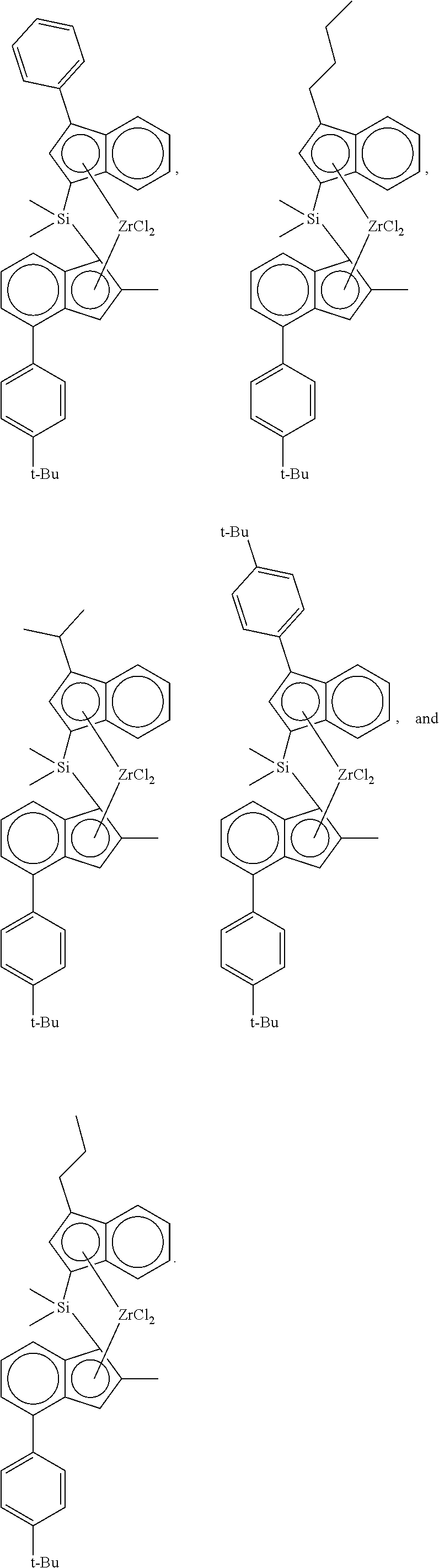

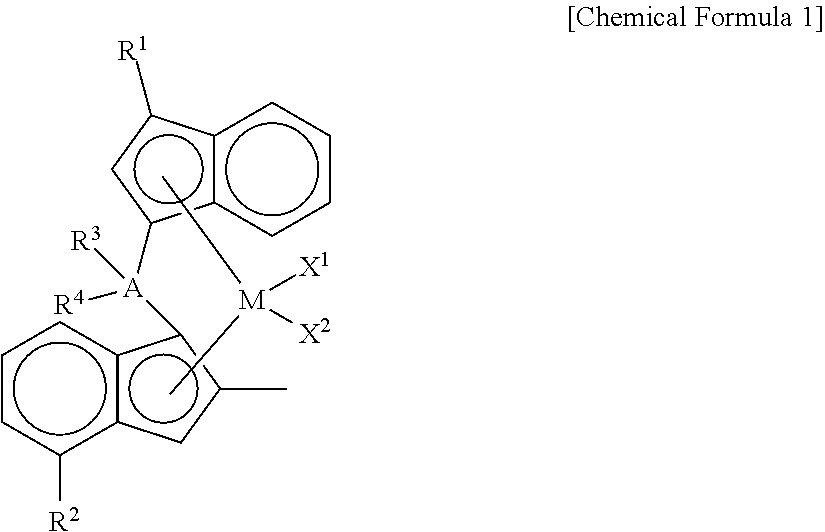

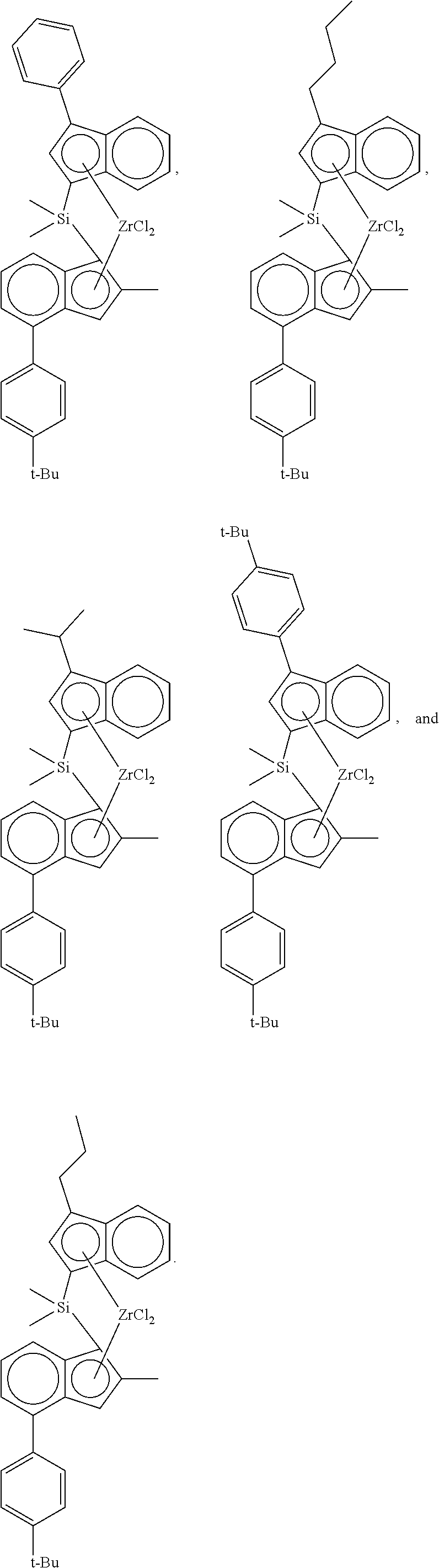

Novel Transition Metal Compound and Method for Preparing Polypropylene Using the Same

ActiveUS20210189025A1Excellent catalytic activityImprove impact strengthMetallocenesPolypropylenePolymer science

The present disclosure provides a novel transition metal compound which exhibits excellent catalytic activity and is useful in the preparation of a polypropylene having high impact strength, and a method for preparing a homo polypropylene using the same.

Owner:LG CHEM LTD

A low-odor and low-emission whiteness red phosphorus flame retardant masterbatch for whiteness red phosphorus and nylon and its preparation method

The invention discloses a low-odor, low-emission, whiteness red phosphorus flame-retardant masterbatch for nylon and a preparation method thereof, which is prepared from the following components in parts by weight: 50-85 parts of whiteness red phosphorus , Hydrophobic odor adsorption masterbatch 1-5 parts, antioxidant 0.2-1.0 parts, lubricant 0.2-1 parts. The red phosphorus flame-retardant masterbatch prepared by the invention has wide versatility, high active ingredients, no obvious odor, low addition amount, and simple preparation method. At the same time, it also breaks through the limitation of color, so that the product is not limited to dark-colored products, and It can effectively reduce dust pollution and improve the working environment.

Owner:HEFEI GENIUS NEW MATERIALS

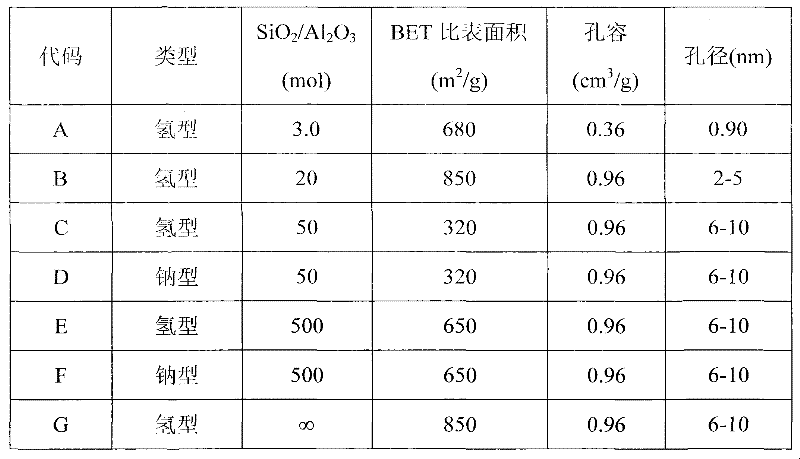

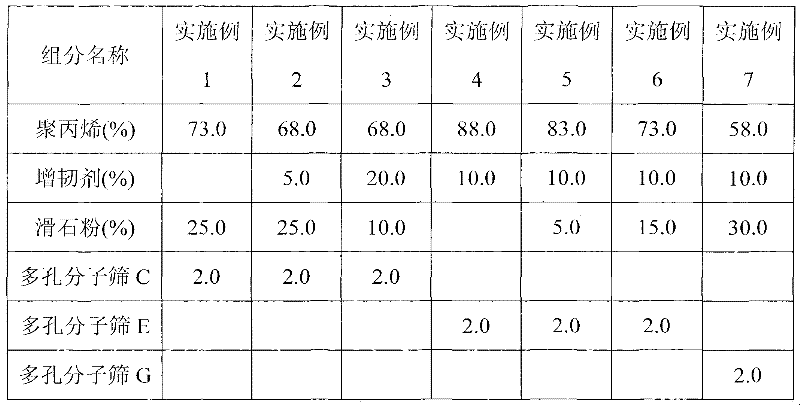

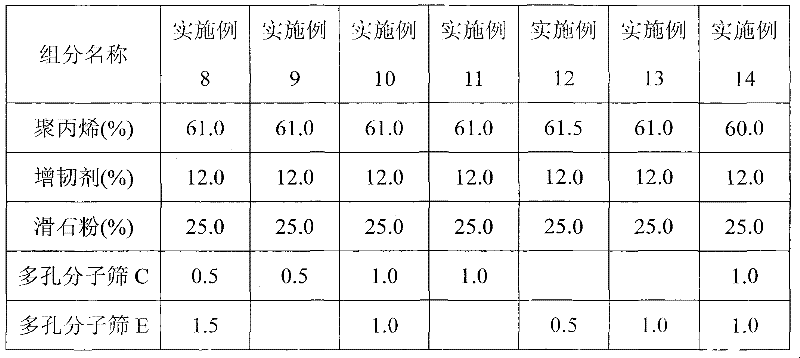

Low TVOC polypropylene composite for motor vehicles and preparation method thereof

The invention discloses a low TVOC polypropylene composite for motor vehicles and a preparation method thereof. A hydrogen type high silica alumina ratio porous molecular sieve is added to the TVOC polypropylene composite for the motor vehicles. The high silica alumina ratio means that the mole ratio of silicon dioxide to aluminium oxide is more than 30.In the invention one or more hydrogen type high silica alumina ratio porous molecular sieve materials which can effectively adsorb volatile and nonpolar organic compound in the polypropylene modified material are adopted, the prepared composite material has the characteristic of low TVOC. The porous molecular sieve materials are free from lyophobic modification and have simple production technology and wide source. The low TVOC polypropylene composite for the motor vehicles has simple preparation technology and low cost.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

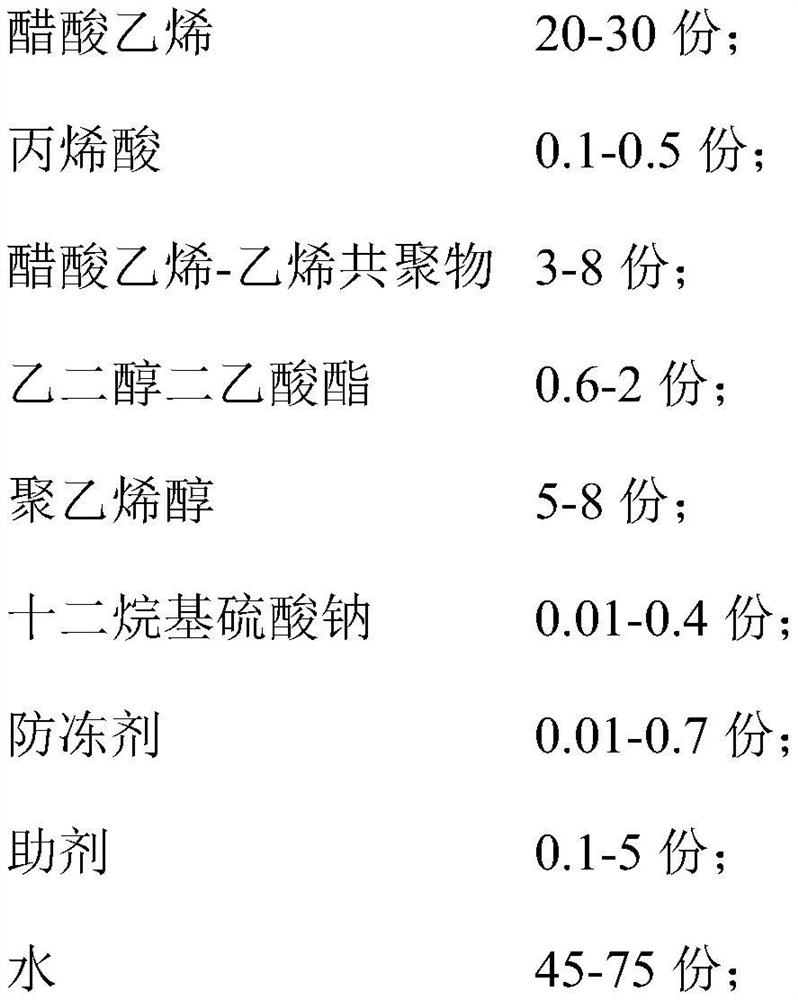

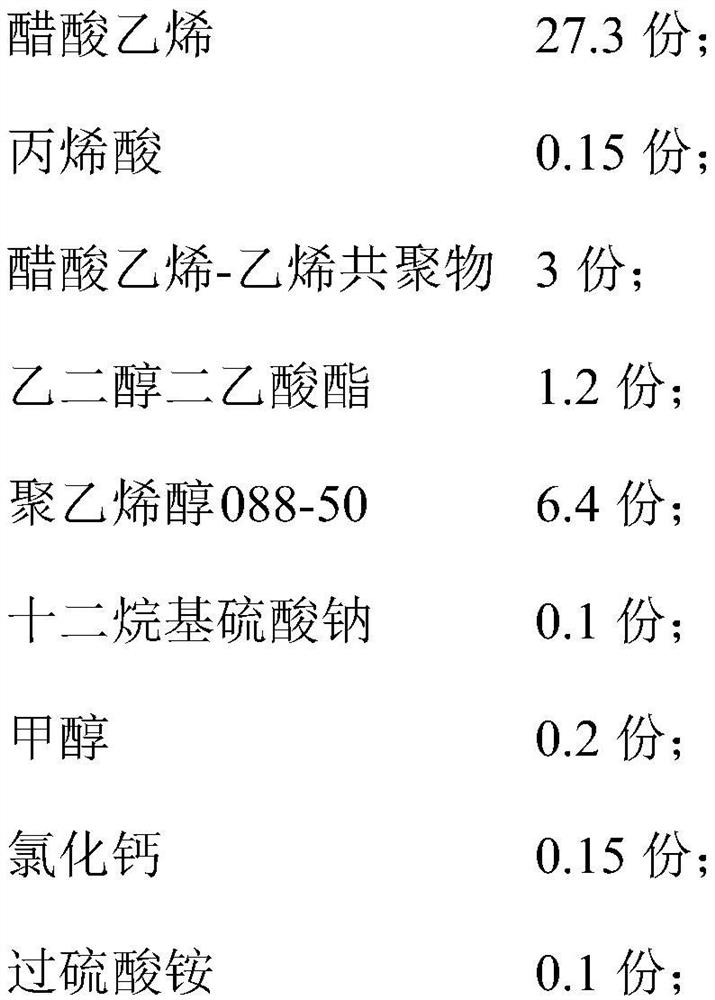

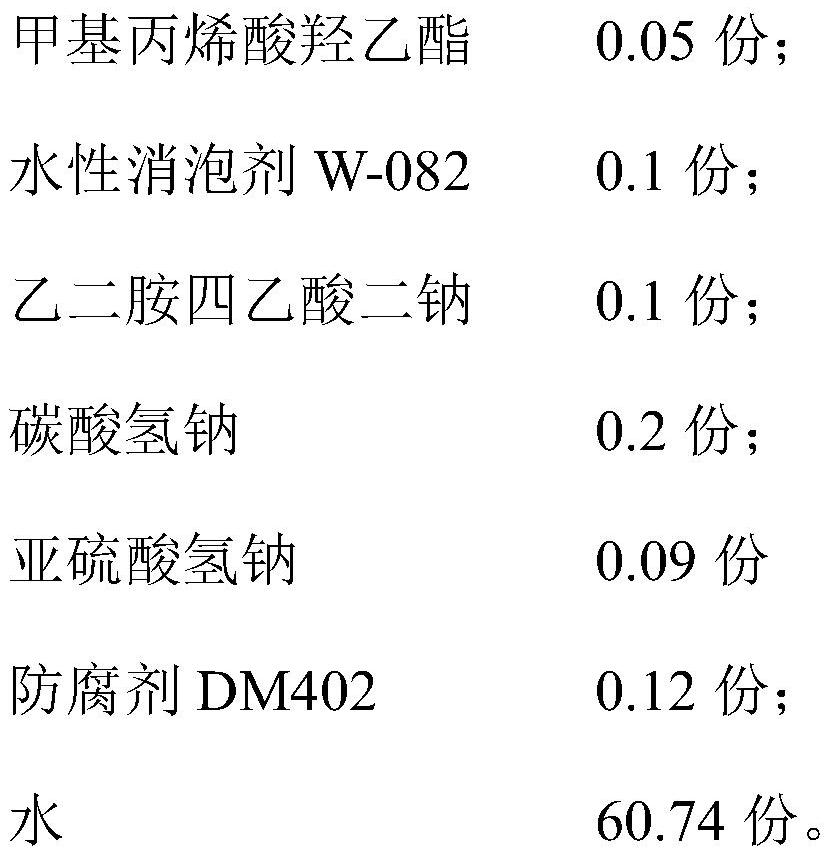

Polyvinyl acetate emulsion and preparation method thereof

ActiveCN110055015BIncrease viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePolyvinyl alcohol

The invention relates to a polyvinyl acetate emulsion and a preparation method thereof. The polyvinyl acetate emulsion is prepared from raw materials comprising the following parts by weight: 15-35 parts of vinyl acetate; 0.1-0.7 parts of acrylic acid; 1-25 parts of vinyl acetate-ethylene copolymer; 0.6 parts of ethylene glycol diacetate ‑4 parts; 3‑9 parts of polyvinyl alcohol; 0.01‑0.4 parts of sodium lauryl sulfate; 0.01‑0.7 parts of antifreeze; 0.1‑5 parts of additives; 45‑75 parts of water. In the polyvinyl acetate emulsion, the content of formaldehyde and TVOC is less than the national standard, does not contain APEO and phthalate, and meets the foreign limit standard.

Owner:广东嘉宝莉科技材料有限公司

Biological peculiar smell scavenger and production method thereof

The invention discloses a biological peculiar smell scavenger and a production method thereof. The scavenger comprises bacillus megaterium (CGMCC 1.2393), candida utillis (CGMCC 2.1012) and azotobacter chroococcum (CGMCC 1.2391). The production method for the scavenger comprises the following steps of: inoculating the activated bacillus megaterium, candida utillis and azotobacter chroococcum into a silicate group bacteria culture medium, a wort culture medium and a nitrogen-fixing culture medium to perform seed liquid culture respectively; and mixing the three seed liquids in a mass part ratio of 0.5-1.5: 1-2: 1-2, and adjusting the concentration of the mixed solution as required. The biological peculiar smell scavenger sprayed to a place with peculiar smell can remarkably reduce the stench TVOC, particularly has obvious effect of reducing ammonia, aldehyde and benzene, and has the advantages of low cost, no secondary pollution and convenient use.

Owner:四川美可迪科技开发有限责任公司

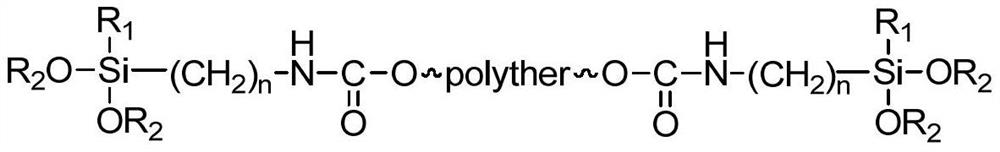

High temperature resistant silane modified adhesive and its preparation method and application

ActiveCN111117546BHigh elongationImprove storage performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMolecular sievePolymer science

The invention relates to a high temperature resistant silane modified adhesive and its preparation method and application. The high temperature resistant silane modified adhesive includes A component and B component, A component includes 100 parts of silane modified polymer, The first plasticizer is 0-15 parts, the filler is 10-40 parts, the crosslinking agent is 2-10 parts, the silane coupling agent is 2-8 parts and the curing agent is 0.5-10 parts, and the B component includes 100 parts of epoxy resin , 10-30 parts of the second plasticizer, 5-20 parts of molecular sieves, 0.5-5 parts of water and 0.1-2 parts of organic tin catalyst. The high-temperature-resistant silane-modified adhesive is suitable for non-polishing aluminum substrates and can meet the performance indicators of good elasticity and good bonding strength after high-temperature resistance. The TVOC is lower than 100mg / L, which can meet the production requirements of passenger car doors. skills requirement.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +2

A kind of odorless, low tvoc polyurethane sealant for automobile interior decoration and its preparation method and application

ActiveCN106753181BNo smellComply with the requirements of the air quality evaluation guidelinesNon-macromolecular adhesive additivesOther chemical processesPolymer scienceAntioxidant

The invention relates to an odor-free and low-TVOC polyurethane sealant for automotive trims, and a preparation method and an application thereof. The polyurethane sealant is prepared from the following components in mass percents: 20-40% of polyurethane prepolymer, 15-40% of environmentally friendly plasticizer, 5-25% of carbon black, 25-60% of white reinforcing filler, 0.2-2% of curing accelerator, 0.2-2% of dehydration stabilizer, 0.2-2% of deodorant, 0-2% of adhesion promoter, 0-30% of thixotropic agent, 0-2% of light stabilizer and 0-2% of antioxidant. Compared with the traditional polyurethane sealant, the polyurethane sealant provided by the invention emits no odor when being used in a long-term closed high temperature (80 DEG C) environment, and the odor rating is 1 level, so the polyurethane sealant has the advantages of being odor-free, low in TVOC and harmless to human body and environment, satisfies the air quality evaluation guidance requirements of passenger cars, and is suitable for sealing and joint filling of automotive trims.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

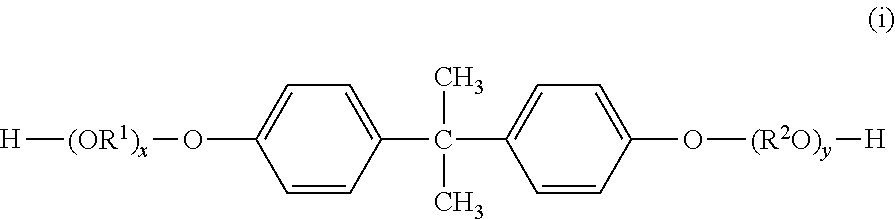

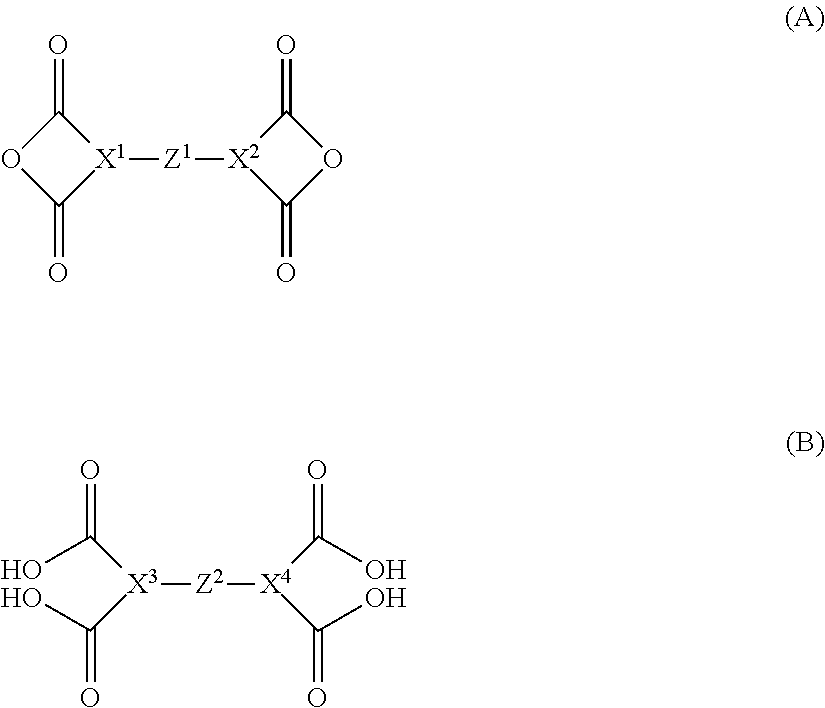

Polyester resin for toners, method for producing same, toner and method for producing toner

A polyester resin, including:(a) a constitutional unit derived from at least one tetravalent carboxylic acid selected from Compounds (A) and (B);a constitutional unit derived from a bisphenol A-alkylene oxide adduct; anda constitutional unit derived from an aliphatic alcohol having a boiling point of lower than or equal to 290° C.,where the polyester resin is free of a constitutional unit derived from a monovalent carboxylic acid, an acid value of the polyester resin is 8 to 55 mg KOH / g, and an amount of the tetravalent carboxylic acid is 1 to 30 mol % when an total amount of the tetravalent carboxylic acid, and other polyvalent carboxylic acid excluding the Compounds (A) and (B) is set to 100 mol %,where X1, X2, X3 and X4 each independently represent a trivalent organic group, and Z1 and Z2 each independently represent a single bond or a divalent organic group, wherein tetravalent carboxylic acid is, for example, 3,3′,4,4′-biphenyltetracarboxylic dianhydride, 2,2′,6,6′-biphenyltetracarboxylic dianhydride, 4,4′-oxydiphthalic dianhydride, 9,9-bis(3,4-dicarboxyphenyl) fluorene dianhydride, and / or 4,4′-(4,4′-isopropylidenediphenoxy) diphthalic anhydride.

Owner:MITSUBISHI CHEM CORP

Air-drying water-soluble acrylic resin and preparation method thereof

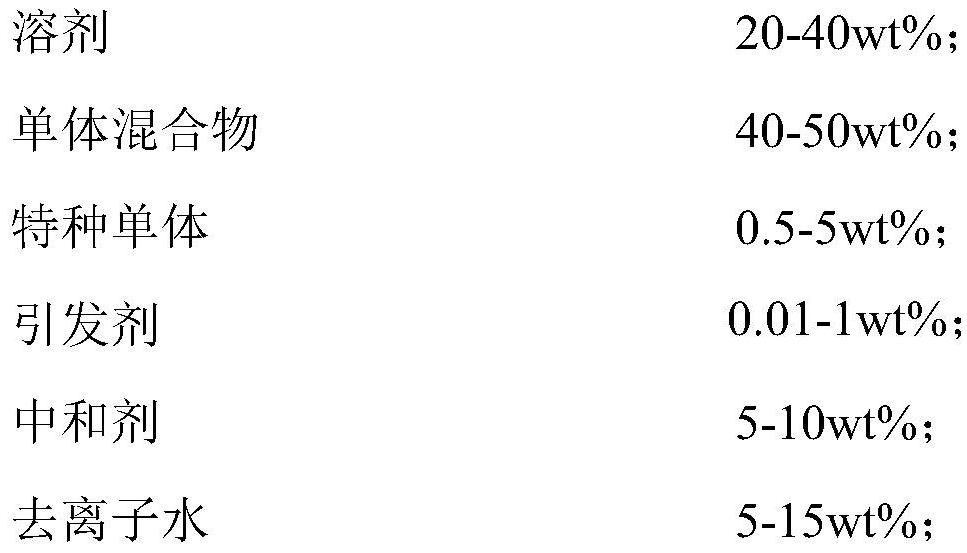

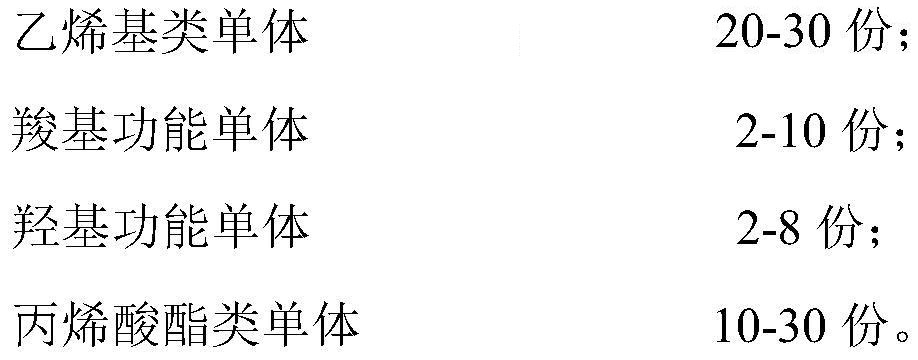

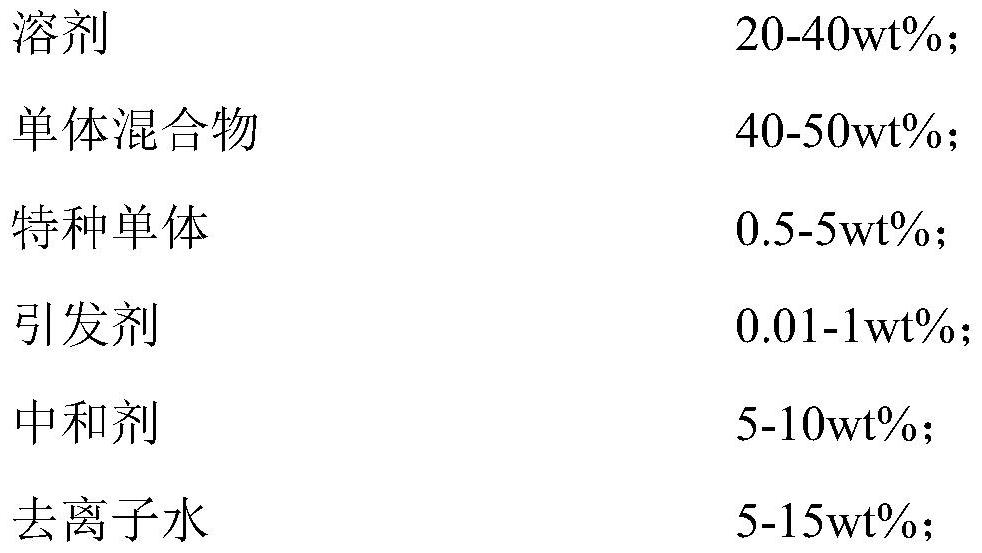

The invention relates to the technical field of polymer preparation, in particular to air-drying water-soluble acrylic resin and a preparation method thereof; the air-drying water-soluble acrylic resin comprises 20-40 wt% of a solvent; 40-50 wt% of a monomer mixture; 0.5-5 wt% of a special monomer; 0.01-1 wt% of an initiator; 5-10 wt% of a neutralizer; and 5-15 wt% of deionized water. The water-soluble acrylic acid disclosed by the invention has excellent water resistance, has good adhesive force on substrates such as tinplate, galvanized steel, aluminum materials, glass, wood and the like, and can be used for preparing self-spraying paint and interior wall waterproof paint. According to the invention, special functional groups, such as phosphate group, amide group, carbamido group, carbamate group, siloxane group and epoxy group, are synthesized through free radical reaction; meanwhile, the material contains the macromolecules with hydrophilic groups such as carboxyl and hydroxyl; after neutralization by adding a neutralizer, air-drying water-soluble acrylic resin is obtained, and the acrylic resin has proper viscosity and can promote formation of a uniform coating on a base material and promote improvement of water resistance.

Owner:广东迪爱生彤德树脂有限公司

Transition metal compound and method for preparing polypropylene using the same

ActiveUS11370851B2High catalytic activityHigh impact strengthMetallocenesPolymer sciencePolypropylene

Owner:LG CHEM LTD

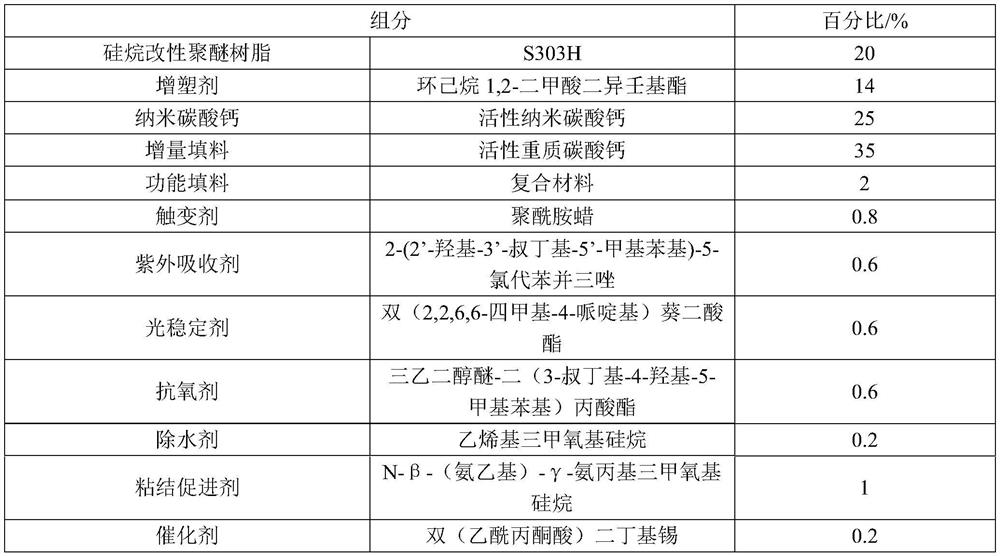

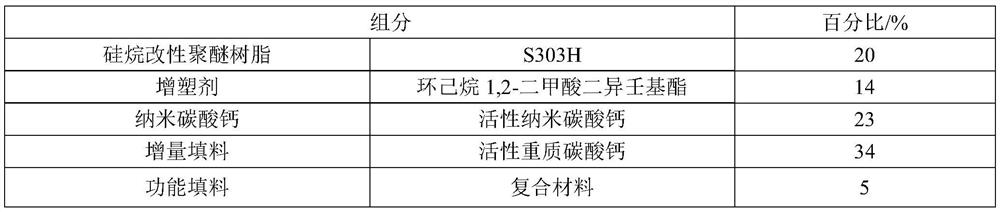

One-component silane-modified polyether sealant for automobiles and preparation method thereof

ActiveCN111253898BAvoid desorptionTVOC reductionNon-macromolecular adhesive additivesMacromolecular adhesive additivesActivated carbonPolymer science

The invention provides a one-component silane-modified polyether sealant for automobiles and a preparation method thereof. The raw materials of the one-component silane-modified polyether sealant for automobiles include silane-modified polyether resins and functional fillers. The raw materials of functional fillers include nano activated carbon, carbonate, silicate, photocatalyst and heat activated catalyst. The present invention utilizes nano-activated carbon, carbonate and silicate to adsorb organic gases, and since the composite material also contains photocatalysts and heat-activated catalysts, the adsorbed small molecules can be catalyzed, oxidized, and degraded under the conditions of light and heating. The degradation products are mainly water and carbon dioxide, thereby reducing the TVOC of the product and avoiding the desorption problem of nano-activated carbon at high temperature.

Owner:GUANGZHOU JOINTAS CHEM

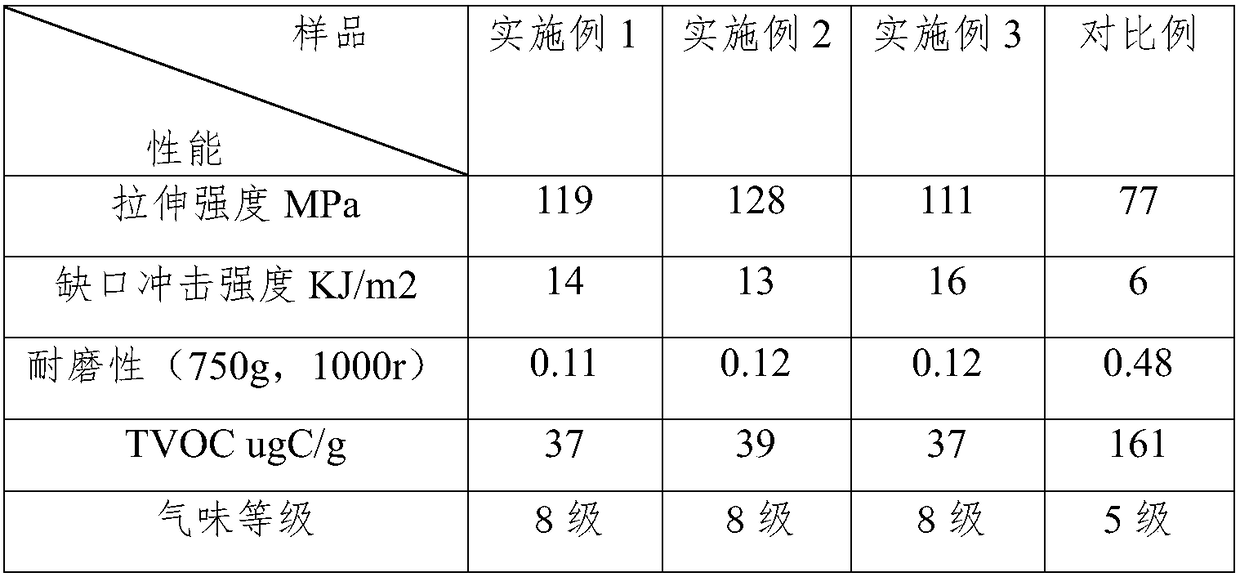

Low-diffusion polypropylene composition and preparation method thereof

The invention relates to a low-diffusion polypropylene composition which comprises the following components in percentage by weight: 55-99.8 percent of polypropylene composite material and 0.2-5 percent of organopolysiloxane silicone oil, wherein the organopolysiloxane silicone oil comprises one or a plurality of hydrogen-type polysiloxane, hydroxyl polysiloxane, methyl polysiloxane, ethenyl polysiloxane, amino polysiloxane, epoxy polysiloxane and methoxyl polysiloxane silicone oil. A preparation method of the low-diffusion polypropylene composition comprises the following steps of: weighing the components of polypropylene, talcum powder, a toughening agent, an antioxidant, a light stabilizer and the organopolysiloxane silicone oil in percentage by weight; mixing the polypropylene, the toughening agent, the antioxidant, the light stabilizer and the organopolysiloxane silicone oil for 1-2 minutes in a high speed mixer firstly and then adding the talcum powder and mixing for 3-5 minutes; and extruding and pelletizing the mixed materials by using a double screw extruder, wherein the process conditions are that: the temperature of a first area is 200-210 DEG C, the temperature of a second area is 210-220 DEG C, the temperature of a third area is 210-220 DEG C and the temperature of a fourth area is 200-215 DEG C, the retention time is 1-2 minutes, and the pressure is 10-20MPa. Thelow-diffusion polypropylene composition has the advantages that: the organopolysiloxane silicone oil forms a layer of even film on the surface of the talcum powder, which can block up a TVOC (Total Volatile Organic Compound) of the polypropylene material so as to reduce the pollution.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com