Process for preparing nano zinc oxide

A nano-zinc oxide and zinc sulfate technology, which is applied in the direction of zinc oxide/zinc hydroxide, nitrogen fertilizer, ammonium salt fertilizer, etc., can solve the problems of high cost and complicated reaction process, and achieve the effect of not easy to agglomerate, simple to operate, and easy to disperse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

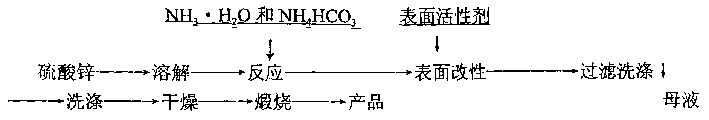

Method used

Image

Examples

Embodiment 1

[0019] The method of embodiment 1. nanometer ZnO, concrete steps are as follows: 1. be 30% zinc sulfate (ZnSO 4 ) solution, dripping the ammoniacal liquor that the weight percentage concentration is 20%, zinc sulfate and ammoniacal liquor (NH 3 ·H 2 O) The weight ratio is 1: 0.8. 2. Add ammonium bicarbonate, 1 part of Zn(OH) 2 Add 0.6 parts of NH 4 HCO 3 , to get ZnCO 3 ·Zn(OH) 2 precipitation. 3. The precipitate was separated and washed with deionized water until no SO was detected by barium chloride (BaCl) 4 2- until. 4. Then vacuum-dried at 85°C to obtain Zn(OH) 2 As the core, the periphery is covered with ZnCO 3 composite precursors. 5. Start calcining the above composite precursor at 150° C., gradually raise the temperature to 600° C., and complete the calcination for 2 hours to obtain nano-ZnO material. The product is white, hexagonal crystal, the average particle size is 20-30nm, the product quality is good, and it has good dispersion in water. The method o...

Embodiment 3

[0021] Select stearic acid as the surfactant, and the consumption is 1 part of zinc sulfate plus 2 parts (both parts by weight) of the surfactant. The method of embodiment 4. nanometer ZnO, step is as described in embodiment 1, difference is:

Embodiment 4

[0021] Select stearic acid as the surfactant, and the consumption is 1 part of zinc sulfate plus 2 parts (both parts by weight) of the surfactant. The method of embodiment 4. nanometer ZnO, step is as described in embodiment 1, difference is:

[0022] Zinc sulfate (ZnSO 4 ) solution weight percent concentration is 25%, and the weight percent concentration of dripping ammoniacal liquor is 18%, and zinc sulfate and ammoniacal liquor (NH 3 ·H 2 O) in a weight ratio of 1:1.

[0023] 1 part Zn(OH) 2 Add 0.8 parts of NH 4 HCO 3 .

[0024] Dry under vacuum at 90°C.

[0025] The calcining time is 2.5 hours, and the obtained nano-ZnO product is white, hexagonal crystal, and the average particle diameter is 25nm. It has good dispersibility in water. The method of embodiment 5.nano ZnO, step is as described in embodiment 1, difference is:

[0026] Zinc sulfate (ZnSO 4 ) solution weight percent concentration is 20%, the weight percent concentration of dripping ammoniacal liquor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com