Super-hydrophobic composite porous film and preparation method thereof

A porous membrane, super-sparse technology, applied in special surfaces, pretreatment surfaces, devices for coating liquids on surfaces, etc., can solve problems such as high liquid breakthrough pressure, and achieve the effect of easy scale and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

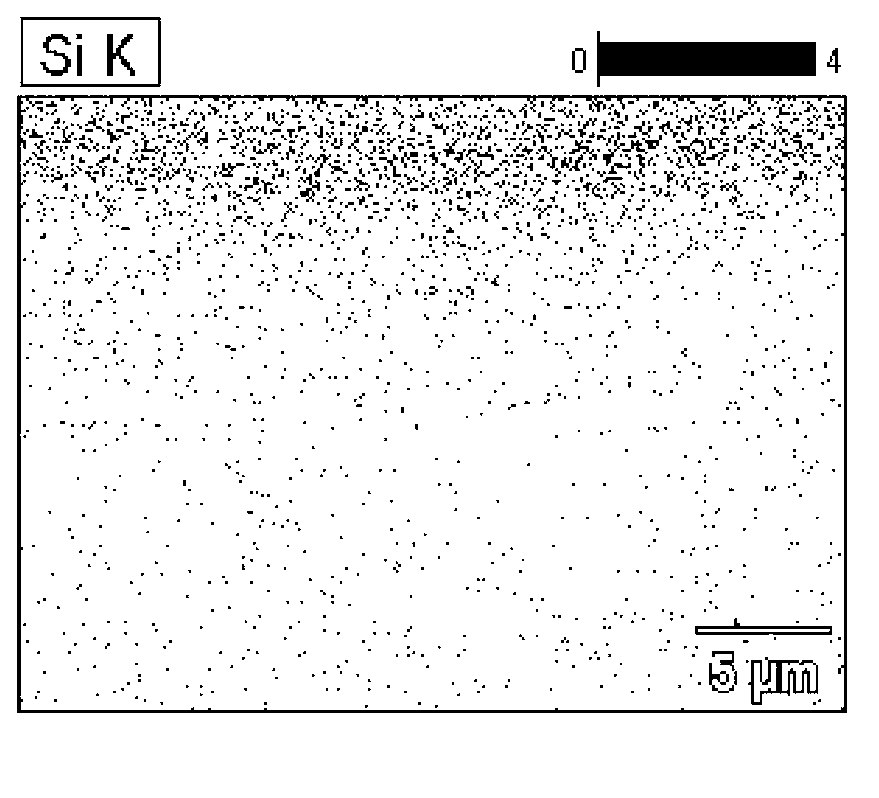

[0029] First, the flat polyvinylidene fluoride membrane is washed with ethanol and deionized water in sequence, and dried to obtain a pretreated clean base membrane. Then weigh a certain proportion of hydrophobic nano-silica particles, polymethylsiloxane and butyl acetate, mix them with butyl acetate, and disperse them ultrasonically for 60 minutes to form nanoparticles with a mass fraction of 2% and polymethylsiloxane with a mass fraction of 3%. of spray liquid. Then, the spray liquid was evenly sprayed on the pre-treated polyvinylidene fluoride base film by spraying-precipitation method, and after natural drying at 30°C for 24 hours, a layer of superhydrophobic film was formed on the surface of the film. After testing, the surface of the obtained superhydrophobic polyvinylidene fluoride film has a contact angle of 156° with water, a rolling angle of less than 5°, and a thin layer of nanostructure on the surface of the film. The scanning electron micrograph of the surface of...

Embodiment 2

[0031] First, the polypropylene flat membrane was rinsed with ethanol and deionized water in sequence, and dried to obtain a pretreated clean base membrane. Then weigh a certain proportion of hydrophobic nano-titanium dioxide particles and polymethyl methacrylate series adhesives and mix them with acetone, and ultrasonically disperse them to form a spray solution with a mass fraction of nanoparticles of 5% and an adhesive mass fraction of 6%. Then, the spray liquid was evenly sprayed on the pre-treated polypropylene base film by spraying-precipitation method, and after natural drying at 40°C for 24 hours, a layer of superhydrophobic film was formed on the surface of the film. After testing, the contact angle between the surface of the obtained superhydrophobic polypropylene film and water was 162°, and the root mean square roughness of the film surface was increased to 177nm.

Embodiment 3

[0033] First, the flat polyvinylidene fluoride membrane is washed with ethanol and deionized water in sequence, and dried to obtain a pretreated clean base membrane. Then weigh a certain proportion of hydrophobic nano-zinc oxide particles and polymethylsiloxane adhesive, mix them with toluene, and disperse them ultrasonically for 60 minutes to form a spray solution with a mass fraction of nanoparticles of 10% and an adhesive mass fraction of 15%. . Then spray the spray liquid evenly on the pre-treated polyvinylidene fluoride base film by spraying-precipitation method, and after natural drying at 80°C for 10 hours, a layer of superhydrophobic film is formed on the surface of the film. After testing, the contact angle between the surface of the obtained superhydrophobic polyvinylidene fluoride film and water was 152°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com