Bubble fastness improver for dyeing polyester and preparation method of bubble fastness improver

A technology of fastness improvement and blistering, which is applied in the field of printing and dyeing auxiliaries, can solve the problems of easy static electricity, easy pilling, and easy fading of polyester fabrics after washing, so as to prevent fading after washing, improve blister fastness, and improve blister fastness. The effect of degree and anti-pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 15 parts of four-terminal allyl cationic monomer, 40 parts of allyl polyether epoxy end capping, 3 parts of crosslinking agent, 0.5 part of initiator, and 40 parts of deionized water.

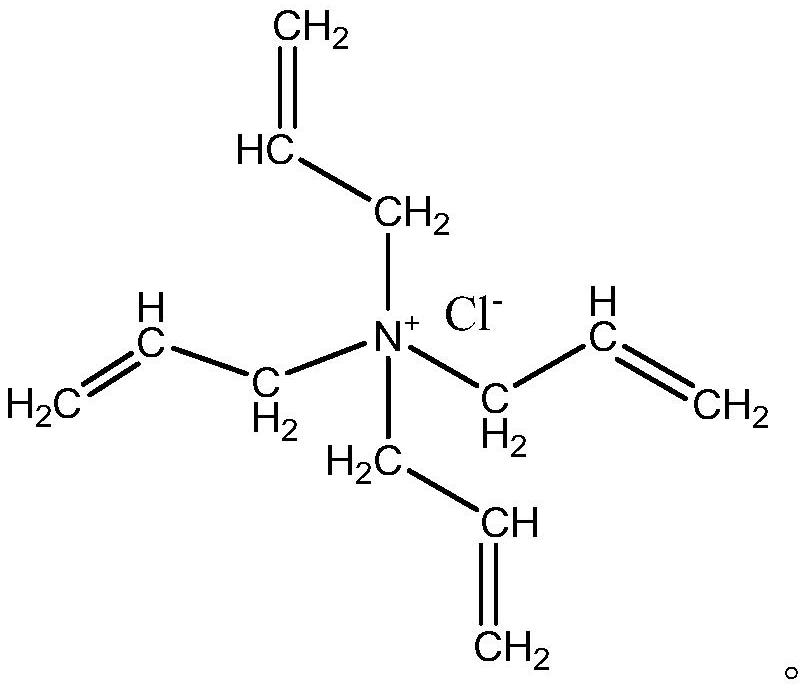

[0022] The structural formula of the four-terminal allyl cationic monomer is:

[0023]

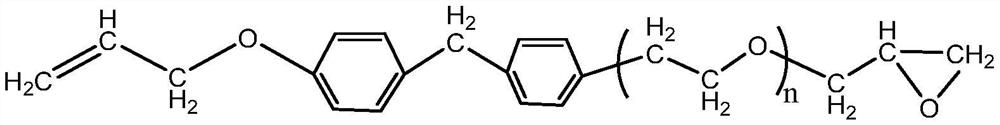

[0024] The structural formula of allyl polyether epoxy end capping is:

[0025]

[0026] Wherein, n is an integer of 2-10.

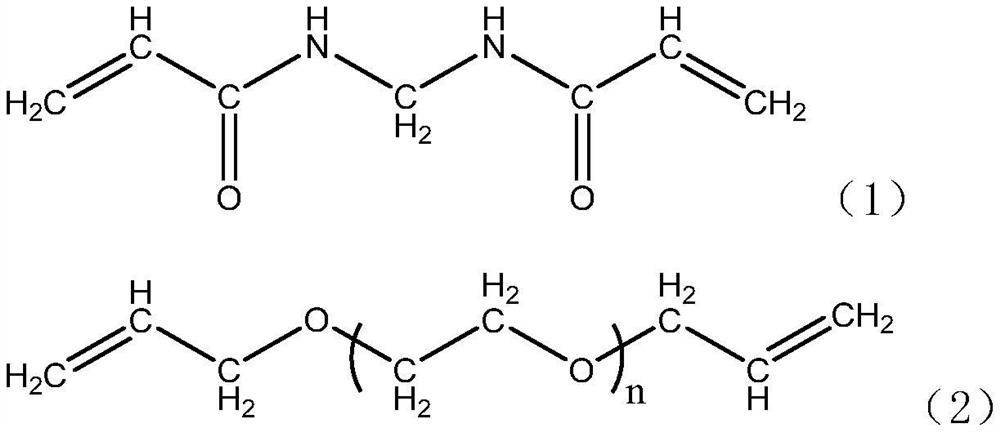

[0027] The crosslinking agent is of the following structural formula (1).

[0028]

[0029] The initiator is at least one of persulfate-bisulfite or azobisisobutyramidine hydrochloride.

[0030] Bubble fastness improving agent for dyeing polyester, its synthesis steps are: adding four-end allyl cationic monomer, allyl polyether epoxy end-capping, cross-linking agent and an appropriate amount of deionized water into a four-necked flask , start stirring, then heat up to 70-75 ° C, then dropwise add the initiator aqueous solution, the dropping time is 1.5 hours, after ...

Embodiment 2

[0032] 18 parts of four-terminal allyl cationic monomer, 55 parts of allyl polyether epoxy end capping, 5 parts of crosslinking agent, 0.6 part of initiator, and 45 parts of deionized water.

[0033] The structural formula of the four-terminal allyl cationic monomer is:

[0034]

[0035] The structural formula of allyl polyether epoxy end capping is:

[0036]

[0037] Wherein, n is an integer of 2-10.

[0038] The crosslinking agent is of the following structural formula (2).

[0039]

[0040] The initiator is at least one of persulfate-bisulfite or azobisisobutyramidine hydrochloride.

[0041] Bubble fastness improving agent for dyeing polyester, its synthesis steps are: adding four-end allyl cationic monomer, allyl polyether epoxy end-capping, cross-linking agent and an appropriate amount of deionized water into a four-necked flask , start stirring, then heat up to 70 ° C, and then dropwise add the initiator aqueous solution, the dropping time is 2 hours, after t...

Embodiment 3

[0043] Body type: 0 parts of four-terminal allyl cationic monomer, 60 parts of allyl polyether epoxy end capping, 6 parts of crosslinking agent, 0.8 parts of initiator, and 50 parts of deionized water.

[0044] The structural formula of allyl polyether epoxy end capping is:

[0045]

[0046] Wherein, n is an integer of 2-10.

[0047] The crosslinking agent is of the following structural formula (1).

[0048]

[0049] The initiator is at least one of persulfate-bisulfite or azobisisobutyramidine hydrochloride.

[0050] The bubbly fastness improving agent for dyeing polyester is synthesized as follows: add allyl polyether epoxy end capping, cross-linking agent and an appropriate amount of deionized water into a four-necked flask, start stirring, then heat up to 70 ° C, and then The initiator aqueous solution was added dropwise for 2 hours. After the dropwise addition, the reaction was continued at 75° C. for 3 hours, cooled, cooled, and discharged to obtain the water-soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com