Polyphenylene sulfide modified PET composition and preparation method thereof

A technology of polyphenylene sulfide and composition, which is applied in the field of polymers, can solve the problems of PET application restrictions, etc., and achieve the effects of avoiding serious performance degradation, ensuring dispersibility, and low odor characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

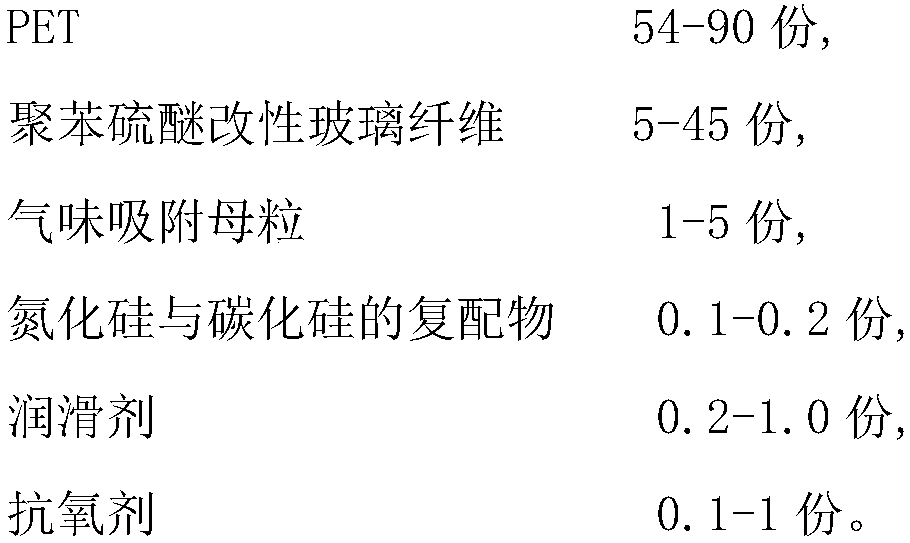

Method used

Image

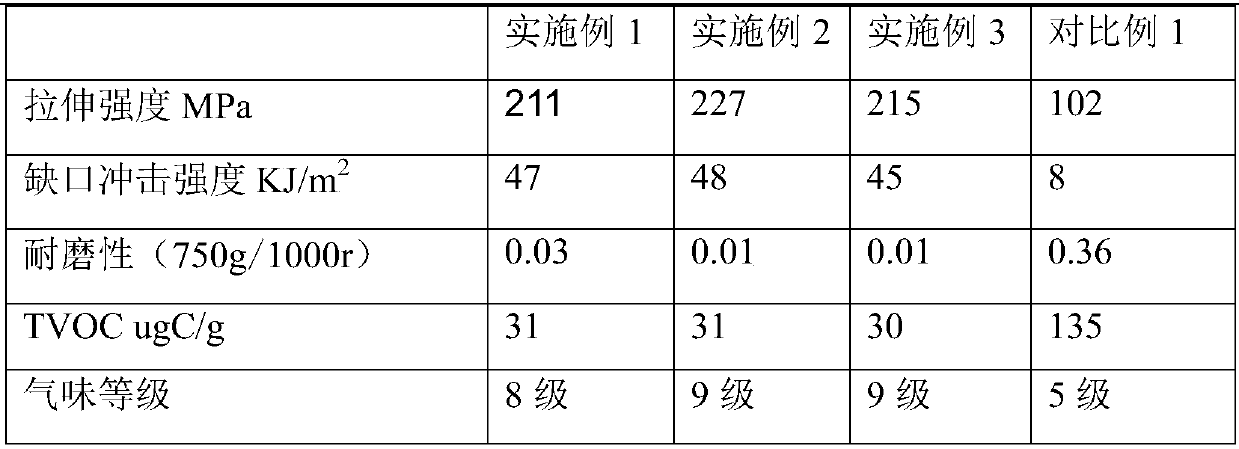

Examples

preparation example Construction

[0028] Preparation of odor adsorption masterbatch: 100 parts of PET, 5 parts of hydrophobic diatomaceous earth, 5 parts of hydrophobic activated carbon, 5 parts of acicular zeolite molecular sieve, 5 parts of zinc ricinoleate, 5 parts of nano silicon dioxide, stearic acid 1 part of calcium and 5 parts of melamine, mixed evenly, and then extruded and granulated in a twin-screw extruder to obtain odor-absorbing masterbatches. Among them, the temperature of the first zone of the twin-screw extruder is 190-225°C, the temperature of the second zone is 275-285°C, the temperature of the third zone is 275-290°C, the temperature of the fourth zone is 285-290°C, and the temperature of the fifth zone is 285-300 °C, the temperature of the sixth zone is 285-300 °C; the main engine speed of the twin-screw extruder is 250-500rpm.

[0029] The weight ratio of silicon nitride and silicon carbide in the compound of silicon nitride and silicon carbide is 1:19.

Embodiment 1

[0031] 70 parts of PET, 3 parts of odor absorption masterbatch, 0.1 part of silicon nitride and silicon carbide compound, 0.2 part of white oil, 0.3 part of silicone oil, 0.5 part of paraffin, 0.5 part of antioxidant 1098, 0.5 part of antioxidant Pour 168 into a high-speed mixer, stir at a high speed, mix until uniform, then add to a twin-screw extruder, add 5 parts of polyphenylene sulfide modified glass fiber from the glass fiber port, melt and extrude, and then granulate to obtain low Odor, low emission, high wear resistance PET composition.

[0032] Among them, the temperature of the first zone of the twin-screw extruder is 190°C, the temperature of the second zone is 275°C, the temperature of the third zone is 275°C, the temperature of the fourth zone is 285°C, the temperature of the fifth zone is 285°C, and the temperature of the sixth zone is 285°C; The host speed of the extruder is 250rpm.

Embodiment 2

[0034] Pour 54 parts of PET, 1 part of odor absorption masterbatch, 0.2 part of silicon nitride and silicon carbide compound, 0.2 part of silicone powder, 0.05 part of antioxidant 1098, and 0.05 part of antioxidant 168 into a high-speed mixer, Stir at high speed, mix until uniform and add to twin-screw extruder, add 30 parts of polyphenylene sulfide modified glass fiber from the glass fiber port, melt and extrude and then granulate to obtain low odor, low emission, high durability Mill the PET composition.

[0035] Among them, the temperature of the first zone of the twin-screw extruder is 225°C, the temperature of the second zone is 285°C, the temperature of the third zone is 290°C, the temperature of the fourth zone is 290°C, the temperature of the fifth zone is 300°C, and the temperature of the sixth zone is 300°C; The host speed of the extruder is 500rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com