Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Uniform cell structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two component thermosettable compositions useful for producing structural reinforcing adhesives

InactiveUS6451876B1Uniform cell structureExcessive heat dissipationEpoxy resin adhesivesEpoxyPartial system

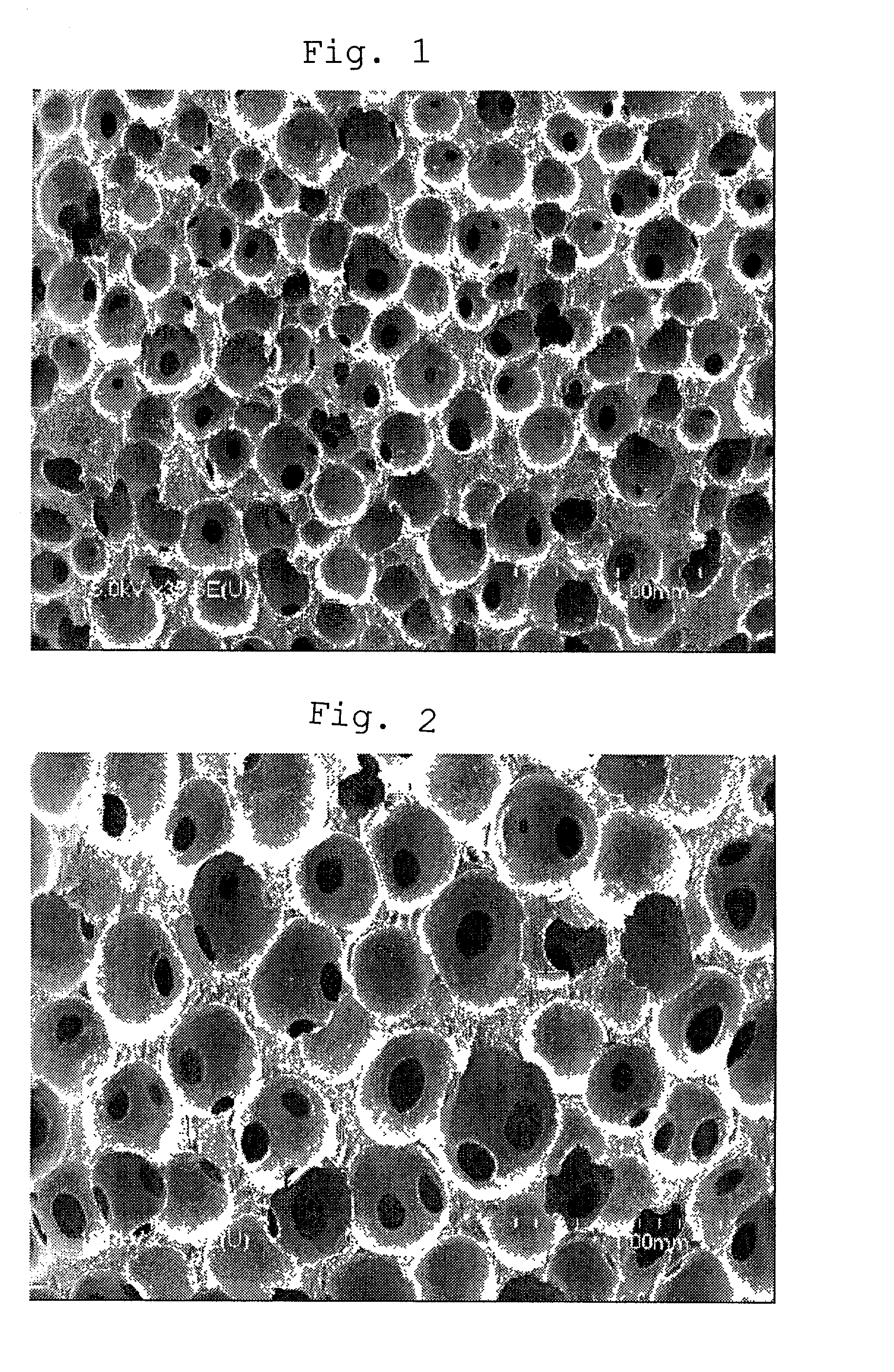

A two part system for producing structural reinforcing adhesives is provided wherein one component containing epoxy resin is combined with a second component containing a specified curative system. An aliphatic polyamine, an amidoamine, an alcohol and an adduct of a polyamine and an epoxide are present in the curative system. When a thermally activated blowing agent is utilized, the resulting foam is remarkably uniform in cell structure and has improved strength and modulus. Hollow inorganic microspheres are employed to reduce the density of the thermoset produced from the two part system.

Owner:HENKEL KGAA

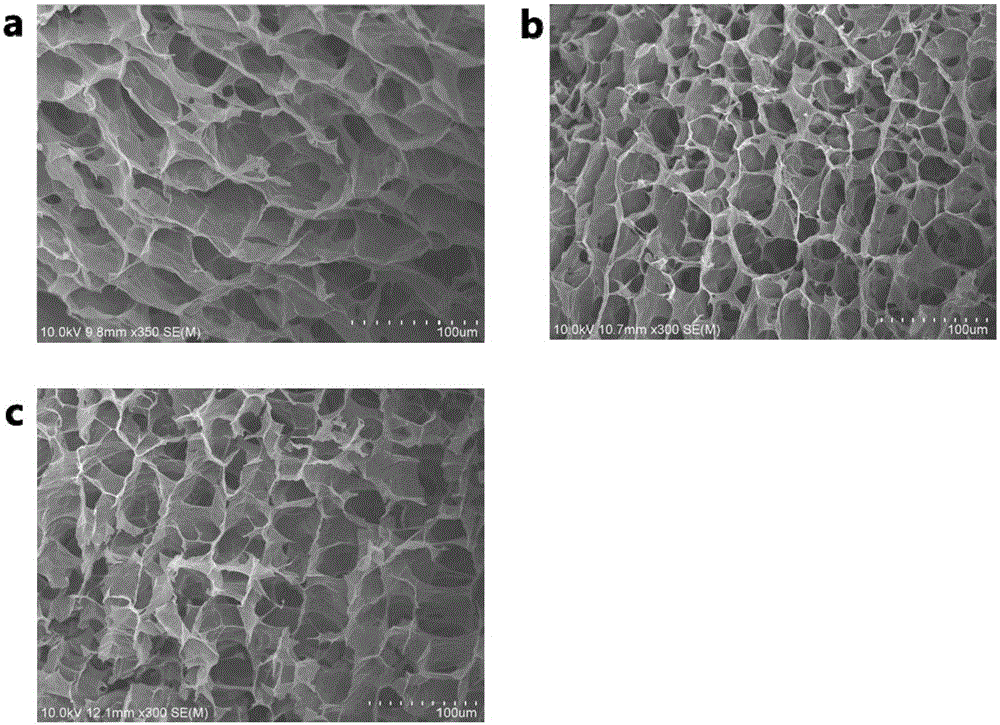

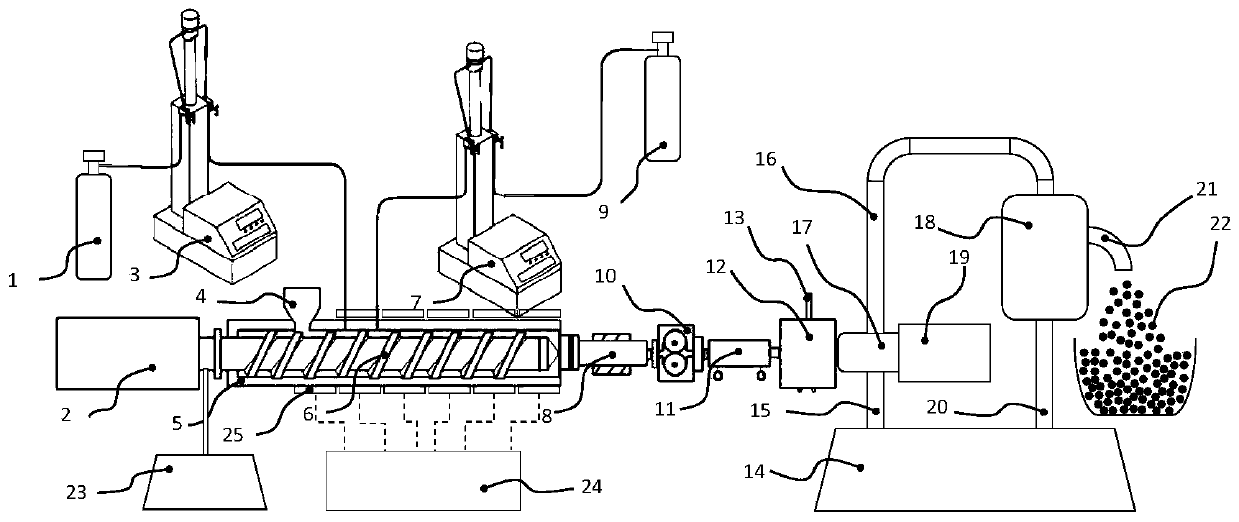

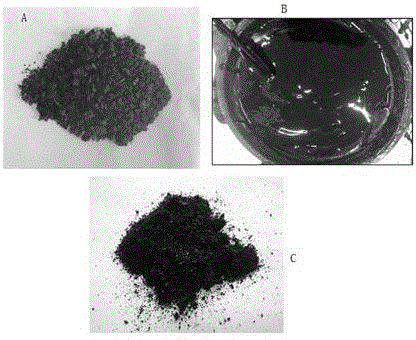

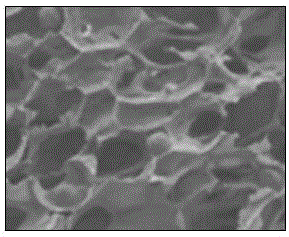

Graphene aerogel and hybrid composite material thereof as well as preparation method and application of graphene aerogel

ActiveCN106422995AUniform cell structureIncrease elasticityColloidal chemistry detailsPotassium persulfateNanoparticle

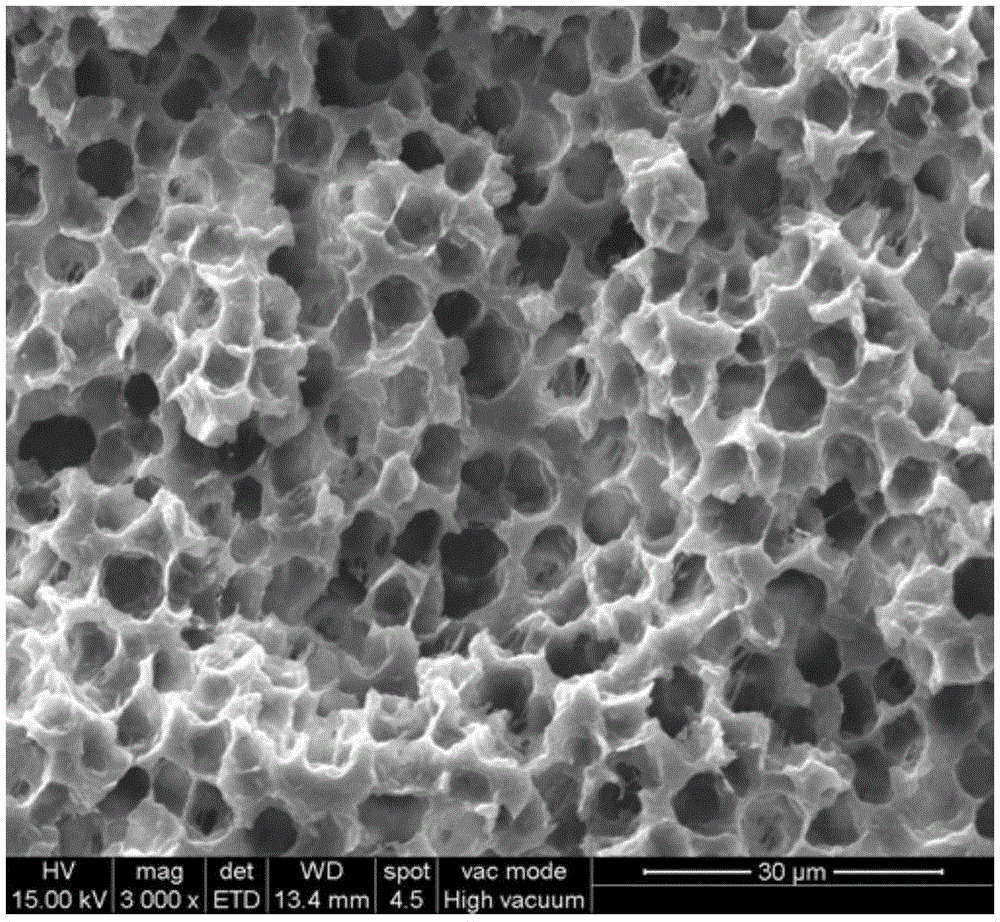

The invention discloses graphene aerogel and a hybrid composite material thereof as well as a preparation method and application of the of graphene aerogel. The preparation method comprises the following steps: 1) mixing graphene oxide, a reducing agent, acrylamide, N,N-methylene-bisacrylamide and potassium persulfate and reacting to obtain partially-reduced graphene / polyacrylamide hydrogel; 2) carrying out pre-freezing and reduction on the partially-reduced graphene / polyacrylamide hydrogel in sequence to obtain graphene / polyacrylamide hydrogel; 3) dialyzing and drying the graphene / polyacrylamide hydrogel in sequence to obtain the graphene aerogel. The graphene aerogel has the characteristics of uniform cellular structure and light weight, excellent resilience, relatively high mechanical strength and good solvent resistance; a preparation process is simple, rapid and low in cost; the graphene aerogel can also be used for preparing polymer / graphene composite aerogel, nanoparticle / graphene composite aerogel and polymer / graphene composite materials and the like, so that application of the graphene aerogel is expanded.

Owner:INST OF CHEM CHINESE ACAD OF SCI

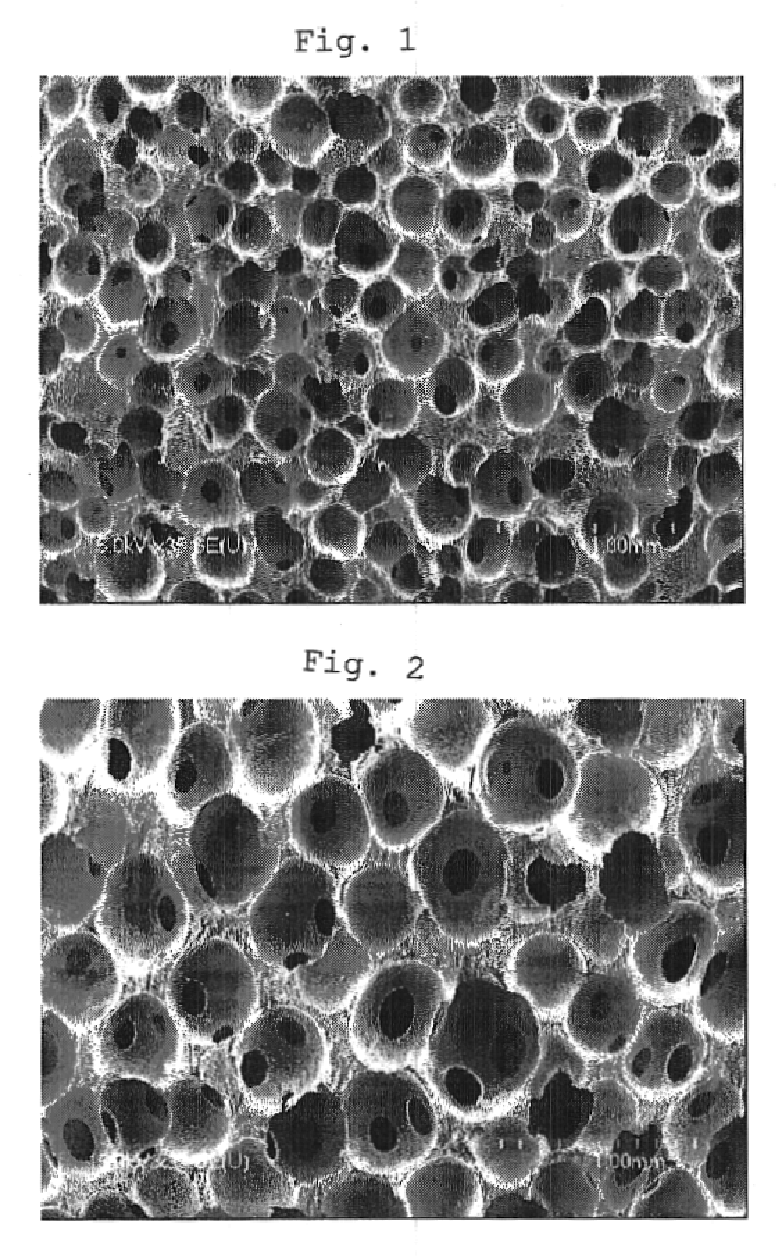

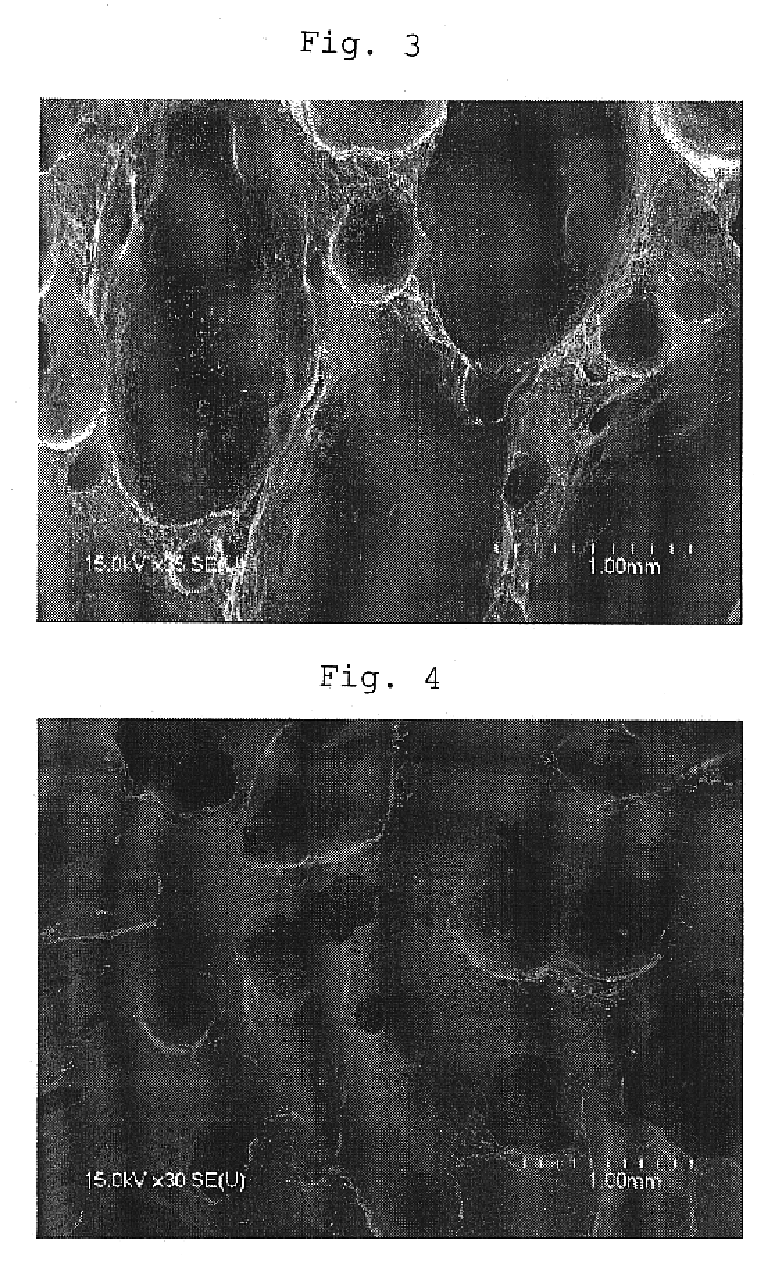

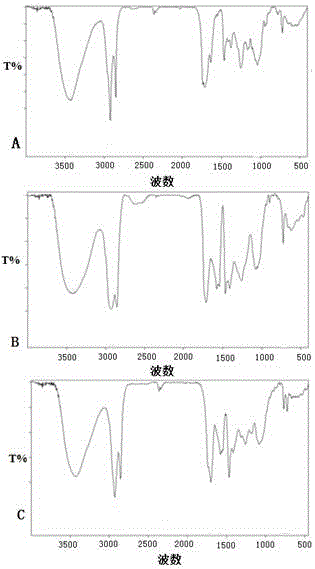

Carbon foam, graphite foam and production processes of these

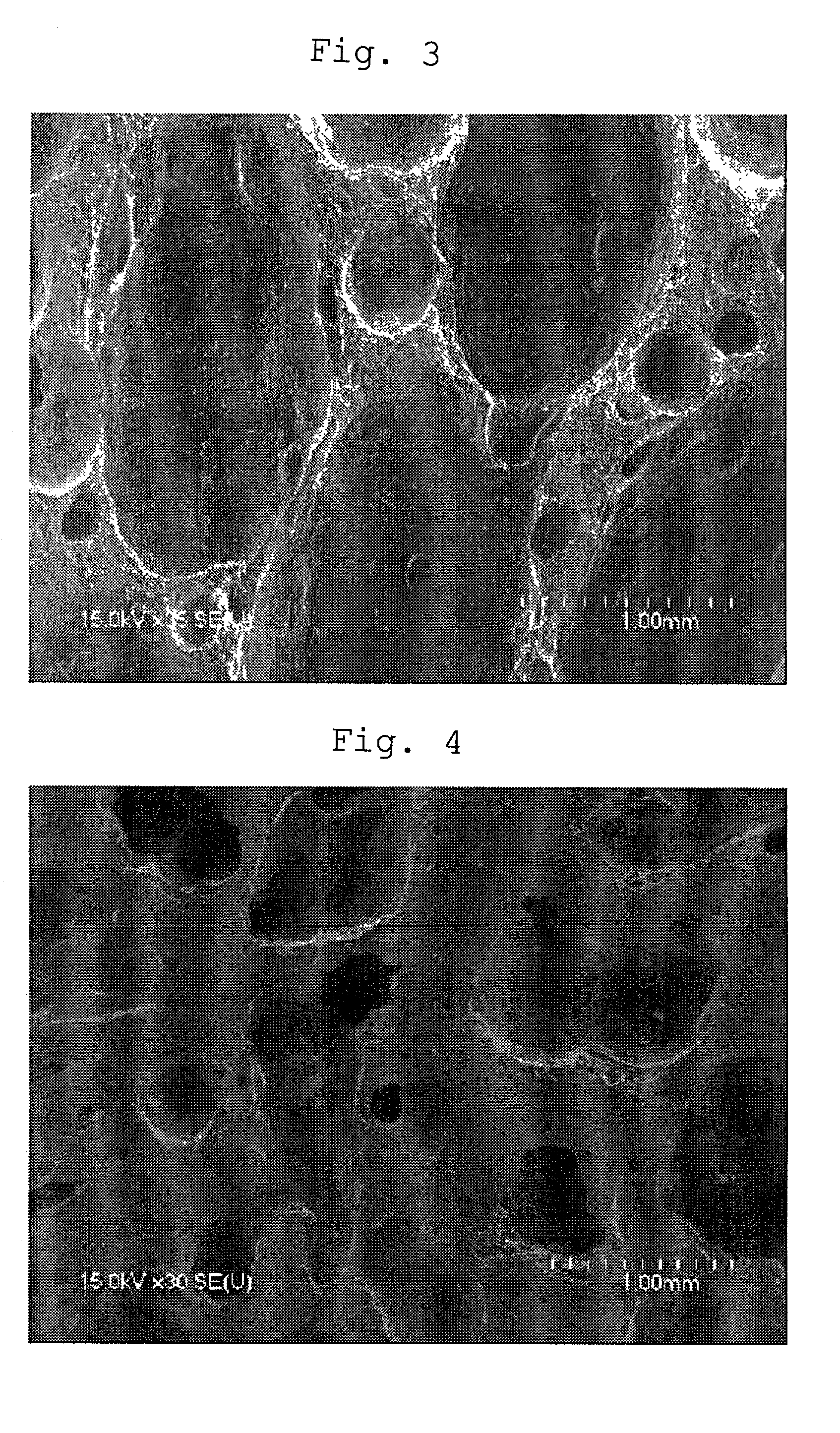

A carbon foam obtained by heat-treating a mesophase pitch whose softening point is 300° C. or less according to an elevated flow tester, whose ratio (Daromatic / Daliphatic) of the absorption intensity of an aromatic C-H stretching vibration, measured with FT-IR, to the absorption intensity of an aliphatic C-H stretching vibration, measured with FT-IR, is 4.0 or less and whose optically anisotropic content is at least 80%, a graphite foam obtained by heat-treating the carbon foam recited above at a temperature of 2,000° C. or higher and production processes of these.

Owner:MITSUBISHI GAS CHEM CO INC

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

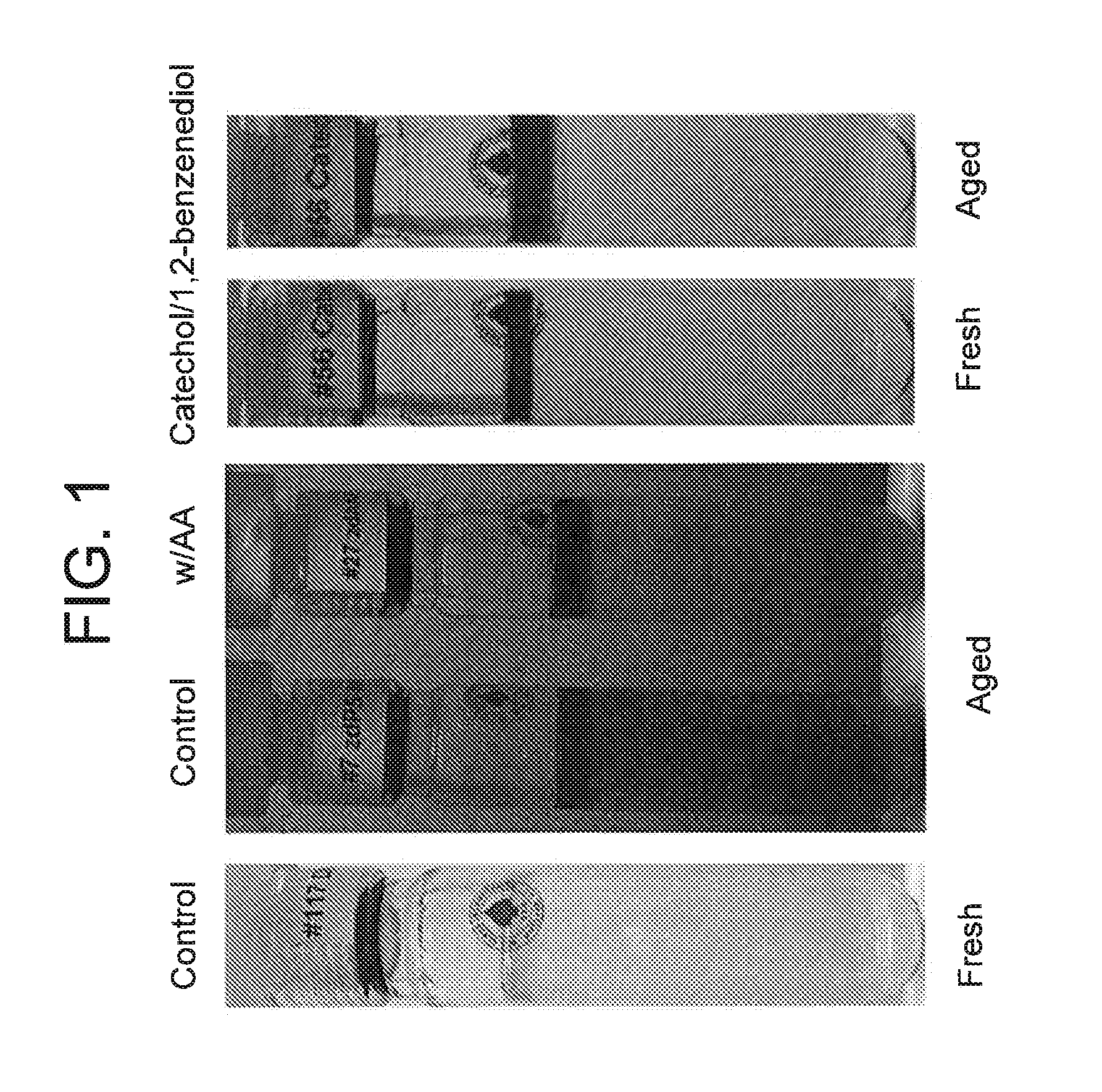

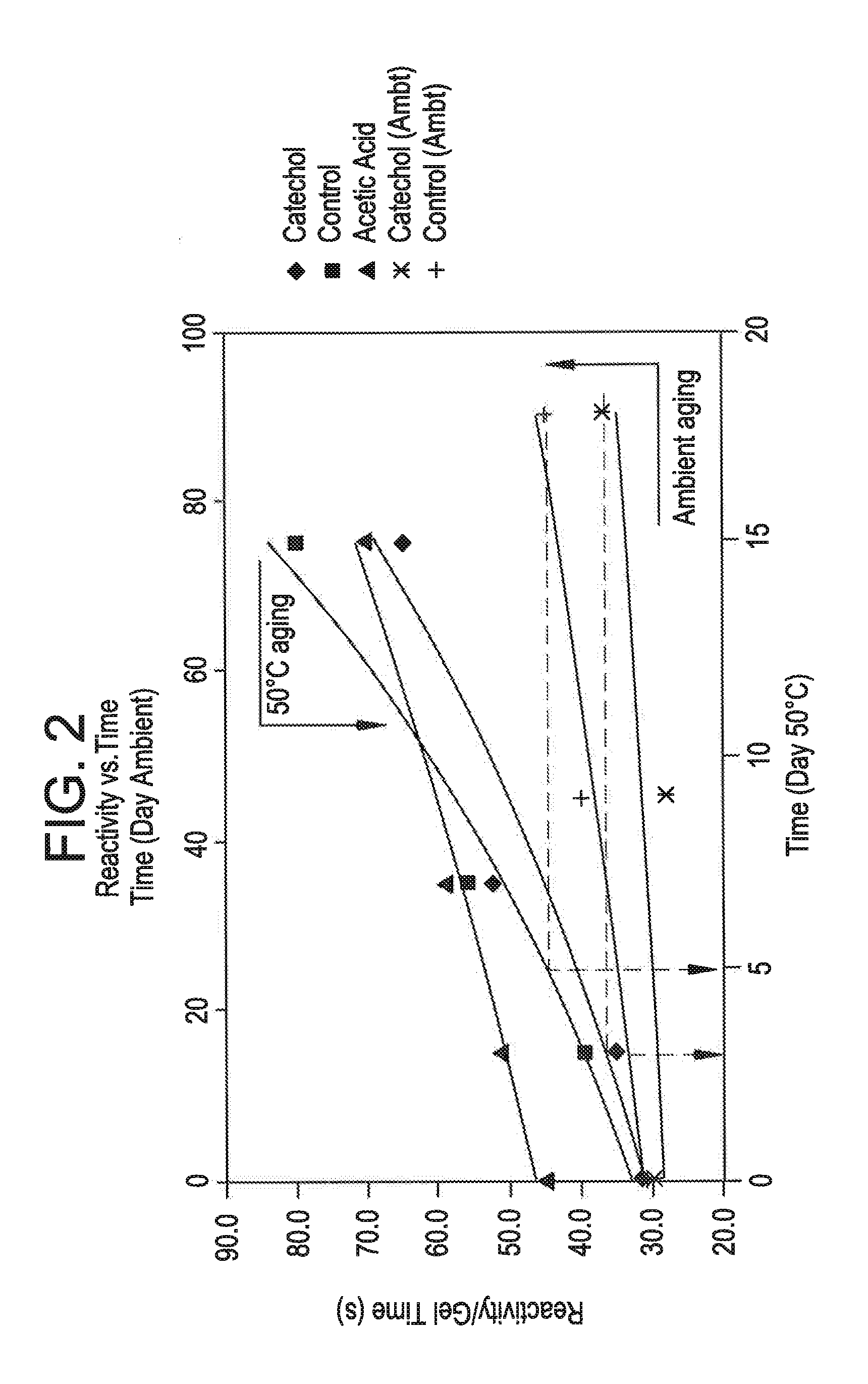

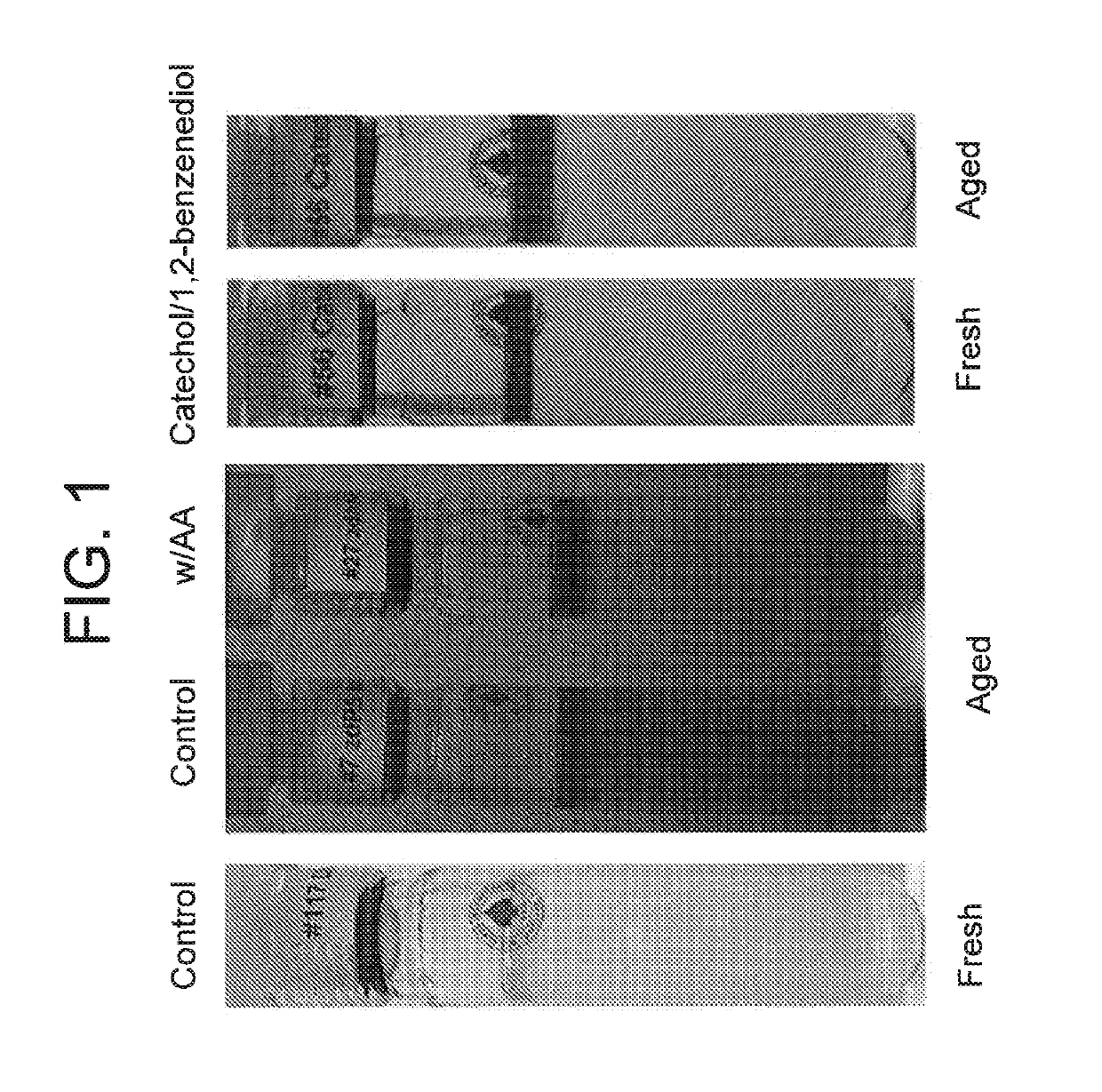

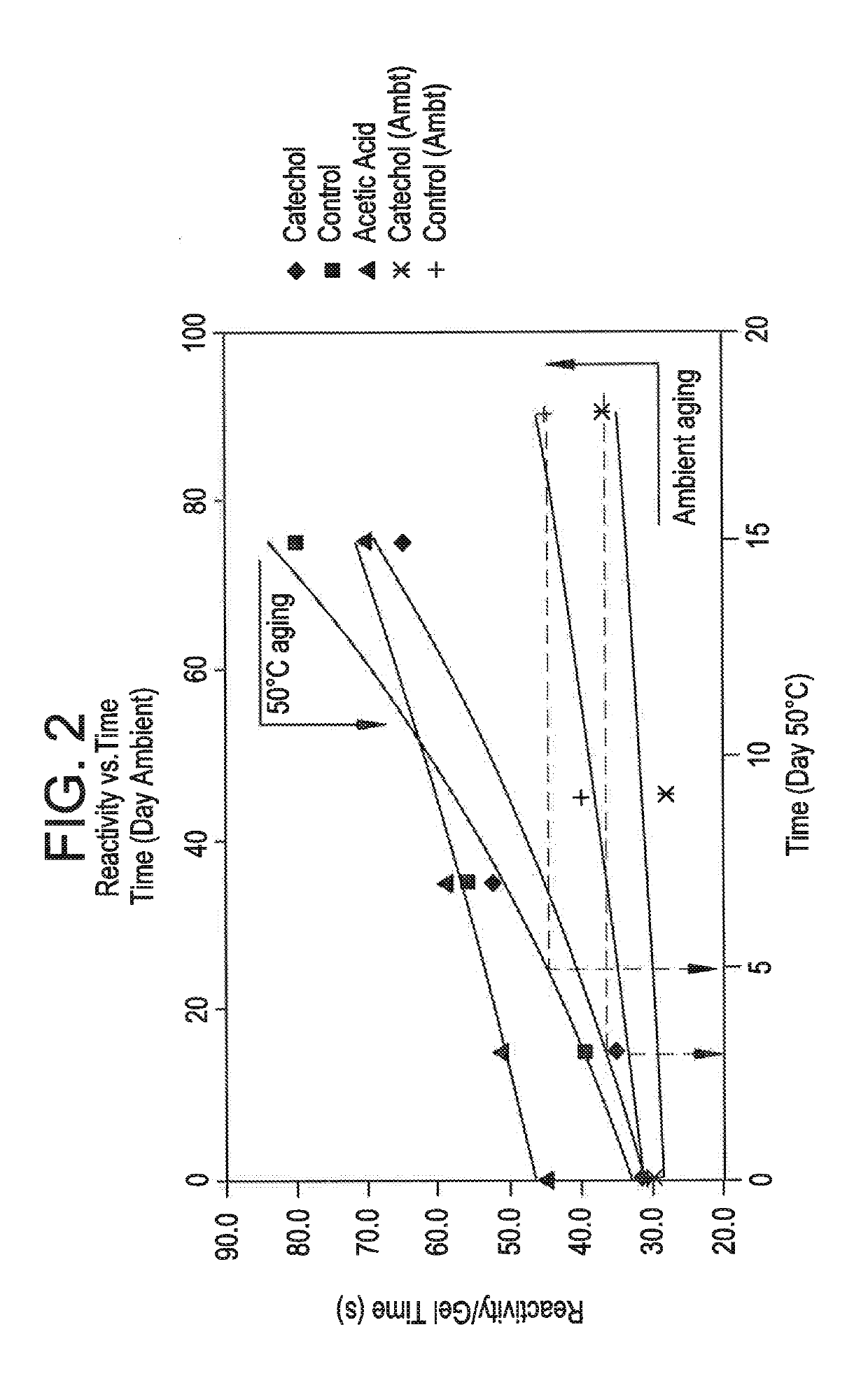

Stability of polyurethane polyol blends containing halogenated olefin blowing agent

ActiveUS20150197614A1Uniform cell structureEasy to prepareOther chemical processesHydrogen halidePolymer science

A polyol pre-mix composition includes a blowing agent having a halogenated hydroolefin, a polyol, a catalyst composition, and an antioxidant. The antioxidant may be, for example, a benzene diol or a benzene triol or other polyhydroxy-substituted aromatic compound, which is optionally substituted with one or more substituents such as alkyl groups. A two-part system for producing a thermosetting foam blend includes (a) a polyisocyanate and, optionally, one or more isocyanate compatible raw materials; and (b) the polyol pre-mix composition. A method for producing a thermosetting foam blend includes combining: (a) a polyisocyanate; and (b) the polyol pre-mix composition.

Owner:ARKEMA INC

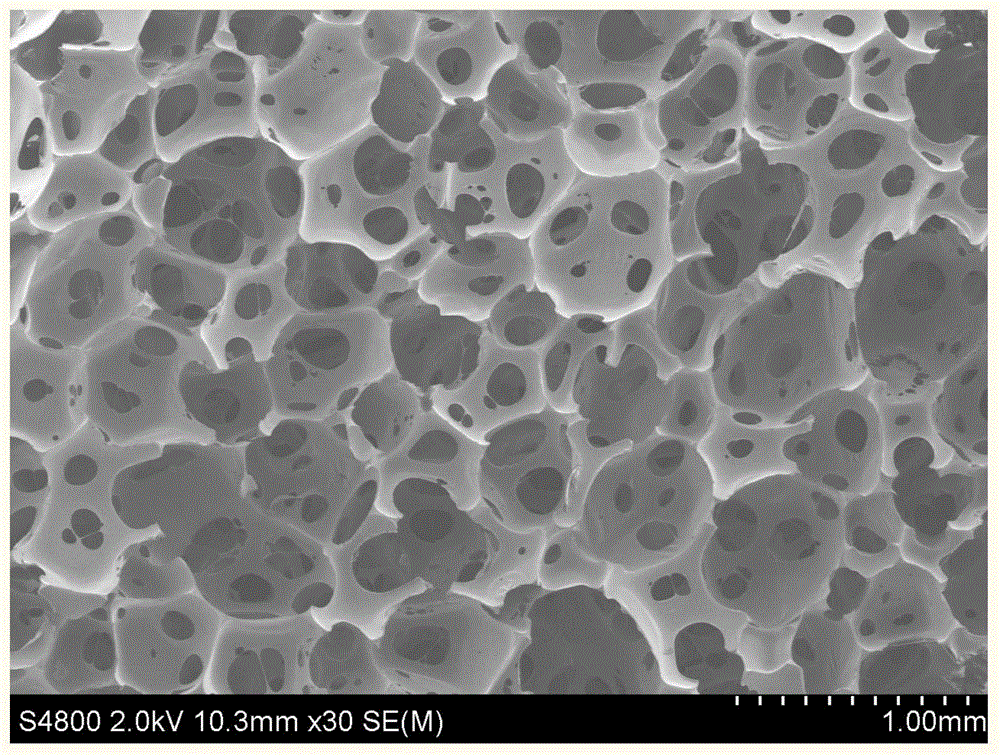

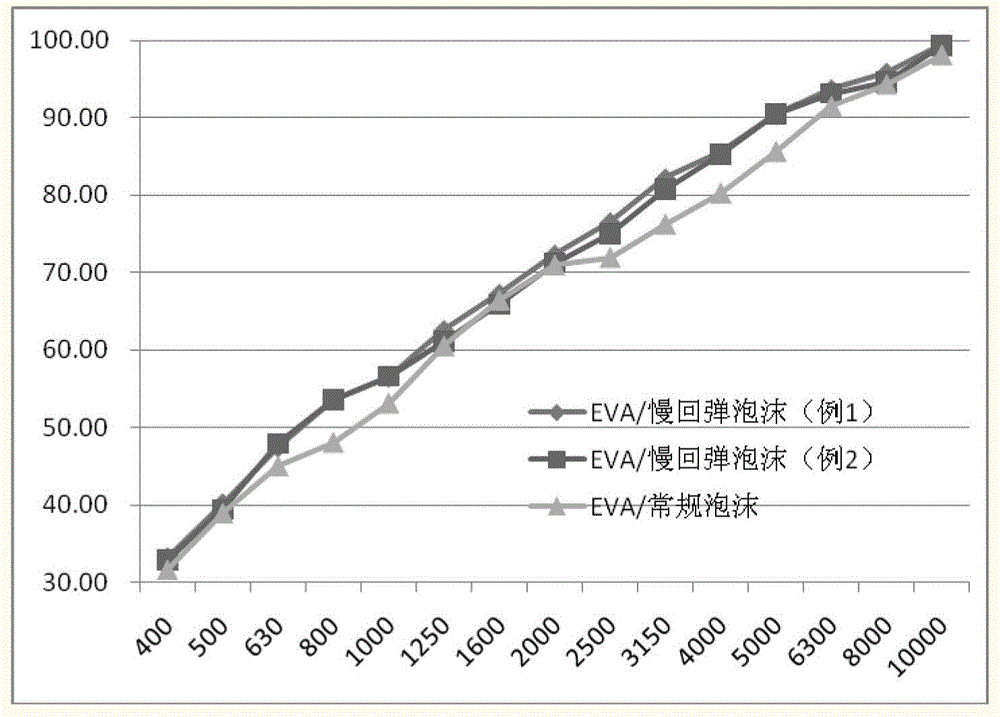

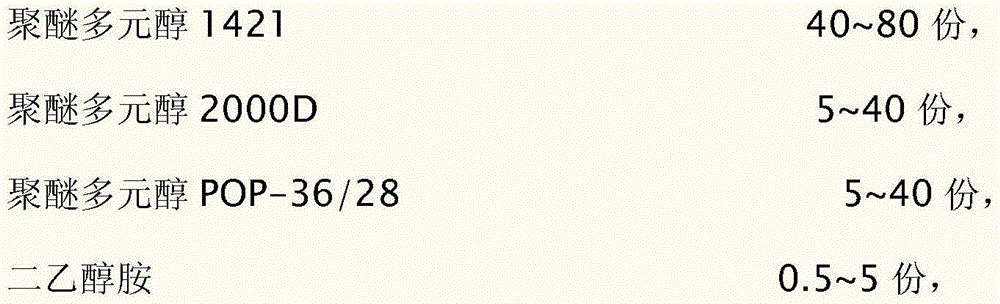

Vehicle-used slowly-springback polyurethane foam composite material

ActiveCN104149455AHigh reactivityGood physical propertiesSynthetic resin layered productsEnvironmental resistanceSilicone oil

The invention discloses a vehicle-used slowly-springback polyurethane foam composite material which is compounded from slowly-springback polyurethane foam and an ethylene-vinyl acetate copolymer. The slowly-springback polyurethane foam is prepared from following components including, by weight, an A material: 40-80 parts of a polyether polyol 1421, 5-40 parts of a polyether polyol 2000D, 5-40 parts of a polyether polyol POP-36 / 28, 0.5-5 parts of diethanolamine, 1-6 parts of water, 0.1-1.5 parts of a catalyst EF-600, 0.1-0.5 parts of a catalyst ZF-10 and 1-6 parts of a silicone oil L-580; a B material: 40-80 parts of a modified MDI. During preparation of the slowly-springback polyurethane foam, a weight usage amount ratio of the A material to the B material is 100:40-80. The vehicle-used slowly-springback polyurethane foam is high in reaction activity, is low in toxicity, is environmental-protective, is high in damp loss factor, is high in sound-insulation performance and is free of addition of a foam-forming agent.

Owner:NINGBO TUOPU GROUP CO LTD

Improved stability of polyurethane polyol blends containing halogenated olefin blowing agents

InactiveUS20140051776A1Extended shelf lifeEnhance foam characteristic of foamOther chemical processesPolymer sciencePtru catalyst

A polyol pre-mix composition includes a blowing agent having a halogenated hydroolefin, a polyol, a surfactant, a catalyst composition, and a metal salt. The metal salt may be, for example, a carboxylate, acetylacetonate, alcoholate of a metal selected from the group consisting of Zn, Co, Ca, and Mg. The metal salt may be, for example, a carboxylate and / or alcoholate of a C1-C21 straight chain or branched aliphatic monocarboxylic acid or monoalcohol, such as magnesium formate, zinc octoate, calcium octoate, cobalt octoate, and magnesium octoate, and mixtures thereof. The metal acetylacetonate may be, for example, zinc acetylacetonate, cobalt acetylacetonate, magnesium acetylacetonate, or calcium acetylacetonate. A two-part system for producing a thermosetting foam blend includes (a) a polyisocyanate and, optionally, one or more isocyanate compatible raw materials; and (b) the polyol pre-mix composition. A method for producing a thermosetting foam blend includes combining: (a) a polyisocyanate; and (b) the polyol pre-mix composition.

Owner:ARKEMA INC

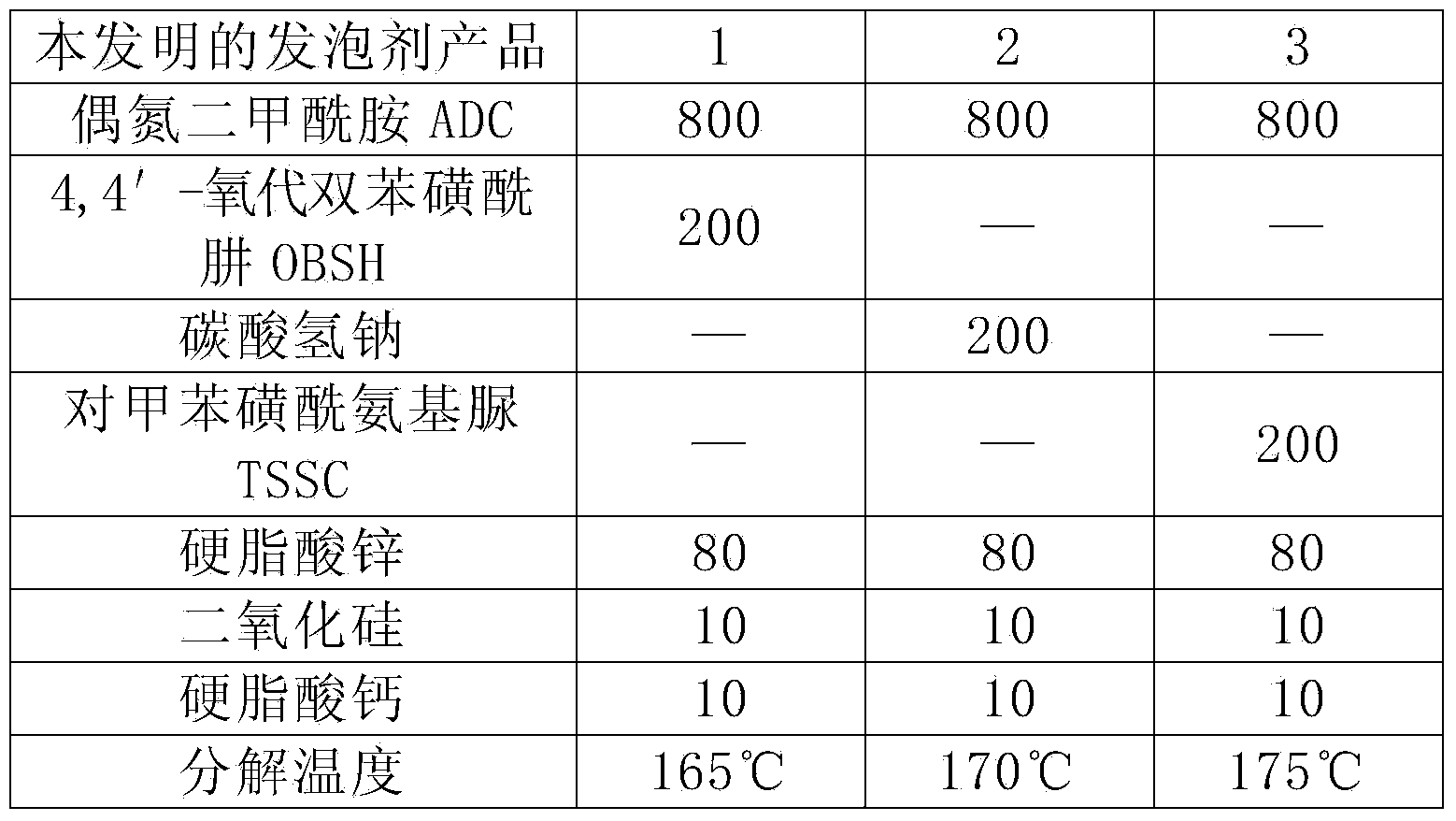

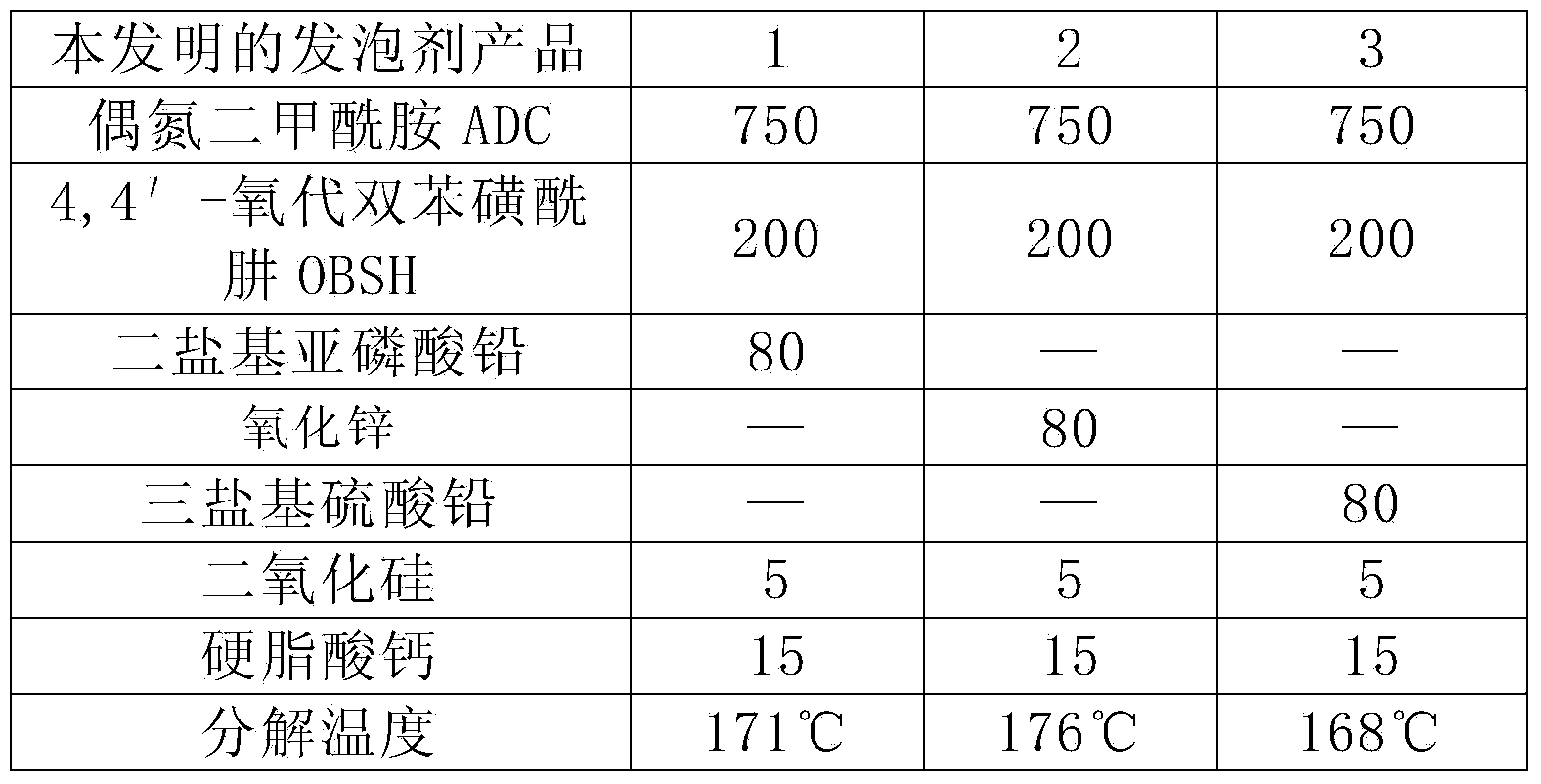

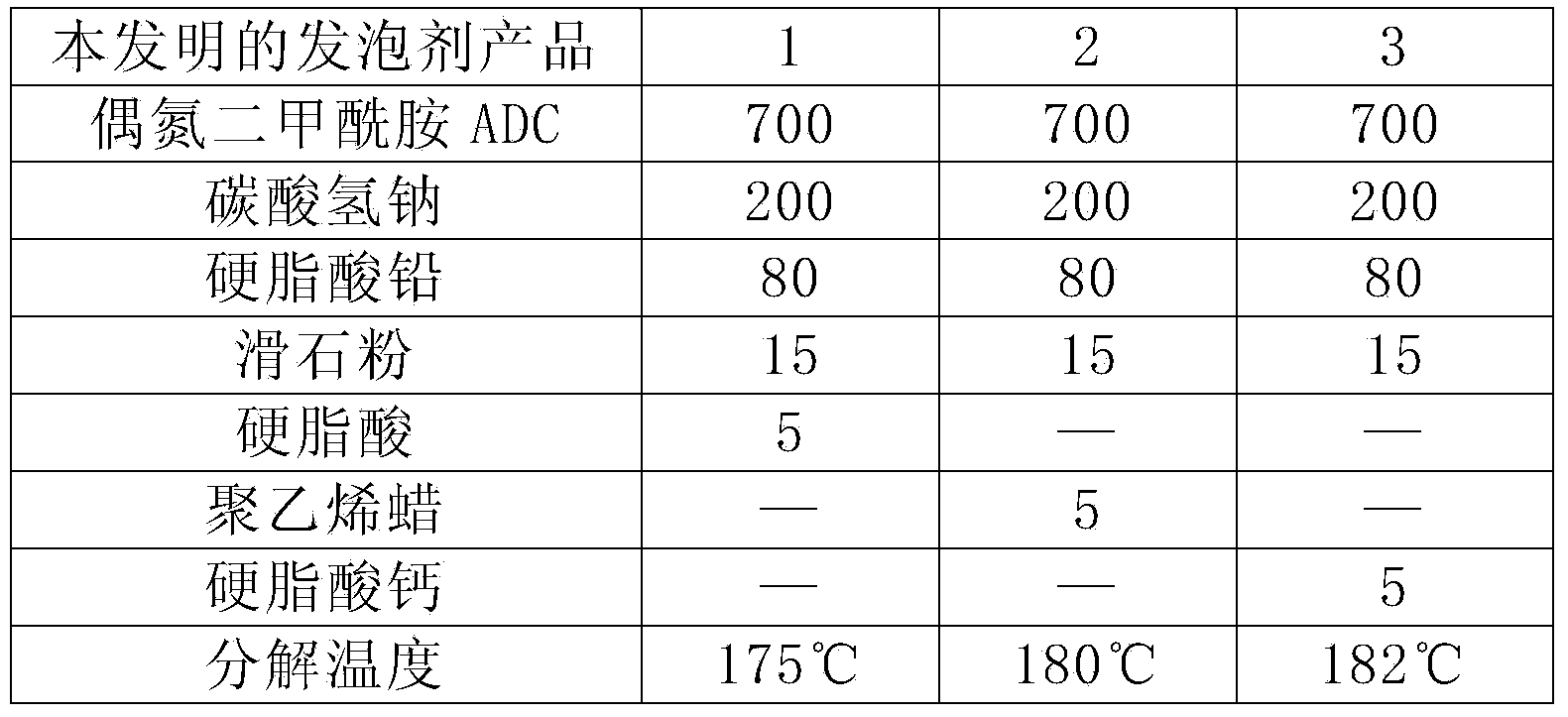

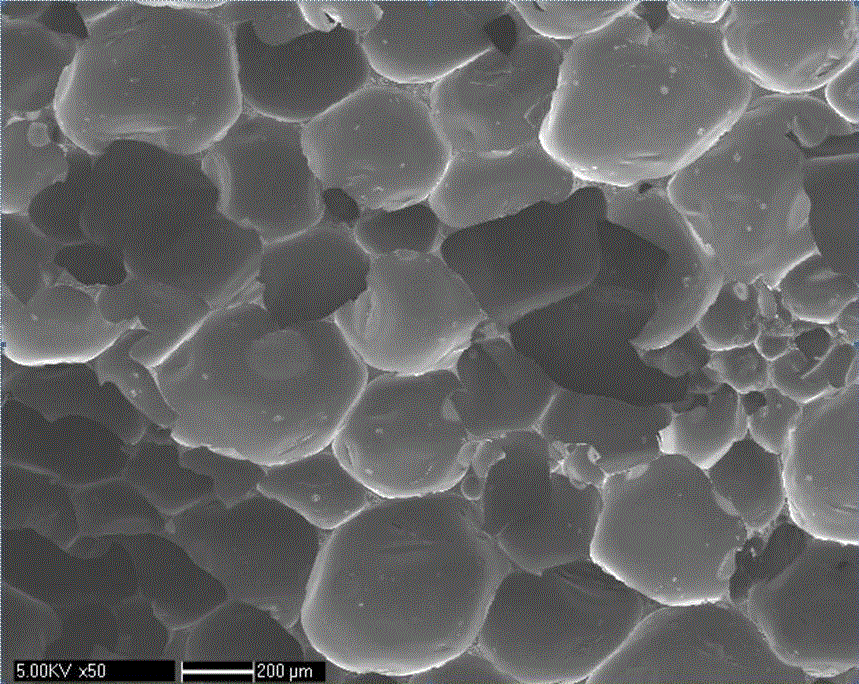

Special foaming agent for hard PVC (polyvinyl chloride) low-foaming material and preparation method thereof

The invention discloses a special foaming agent for a hard PVC (polyvinyl chloride) low-foaming material and a preparation method thereof. The special foaming agent comprises the following materials in parts by weight: 20-80 parts of azodicarbonamide (ADC), 20-80 parts of auxiliary foaming agent, 1-20 parts of activating agent, 0.2-10 parts of dispersing agent and 0.2-5 parts of processing agent. The preparation method comprises the steps: adding the dispersing agent and the processing agent in a mixer, mixing for 3-7 minutes, and sequentially uniformly mixing the ADC, the auxiliary foaming agent and the activating agent in the mixer to prepare the special foaming agent. The special foaming agent is suitable for hard PVC low-foam materials such as PVC crushing and low-foaming sectional bars, tubular products and sheets, a wood-plastics low-foaming material and the like. The special foaming agent has the positive effects that 1, the decomposition temperature is 160-190 DEG C, and is within a processing temperature range of the hard PVC low-foaming material; 2, the foaming process is short in induction period, the decomposition is performed without mutation, and the foaming process is easily controlled; 3, the hard PVC low-foaming material is used on a hard PVC low-foaming product, and has a smooth surface and has no discoloring and ageing phenomena; and 4, the special foaming agent is low in cost and good in comprehensive performance, and accords with the use requirement.

Owner:WEIFANG YAXING GRP CO LTD

Formula for producing polyurethane material with uniform bubbles and high air permeability and fabrication technology thereof

The invention relates to the field of a plastic material, and particularly relates to a polyurethane material. A formula for producing a polyurethane material with uniform bubbles and high air permeability comprises a polyurethane material, wherein the polyurethane material comprises the following components by weight percent: 20-60% of isocyanate, 50-100% of polyether polyol, 30-70% of polymer polyols, 0.05-1.0% of amine catalyst, 1.0-4.0% of water, 0.5-2.5% of silicon oil, 0.5-1.0% of antibacterial agent, 0.03-1.0% of tin, and 0.5-5.0% of other assistants. A fabrication technology of the polyurethane material with uniform bubbles and high air permeability comprises the following steps: mixing the raw materials, foaming and molding the raw materials, and cutting polyurethane foam. The technical scheme is adopted, so that nitrogen instead of air is utilized to foam the polyurethane material, so that the foamed polyurethane sponge is regular and even in bubble structure, good in air permeability, safer and more healthful, and bacterial replication is reduced.

Owner:SHANGHAI GLORY HOME TECH CO LTD

High-temperature-resistant foamed plastic composition and preparation method thereof

The invention provides a high-temperature-resistant foamed plastic composition and a preparation method thereof. The high-temperature-resistant foamed plastic composition comprises 30%-99% of cyanate ester resin, 0%-60% of epoxy resin, 0%-10% of a catalyst, 0.01%-10% of a surface active agent, 0.01%-10% of a foaming agent and 0%-40% of filler. The preparation method provided by the invention comprises the following steps: reacting cyanate ester resin with epoxy resin at a certain temperature to synthesize a prepolymer; adding the surfactant, the foaming agent, the filler and the like into the prepolymer, uniformly mixing, pouring the mixture into a die preheated to a certain temperature to be foamed, and curing, cooling and demoulding to obtain the high-temperature resistant foamed plastic composition. The high-temperature resistant foamed plastic composition prepared by adopting the method disclosed by the invention has excellent heat-resistant performance and mechanical property, and also has good dielectric property, and the requirements of thermal insulation and heat preservation, structural support and microwave absorption at a high temperature of 150 DEG C-200 DEG C are met.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

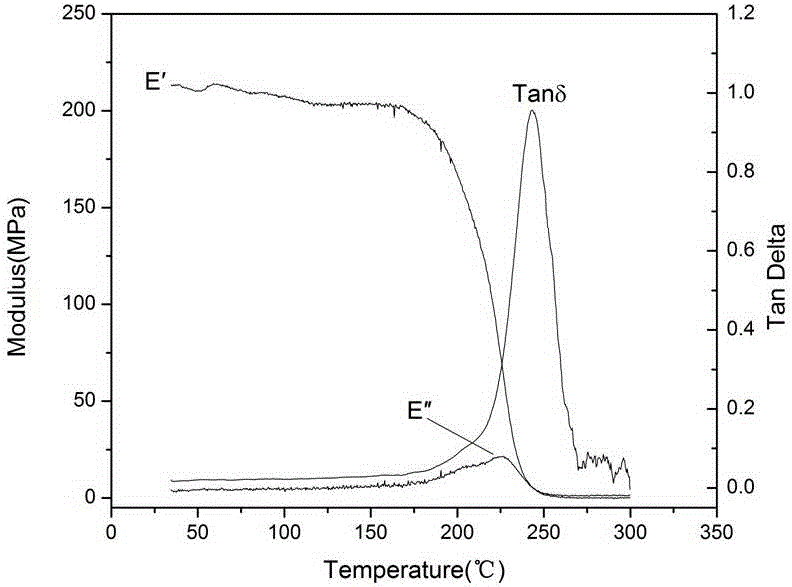

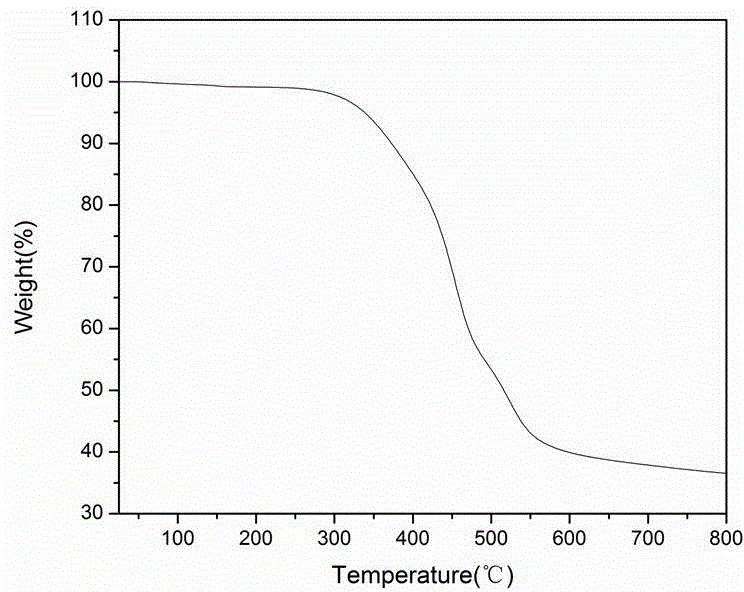

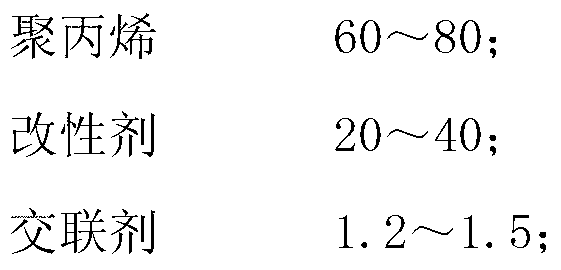

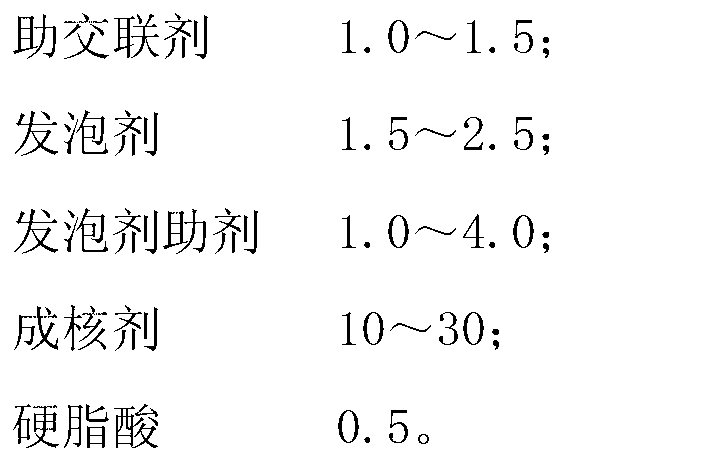

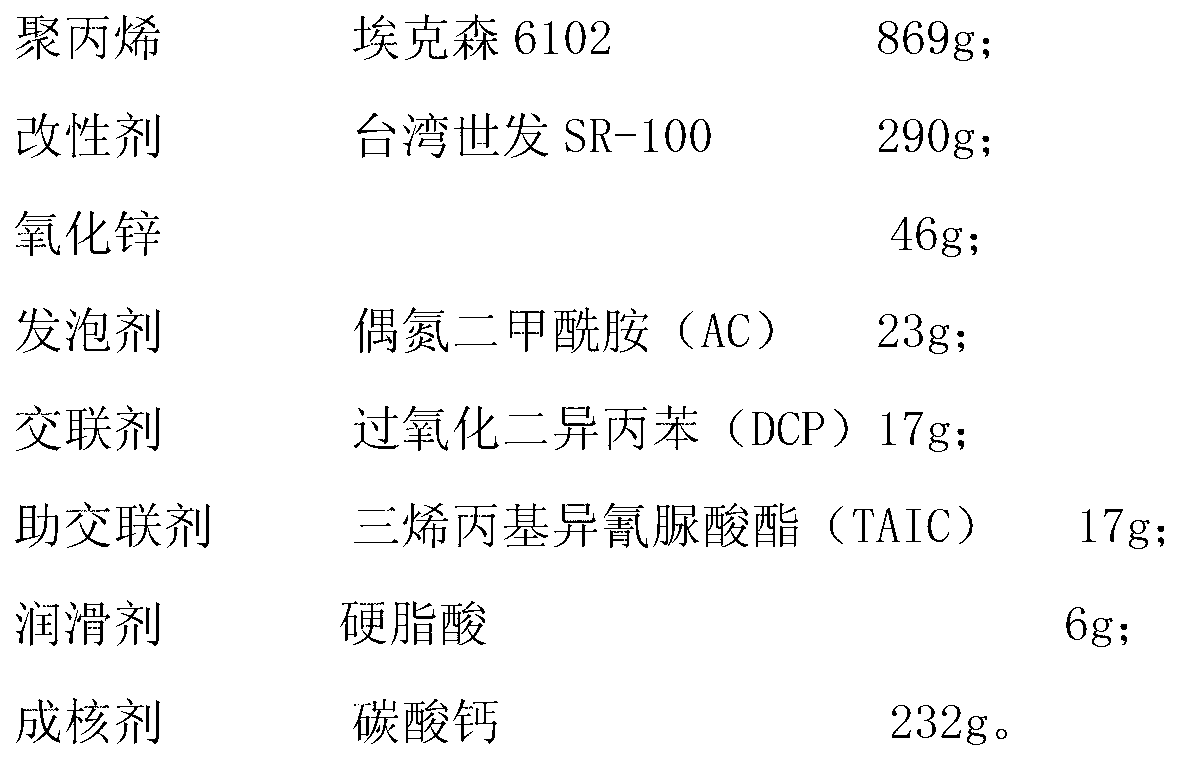

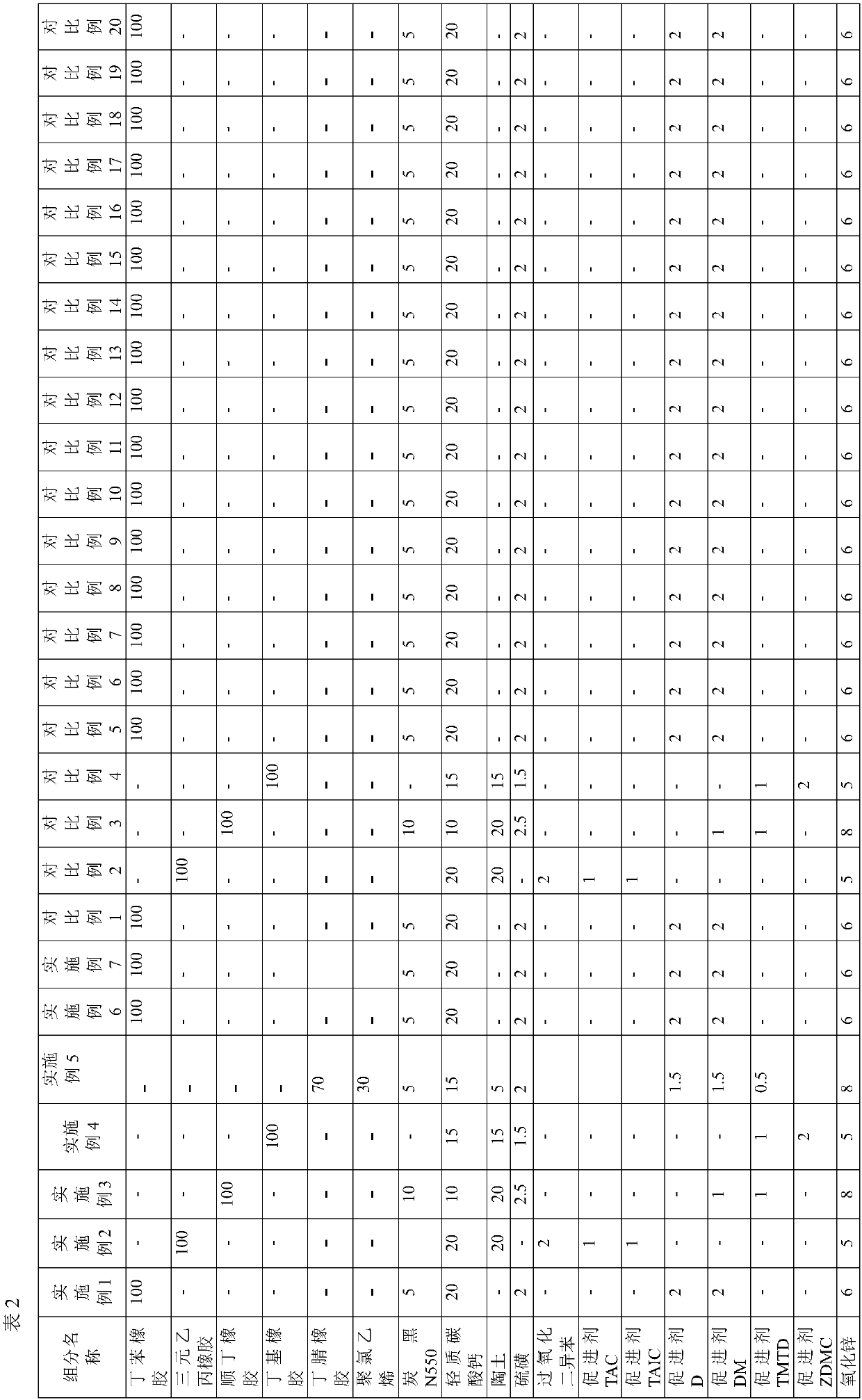

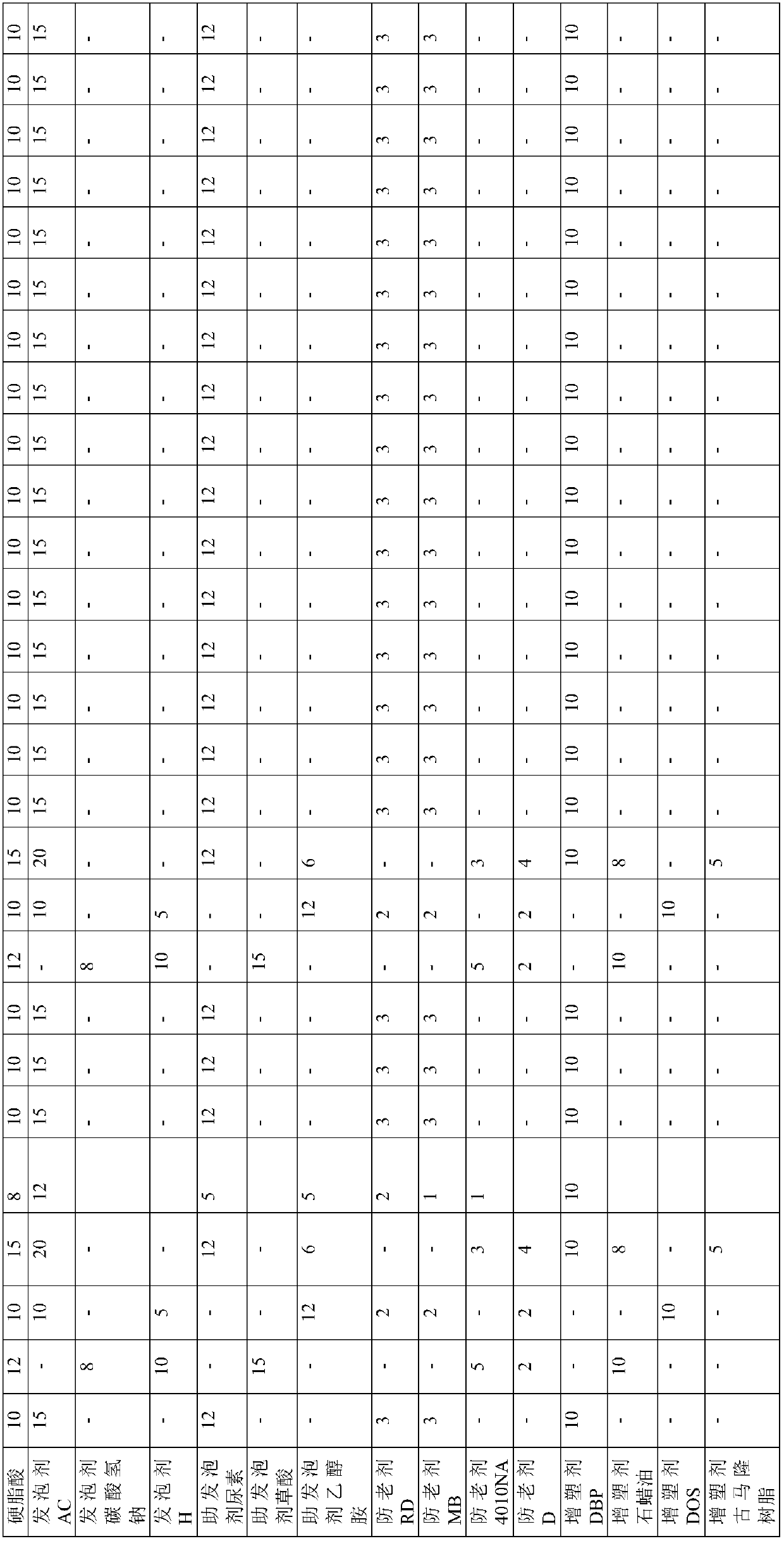

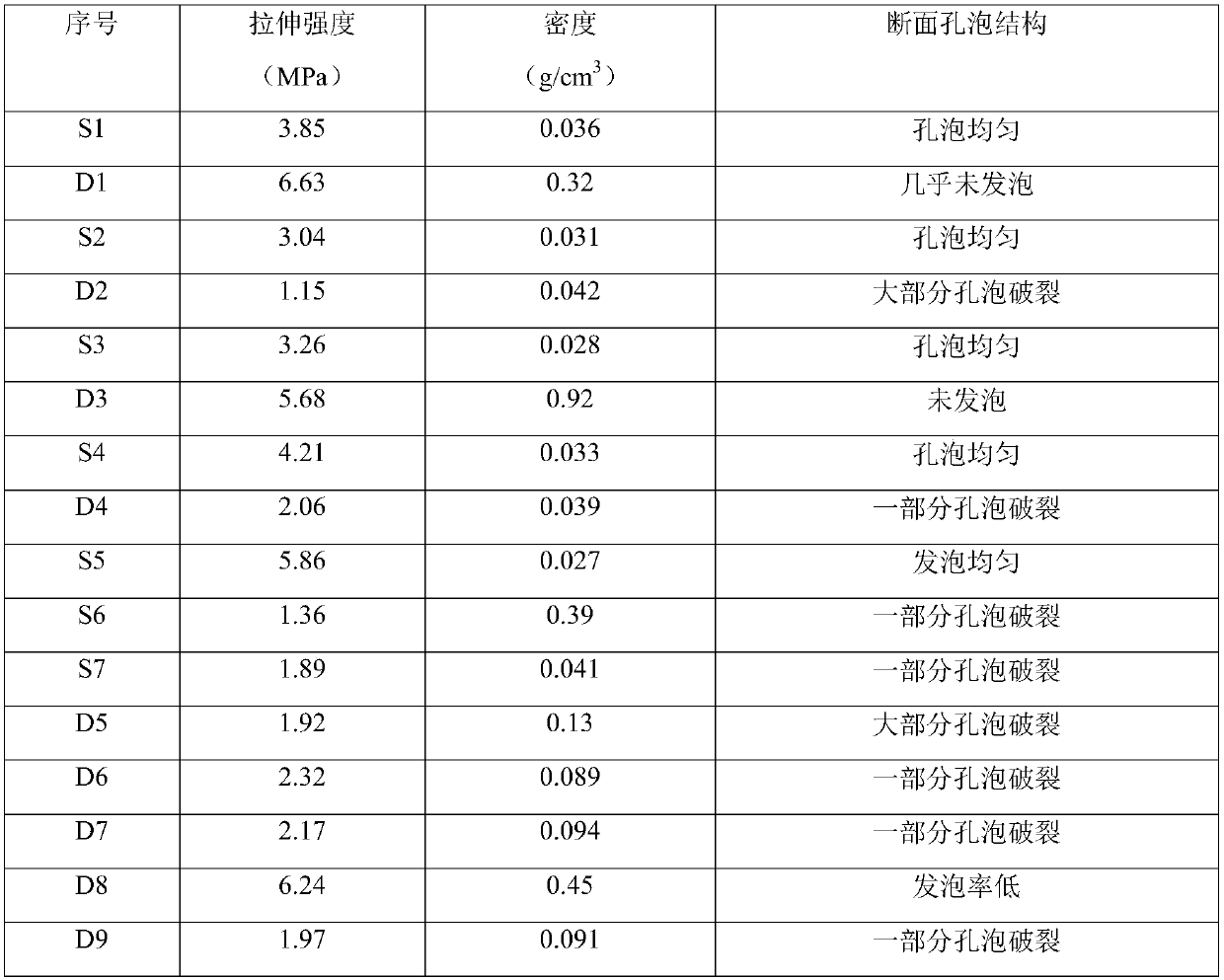

Modified micropore foaming polypropylene material and preparation method thereof

The invention discloses a modified micropore foaming polypropylene material and the preparation method thereof, and relates to a superpolymer processing method. The modified micropore foaming polypropylene material comprises the following ingredients in weight parts: 60-80 parts of polypropylene, 20-40 parts of modifier, 1.2-1.5 parts of cross-linking agent, 1.0-1.5 parts of auxiliary cross-linking agent, 1.5-2.5 parts of foaming agent, 1.0-4.0 parts of auxiliary foaming agent, 10-30 parts of nucleating agent, and 0.5 part of stearic acid. The preparation method comprises the following steps: all raw and auxiliary materials are put into an internal mixer for mixing; the mixed material is caused to pass through a two-roll open mill and is then packed in triangular package; the material is uniformly mixed; the material in sheet form is then sliced into sheets; the sheets sliced according to specification are placed into a preheated mould; the mould is closed; and the modified micropore foaming polypropylene material is obtained after pressure release and mould opening. The further cross-link foaming mould pressing method is adopted, so that the manufacture process is simple and feasible, the manufacture cost is low, and the method is suitable for popularization and application; and the structure of the bubble holes of the prepared modified micropore foaming polypropylene material is compact and uniform, and the prepared modified micropore foaming polypropylene material has a good hand feeling and good physical properties.

Owner:FUJIAN JINJIANG JINYI SHOES MATERIAL

Method for preparing hard open-cell polyimide foam

The present invention relates to a method for preparing hard open-cell polyimide foam, and belongs to the technical field of preparation of macromolecular polyimide foam materials. The method comprises the following steps: adding aromatic dianhydride into a polar solvent, and then adding fatty alcohol, so as to perform heating reaction; adding a catalyst, deionized water and a foam stabilizer, so as to obtain precursor solution; mixing the precursor solution with an end-capped reagent end-capped polyisocyanate, leaving to stand, foaming, crushing and drying, so as to obtain powder; putting the powder into a pressure vessel, and performing heating and pressurization, so as to obtain a polyimide foam material. The method has the characteristics that the solvent is small in volatile quantity and can be recycled during foam preparation, and is applied to various anhydride systems, the preparation cost is low, and mass production is easy to realize. The formed foam material has the characteristics that a foam structure is uniform, the apparent density is adjustable, the material is heat-resistant, high in strength, and drop of dregs hardly occurs.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

Vulcanized foam rubber and preparation method thereof

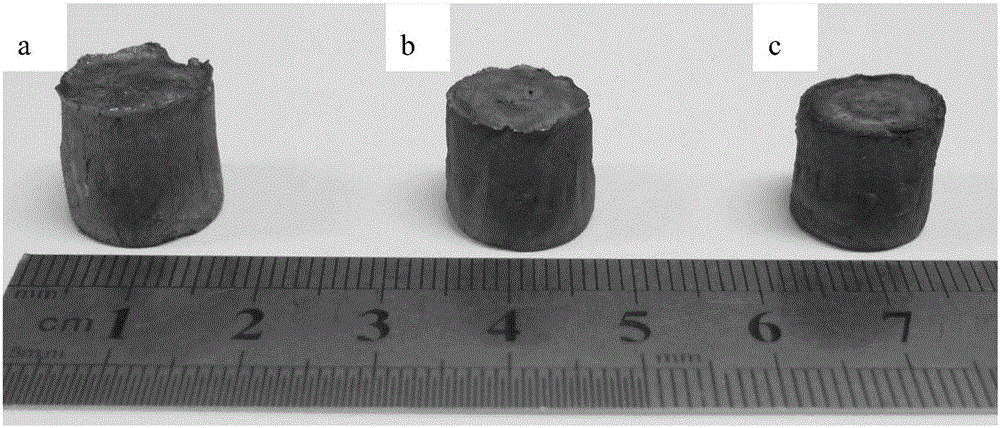

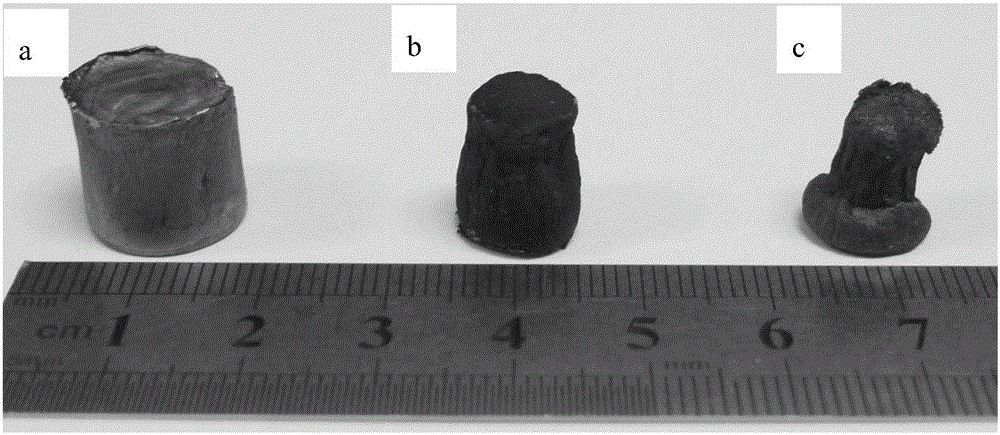

The invention relates to the field of rubber, and discloses vulcanized foam rubber and a preparation method thereof. The method comprises the following steps that (1) primary mixing is conducted on acomponent A containing a rubber base and a vulcanization activator; (2) secondary mixing is conducted on the primary mixed rubber and a component B containing a vulcanizing agent, a vulcanization accelerator and a foaming agent; (3) vulcanization is conducted on the secondary mixed rubber, wherein the vulcanization comprises three stages in sequence, the temperature of first stage vulcanization is100-170 DEG C, vulcanization pressure is 10-20MPa, and vulcanization time is 2-20min; and the second stage vulcanization is conducted under the condition that pressure of the first stage vulcanization is not changed, temperature of the second stage vulcanization is higher than the temperature of the first stage vulcanization, vulcanization time of the second stage vulcanization is shorter than that of the first stage vulcanization, the third stage vulcanization is conducted under the condition that the temperature of the second stage vulcanization is not changed, the pressure of the third stage vulcanization is lower than that of the second stage vulcanization, and the time of the third stage vulcanization is longer than the time of the second stage vulcanization. The vulcanized foam rubber prepared by the method is low in density and uniform in foam structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for manufacturing high heat conducting foam material of graphite with even apertures

This invention discloses a method for preparing graphite foam material with uniform pore sizes and high heat conductivity. The method comprises: (1) placing mesophase pitch into a high-pressure reactor, adding surfactant, mixing uniformly, vacuumizing, heating to 260-350 deg.C, pressurizing to 2-6.0 MPa, heating to 450-650 deg.C, keeping for 15 min-2 h, cooling, and exhausting to obtain pitch foam; (2) heating the pitch foam at a heating rate not higher than 1 deg.C / min to 950-1100 deg.C, and carbonizing under nitrogen protection to obtain carbonized pitch foam; (3) heating the carbonized pitch foam at a heating rate not higher than 1 deg.C / min to 2500-3000 deg.C under Ar protection, and cooling naturally to obtain graphite foam material with high heat conductivity. The obtained graphite foam material can be widely used in radiators, heat exchangers, brake pads of automobiles and planes, catalyst carriers, and gas adsorbents.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

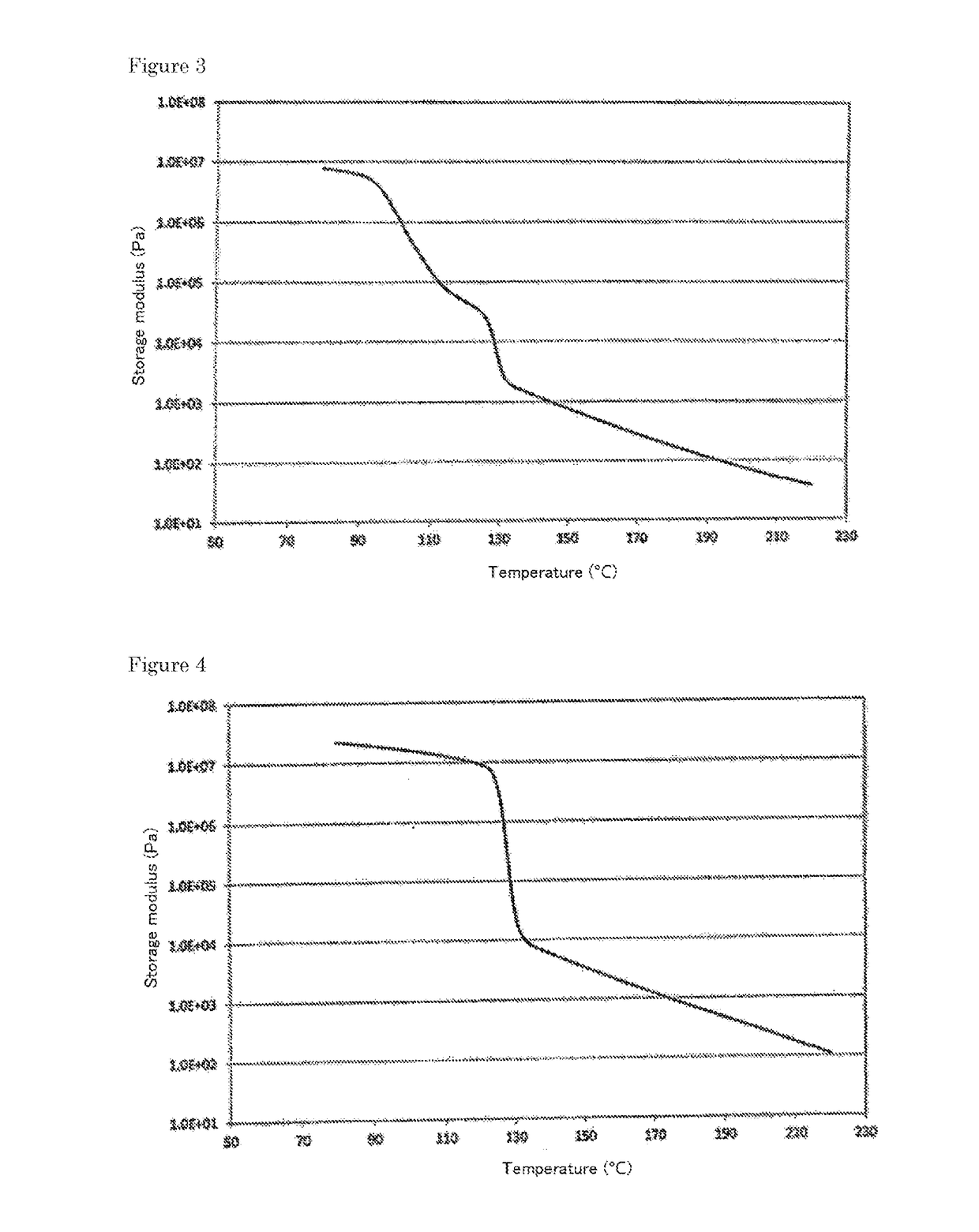

Polylactide-based blended material, preparation method thereof and method for preparing foam material from polylactide-based blended material

The invention discloses a polylactide-based blended material, a preparation method thereof and a method for preparing a foam material from the polylactide-based blended material. The mass ratio of PLA to an elastomer in main components of the blended material is (70-90):(30-10), and the mass percentage of a chain extender is 0.2-2.0% calculated according to the fact that the mass sum of PLA and the elastomer is 100%. The preparation method of the blended material comprises the following steps: mechanically mixing PLA, the elastomer and the chain extender according to the ratio to form a premix; then, placing the premix into an extruder; and reacting and carrying out melt blending to obtain the polylactide-based blended material. According to the preparation method of the foam material, the prepared polylactide-based blended material is placed in a high-pressure kettle cavity and is foamed through introducing a supercritical fluid, or the prepared polylactide-based blended material is added into an injection molding machine or extruder and is foamed through introducing the supercritical fluid. The blended material prepared by using the preparation method not only has very high toughness, but also remains the original strength of a polylactic acid material.

Owner:SOUTH CHINA UNIV OF TECH

Carbon foam, graphite foam and production processes of these

A carbon foam obtained by heat-treating a mesophase pitch whose softening point is 300° C. or less according to an elevated flow tester, whose ratio (Daromatic / Daliphatic) of the absorption intensity of an aromatic C-H stretching vibration, measured with FT-IR, to the absorption intensity of an aliphatic C-H stretching vibration, measured with FT-IR, is 4.0 or less and whose optically anisotropic content is at least 80%, a graphite foam obtained by heat-treating the carbon foam recited above at a temperature of 2,000° C. or higher and production processes of these.

Owner:MITSUBISHI GAS CHEM CO INC

Epoxy resin modified polyisocyanurate high temperature-resistant rigid foamed plastic and preparation method thereof

InactiveCN103059242AUniform cell structureImprove thermal stabilityThermal insulationIsocyanate compound

The invention discloses an epoxy resin modified polyisocyanurate high temperature-resistant rigid foamed plastic and a preparation method thereof. The high temperature-resistant rigid foamed plastic comprises a modified mixture and isocyanate, wherein the mass ratio of the modified mixture to the isocyanate is 1:(1.10-1.15); and the modified mixture comprises the following components by mass percent: 30%-35% of polyether glycol, 22%-27% of epoxy resin, 0.5-5% of foam stabilizer, 2-6% of catalyst and 32%-40% of foaming agent. The epoxy resin modified polyisocyanurate high temperature-resistant rigid foamed plastic is used for ideal uniform foam structures, and has excellent thermal stability at high temperatures, good product brittleness and thermal insulation performance, and excellent sound absorption performance and flame retardance.

Owner:JIANGSU KETAI NEW HEAT INSULATION MATERIAL

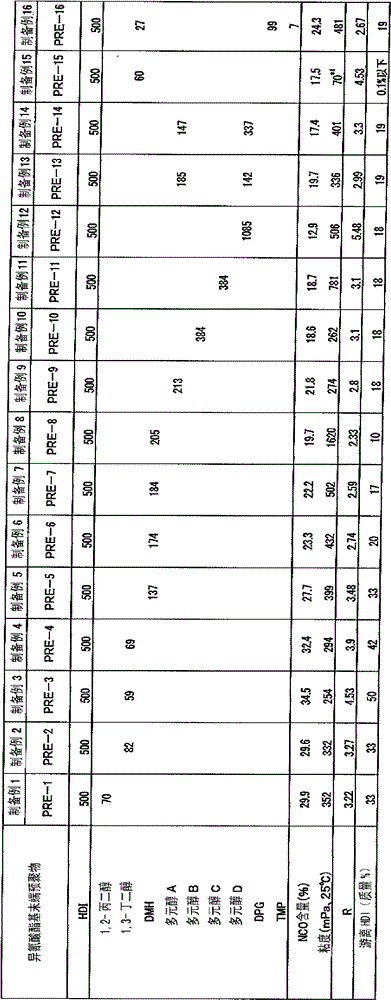

Flexible polyurethane?foam and manufacturing method thereof

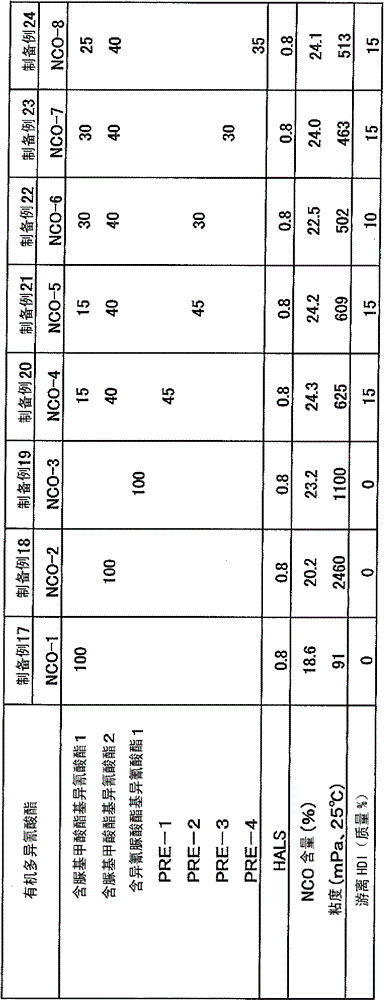

InactiveCN102746485AUniform cell structureExcellent discoloration resistanceAbsorbent padsPackaging toiletriesAllophanePolyol

The invention provides a yellowing-proof flexible polyurethane?foam and a manufacturing method thereof. The manufacturing method of the flexible polyurethane?foam is a manufacturing method allowing reaction of an organic polyisocyanate (A), a polyalcohol (B), a catalyst (C), a foaming agent (D) and a foam stabilizer (E) to form and to be solidified, so as to obtain the flexible polyurethane?foam. The manufacturing method is characterized in that the organic polyisocyanate (A) is mixture of the following substances: an allophanate group-containing organic polyisocyanate composition (A1) which is generated by a monohydric alcohol and an aliphatic and / or alicyclic diisocyanate, an allophanate group-containing organic polyisocyanate composition (A2) which is generated by a hydroxyl group-containing compound having more than two hydroxyl groups and an aliphatic and / or alicyclic diisocyanate, and an organic polyisocyanate compound (A3) which is generated by reaction of an aliphatic and / or alicyclic diisocyanate and a polyalcohol component (a1).

Owner:NIPPON POLYURETHANE IND CO LTD

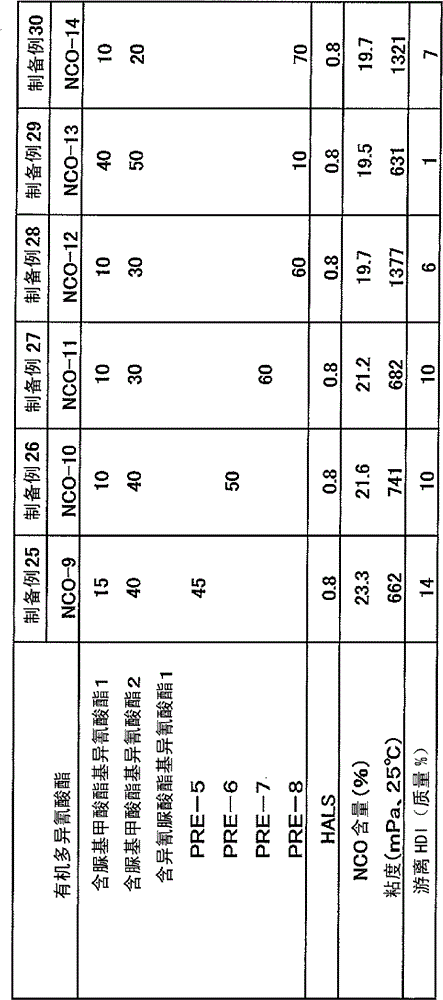

Low-density polypropylene bead foam as well as preparation method and application thereof

The invention belongs to the technical field of microporous plastic preparation, and particularly relates to low-density polypropylene bead foam as well as a preparation method and application thereof. The invention provides a method for preparing low-density polypropylene bead foam through extrusion foaming based on coupling modification of ultra-high molecular weight polyethylene and a nano carbon material. The preparation method comprises the following steps: mixing PP, UHMWPE and a nano carbon material in proportion, and then injecting a physical foaming agent into the mixture; fully and uniformly mixing the materials in a double-screw extruder, extruding the mixture, enabling the extruded mixture to sequentially flow through a static mixer, a gear pump, a melt cooler, an extrusion dieand the like which are arranged at the downstream of the double-screw extruder for extrusion foaming, and carrying out underwater pelletizing and drying to obtain the PP bead foam. The PP bead foam prepared by the method is low in density, uniform and full in appearance, small in shrinkage, uniform in cell structure, low in aperture ratio and easy for later steam molding.

Owner:福建鑫瑞新材料科技有限公司

Preparation method of rigid polyimide foam material

The invention relates to a hard polyimide foam material and a preparation method thereof, and belongs to the technical field of preparation of high-molecular polyimide foam materials. The preparationmethod comprises the steps of adding an aromatic dianhydride into a tetrahydrofuran / fatty alcohol mixed solvent, and conducting heating to dissolve the aromatic dianhydride; after the solution is transparent, adding an aromatic diamine for reaction to form a foam precursor solution, then adding a foam stabilizer and a foaming aid, and conducting uniform mixing; placing the solution in a drying oven to remove the solvent, and then raising the temperature to carry out primary foaming; and carrying out mold pressing on a primary foamed product to a compact state, further raising the temperature,and carrying out secondary foaming to obtain the polyimide foam. The method has the characteristics of low preparation cost, rich candidate raw materials, easiness in realizing large-scale productionand the like; and the prepared foam material has the characteristics of being uniform in foam structure, adjustable in apparent density, high in compressive strength, high in closed cell rate and almost free of slag falling.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +2

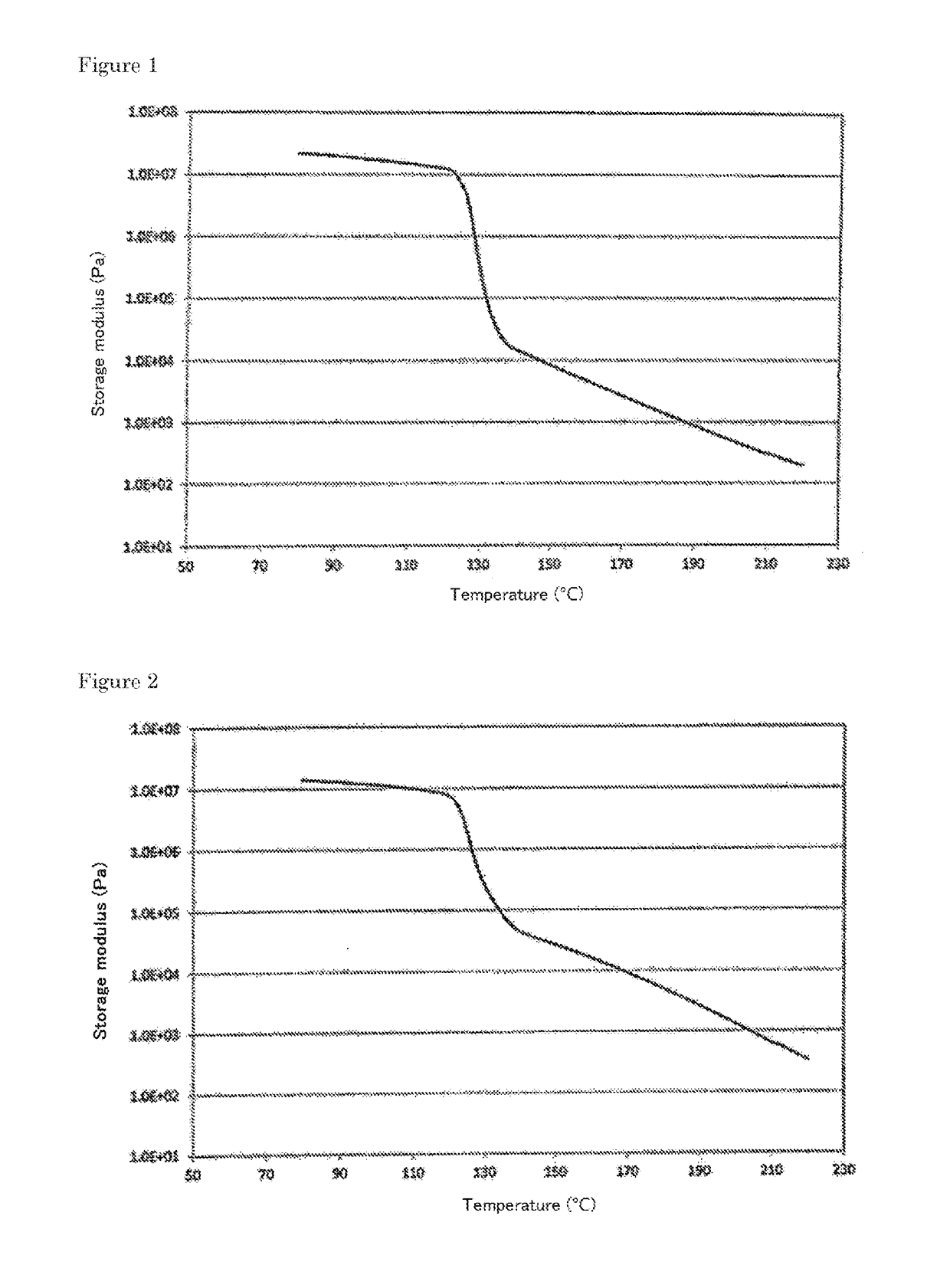

Insulating foam composition

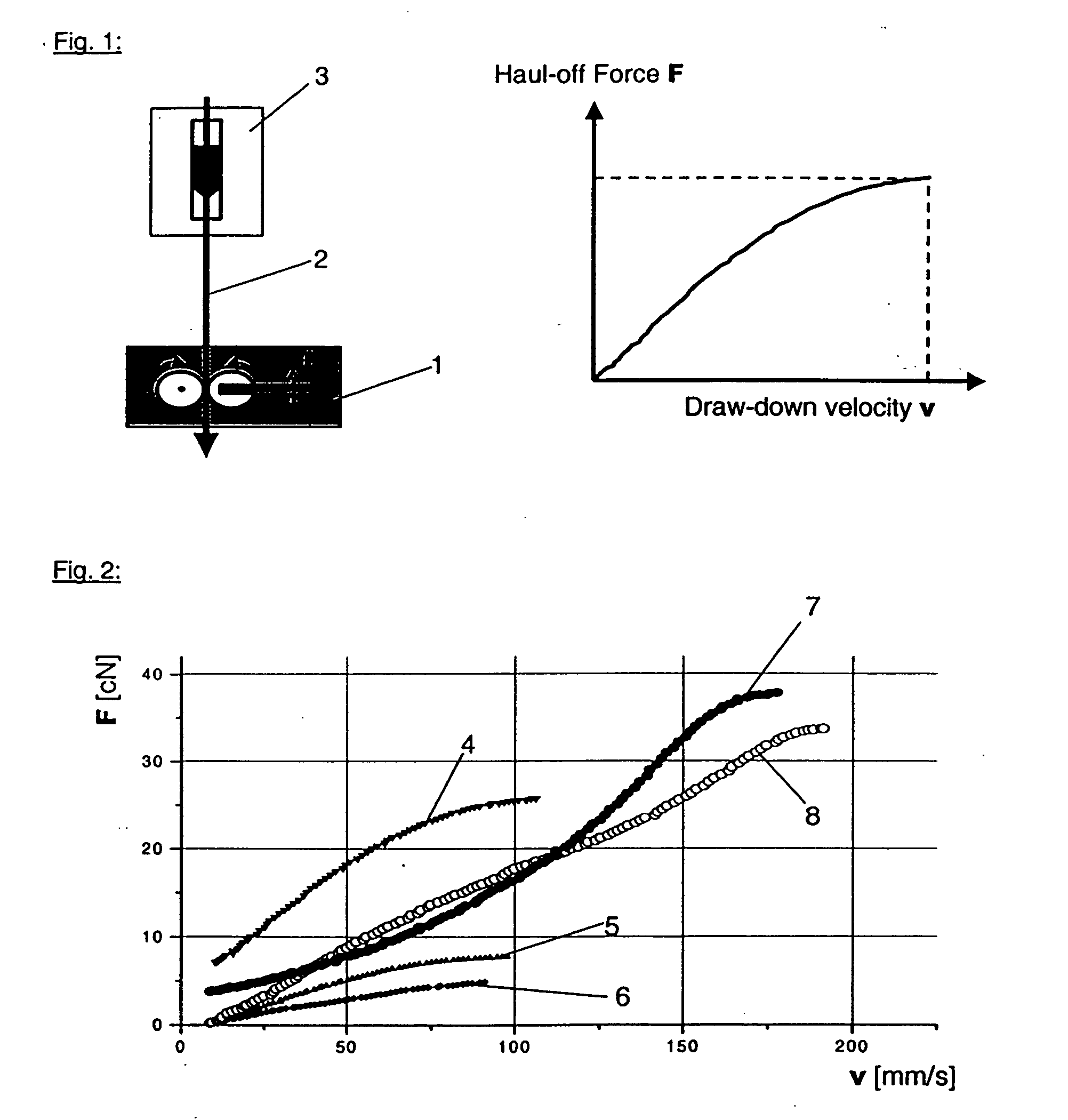

InactiveUS20040242716A1Good electrical propertiesImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesImidePolymer science

Insulating foam composition for insulation on communication cables, contains 20-95 wt % of an unmodified propylene polymer, having a melt index of 0.1 to 10 g / 10 min at 230° C. / 2.16 kg; and 5-80 wt % of a modified propylene polymer, with a propylene content of up to 100 wt %, and a melt index of 0.05 to 10 g / 10 min at 230° C. / 2.16 kg. The unmodified propylene polymer is a propylene homopolymer; a propylene copolymer of propylene and ethylene or an alpha-olefin; a polyolefin mixture containing a crystalline copolymer of propylene and ethylene or an alpha-olefin, and an elastic copolymer containing ethylene and propylene or an alpha-olefin; or an amorphous, non-isotactic propylene polymer such as a propylene homopolymer, a propylene copolymer containing propylene and an alpha-olefin. The modified propylene polymer is a polypropylene modified by reaction with a bismaleimido compound, ionizing radiation, or a peroxide.

Owner:BOREALIS GMBH

Amide elastomer foam particles, method for producing same, foam molded body and method for producing foam molded body

PendingUS20170283555A1Improve recoverabilityIncrease elasticityMaterial heat developmentElastomerHardness

Owner:SEKISUI PLASTICS CO LTD

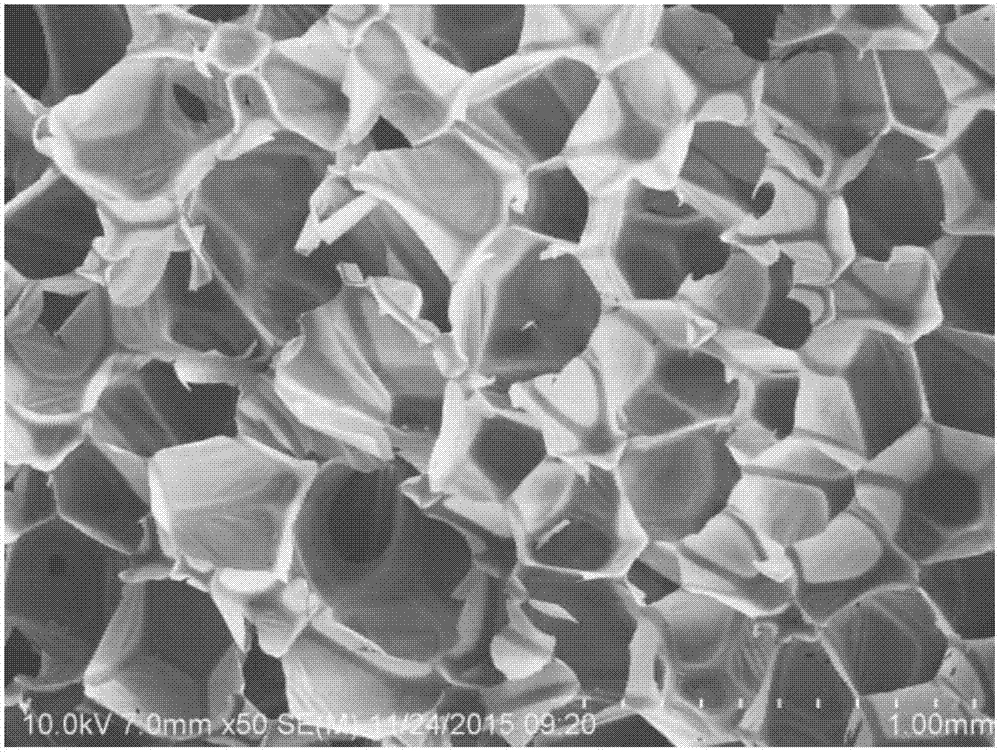

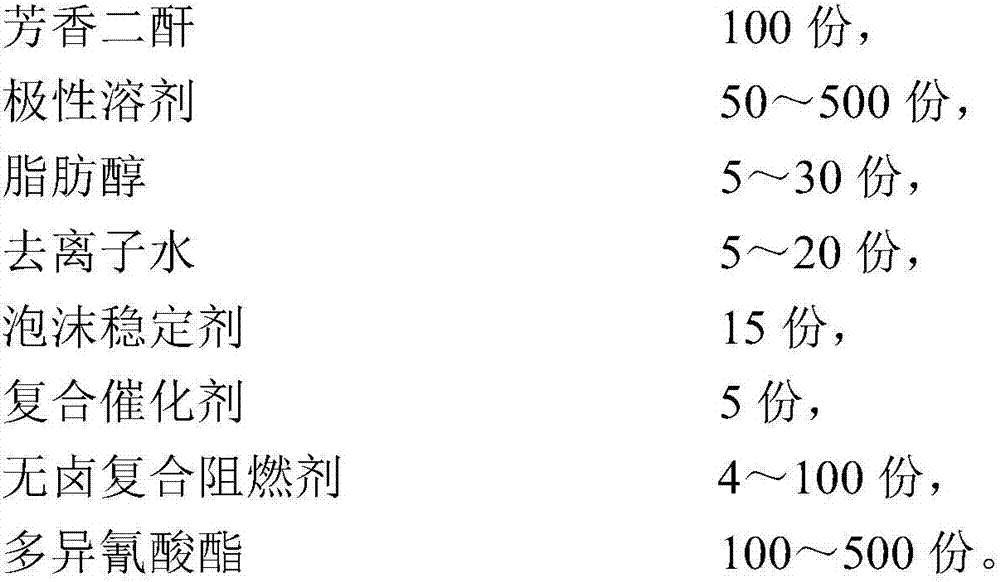

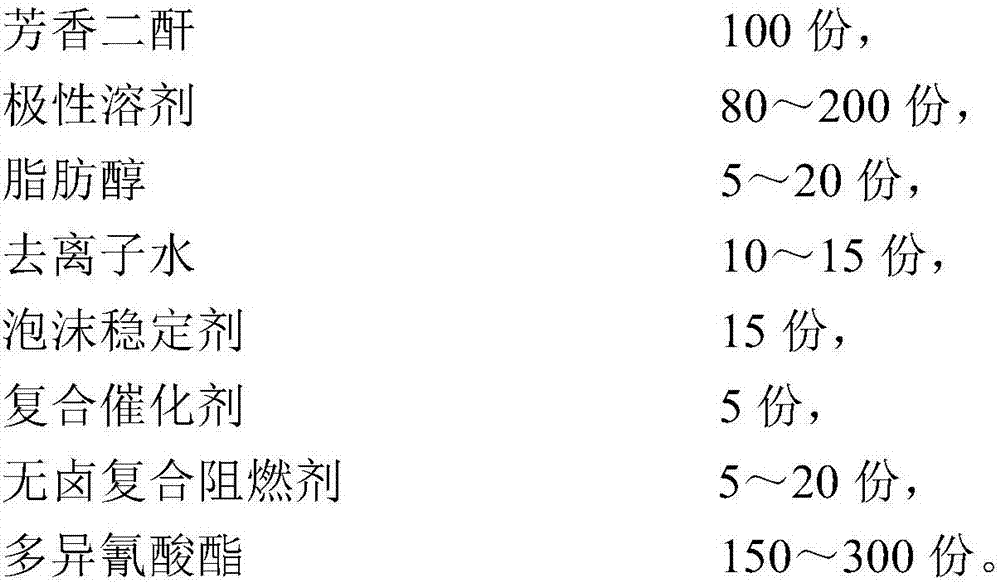

Halogen-free and flame-retardant composite polyimide foam material and preparation method thereof

The invention discloses a halogen-free and flame-retardant composite polyimide foam material and a preparation method thereof. The foam material is prepared from raw materials in parts by weight as follows: 100 parts of aromatic dianhydride, 50-500 parts of a polar solvent, 5-30 parts of fatty alcohol, 5-20 parts of deionized water, 15 parts of a foam stabilizer, 5 parts of a composite catalyst, 4-100 parts of a halogen-free composite flame retardant and 100-500 parts of polyisocyanate. The preparation method comprises the steps as follows: aromatic dianhydride is heated in the polar solvent to react with fatty alcohol; the deionized water, the foam stabilizer, the composite catalyst and the halogen-free composite flame retardant are added, and a suspension is obtained; finally, polyisocyanate is added, foaming and vacuum heating curing are performed, and the flame-retardant polyimide foam material is obtained finally. The prepared foam material has the characteristics of low density, uniform pore size distribution, excellent mechanical property, heat resistance and flame-retardant and smoke-suppression performance and the like, and the requirement for the polyimide foam material used in aerospace, navigation and other high-end fields can be met.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Refuse lac chain-extended modification powder and preparation method thereof

The invention discloses a refuse lac chain-extended modification powder, which comprises the following compositions in parts by weight: 100 parts of refuse dehydrated lac and 5-13 parts of multi-epoxy compound chain extending agent; by adopting macromolecular multi-functional epoxy compounds as chain extending agents, the chain extension and / or crosslinking modification reaction can be realized by performing heating reaction to carried epoxy groups with shelloic acid in the refuse lac or carboxyl and / or hydroxyl in the condensation compounds, so that the molecular weight can be increased, and further the purpose of improving the melting point of the refuse lac and increasing the relative viscosity can be achieved, the refuse lac chain-extended modification powder with the melting point ranging from 75 DEG C to 104 DEG C can be prepared, the powder can keep the dissolvability in ethanol and aqueous alkali solution while the melting point and the relative viscosity are remarkably increased, thus providing physical basis for the follow-up use of the refuse lac, and being capable of promoting the recycling of the refuse lac.

Owner:KUNMING UNIV OF SCI & TECH

Blowing agents, foam premixes and foams containing halogenated olefin blowing agent and adsorbent

InactiveUS20130210946A1Reduced stabilityReduce contentOrganic chemistryPolyisocyanurateBlowing agent

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof. More particularly, the invention relates to closed-celled, polyurethane and polyisocyanurate foams and methods for their preparation. Preferably, the foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a catalyst and an adsorbent material.

Owner:HONEYWELL INT INC

Low-cost flame-retardant polyimide heat insulation foam and preparation method and application thereof

The invention discloses low-cost flame-retardant polyimide heat insulation foam and a preparation method and application thereof. The preparation method comprises the following steps: S1, mixing a phosphorus-based liquid flame retardant and a polyol surfactant, adding a catalyst, and conducting an ester exchange reaction to synthesize a phosphorus-containing polyol flame retardant; S2, mixing a pyromellitic diester solution, a foam stabilizer, a compound catalyst and a foaming agent to obtain a foaming white material; S3, stirring and mixing the phosphorus-containing polyol flame retardant andisocyanate, and carrying out a room-temperature prepolymerization reaction to obtain a phosphorus-containing foaming black material; S4, stirring and mixing the foaming white material and the foamingblack material to a uniform state at a high speed to obtain foaming slurry; and S5, pouring the foaming slurry into an open mold, carrying out a free foaming molding process to obtain a polyimide foam intermediate, and curing the foam intermediate after the foam intermediate is shaped. The obtained polyimide foam has good flame retardant property and can improve safety performance and heat insulation performance, so that the polyimide foam can be used for preparing a wall heat insulation material.

Owner:HARBIN ENG UNIV

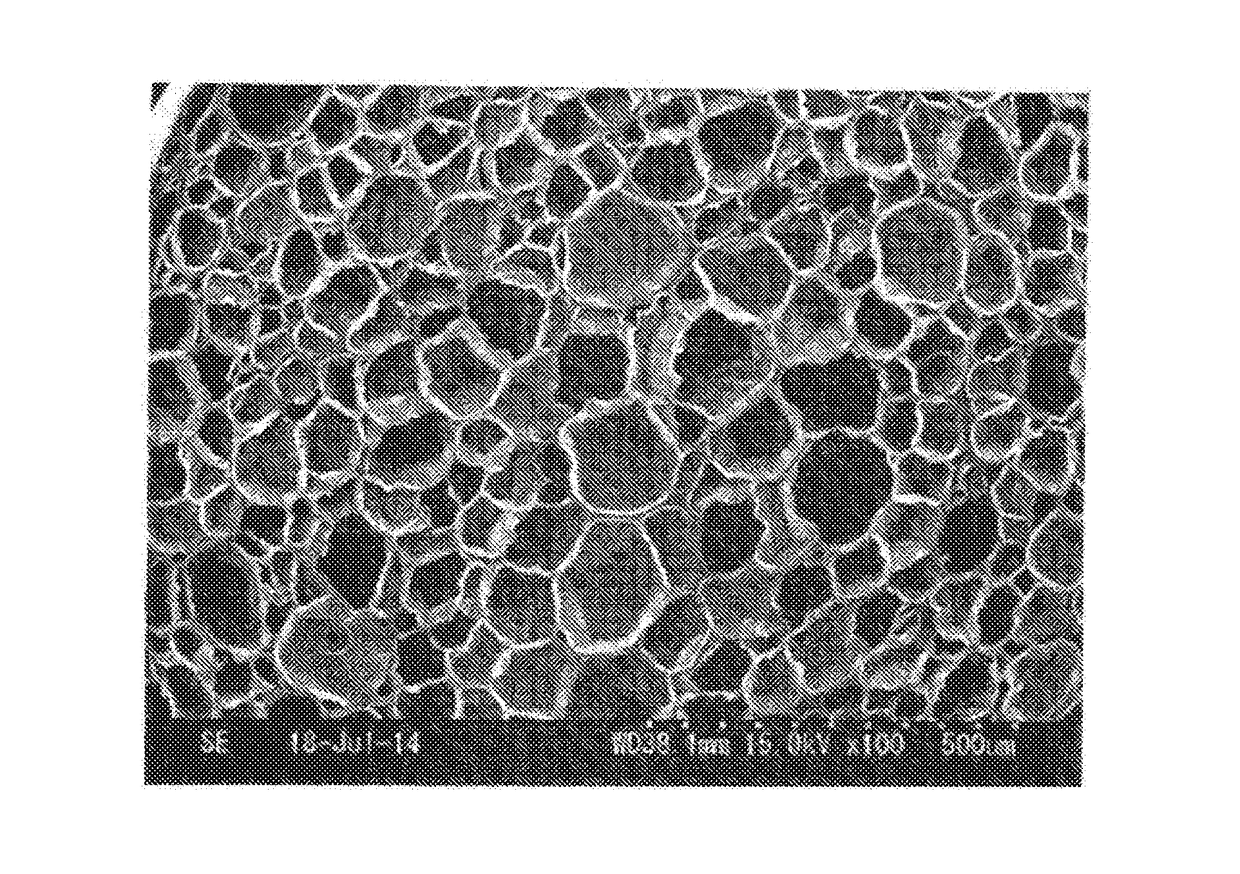

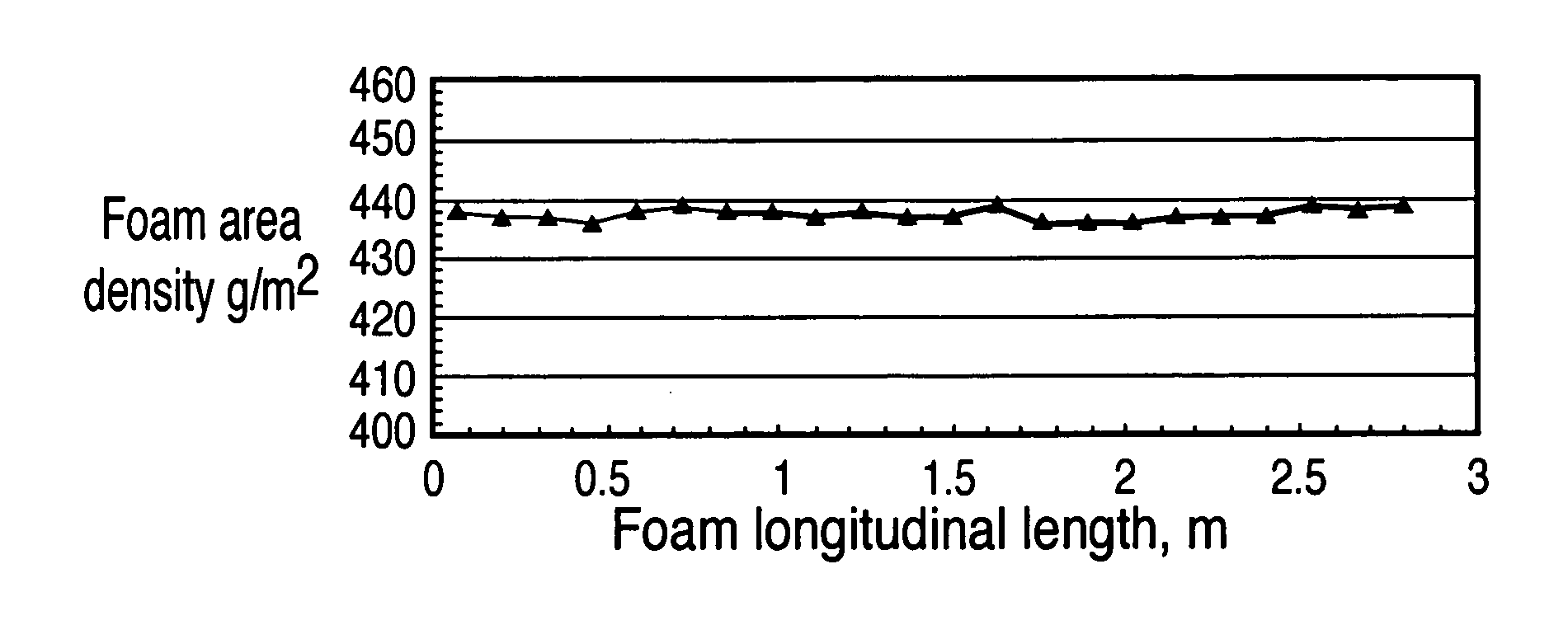

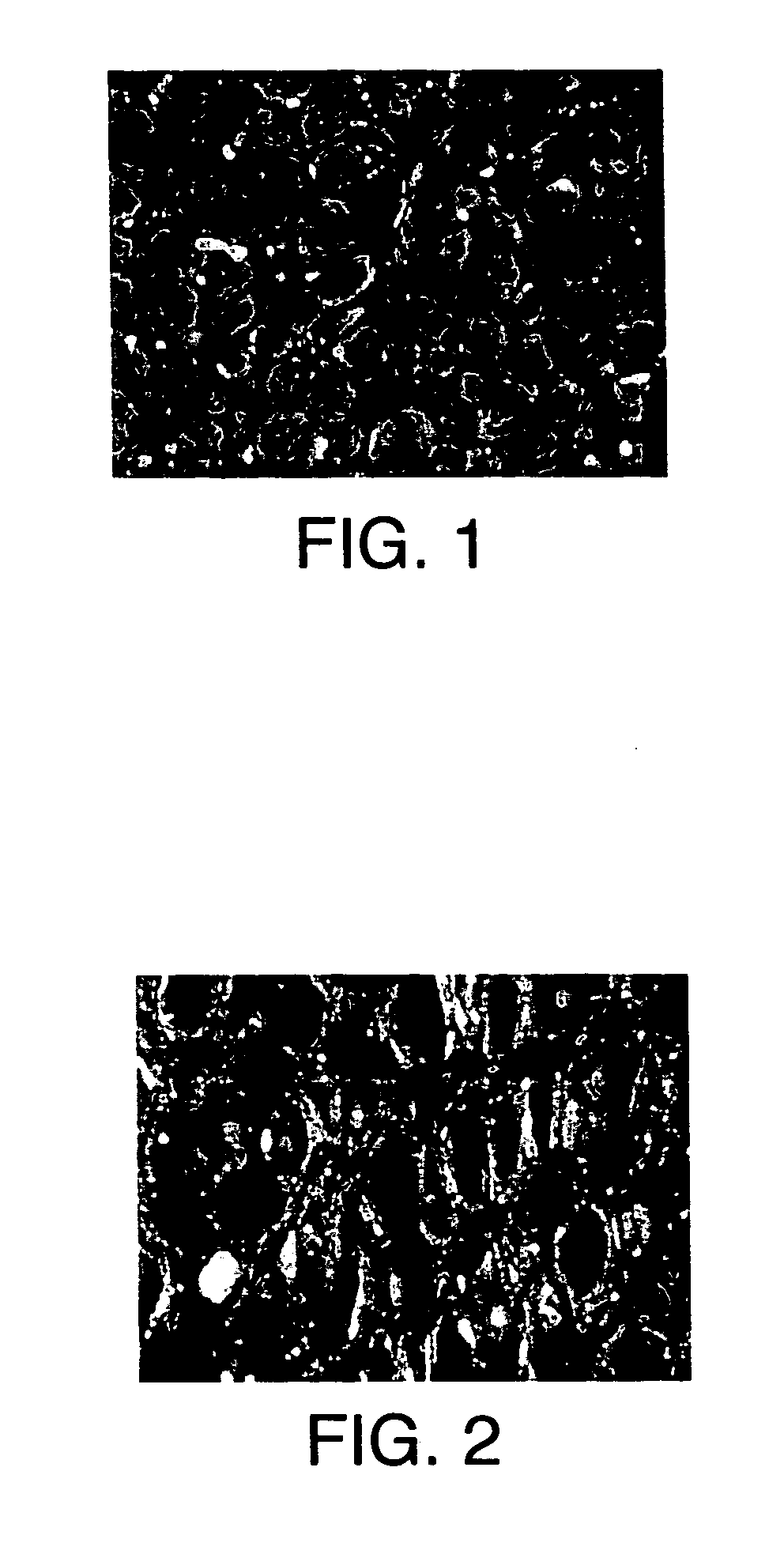

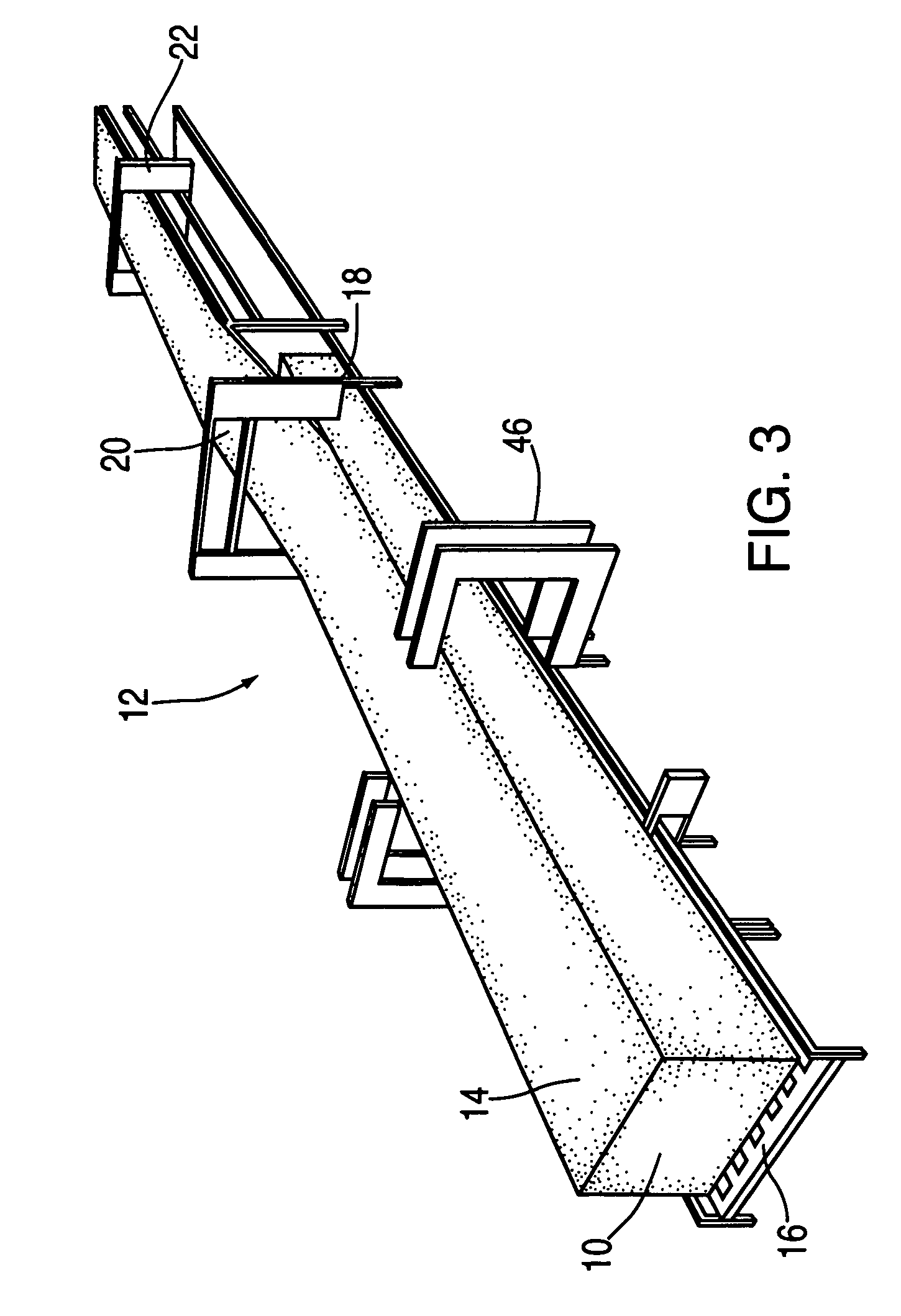

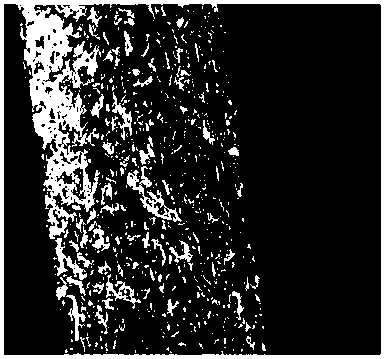

Process for producing metal foams having uniform cell structure

InactiveUS20070051636A1Increase effective lengthUniform cell structureCell electrodesVacuum evaporation coatingReticulated foamCell wall

A method for producing porous metal plated polymeric foam having uniform pore properties. Polymeric foam buns are horizontally cut along a longitudinal surface thereby lifting off a foam sheet. The sheet is spooled and then reticulated to remove any remaining cell walls and to round off the internal pore struts to enlarge the openings between the adjacent cells. The reticulated foam sheet is unwound and then plated. Slabs may be attached end to end and loop slitted and then reticulated. The resulting plated uniform foam provides a superior substrate for battery plaques and other applications.

Owner:INCO

Micro foamed nylon material for automobile engine covers and preparation method of micro foamed nylon material

The invention relates to a nylon material and a preparation method thereof, in particular to a micro foamed nylon material for automobile engine covers and a preparation method of the micro foamed nylon material. The material of the present invention comprises the following compositions in parts by weight: 60 to 80 parts of nylon, 5 to 25 parts of glass fiber, 0 to 15 parts of filler, 0.3 to 1 part of tackifier, 0.2 to 0.6 part of anti-hydrolysis agent, 0.5 to 5 parts of foaming agent, 2 to 10 parts of foaming auxiliary agent, 0.2 to 0.5 parts of lubricant, and 0.2 to 0.5 parts of stabilizer.The micro foamed nylon material of the invention has the characteristics of high cell density and good apparent quality. An automobile engine cover product prepared from the material has the characteristics of high rigidity, good dimensional stability, high yield, etc.; under the circumstance that the overall product weight loss is over 18%, the strength retention is more than 88%; moreover, the product also has good long-term thermal aging performance, which meets the requirements of long-term thermal oxygen ageing of a host plant at 150 DEG C for 1000 hours; and in addition, the product process is easy to industrialize.

Owner:NANJING JULONG SCI&TECH CO LTD

Conductive fluorinated silicone rubber foam composite material as well as preparation method and application thereof

ActiveCN113150358AWell mixedEnvironmentally friendly manufacturing processMaterial analysis by electric/magnetic meansOrganic solventFoaming agent

The invention discloses a conductive fluorinated silicone rubber foam composite material, a preparation method thereof and application of the conductive fluorinated silicone rubber foam composite material in the field of gas-sensitive detection. The preparation method comprises the following steps: ultrasonically dispersing carbon conductive particles in an organic solvent which is volatile at normal temperature to obtain conductive particle dispersion liquid; stirring perfluorosilicone oil, hydrogen-containing fluorosilicone oil and conductive particle dispersion liquid in an organic solvent until the organic solvent is completely volatilized, then adding a foaming agent and an inhibitor, performing uniform mixing to obtain a component A, and uniformly mixing perfluorosilicone oil and a platinum catalyst to obtain a component B; mixing the component A and the component B, performing uniform stirring, reacting at room temperature for 5-30 minutes, and crosslinking and curing the obtained product at 50-125 DEG C for 10-60 minutes to obtain the conductive fluorinated silicone rubber foam composite material.

Owner:HANGZHOU NORMAL UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com