Engine oil filter element end cover non-woven fabric material and manufacturing process thereof

A production process and oil filtration technology, which is applied in non-woven fabrics, textiles and papermaking, heating/cooling fabrics, etc., can solve the problems of high material cost and manufacturing cost, complicated and cumbersome production processes, and not easy to degrade, and achieve good product quality. , low cost, the effect of ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

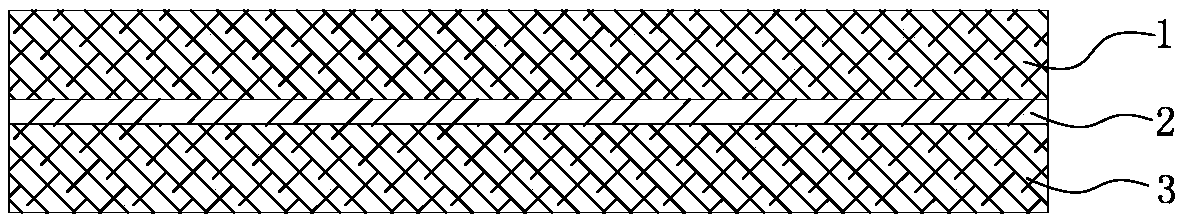

[0018] See figure 1 As shown, it is a non-woven fabric material for the end cover of an oil filter element, which includes a first polyester staple fiber cotton net layer 1, a polyester reinforcing cloth 2, and a second polyester staple fiber cotton net layer 3 fixed together in sequence. The first and second polyester staple fiber cotton net layers have good thermoplastic properties, which can ensure that they are used in the ultrasonic thermal bonding process for making finished oil filter elements, and provide good bonding strength. The polyester reinforcing cloth can enhance the structural strength of the non-woven material of the end cover of the oil filter element, maintain dimensional stability, and increase the service life. The non-woven fabric material of the end cover of the oil filter element is fixed with the oil filter element throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com