Coupling method between making hydrogen and desulfurizing petroleum coking gas

A technology for petroleum coke and gasification reaction, which can be used in the petroleum industry, hydrogen production, catalytic conversion gas purification of impurities, etc., and can solve problems such as increasing the complexity of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

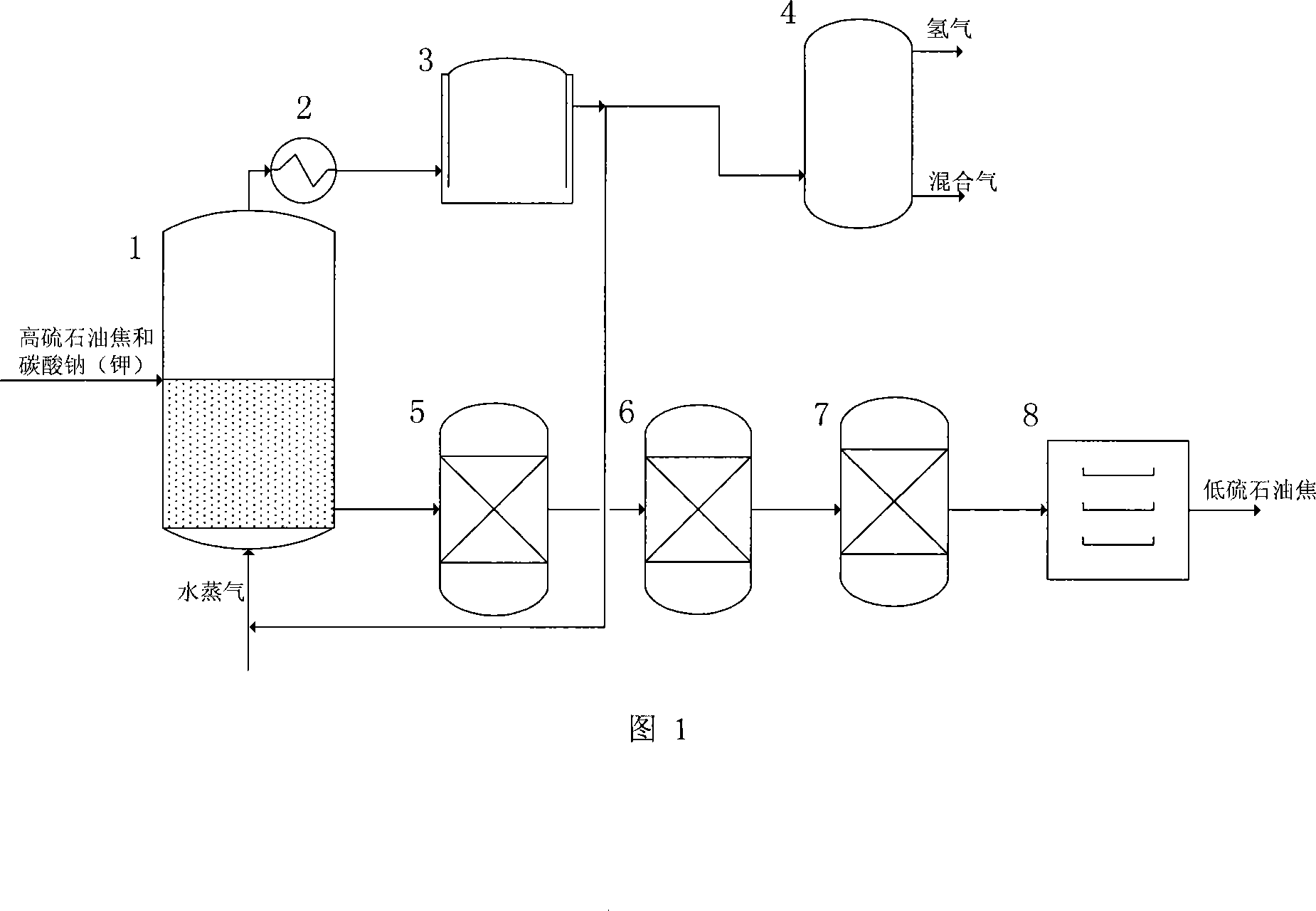

Image

Examples

Embodiment 1

[0011] Take 5g of petroleum coke from a refinery, its elemental analysis shows C 89.08%, H 3.25%, N 1.86%, S 3.6%. Grind to below 100 mesh, mix with sodium carbonate particles at a ratio of 1:1, add to reactor 1, feed water vapor, flow rate is 200ml / min, reactor temperature is 750°C, and reaction time is 6 hours. After the outlet gas of the reactor is cooled, samples are taken, and the generated gas is analyzed. The composition of the gas is obtained by removing H 2 O and N 2 Calculate H 2 48%, CH 4 22%, CO 12%, CO 2 13%, C 2 h 4 3%, C 2 h 6 2%, H 2 S 5ppm and NH 3 100ppm. After the reaction, the solid product in the reactor 1 was first washed with water at 80°C for half an hour to remove most of the sodium carbonate, then acid-washed with hydrochloric acid at a temperature of 80°C for 1 hour, and then washed with water at 80°C for 2 hours to remove the hydrochloric acid. Finally, it was dried at 120° C. for 2 hours. The desulfurization rate of petroleum coke...

Embodiment 2

[0013] Substantially the same as Example 1, the difference is that the flow rate of feeding water vapor is 160ml / min, and simultaneously, the hydrogen gas of 20% of the flow rate of Example 1 is mixed, that is, the flow rate is 40ml / min. The desulfurization rate of petroleum coke is 72.5%.

Embodiment 3

[0015] Substantially the same as Example 1, the difference is that the flow rate of feeding steam is 120ml / min, and simultaneously, the hydrogen gas of 40% of the flow rate of Example 1 is mixed, that is, the flow rate is 80ml / min. The desulfurization rate of petroleum coke is 82.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com