Method for dyeing cheese prepared from polyester-cotton blending stretch yarn

A technology of polyester-cotton blending and dyeing method, which is applied in the directions of dyeing, textile and papermaking, biochemical fiber processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

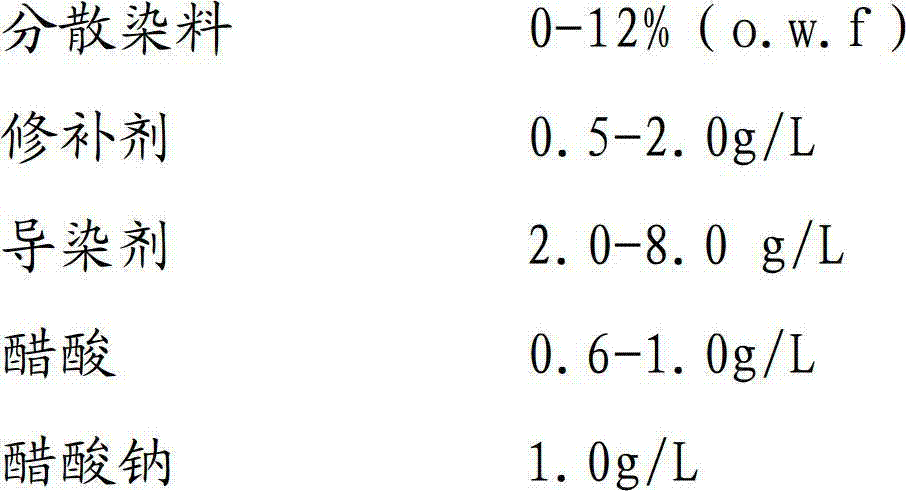

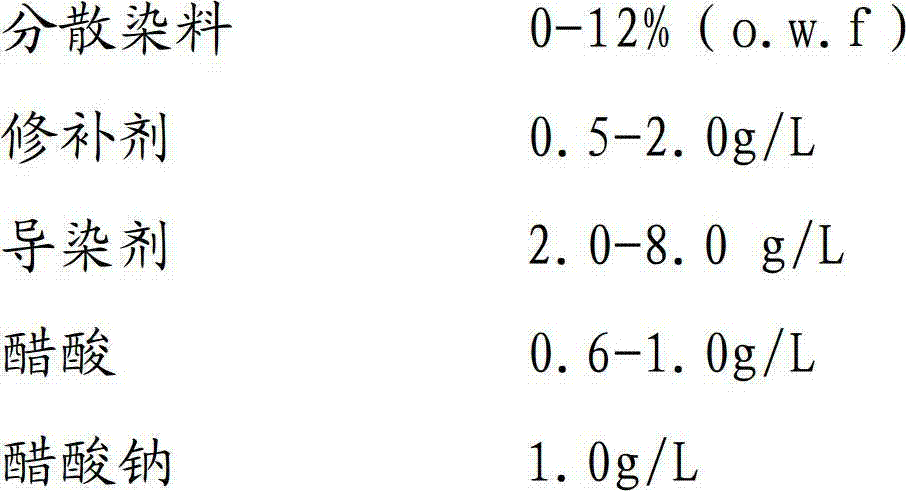

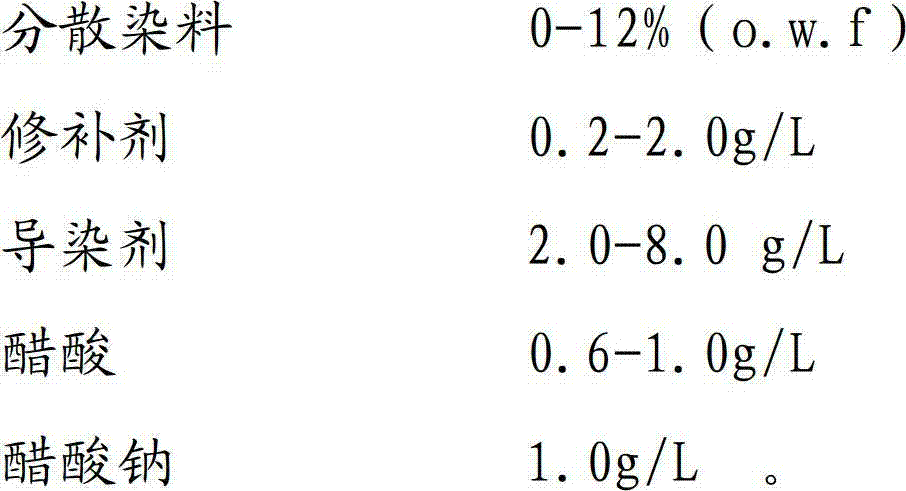

[0018] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments. A method for dyeing polyester-cotton blended elastic yarn as cheese, the process steps are as follows,

[0019] The blending ratio of 100kg polyester and cotton is 60 / 40, and the elastic yarn of 45 British counts is used for cheese dyeing.

[0020] 1. Winding process: SSM winder is used for winding, the speed is 800 rpm, the back pressure is 2.0N, the fixed weight of loose winding bobbins is 1.2kg / piece, and the density is 0.38g / cm 3 ;

[0021] 2. Pretreatment process: Inject water into the dyeing bath at a ratio of 1:10, add 2g / L refining agent, 2g / L solid sodium hydroxide, 6g / L hydrogen peroxide with a concentration of 27.5%, raise the temperature of the dyeing bath to 115°C, and keep warm for 30 minutes , empty after treatment; refill the dye vat with bath ratio 1:10, heat up to 80°C, wash with water for 10 minutes, empty after treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com