Modified micropore foaming polypropylene material and preparation method thereof

A polypropylene material and microcellular foaming technology, which is applied in the field of polymer processing, can solve problems such as high cost and increase production equipment, and achieve the effects of low production cost, improved melt strength, and dense cell structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of modified microcellular foamed polypropylene material comprises the following steps:

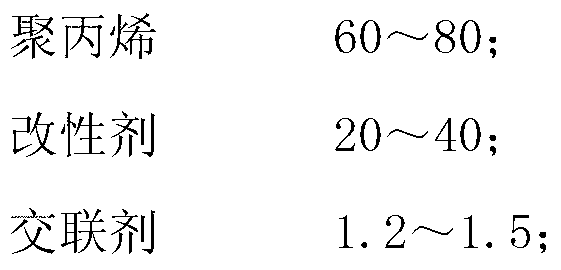

[0049] The formula is as follows:

[0050]

[0051] Put the above-mentioned raw and auxiliary materials into the internal mixer for internal mixing, the temperature is 130°C, and the internal mixing time is 12 minutes. Put the internally mixed material on a two-roller open mixer at 115°C for a thick pass, and then make triangular bags for three times. After the materials are evenly mixed Immediately out of the sheet, cut a 24cm×24cm sheet, weigh 1095g of the sheet and place it in a 25cm×25cm×2.3cm mold, close the mold and heat for 38min under a steam pressure of 0.65MPa to make the material in the mold cross-linked and foamed , the microcellular foamed polypropylene material is obtained by unloading the oil pressure and opening the mold. The physical properties of the tested foamed material are as follows:

[0052]

Embodiment 2

[0054] A preparation method of modified microcellular foamed polypropylene material comprises the following steps:

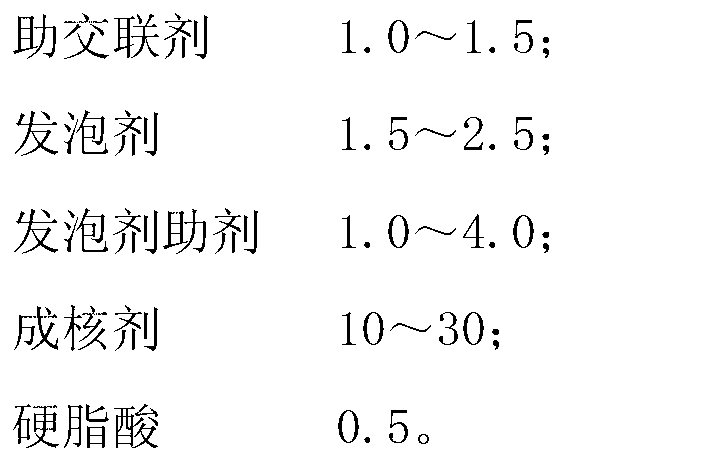

[0055] The formula is as follows:

[0056]

[0057] Put the above-mentioned raw and auxiliary materials into the internal mixer for internal mixing, the temperature is 130°C, and the internal mixing time is 12 minutes. Put the internally mixed material on a two-roller open mixer at 120°C for a thick pass once, and then make triangular bags for three times. After the materials are evenly mixed Take out the sheet, cut the sheet into a 24cm×24cm sheet, weigh 1095g of the sheet and place it in a 25cm×25cm×2.3cm mold, close the mold and heat for 38min under a steam pressure of 0.65MPa to make the material in the mold cross-linked Foam, release the oil pressure and open the mold to get the microcellular foamed polypropylene material Test the physical properties of the foamed material as follows:

[0058]

Embodiment 3

[0060] A preparation method of modified microcellular foamed polypropylene material comprises the following steps:

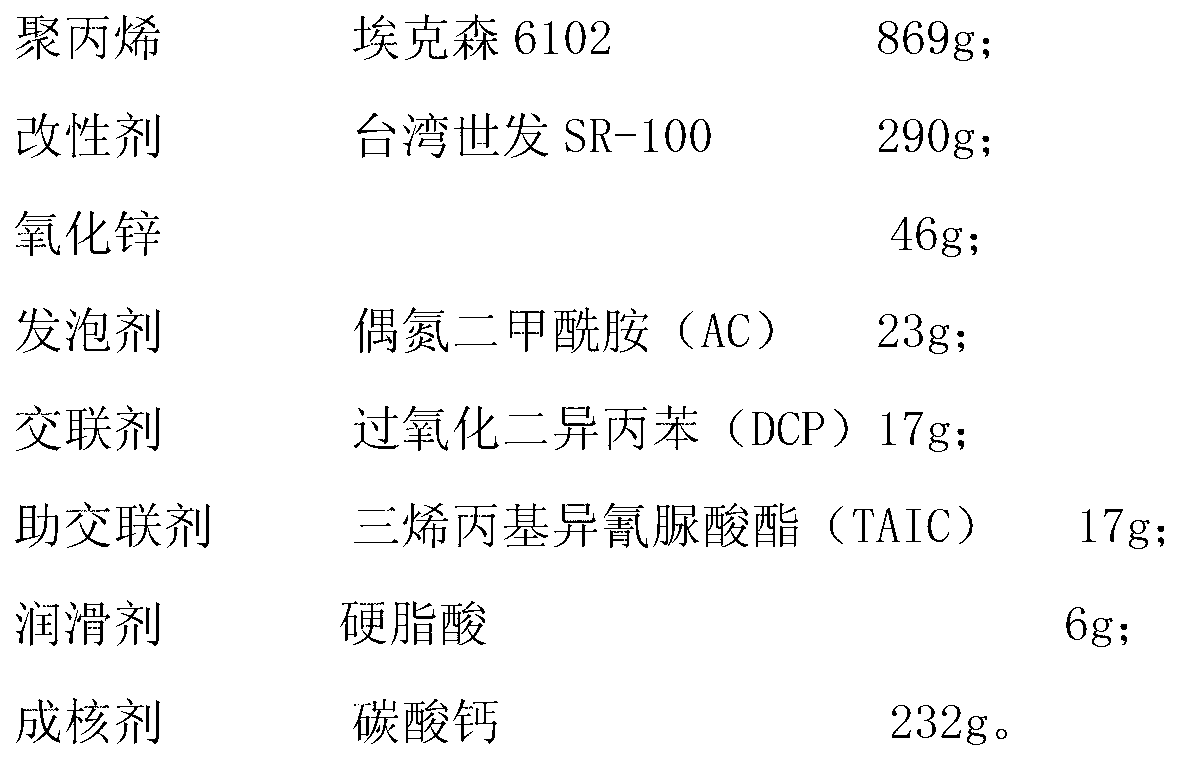

[0061] The formula is as follows:

[0062]

[0063] Put the above-mentioned raw and auxiliary materials into the internal mixer for internal mixing, the temperature is 130°C, and the internal mixing time is 12 minutes. Put the internally mixed material on a two-roller open mixer at 120°C for a thick pass once, and then make triangular bags for three times. After the materials are evenly mixed Take out the sheet, cut the sheet into a 24cm×24cm sheet, weigh 1095g of the sheet and place it in a 25cm×25cm×2.3cm mold, close the mold and heat for 38min under a steam pressure of 0.65MPa to make the material in the mold cross-linked Foam, release the oil pressure and open the mold to get the microcellular foamed polypropylene material Test the physical properties of the foamed material as follows:

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com