Polypyrrole-clad nano spherical zinc oxide material and preparation method

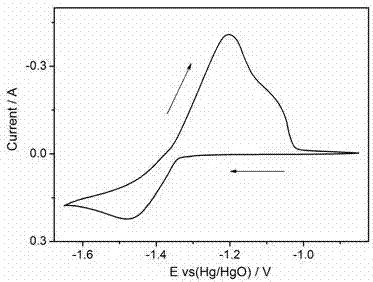

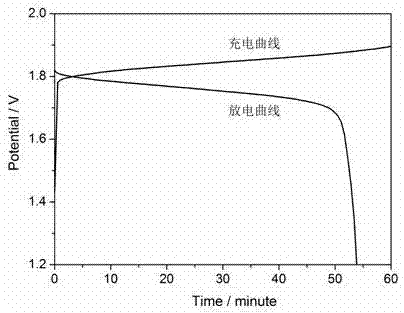

A technology of zinc oxide and polypyrrole, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problem of insufficient contact between inorganic additives and active substances, no obvious effect of the dissolution of discharge products, and organic additives. Increase electrode polarization and other issues, achieve significant electrochemical reversibility and charge-discharge cycle performance, inhibit the formation of zinc dendrites, and improve reversibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

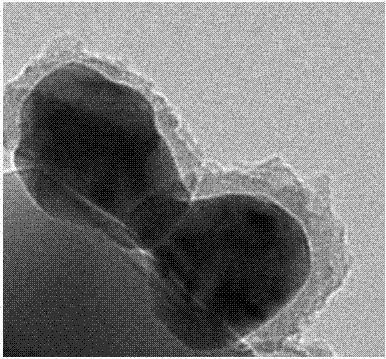

[0030] Take 200mg of zinc acetate and dissolve it in 50ml of deionized water, and take another 70mg of hexamethylenetetramine and dissolve it in 50ml of deionized water, mix the above two solutions, stir for 5 minutes, then transfer to a 200ml hydrothermal reactor, keep the water The thermal reaction temperature is 160° C. After 8 hours of reaction, it is naturally cooled, taken out for suction filtration, washed with deionized water and ethanol for several times, and dried to obtain nano-spherical zinc oxide particles. Dissolve 37mg of sodium dodecyl sulfonate in 50ml of deionized water, and add 100mg of nano-zinc oxide to the above solution, ultrasonically stir for 10 minutes to make the zinc oxide form a stable and dispersed nano-sol, and place the above-mentioned sol in a 5°C incubator. , continue stirring, add 20 mg of pyrrole monomer, stir for 30 minutes to fully dissolve, and dissolve 68 mg of ammonium persulfate in 10 ml of deionized water, add the ammonium persulfate s...

Embodiment 2

[0032]Dissolve 200mg of zinc acetate in 80ml of ethylene glycol, and take another 15mg of sodium hydroxide and dissolve it in 20ml of deionized water, mix the above two solutions, stir for 30 minutes, then transfer the mixed solution to a 200ml hydrothermal reactor, keep The hydrothermal reaction temperature is 150° C. After 10 hours of reaction, it is naturally cooled, taken out for suction filtration, washed with deionized water and ethanol for several times, and dried to obtain nano-spherical zinc oxide particles. Take 55mg of polyethylene glycol (PEG400) and dissolve it in 50ml of deionized water, add 100mg of nano-zinc oxide to the above solution, ultrasonically stir for 30 minutes to make zinc oxide form a stably dispersed nano-sol, and place the above-mentioned sol in a 0°C incubator. , continue stirring, add 15mg of pyrrole monomer, stir for 30 minutes to make it fully dissolved, take another 10ml of hydrogen peroxide and dissolve it in 10ml of deionized water, add the ...

Embodiment 3

[0034] Take 200mg of zinc acetate and dissolve it in 50ml of deionized water, take another 25mg of urea in 50ml of deionized water, mix the above two solutions, stir for 10 minutes, then transfer to a 200ml hydrothermal reaction kettle, keep the hydrothermal reaction temperature at 180 degrees Celsius, After 6 hours of reaction, it was naturally cooled, taken out for suction filtration, washed with deionized water and ethanol for several times, and dried to obtain nano-spherical zinc oxide particles. Dissolve 30 mg of sodium laurate in 50 ml of deionized water, and add 100 mg of nano-zinc oxide to the above solution, and ultrasonically stir for 20 minutes to form a stable and dispersed nano-sol. , add 15mg of pyrrole monomer, stir for 30 minutes to fully dissolve, and take another 55mg of ammonium persulfate and dissolve it in 10ml of deionized water, add the ammonium persulfate solution dropwise to the nano-zinc oxide sol containing pyrrole monomer, the addition is completed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com