ZIF-8 film-coated Pd/ZnO core-shell catalyst and preparation method thereof

A ZIF-8, core-shell catalyst technology, applied in physical/chemical process catalysts, catalyst protection, organic compound/hydride/coordination complex catalysts, etc., to solve the problem of easy loss and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of PVP-stabilized Pd nanoparticles

[0024] Prepare 2mM H 2 PdCl 4 Aqueous solution 15ml, with 0.0667g PVP, 21ml H 2 O mixed, adding 1M HCl aqueous solution to adjust the mixture pH = 9, heated to boiling, immediately added 14ml of ethanol, refluxed for 3h, to obtain Pd nanoparticles stabilized by PVP;

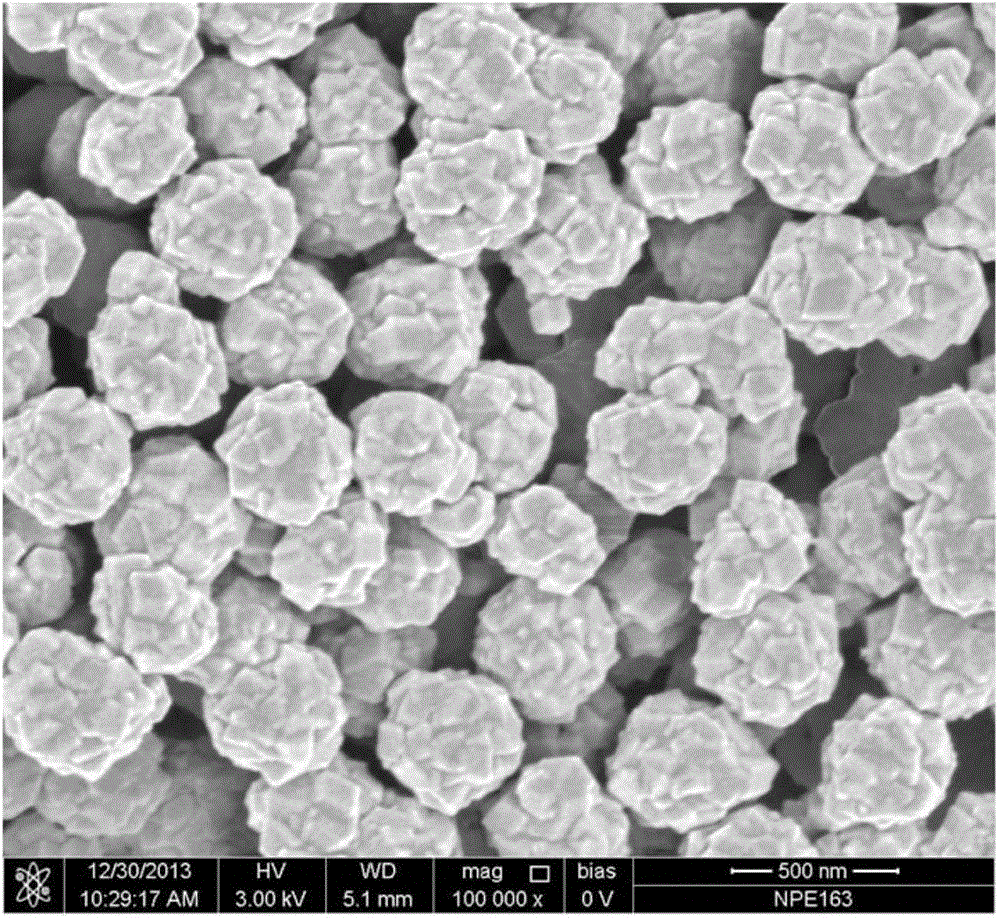

[0025] (2) Preparation of ZnO carrier

[0026] Mix 1.098g of zinc acetate dihydrate with 50ml of diethylene glycol (DEG), and reflux at 160°C for 2 hours to obtain a spherical ZnO carrier with a particle size of 300-500nm;

[0027] (3) The PVP stabilized Pd nanoparticles obtained in step (1) are mixed with the spherical ZnO carrier obtained in step (2) at room temperature for 15h to obtain the ethanol solution of the Pd / ZnO catalyst;

[0028] (4) The ethanol solution of the Pd / ZnO catalyst obtained in step (3) is mixed with the 2-methylimidazole solution, wherein the concentration of 2-methylimidazole is 0.5M, and the molar amount of 2-methylimidazol...

Embodiment 2

[0031] (1) Preparation of PVP-stabilized Pd nanoparticles

[0032] Prepare 2mM H 2 PdCl 4 Aqueous solution 15ml, with 0.0667g PVP, 21ml H 2 O mixed, adding 1M HCl aqueous solution to adjust the mixture pH = 9, heated to boiling, immediately added 14ml of ethanol, refluxed for 3h, to obtain Pd nanoparticles stabilized by PVP;

[0033] (2) Preparation of ZnO carrier

[0034] Mix 1.098g of zinc acetate dihydrate with 50ml of diethylene glycol (DEG), and reflux at 160°C for 2 hours to obtain a spherical ZnO carrier with a particle size of 300-500nm;

[0035] (3) The PVP stabilized Pd nanoparticles obtained in step (1) are mixed with the spherical ZnO carrier obtained in step (2) at room temperature for 15h to obtain the ethanol solution of the Pd / ZnO catalyst;

[0036] (4) The ethanol solution of the Pd / ZnO catalyst obtained in step (3) was vacuum-dried overnight at 80° C., and placed in a desiccator for testing.

Embodiment 3

[0038] Take 0.1g of catalyst and put it in the reaction device, then add 15ml of ethyl acetate and 0.3ml of n-hexene, use hydrogen to purge the reaction device for 3 times, and react at 35°C for 24h. After the reaction, the catalyst and feed liquid were centrifuged, and the results were detected by gas chromatography (chromatographic column: HP-5; FID).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com