High-strength high-wear-resistant bainite cast steel used for block cast middle groove, and preparation technology thereof

A preparation process and high-strength technology, applied in the direction of manufacturing tools, casting equipment, and process efficiency improvement, can solve the problems of changing the wear resistance of grooves, increasing production costs, and high costs, preventing fracture failure, and improving use. Longevity and the effect of reducing the cost of fully mechanized mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

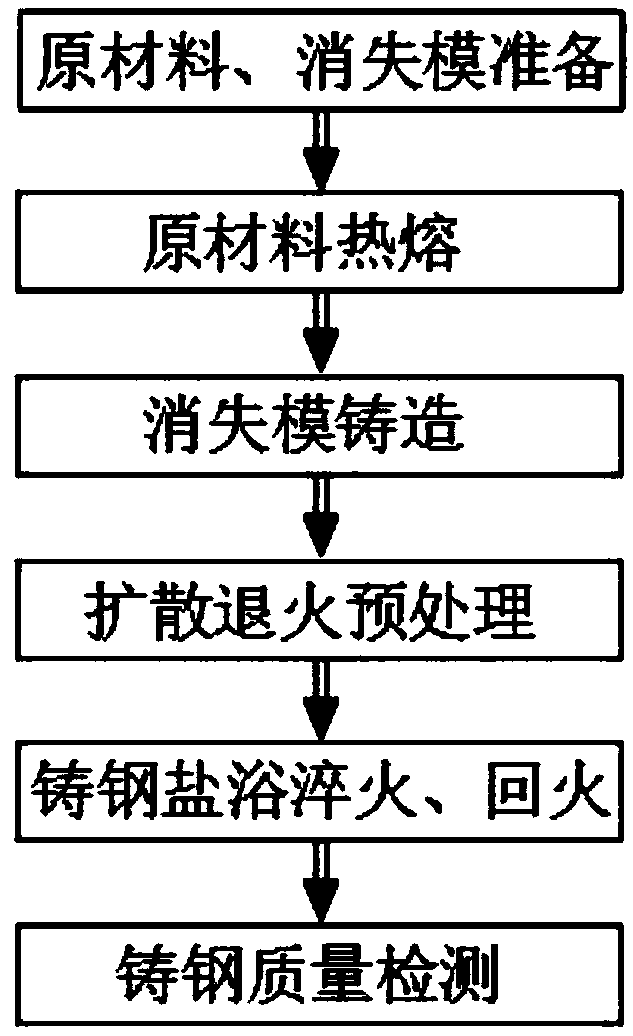

[0046] like figure 1 As shown, a high-strength and high-wear-resistant bainite cast steel for the entire casting middle tank and its preparation process, including raw materials, lost foam preparation - raw material hot melting - lost foam casting - diffusion annealing pretreatment - cast steel salt bath quenching , Tempering—the process steps of cast steel quality inspection, the specific steps are as follows:

[0047] (1) Preparation of raw materials and lost foam: prepare different raw materials according to a certain ratio, and customize a suitable lost foam corresponding to the middle groove to be produced;

[0048] (2) Hot melting of raw materials: Put the raw materials into the high-temperature furnace to heat and melt the raw materials;

[0049] (3) The lost foam casting steps are as follows:

[0050] ① Put the lost foam into the lost foam sand box;

[0051] ②Fill a small amount of molding sand around the bottom of the lost foam to locate the position of the lost fo...

Embodiment 2

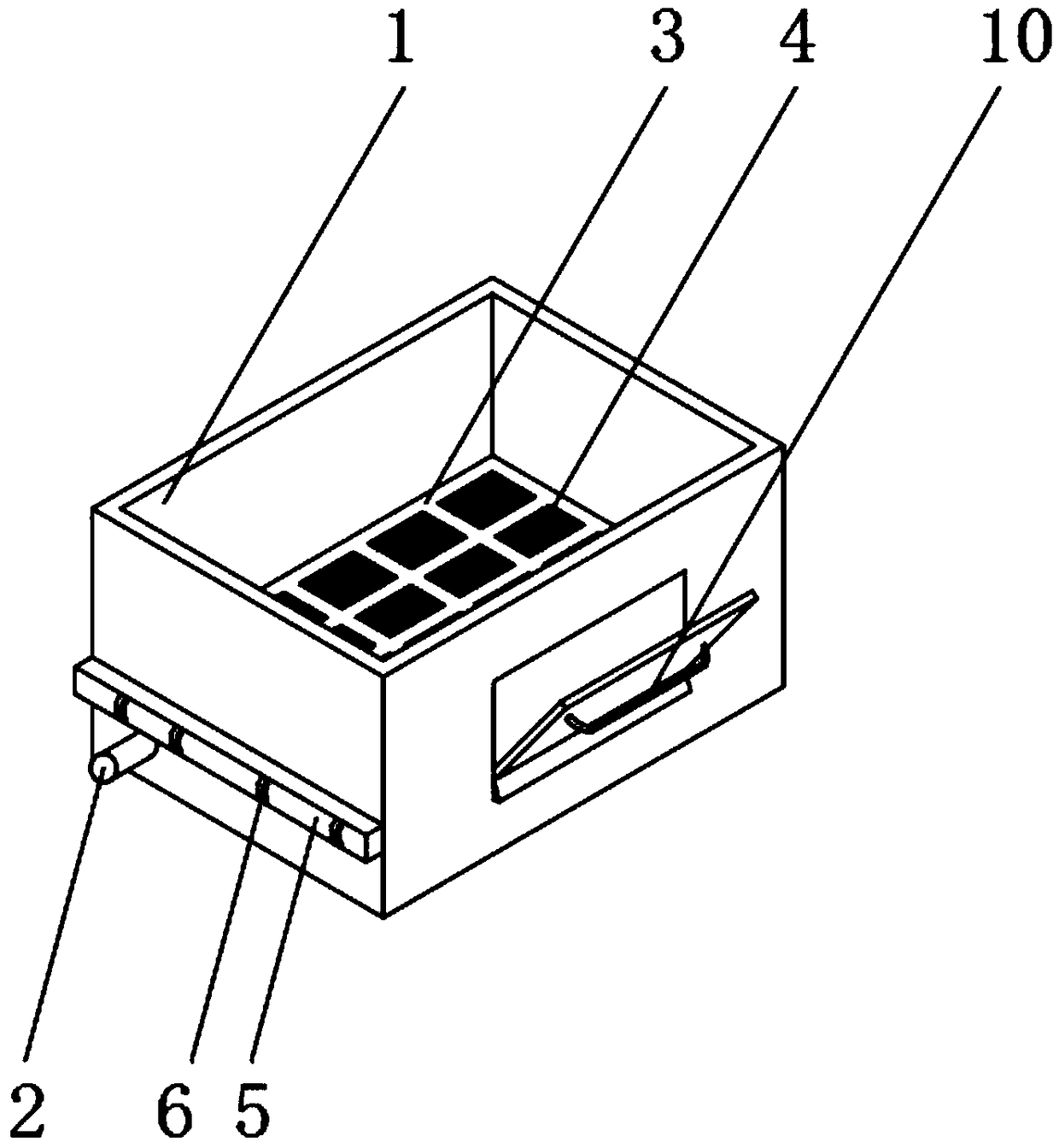

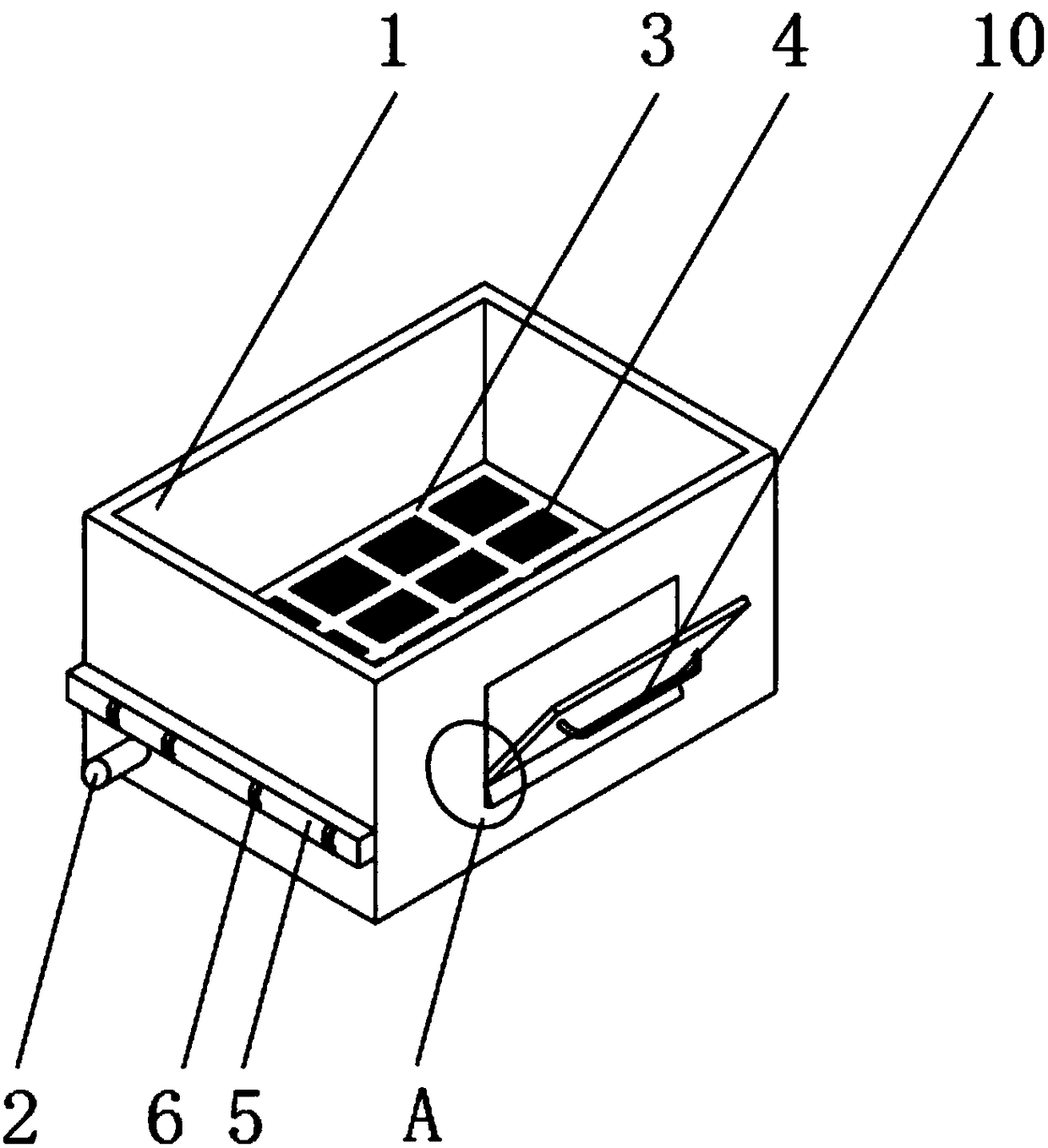

[0063] like Figure 2-4 As shown, in the lost foam sand box treasure sand box body 1 described in step (3), the inside and outside surface of the sand box body 1 is provided with a gauze frame 3 , and the inside of the gauze frame 3 is provided with a gauze 4 The outer surface of the front end of the main body of the sand box 1 is provided with a connecting block 5, the outer surface of the front end of the connecting block 5 is provided with a handle 6, and the outer surface of one side of the main body of the sand box 1 is provided with a movable plate 7. An inclined block 9 is provided on one side of the outer surface of the main body 1 of the flask near the movable plate 7 , and a pulling rod 10 is provided on the outer surface of the movable plate 7 .

[0064] A further improvement of the present invention is that: the salt bath furnace in step 5 includes a furnace shell 11, the inner and outer surface of the furnace shell 11 is provided with a heat insulating layer 12, a...

Embodiment 3

[0071] like Figure 5-7 As shown, the outer surface of the lower end of the chimney 15 and the furnace roof 14 are flexibly connected, the spacer 17 is fixedly connected to the chimney 15, and the spacer 18 and the roof 14 are connected to each other. For the fixed connection, the spacer frame 18 and the spacer block 17 are connected flexibly.

[0072] A further improvement of the present invention is that: the inside of the furnace inner layer 13 is provided with an electrode rod 19, the electrode rod 19 penetrates the upper surface of the furnace roof 14, and the electrode rod 19 and the furnace roof 14 are fixed There is a certain distance between the lower end of the electrode rod 19 and the outer surface of the lower end of the furnace inner layer 13 .

[0073] The working principle of the carburizing box in this mold processing technology: customize the lost foam corresponding to the middle groove that needs to be manufactured, place the lost foam inside the main body o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com