Vacuum seal modeling method for refrigerator cold closet plastic uptake mould casting

A technology of vacuum-sealed molding and refrigerators, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve the problems of manual mold size deviation, etc., achieve low environmental pollution, short manufacturing model cycle, and improve model freedom. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

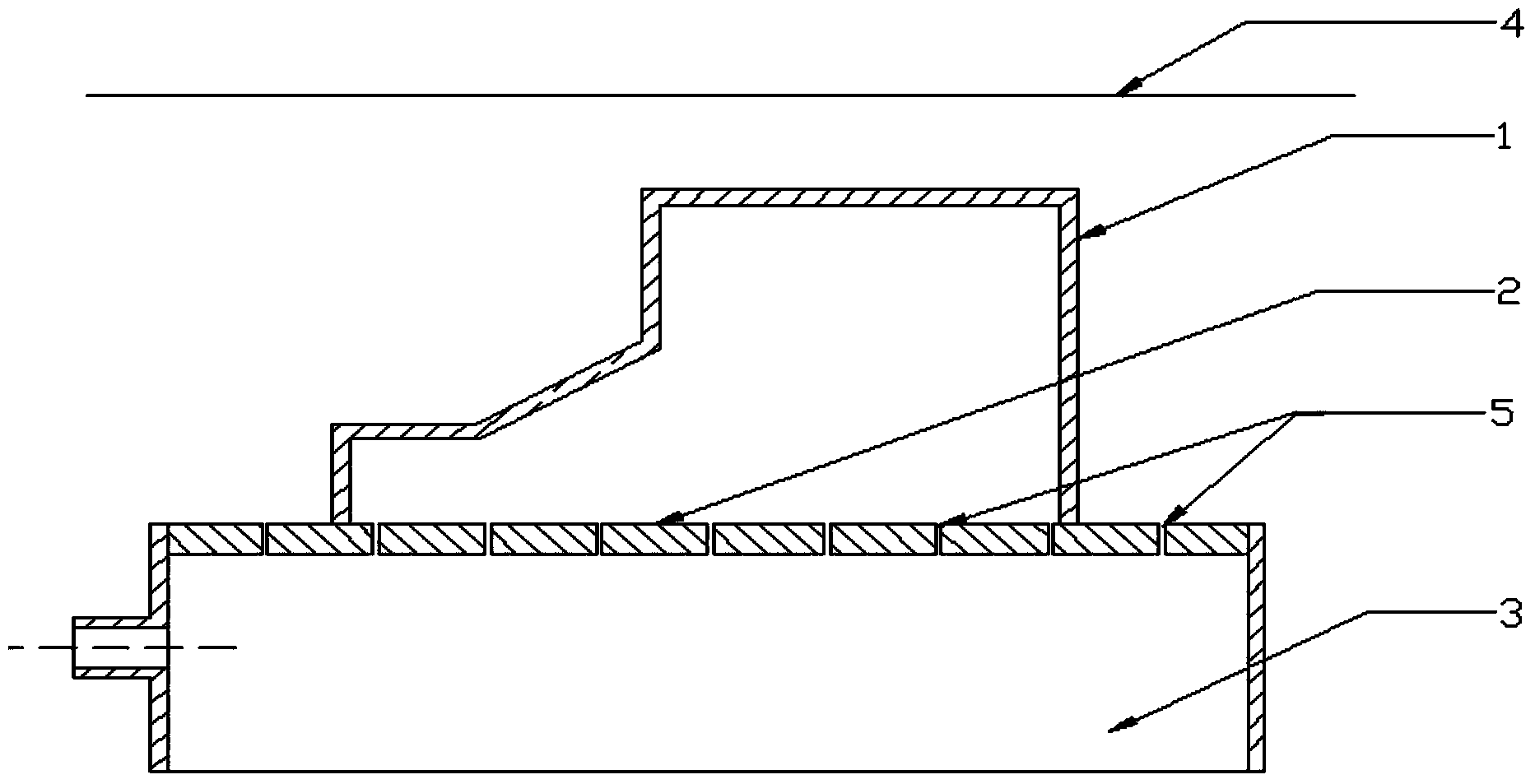

[0019] A vacuum-tight molding method for a refrigerator freezer blister mold casting, comprising the following method steps: see Figure 1 to Figure 3 ,

[0020] (1) Draw the solid model of the refrigerator freezer in the 3D software, then convert the 3D model into G code, import the G code into the CNC machine tool, and use the CNC machine tool to automatically process the polyurethane material to produce a product that is exactly the same as the 3D picture drawn Polyurethane Model 1;

[0021] (2) Assemble the template 2 evenly covered with pores 5 and the pumping chamber 3, then place the polyurethane model 1 with a support plate inside the template 2 in the middle of the template 2, and cover the template 2 and the mold with the softened pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com