Inorganic nanoparticles-modified polyurethane sponge mask material, and preparation method and application thereof

A polyurethane sponge, inorganic nanotechnology, applied in applications, protective clothing, clothing, etc., can solve problems such as single function, and achieve the effects of simple preparation process, good adsorption and filtration performance, and many pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

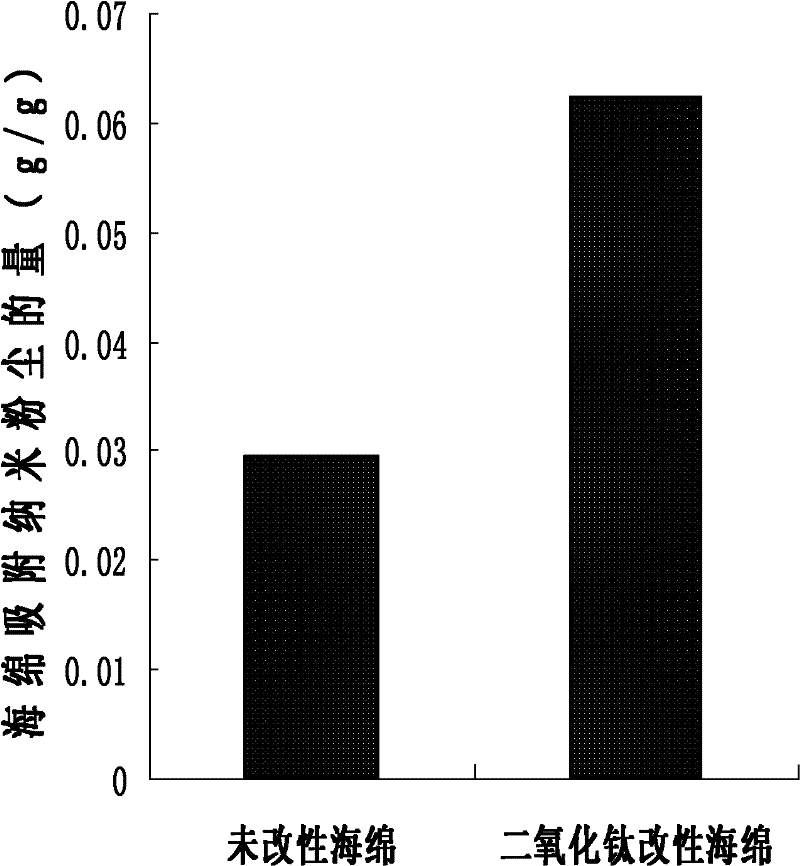

[0019] The preparation of titanium dioxide nanoparticle modified polyurethane sponge mask material: after getting 100 parts by weight of polyether polyols with a molecular weight of 3050, 1 part by weight of silicone oil, 0.4 parts by weight of stannous octoate, 0.2 parts by weight of triethylenediamine and 4.6 parts by weight of water, Mix together and stir evenly, add 2 parts by weight of nano-titanium dioxide, high-speed mechanical stirring and ultrasonic dispersion, add 45 parts by weight of 2,4-toluene diisocyanate after degassing, stir with a mechanical stirrer at high speed for 6-8 seconds, and quickly pour into the foaming mold foaming in a constant temperature environment of 28°C, and demolded after aging for 24 hours, the nano-particle modified polyurethane sponge material was obtained. Adopt saturated adsorption method to measure the amount of this sponge material adsorption nano-dust, it is 2.1 times of unmodified polyurethane sponge material adsorption nano-dust am...

Embodiment 2

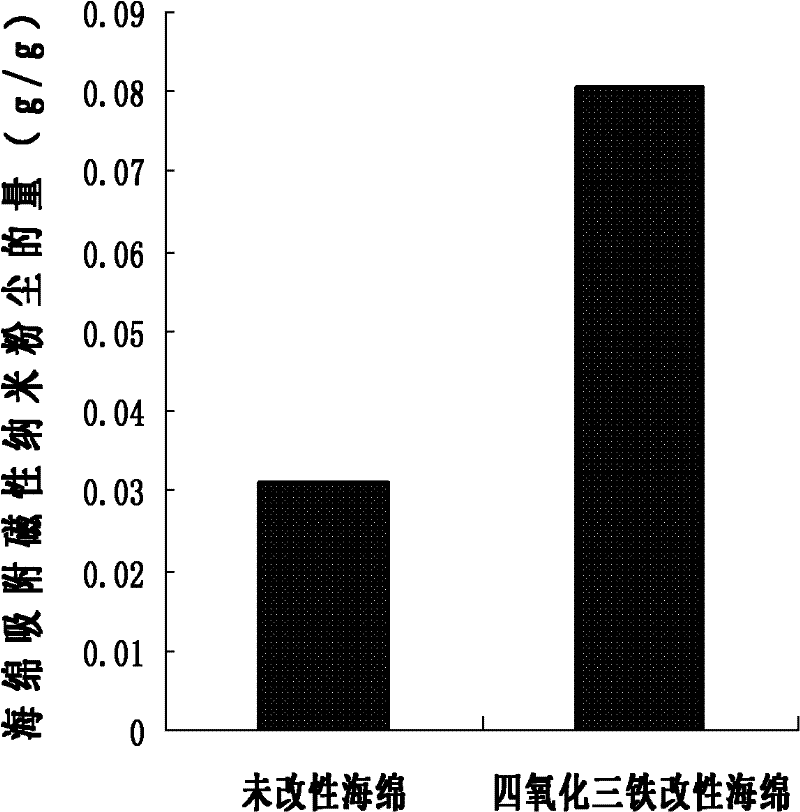

[0021] The preparation of magnetic iron ferric oxide nanoparticles modified polyurethane sponge mask material: get 100 parts by weight of polyether polyol with a molecular weight of 3050, 1 part by weight of silicone oil, 0.5 part by weight of stannous octoate, 0.25 parts by weight of triethylenediamine and 5 parts by weight of water. After the parts by weight, mix together and stir evenly, and add 2 parts by weight of magnetic iron ferric oxide nanoparticles, high-speed mechanical stirring and ultrasonic dispersion, add 45 parts by weight of 2,4-toluene diisocyanate after degassing, and stir with a mechanical stirrer at high speed After 6-8 seconds, quickly pour it into a foaming mold, foam in a constant temperature environment of 28°C, and release it after aging for 24 hours to obtain the magnetic nanoparticle modified polyurethane sponge mask material. Adopt saturated adsorption method to measure and show: the amount of this sponge material adsorption magnetic nanometer dust...

Embodiment 3

[0023] The basic dimensions of the mask are determined by referring to the No. 13 nose depth and opening size of the Chinese standard head type: the length is 130mm, the width is 110mm, and the depth (height) is 25mm. Prepare the mask mold according to this size.

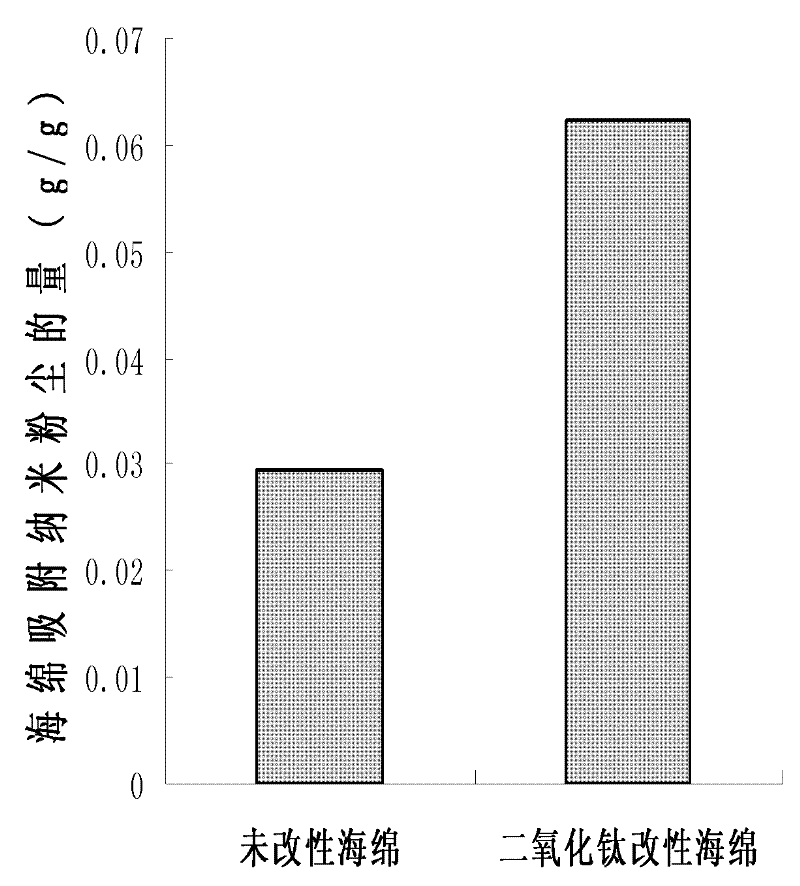

[0024] Preparation of titanium dioxide nanoparticle modified polyurethane sponge mask material: get 100 parts by weight of polyether polyol (molecular weight 3050), 1 part by weight of silicone oil, 0.4 part by weight of stannous octoate, 0.2 part by weight of triethylenediamine and 4.6 parts by weight of water and mix in Stir together evenly, add 2 parts by weight of titanium dioxide nanometer, high-speed mechanical stirring and ultrasonic dispersion, add 45 parts by weight of 2,4-toluene diisocyanate after degassing, stir with a mechanical stirrer at high speed for 6-8 seconds, and quickly pour it into the mask mold, 28 Foaming in a constant temperature environment at ℃, aging for 24 hours and demoulding to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com