Method for preparing nano zinc oxide and crystal whisker zinc oxide by using industrial zinc sulfate as raw material

A nano-zinc oxide and zinc sulfate technology, applied in the direction of zinc oxide/zinc hydroxide, chemical instruments and methods, nanotechnology, etc., can solve the problem of impurity removal measures that have not been considered, the effect of impurity removal and zinc recovery rate, fluorine Problems such as secondary pollution of ions are outstanding, and the effects of superior product performance, good impurity removal effect, and high total zinc yield are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

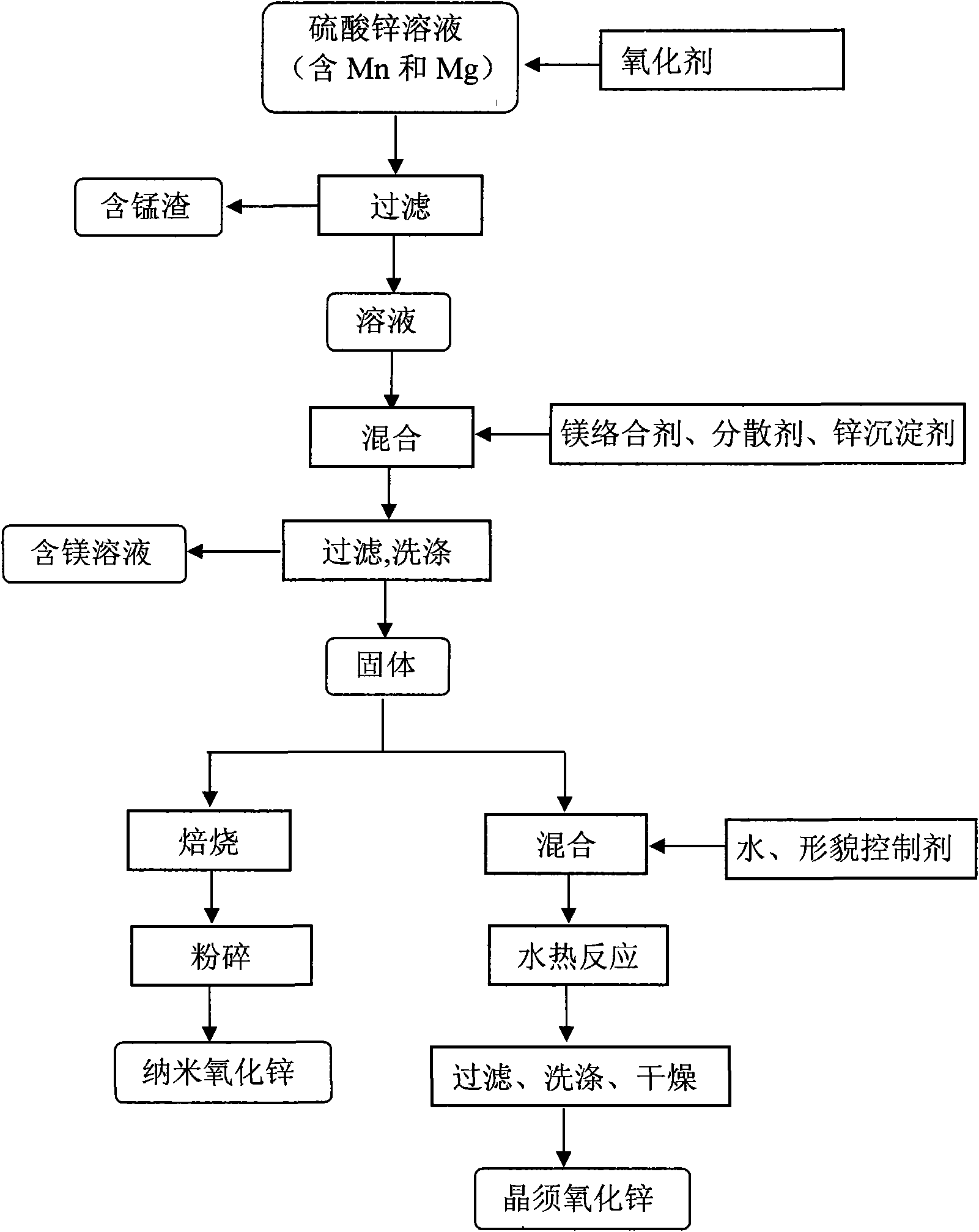

[0031] The method of preparing nano-zinc oxide and whisker zinc oxide with industrial zinc sulfate as raw material, using simulated industrial zinc sulfate solution containing manganese and magnesium impurities as raw material, first adopts oxidation method to remove manganese, neutral complexation magnesium dissolution-precipitation zinc method Separation of magnesium and zinc to prepare high-purity and highly dispersed nano-zinc salt precursors, and then prepare whisker zinc oxide with regular morphology by hydrothermal directional growth method, or prepare high-purity nano-zinc oxide by roasting method, process flow diagram Such as figure 1 As shown, the method steps are as follows:

[0032] (1) Take zinc sulfate, manganese sulfate and magnesium sulfate as raw materials and add deionized water to prepare simulated industrial zinc sulfate solution, wherein, zinc sulfate is 0.2 mole / liter, manganese sulfate is 0.01 mole / liter, and magnesium sulfate is 0.1 mole / liter , using ...

Embodiment 2

[0041] The method of preparing nano-zinc oxide and whisker zinc oxide with industrial zinc sulfate as raw material, using simulated industrial zinc sulfate solution containing manganese and magnesium impurities as raw material, first adopts oxidation method to remove manganese, neutral complexation magnesium dissolution-precipitation zinc method Separating magnesium and zinc, thereby preparing a high-purity, highly dispersed nano-zinc salt precursor, and then preparing whisker zinc oxide with regular morphology by hydrothermal directional growth method, or preparing high-purity nano-zinc oxide by roasting method, the method steps as follows:

[0042] (1) Take zinc sulfate, manganese sulfate and magnesium sulfate as raw materials and add deionized water to prepare simulated industrial zinc sulfate solution, wherein, zinc sulfate is 4 moles / liter, manganese sulfate is 0.5 moles / liter, and magnesium sulfate is 2 moles / liter , take potassium hypochlorite as oxidant, add deionized ...

Embodiment 3

[0051] The method of preparing nano-zinc oxide and whisker zinc oxide with industrial zinc sulfate as raw material, using simulated industrial zinc sulfate solution containing manganese and magnesium impurities as raw material, first adopts oxidation method to remove manganese, neutral complexation magnesium dissolution-precipitation zinc method Separating magnesium and zinc, thereby preparing a high-purity, highly dispersed nano-zinc salt precursor, and then preparing whisker zinc oxide with regular morphology by hydrothermal directional growth method, or preparing high-purity nano-zinc oxide by roasting method, the method steps as follows:

[0052] (1) Take zinc sulfate, manganese sulfate and magnesium sulfate as raw materials and add deionized water to prepare simulated industrial zinc sulfate solution, wherein, zinc sulfate is 2 moles / liter, manganese sulfate is 0.05 moles / liter, and magnesium sulfate is 1 mole / liter , with ammonium hypochlorite as oxidant, add deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com