High-temperature-resistant foamed plastic composition and preparation method thereof

A foamed plastic and composition technology, which is applied in the field of high temperature resistant foamed plastic composition and its preparation, can solve the problems of increased viscosity of blended resin, poor processability, unfavorable application of cyanate ester foam, etc., and achieves a cell structure. The effect of uniformity and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

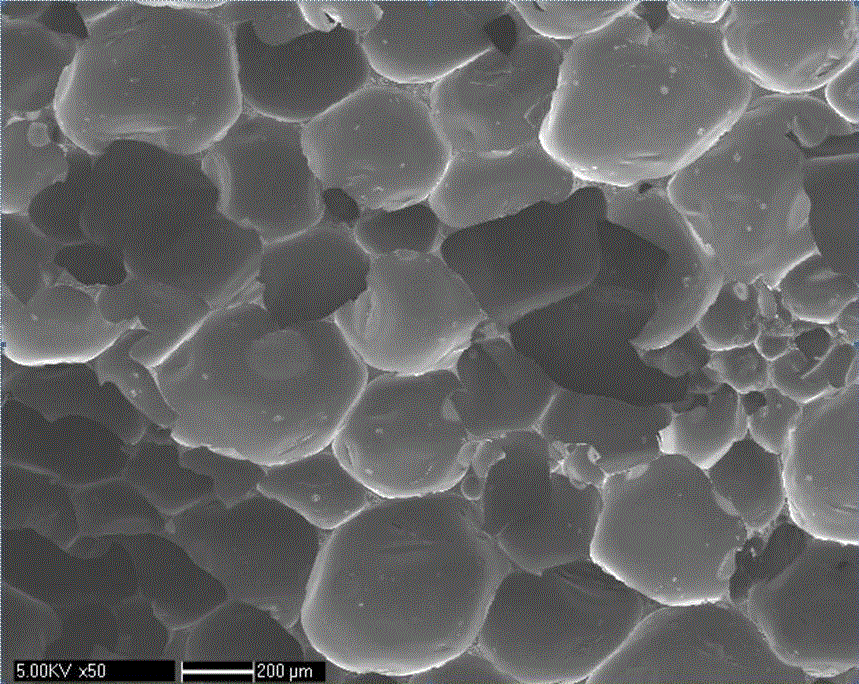

[0064] Put 94.74 parts of bisphenol A type cyanate resin and 0.01 part of dibutyltin dilaurate into a 250ml beaker and mix evenly, then move it into an oil bath at 140°C for prepolymerization, and keep stirring with a mechanical stirrer at a stirring speed of 500 r / min, add 0.8 parts of surfactant AK8807 after 90 minutes, add 4.45 parts of azodicarbonamide after 40 minutes, stir at 800 r / min for 10 minutes, pour into a mold with a temperature of 150°C for foaming, and then Curing in an oven for 1 hour, followed by curing in ovens at 180° C., 200° C. and 220° C. for 2 hours respectively, then naturally cooling to room temperature, and demoulding to obtain a high temperature resistant foam plastic composition.

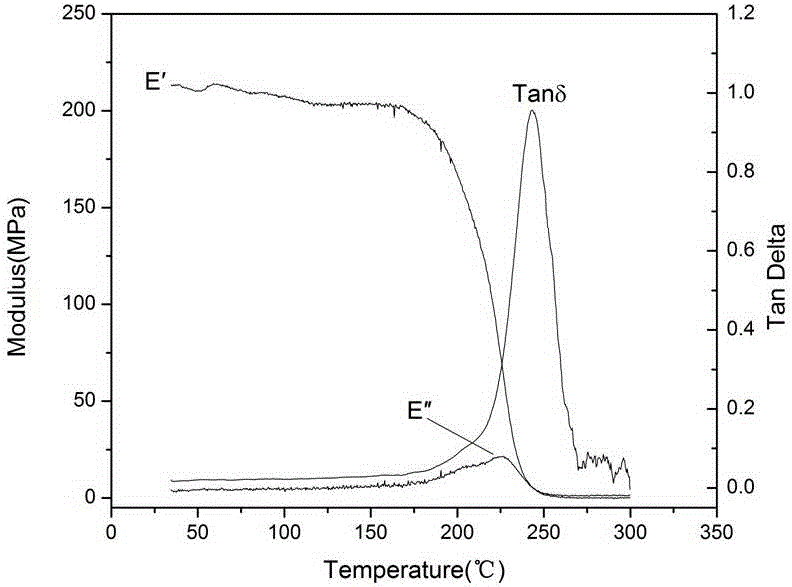

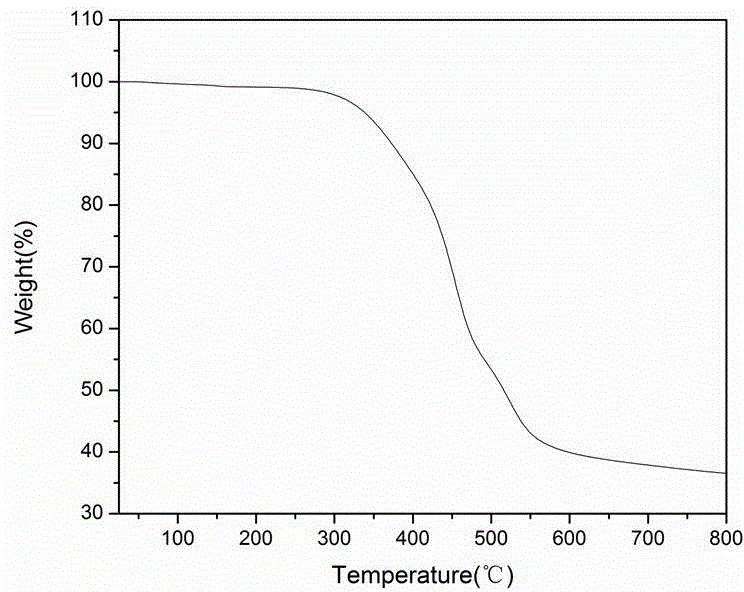

[0065] The density of the high temperature resistant foam plastic composition is 0.131g / cm 3 , the compressive strength is 1MPa, the compressive modulus is 33 MPa, the initial decomposition temperature is 338.5°C, the glass transition temperature is 245°C, and the diele...

Embodiment 2

[0068] Put 93.45 parts of bisphenol E type cyanate resin, 0.93 parts of surfactant AK8807 and 0.01 part of dibutyltin dilaurate into a 250ml beaker and mix evenly, then move it into a 140°C oil bath for prepolymerization, and keep stirring with a mechanical stirrer , the stirring speed is 500 r / min, after 150 minutes, add 5.61 parts of azodicarbonamide, stir at 900 r / min for 10 minutes, pour into a mold with a temperature of 150°C for foaming, and then solidify in an oven at 150°C 1h, and then solidified in an oven at 180°C and 200°C for 2h, then naturally cooled to room temperature, and demolded to obtain a density of 0.105g / cm 3 The high temperature resistant foamed plastic composition has a glass transition temperature of 238°C.

Embodiment 3

[0070] Put 97.08 parts of bisphenol E cyanate resin, 0.97 parts of surfactant AK8807 and 0.01 part of dibutyltin dilaurate into a 250ml beaker and mix evenly, then move it into an oil bath at 140°C for prepolymerization, and keep stirring with a mechanical stirrer , the stirring speed is 500 r / min, after 150 minutes, add 1.94 parts of azodicarbonamide, stir at 900 r / min for 10 minutes, pour into a mold with a temperature of 150°C for foaming, and then solidify in an oven at 150°C 1h, and then solidified in an oven at 180°C and 200°C for 2h, then naturally cooled to room temperature, and demolded to obtain a density of 0.451g / cm 3 High temperature resistant foam plastic composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com