Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Feel full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygenase-bath alkali-free desizing process for polyester/cotton high-count and high-density fabric

InactiveCN102011298AQuality improvementFeel goodDry-cleaning apparatus for textilesBleaching apparatusPolyesterAlkali free

The invention relates to an oxygenase-bath alkali-free desizing process for a polyester / cotton high-count and high-density fabric. The process sequentially comprises the following steps of: sewing and singeing the fabric; washing the fabric with three-grid hot water; washing the fabric with two-grid coldwater; padding oxidation bleaching working solution; steaming at the temperature of 102 DEG C for 50 minutes; washing the fabric with four-grid hot water; drying; and shaping, wherein in the step of padding oxidation bleaching working solution, the formula of the oxidation bleaching working solution comprises 10g / L of high-efficient scouring agent HS-120B, 65g / L of 288 dispersing agent, 5g / L of scouring enzyme 188, 5g / L of wax regent WR, 10g / L of hydrogen peroxide stabilizing agent P and 14.0 to 15.0g / L of hydrogen peroxide (wherein the concentration is 33 percent). Compared with the prior art, the desized fabric has greatly improved quality, namely the handfeel is plump; the fabric surface loss ratio is low; the fabric surface whiteness is good; and the fabric has no cotton, multiple nodes and no alkaline spots.

Owner:HUAFANG

Barley seedling clear juice solid beverage and preparation method thereof

InactiveCN103519311AMaintain biological activityLow costFood preparationKonjac glucomannanHealth protection

The invention discloses a barley seedling clear juice solid beverage and a preparation method thereof, which belong to the technical field of health protection food. The barley seedling clear juice solid beverage consists of the following components in percentage by weight: 40-70 percent of barley seedling juice powder, 10-40 percent of barley seedling powder and 3-20 percent of konjac glucomannan. The barley seedling clear juice solid beverage produced by the preparation method is low in production cost, stable in quality, high in nutritional value, high in functionality, good in taste and uniform in state and does not have astringency and precipitates.

Owner:章嘉泽

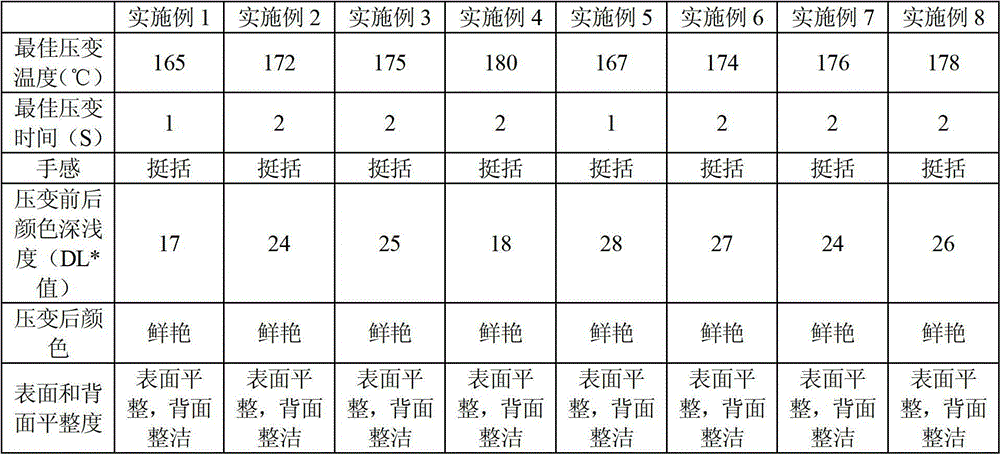

Manufacture method for PU embossed color-changing decoration leather

ActiveCN102747612AFeel crispFeel fullSynthetic resin layered productsLaminationThermal compressionSlurry

The invention provides a manufacture method for PU embossed color-changing decoration leather. According to the method, a layer of polyurethane work slurry prepared by using a wet method is coated onto a spunlaced non-woven fabric, and concrete steps of the method comprise: (a) preparing base cloth and unreeling and ironing the base cloth; (b) coating the polyurethane work slurry changeable at a pressure with a knife, wherein a formula for the work slurry comprises, by mass, 20 to 40 parts of high-modulus resin, 80 to 60 parts of low modulus resin, 90 to 200 parts of a solvent, 15 to 25 parts of a filling material, 3 to 15 parts of color paste, 0 to 4 parts of a microporous regulator, 0.1 to 1 part of an antifoaming agent and 0.1 to 1 part of a leveling agent; (c) carrying out solidification and rinsing; and (d) carrying out drying and reeling, wherein drying temperature is 120 to 155 DEG C. The prepared decoration leather has stiff and smooth touch, smooth surface and neat back; temperature for thermal changes of the decoration leather at a pressure is adjustable and is in a range of 165 to 180 DEG C; time for changes at a pressure is short; and the color of the decoration leather having undergone changes at a pressure is brilliant and full, presenting great contrast.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

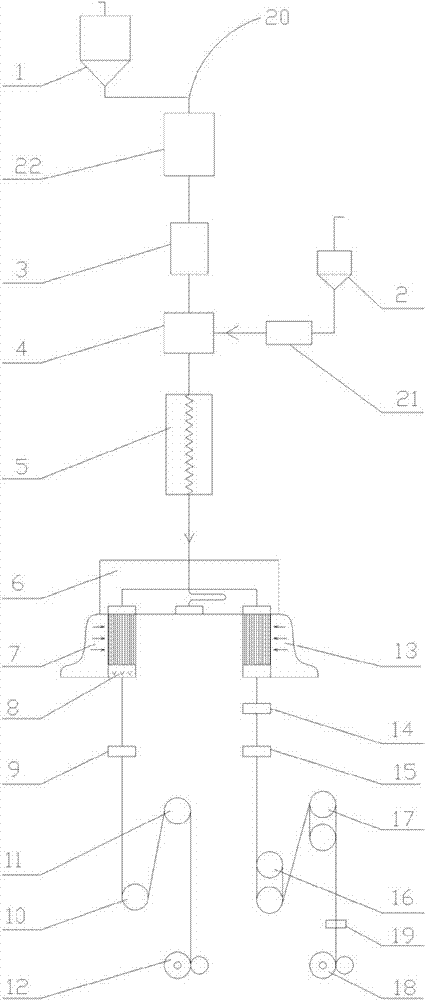

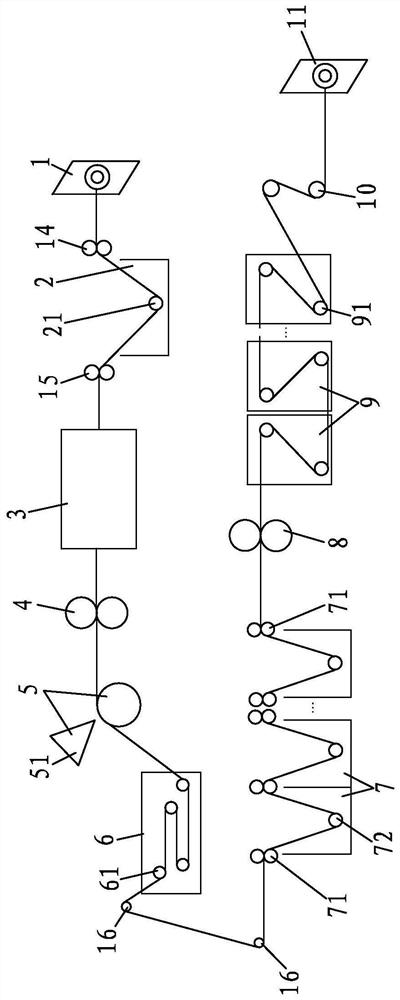

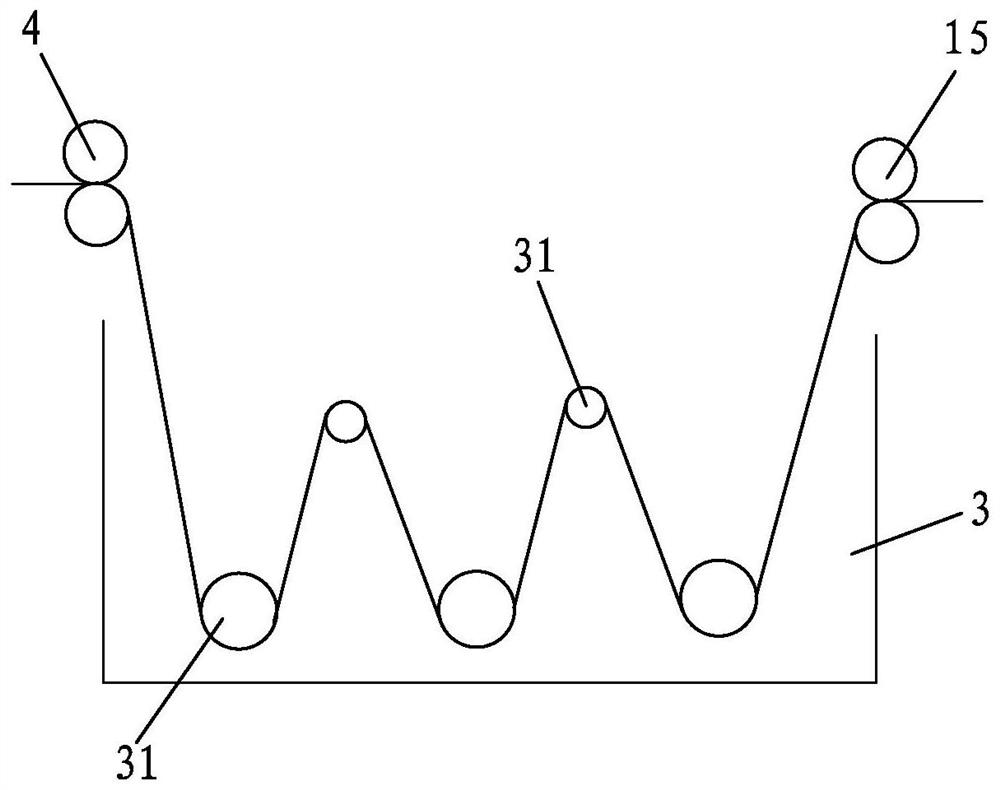

System for producing POY-FDY compound polyester yarns from melt direct-spinning stock solution and preparation method thereof

ActiveCN103757724AWide range of post-processingImprove stiffnessArtificial thread manufacturing machinesSpinning head liquid feederPolyesterYarn

The invention relates to a spinning method, and in particular relates to a system for producing POY-FDY (Pre-Oriented Yarn-Full Drawn Yarn) compound polyester yarns from a melt direct-spinning stock solution and a preparation method thereof. The system is used for spinning POY and FDY. A PET (Poly Ethylene Terephthalate) melt tower is communicated with a melt cooler, a color paste stock bin and the melt cooler are communicated with a multi-factor coupler, the multi-factor coupler is communicated with a dynamic mixer, the dynamic mixer is communicated with a spinning manifold, and the spinning manifold is communicated with a POY device and an FDY device. The preparation method comprises the steps of PET melt delivery, color paste delivery, split-flow treatment in the spinning manifold, POY spinning and FDY spinning. The system for producing the POY-FDY compound polyester yarns from the melt direct-spinning stock solution and the preparation method thereof have the advantages of compact structure, shorter production process flow, simpler and more convenient operation, higher production efficiency, lower energy consumption and loss, more stable quality, reduction of pollutant emission, and ecological environmental protection.

Owner:杭州华成聚合纤有限公司

Health type viscose fiber with high wet modulus and its production process and use

InactiveCN1332276AEasy to prepareSuitable for industrial productionArtificial filaments from viscoseWet spinning methodsCelluloseMechanical property

The present invention is composed of cellulose and chitin with weight ration 2-9:0.02-2. Alkalifying and etiolating cellulose and chitin obtain the xanthogenate of cellulose and chitin. Dissolving the said xanthogenate of cellulose and chitin in sodium of hydroxide and water makes spinning dope. Using wet spinning or wet pipe forming methods, after drawing procedure makes the fiber. The physical and mechanical performance of the fiber can be enhanced after treatment with simple technique. The fiber can fabricate textile and cloth providing features of antibiosis, stopping itch and bleeding, odor dispelling. Fibrous membrane made by mixed cellulose with chitin as raw material can be used in artificial organs or water purifier.

Owner:DONGHUA UNIV

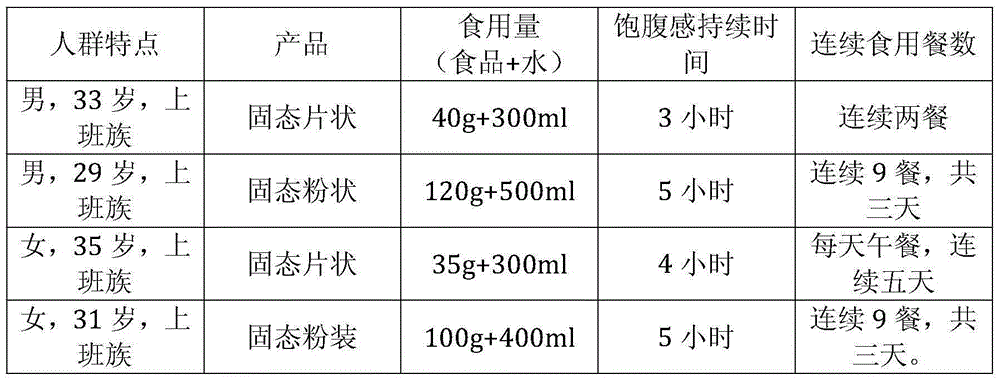

All-nutrition rapid staple food grain and preparing method thereof

The invention discloses all-nutrition rapid staple food grain which comprises, by weight, 5-25 parts of vegetable protein, 2-20 parts of animal protein, 5-30 parts of sweetening agent, 20-50 parts of carbohydrate, 5-25 parts of lipid, 1-30 parts of cellulose, 0-0.5 part of decavitamin, 1-4 parts of composite mineral substance, 0-10 parts of natural plant milled powder, 0-10 parts of edible essence and 0-3 parts of salt. The vegetable protein can be one or a combination of multiple of rice protein, soy protein or wheat protein, and the animal protein can be one or a combination of multiple of whey protein, positive nitrogen protein or fish protein. The invention further discloses a preparing method of the all-nutrition rapid staple food grain. According to the all-nutrition rapid staple food grain and the preparing method of the all-nutrition rapid staple food grain, the all-nutrition rapid staple food grain contains all nutrients obtained from dinners of people under current standards, can replace the dinner of three meals in a day and can also be eaten for a long time, people have satiety with the all-nutrition rapid staple food grain, and the standard of replacing the staple food grain of people is reached.

Owner:HANGZHOU YOUGOU NET TECH CO LTD

Figured sea-island superfine fiber suede leather with writing effect and preparation method thereof

ActiveCN103741497AStrong cashmereFeel fullPattern makingLiquid/gas/vapor textile treatmentAlcoholEmery paper

The invention discloses figured sea-island superfine fiber suede leather with a writing effect and a preparation method thereof. The preparation method comprises the following steps: (1) impregnating a superfine fiber polyurethane synthetic leather base cloth into a raising finishing agent to be padded, and then drying and setting the product to prepare superfine fiber suede leather with an oriented nap effect, wherein the raising finishing agent comprises the following components in parts by weight: 1-8 parts of pilling agent and 100 parts of deionized water; the pilling agent is a polyvalent alcohol interfacial agent compound; (2) unidirectionally polishing the two sides of the product obtained in the step (1) with raw emery paper, and then unidirectionally polishing the two sides with fine emery paper, wherein the polishing directions of the raw emery paper and the fine emery paper are consistent; (3) rubbing the product in the step (2) to generate grains, thus obtaining the figured sea-island superfine fiber suede leather with the writing effect. The suede leather has full hand feeling, writing effect, beautiful appearance, good genuine leather imitating effect and high added value.

Owner:HUAFON MICROFIBER SHANGHAI

Dry method paper cigarette filter candle and preparation method thereof

InactiveCN1669491AThe production process is simpleFeel fullTobacco smoke filtersPaper sheetCigarette filter

The invention discloses a dry method paper cigarette filter candle and preparation method, wherein the filter candle comprises filtering element base material and forming paper, the filtering element base material is prepared paper made through dried bulking process. During the filter candle manufacturing procedure, the dry method paper meeting the index point is arranged onto the feed arrangement of the conventional filter candle forming machine, wherein filter candles are formed on the forming machine through bundled modeling. Since no cellosolve or modeling adhesive are needed, the preparation process can be simplified. The filtering ratio of the obtained cigarette filter tip is over 40%.

Owner:梅建华

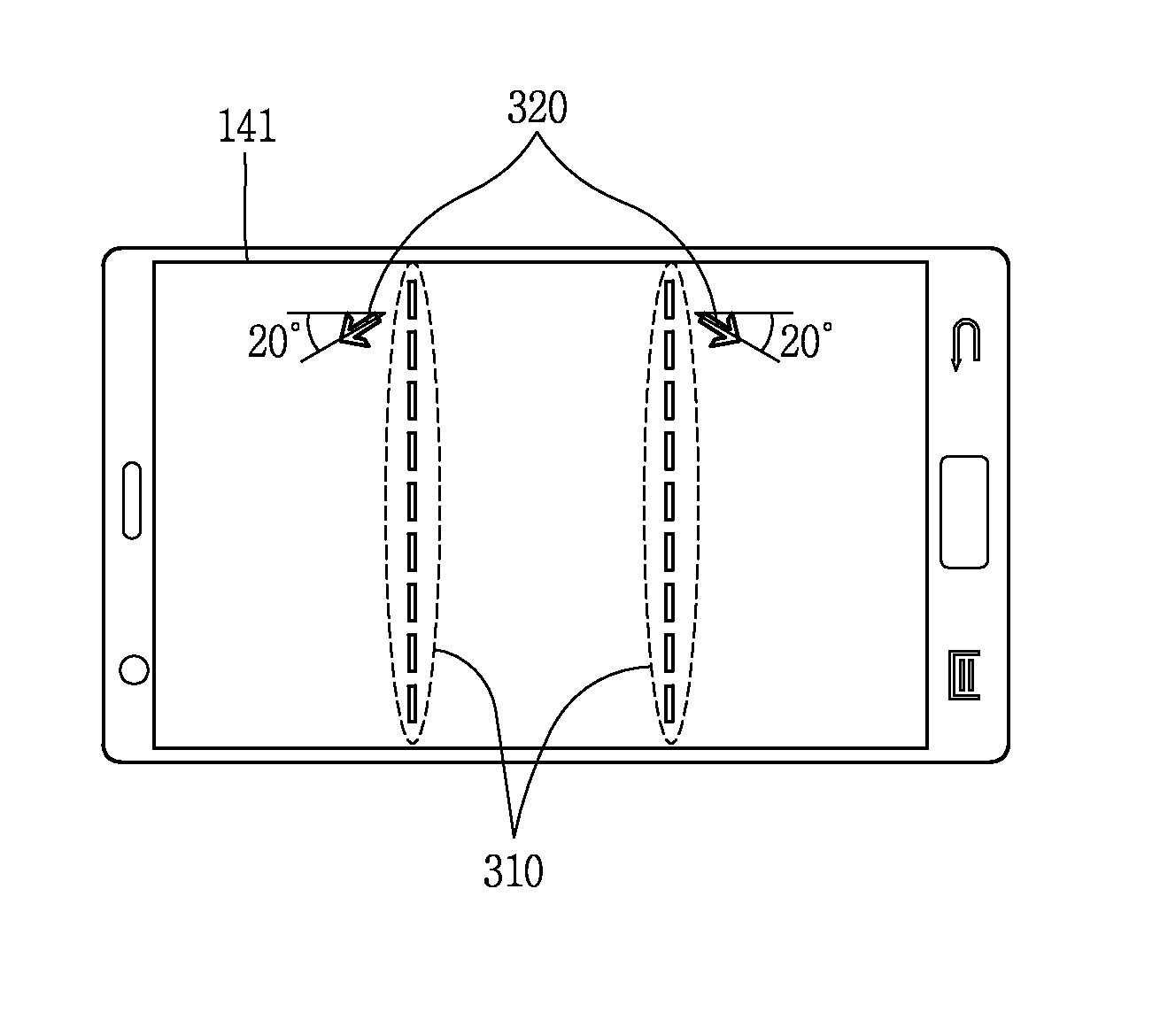

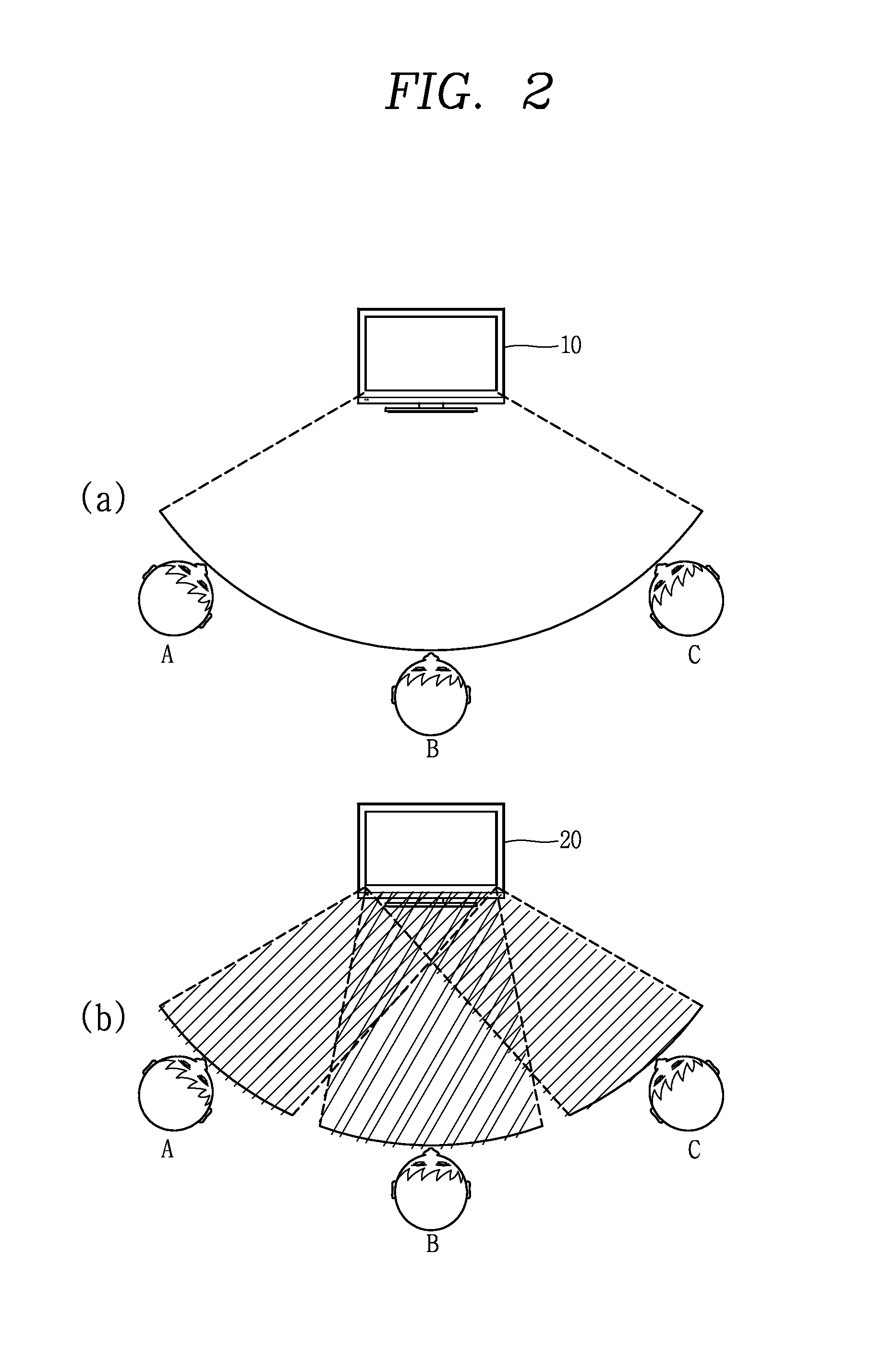

Image display device and method for controlling same

ActiveUS20150002643A1Feel fullStatic indicating devicesDigital data processing detailsComputer graphics (images)Display device

The present invention relates to a method for controlling an image display device including a flexible display unit, comprising the steps of: obtaining a multi-view image signal including camera position information; obtaining information on the shape of the flexible display unit on the basis of the obtained multi-view image signal; and modifying the shape of the flexible display unit on the basis of the obtained shape information.

Owner:LG ELECTRONICS INC

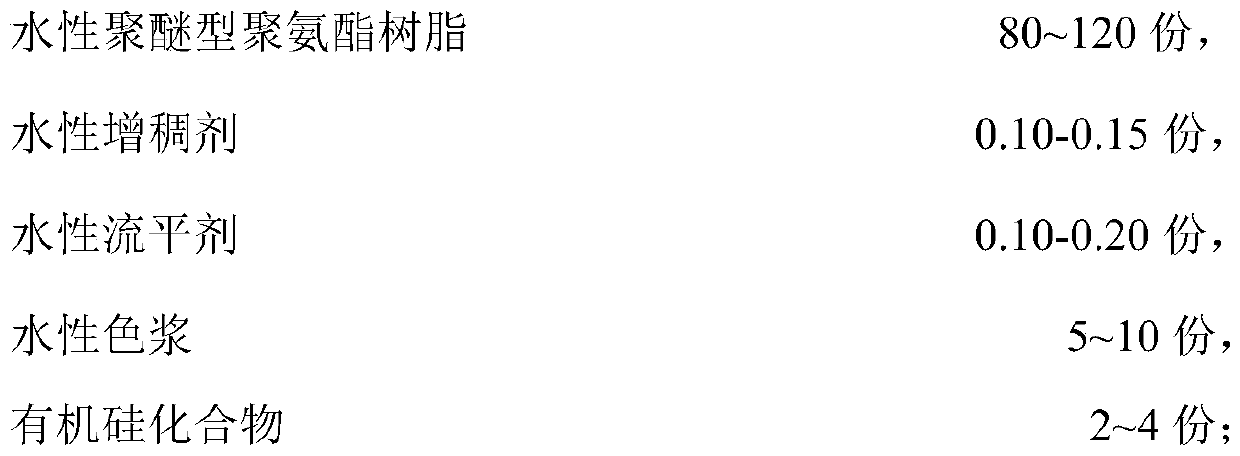

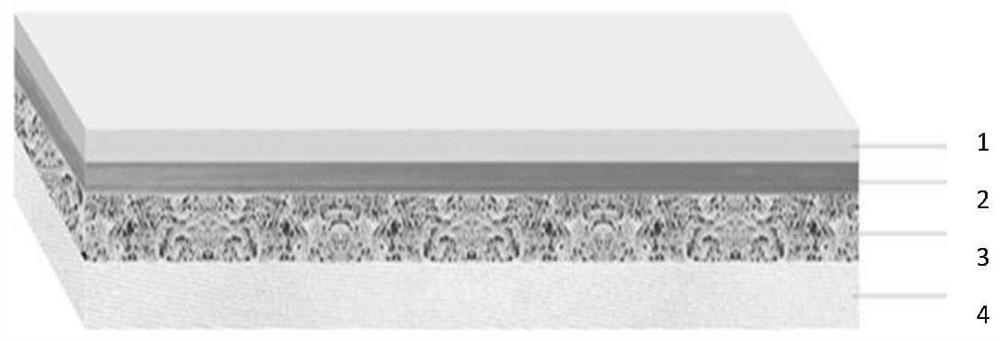

Skin-friendly and environment-friendly polyurethane synthetic leather for earphone sleeve and preparing method of leather

InactiveCN110541312APromote environmental protectionReduce usageGrip property fibresCoatingsSurface layerSolvent free

The invention discloses skin-friendly and environment-friendly polyurethane synthetic leather for an earphone sleeve and a preparing method of the leather. The leather sequentially comprises a dry-method surface layer, a middle layer, a foaming layer and a base cloth layer from outside to inside. The dry-method surface layer is prepared from, by weight, 80-120 parts of waterborne polyether type polyurethane resin, 0.10-0.15 part of a waterborne thickener, 0.10-0.20 part of a waterborne leveling agent, 5-10 parts of waterborne color paste and 2-4 parts of an organic silicon compound. The middlelayer is prepared from, by weight, 80-120 parts of waterborne polyether type polyurethane resin, 0.10-0.15 part of a waterborne thickener, 0.10-0.20 part of a waterborne leveling agent, 5-10 parts ofwaterborne color paste and 1-2 parts of a waterborne crosslinking agent. By means of the waterborne solvent-free process, the finished product can be controlled to be free of DMF, environmentally friendly and healthy; the prepared polyurethane synthetic leather is long in service life, excellent in hydrolysis resistance, soft in surface touch and plump in texture.

Owner:ANHUI ANLI MATERIAL TECH

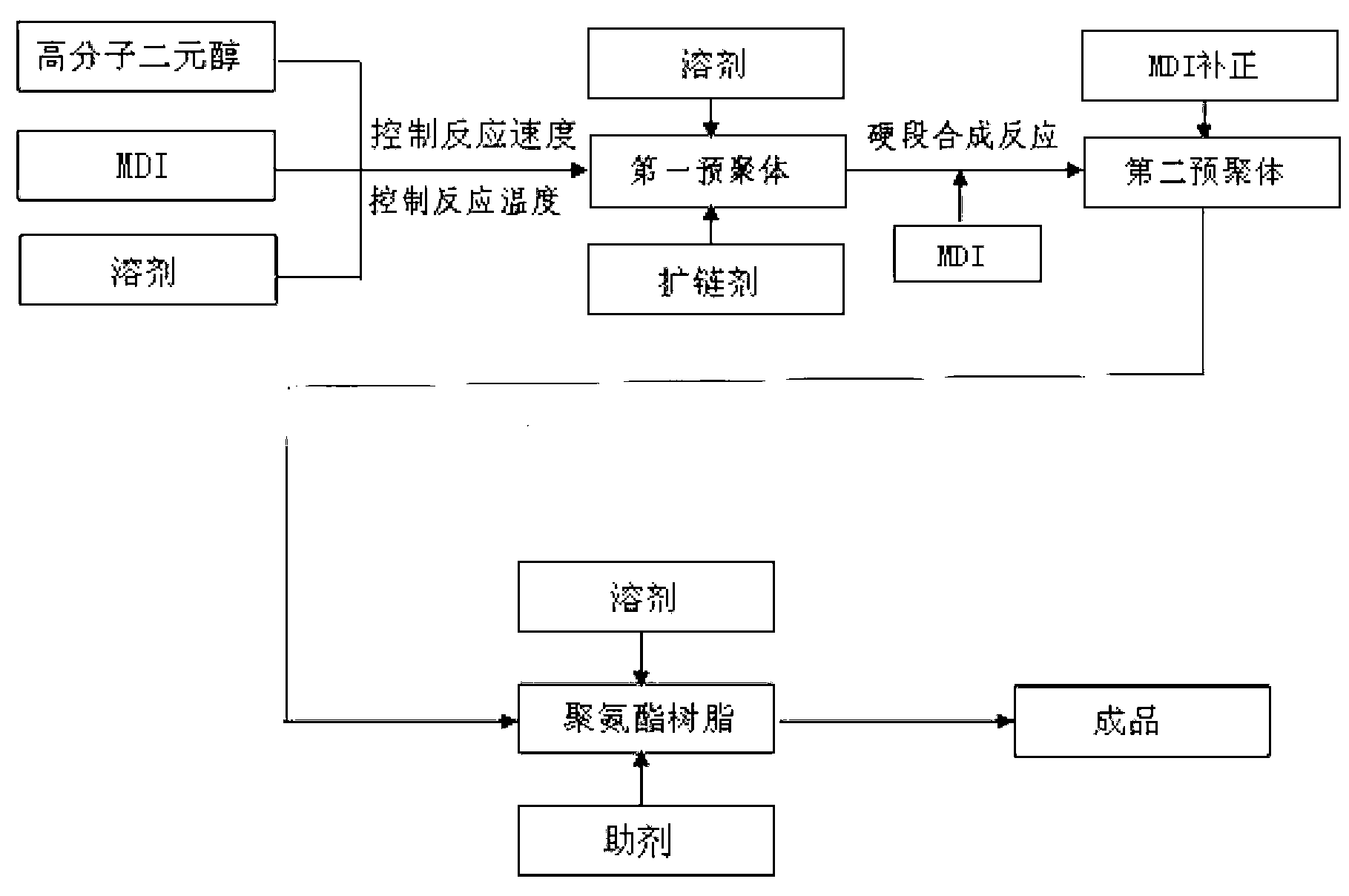

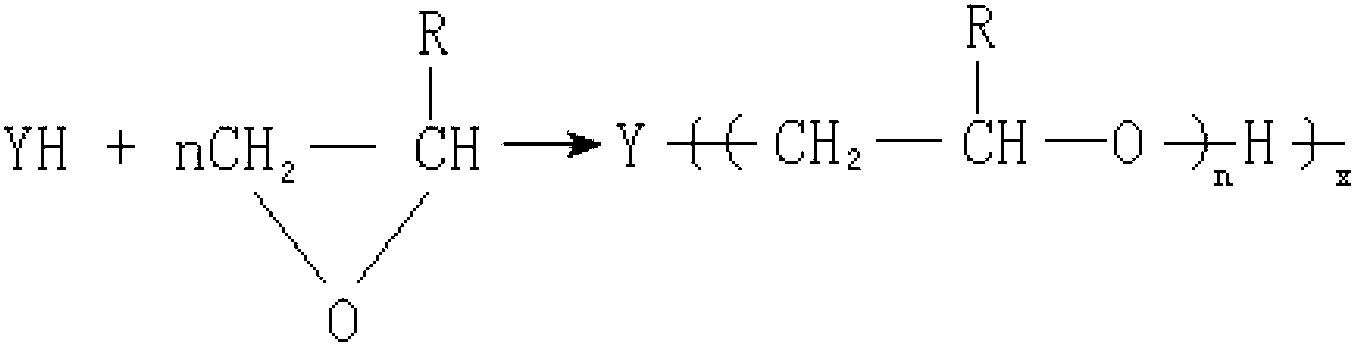

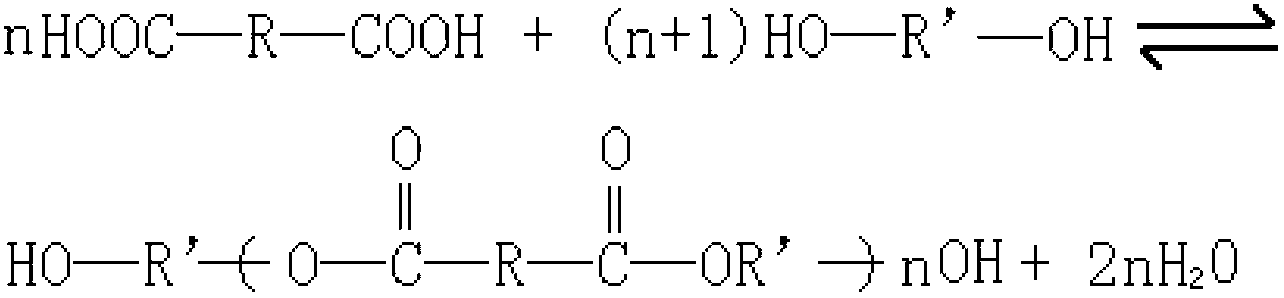

Wet type polyurethane resin, production process and application method thereof

ActiveCN102993398AHigh viscosityFeel fullSynthetic resin layered productsTextiles and paperAlcoholDiol

The invention provides a wet type polyurethane resin, a production process and an application method thereof. The production process mainly comprises the following steps: 1, carrying out a soft-segment synthetic reaction on macromolecule dihydric alcohol and diphenyl methane diisocyanate; 2, enabling a first prepolymer to react; 3, adding a chain extender, and carrying out hard-segment synthetic reaction; and 4, adding an auxiliary. The wet type polyurethane resin manufactured by the production process is in form of yellowish transparent and thick viscous fluid, has viscosity of 180,000 to 220,000 (cps / 25 DEG C), modulus of 100% under 4.5 to 5.5 Mpa, elongation of not less than 550% and strippability of not less than 12.0kg / 3cm, the hydrolysis resistance is that 10% of NaOH is hydrated for 24 hours, and the wet type polyurethane resin has texture formation of 50 to 65%. The production process has the advantages that the texture formation, peeling strength and hydrolysis resistance of the wet type polyurethane resin are improved; the auxiliaries are selected before forming the leather, so that the density of the wet type polyurethane resin is improved, the finished artificial leather has washing durability and is high in strippability and full in touch.

Owner:FUJIAN GUOBANG RESIN

Preparation method of stereoscopic natural bright microfiber material and products thereof by lustring

InactiveCN106544883AStrong three-dimensional senseNatural lusterFibre typesPolyurethane dispersionPolymer science

The invention discloses a method for preparing a stereoscopic natural bright microfiber material by lustring, comprising the following steps: step one, preparing a fiber bat; step two, preparing base cloth; step three, carrying out impregnation via polyvinyl alcohol; step four, carrying out impregnation via PU by dipping an intermediate product prepared by the step three via wet polyurethane size, solidifying, washing at normal temperature, pre-drying for a second time, dipping via dispersoid, drying for a second time, washing with water at high temperature, drying and shaping to prepare a semi-finished product, wherein a solidification solution is dimethylformamide, and the dispersoid is water-soluble polyurethane dispersoid; step five, carrying out alkali minimization; and step six, carrying out leather facing effect treatment and treating via a functional agent. The invention also discloses a preparation method of the microfiber material and the products thereof. The prepared microfiber material and the products thereof are strong in texture stereoscopic feeling, natural in gloss and rich and full in hand feeling; various physical indexes such as peeling strength, abrasion resistance, tearing resistance, maximum tension force, yellowing resistance and breathability and the like are significantly higher than that of the similar products; the microfiber material and the products thereof can be widely applied to high-grade fashionable clothes, household articles and working articles.

Owner:泉州众信超纤科技股份有限公司

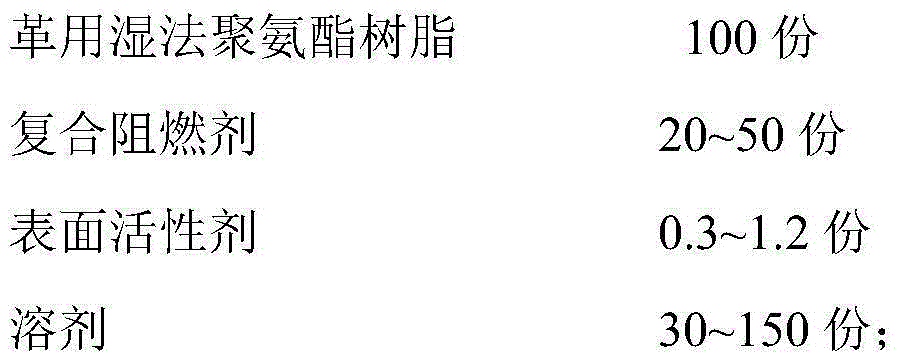

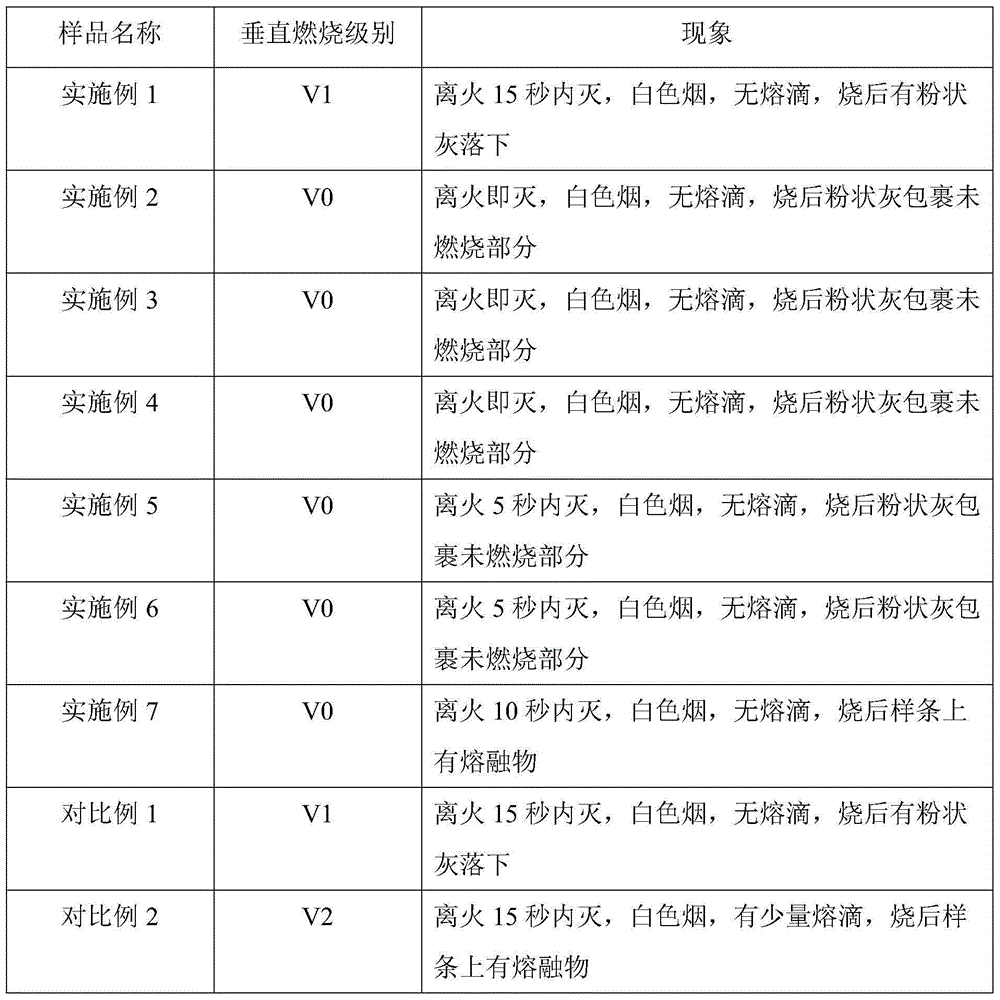

Halogen-free flame-retardant polyurethane resin slurry for leather and application thereof

The invention discloses halogen-free flame-retardant polyurethane resin slurry for leather and application thereof. The halogen-free flame-retardant polyurethane resin slurry for leather is prepared from, by weight, 100 parts of wet-process polyurethane resin for leather, 20-50 parts of composite flame retardant, 0.3-1.2 parts of surfactant and 30-150 parts of solvent. The composite flame retardant is a mixture of water-insoluble ammonium polyphosphate and dialkyl aluminum phosphinic acid, and the mass ratio of water-insoluble ammonium polyphosphate to dialkyl aluminum phosphinic acid is 1:0.5-2.0. Powdery ash generated after combustion of prepared base cloth wraps a non-combusted part to form a flame-retardant carbon layer, the flame retardancy reaches the vertical combustion level V0 as is determined according to a vertical combustion method in GB / T 2408-2008, a spline dies out once away from fire, smoke is white and free of undesirable odor, no molten drop is generated, the flame-retardant effect is better than that of a product prepared from dialkyl aluminum phosphinic acid only, the price can be lowered by about 50%, and the aim of actual industrial application is achieved.

Owner:江苏华峰超纤材料有限公司

Preparation method of knitted cotton-simulated collar-sleeve material

InactiveCN103074729AFeel fullGood warmth retentionSucessive textile treatmentsWeft knittingAdditive ingredientSurface-active agents

The invention relates to a preparation method of a knitted cotton-simulated collar-sleeve material, and the method comprises the following steps of step 1, utilizing a flat knitting machine to weave the following materials by weight percent into fabric: 3 percent of 30D spandex, 78 to 82 percent of 140D / 144F dacron and 15 to 19 percent of 75D / 48F Dacron; step 2, placing the woven fabric into a post-treatment pond to be soaked for 5min under the temperature of 45DEG C, wherein the post-treatment pond comprises the following assistants: smoothing agent accounting for 2.5 to 3.5 percent of total weight of water in the post-treatment pond and loosening agent accounting for 1.5 to 2.5 percent of the total weight of the water in the post-treatment pond; the smoothing agent comprises the following ingredients in parts by weight: 20 parts of segmental silicon oil, 10 parts of polyether and 20 parts of nonionic surface active agent; the loosening agent comprises the following ingredients in parts by weight: 15 parts of emulsifier, 40 parts of polyurethane and 5 parts of permeable paste; and step 3, utilizing vapor to softly iron the well-soaked fabric, and completing the treatment step. The knitted cotton-simulated collar-sleeve material prepared through the preparation method is full to touch and excellent in warmth, sweat absorption and ventilation.

Owner:泉州市劲超针织实业有限公司

Preparation technology of natural organism and vegetable fiber microfiber material, and preparation technology of product

The invention discloses a preparation technology of a natural organism and vegetable fiber microfiber material. The technology comprises the following steps: 1, preparing fiber batting composed of dermal fiber-containing composite fibers, modified high-shrinkage polyester fibers and vegetable fibers; 2, preparing a base cloth; 3, carrying out polyvinyl alcohol impregnation treatment; 4, carrying out PU impregnation treatment; 5, carrying out alkali decrement treatment; and 6, carrying out surface effect and function agent treatment: coating the surface of a semi-finished product to form a surface layer, and preparing the microfiber material from the surface layer according to a needed surface effect, wherein the surface layer is coated through the following steps: coating an air-permeable lining film, coating a surface slurry, drying the slurry, coating the surface slurry, and drying the slurry to obtain the finished microfiber material. The invention also discloses the microfiber material prepared through adopting the above technology, and a preparation technology of a product. The microfiber material and the product produced through the above technologies are comparable to derma in physical properties, and has the appearance, quality, strength, softness, air permeability and other physical properties of the derma.

Owner:泉州众信超纤科技股份有限公司

Negative ion cellulose/alginate composite fiber and its preparing method

InactiveCN100415959CLess investmentLow costFilament/thread formingConjugated cellulose/protein artificial filamentsWound healingCellulose

The present invention discloses a kind of composite negative ion cellulose / alginate fiber and its preparation process. Technologically, the present invention features that viscous sodium alginate solution prepared in certain technological condition, functional finishing agent slurry of negative ion generating material and cellulose xanthate in certain weight proportion are mixed to form the spinning solution, and the through further spinning and refining steps, the composite negative ion cellulose / alginate fiber is prepared. The composite fiber consists of cellulose 76-99.6 weight portions, sodium alginate 0.02-15 weight portions and negative ion generating material 0.02-9 weight portions. The composite fiber may be used in weaving fabric with the functions of killing bacteria, protecting skin, promoting wound healing, generating negative ion, etc. and is suitable for use in medical field and in making various kinds of high grade underwear, etc.

Owner:BOFINE TEXTILE

Dry process paper filter tip and its prepn process

ActiveCN1810167AElasticity does not affectFeel full and firmTobacco smoke filtersFiberElectrical resistance and conductance

The present invention reveals one kind of dry process paper filter tip and its preparation process. The filter tip material including wood pulp fiber and coat core fiber is first antistatic treated with non-toxic ester or ether to specific resistance smaller than 900 megohm.cm; and the opened material is then metered, conveyed, airflow netted, heated to form under negative pressure, sprayed with glue, stoved, matured, puffed and settled in cold wind to form dry process paper of plane weight 35-75 g / sq m and thickness of 0.8-3.5 mm. The dry process paper is finally formed into the filter tip, and the filter tip has filter rate over 43 %, hardness over 89 % and ideal rebounding effect after kneads.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

Soft and scratch-resistant fixed island ultrafine fiber suede leather and preparation method thereof

ActiveCN106245338AFeel fullSoft and scratch resistantFabric breaking/softeningLiquid/gas/vapor removalFiberEmulsion

The invention discloses soft and scratch-resistant fixed island ultrafine fiber suede leather and a preparation method thereof. The preparation method includes the following steps that 1, fixed island ultrafine fiber suede leather is soaked in a finishing agent, padding is carried out, and then dry-shaping is carried out, wherein the finishing agent is prepared from, by weight, 0.5-10 parts of softener, 0.1-8 parts of assistant A, 1-10 parts of assistant B and 100 parts of water, the softener is one or more of organosilicone softeners and films, the assistant A is one or more of ethylene-vinyl acetate copolymer emulsion, hydroxyethyl cellulose, polyvinyl alcohol and carboxymethylcellulose, and the assistant B is waterborne polyurethane emulsion; 2, the product obtained in the step 1 is subjected to grain kneading in a grain kneading machine or an air kneading machine, and the product can be obtained. Fine hair of the suede leather is denser and full in hand feeling, and the prepared ultrafine fiber suede leather has the advantages of being soft, resistant to scratches, attractive in appearance, good in leather imitation effect and high in added value.

Owner:HUAFON MICROFIBER SHANGHAI

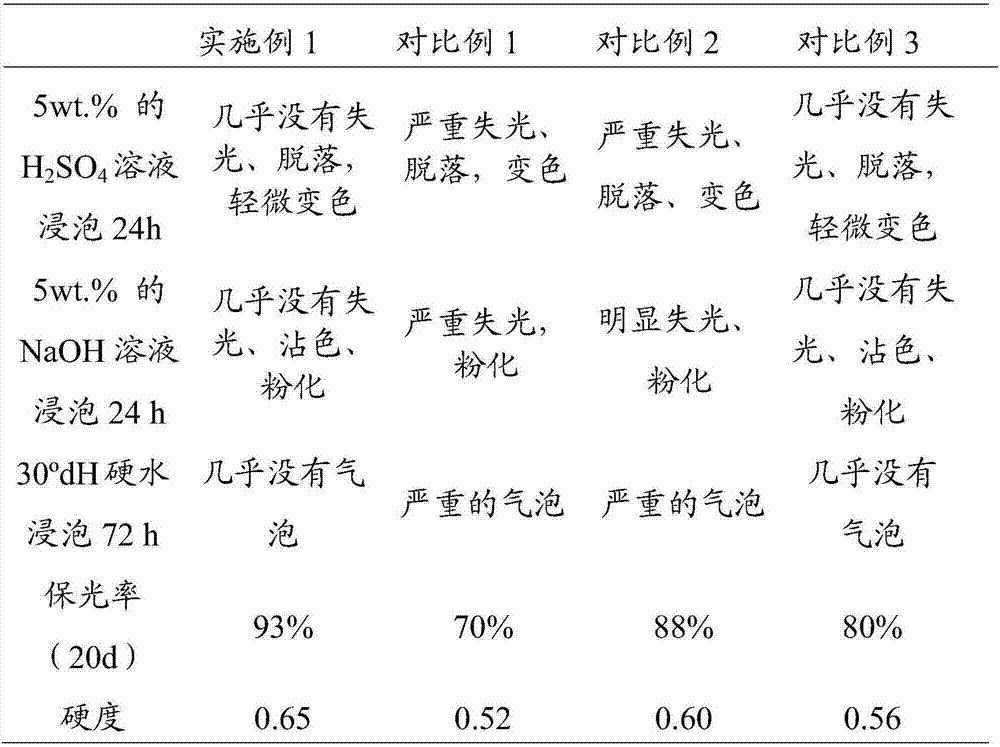

Electric aluminium

ActiveCN107253409AImprove friction resistanceFeel smoothNon-macromolecular adhesive additivesMacromolecular adhesive additivesWaxIon

The invention relates to electric aluminium comprising a base film layer, a release layer, a color layer, an aluminized layer and an adhesive layer which are sequentially arranged in a laminating mode. The release layer comprises, by weight, 2-5 parts of liquid wax, 1-3 parts of plate release wax, 20-30 parts of ethyl alcohol and 20-30 parts of deionized water, wherein the plate release wax is modified oxidized polyethylene wax with silicon hydroxyl. The modified oxidized polyethylene wax is added in the release layer to serve as the plate release wax, the modified oxidized polyethylene wax has the silicon hydroxyl (Si-OH), the friction resisting property of the release layer can be improved, and thus the release layer has smooth and full hand feelings and accordingly has the good stripping property; and meanwhile the modified oxidized polyethylene wax can be matched with the liquid wax mutually, so that the release layer has good acid resistant, alkali resistant and hard-water resistant properties, and the uniformity of smearing of the color layer on the release layer can be further improved. By adjusting the adding amount of the modified oxidized polyethylene wax, the electric aluminium can have different degrees of the friction resisting property and the acid resistant, alkali resistant and hard-water resistant properties, and accordingly the application requirement can be better met.

Owner:ANHUI JIYOU NEW MATERIAL CO LTD

Negative ion cellulose/alginate composite fiber and its preparing method

InactiveCN1858311ALess investmentLow costFilament/thread formingConjugated cellulose/protein artificial filamentsWound healingCellulose

The present invention discloses a kind of composite negative ion cellulose / alginate fiber and its preparation process. Technologically, the present invention features that viscous sodium alginate solution prepared in certain technological condition, functional finishing agent slurry of negative ion generating material and cellulose xanthate in certain weight proportion are mixed to form the spinning solution, and the through further spinning and refining steps, the composite negative ion cellulose / alginate fiber is prepared. The composite fiber consists of cellulose 76-99.6 weight portions, sodium alginate 0.02-15 weight portions and negative ion generating material 0.02-9 weight portions. The composite fiber may be used in weaving fabric with the functions of killing bacteria, protecting skin, promoting wound healing, generating negative ion, etc. and is suitable for use in medical field and in making various kinds of high grade underwear, etc.

Owner:BOFINE TEXTILE

Preparation method of soft line-suction microfiber leather without thickness loss

PendingCN110130118AShort development cycleSoft touchHeat resistant fibresGrip property fibresEngineeringMicrofiber

The invention discloses a preparation method of soft line-suction microfiber leather without thickness loss. The preparation method comprises following steps: S1, base fabric is subjected to softeningtreatment; S2, dry surface making is performed, and microfiber leather is obtained; S3, printing treatment is performed, and a printing layer is obtained; S4, a line-suction process is adopted, a vacuum line suction machine is utilized for sucking lines, a heating hood passes through two heating areas, the first heating area is used for heating a main body, the second heating area is used for supplementing heat, and cooling is performed; the soft line-suction microfiber leather without thickness loss is obtained. The thickness of the line-suction microfiber leather prepared with the method ofthe soft line-suction microfiber leather without thickness loss is increased by about 0.05 mm; the product which is 1.0 mm-1.5 mm touches soft and full; the lines are natural and are copied from genuine leather directly, a line-suction roller is made, the lines are transferred to the surface of the product by the line-suction roller, and the lines have a short development cycle and change fast compared with release paper.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Anti-mold detergent for wallpaper

InactiveCN108102802AEasy to cleanFunction increaseInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEthylenediamineSolvent

The invention relates to the technical field of detergents and in particular to an anti-mold detergent for wallpaper. The anti-mold detergent comprises the following raw materials: starch, bleaching clay, pumice powder, shell powder, ethylenediamine acetic acid disodium, dimeticone water-soluble siloxane, hydroxyethyl cellulose, shikakai powder, potassium oxalate, aluminum potassium sulfate, a surfactant, plant oil and a solvent. The anti-mold detergent for wallpaper, which is provided by the invention, is excellent in cleaning effect, a full hand feeling is achieved after treatment, a productvalue feeling is improved, in addition, a product treated with the detergent has a long-lasting antibacterial function on multiple microorganisms, and the anti-mold effect is remarkable.

Owner:GUANGDONG YULAN GRP

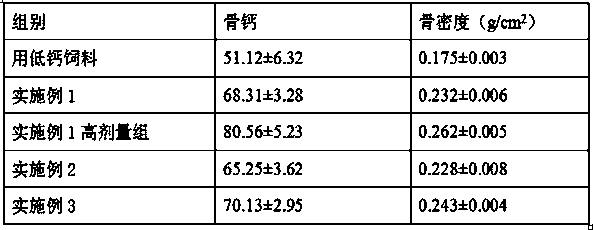

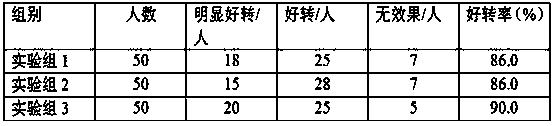

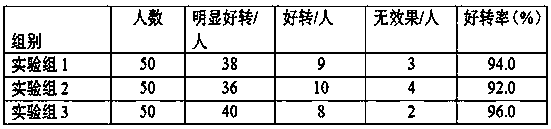

Hypoglycemic health-care food for diabetes type II;

InactiveCN1460480AEffective ingredients are clearLess componentsOrganic active ingredientsMetabolism disorderMedicineRadiation Sterilization

The present invention uses kelp extract as main raw material, and adopts the processes of drying, pulverizing, adding nutrient organic chromium or some auxiliary materials according to a certain proportion, using gamma-ray radiation sterilization to make them into the invented health-care food which can be made into powder preparation, oral liquor, paste preparation, table and capsule preparation for curing diabetes type II and preventing its complication.

Owner:广州蓝钥匙海洋生物工程有限公司

Cloth for PU synthetic leather and preparation method thereof

InactiveCN105484056AFeel fullIncreasing the thicknessPolyurea/polyurethane coatingsMedical preparationsChemistryYarn

The invention provides cloth for PU synthetic leather and a preparation method thereof. The cloth comprises a yarn layer and a fluffing layer, wherein the fluffing layer is coated with PU slurry; the PU slurry is prepared from, by weight, 80-100 parts of wet polyurethane resin, 70-100 parts of organic solvent, 10-35 parts of filler and 6-12 parts of penetrant. According to the preparation method, the fluffing layer of the cloth is directly coated with the PU slurry, the cloth is put into a solidification tank for solidification and then washed, water in the washed cloth is squeezed through a pressing wheel, and then the cloth is dried, cooled and rolled. According to the cloth, the PU slurry permeates into the fluffing layer, the fluffing layer is filled fully like leather, original soft cloth fluff gaps are filled up, and the filling layer is provided with a large number of air holes according to the principle of the wet process.

Owner:HESHAN XINKEDA ENTERPRISE CO LTD

Modified organic silicon resin and application thereof in polyurethane solvent-free decorative leather, furniture leather and automobile leather

ActiveCN112832034AFeel fullLow costTextile/flexible product manufactureTextiles and paperPolymer sciencePolyol

The invention relates to organic silicon resin, in particular to modified organic silicon resin and application thereof in polyurethane solvent-free decorative leather, furniture leather and automobile leather. The modified organic silicon resin is prepared from the following raw materials in parts by weight of 30 to 60 parts of organic silicon resin, 10 to 20 parts of polyether polyol, 10 to 30 parts of fumed silica, 10 to 40 parts of liquid silica gel, 0.01 to 0.5 part of platinum catalyst, 0.1 to 1 part of inhibitor, 10 to 40 parts of 1, 3-diethenyl-1,1,3,3-tetramethyldisiloxane, 5 to 20 parts of high-hydrogen-content silicone oil, 0.5 to 2 parts of anti-doodling additive and 1 to 5 parts of a hand feeling agent. Compared with pure silica gel leather, the product has the advantages that the scratch resistance is improved by 80%, the hand feeling of the leather is full, the cost is reduced by 50%, and the product performance exceeds that of solvent-free leather and pure silica gel leather.

Owner:路联新材料集团股份有限公司

Super soft cellulose fiber fabric afterfinishing process

InactiveCN106868871ALess prone to wrinklesFeel fullHeating/cooling textile fabricsGrip property fibresPulp and paper industryCellulose fiber

The invention discloses a post-finishing process for super-soft cellulose fiber fabrics, which comprises drying, raising, softening, reshaping, ironing and shearing of dyed fabrics or printed fabrics; in the softening treatment, adding fiber fabrics Softener, the mass percentage of the active ingredients of the fiber fabric softener is 17~21%, the bath ratio is 1:15~16, the temperature of the softening treatment is 44~45°C, the treatment time is 5~10min, and the drying The temperature is 130~150℃, and the feeding speed is 15~20m / min. The invention adopts the fiber fabric softener to soften the fabric, and the process conditions are easy to control, and the performance of the final product is stable. , the texture is strong and smooth.

Owner:CHANGSHU XINXIN WARP & KNITTING

Prescription of Gaosi (Chinese Name) cotton and preparation process of Gaosi cotton

InactiveCN102888710AImprove breathabilityGood hygroscopicityNew-spun product collectionSevering to form staple fibresPolyesterFiber

The invention provides a prescription of Gaosi (Chinese Name) cotton and a preparation process of the Gaosi cotton, which relate to the field of textile products. The prescription comprises 10-15% of low-solubility cotton, 40-50% of silicon-added superfine polyester fiber and 20-35% of silicon-added superfine polyester fiber. The preparation processes comprise the following steps of: bundling, drawing, washing by water, oiling, crimping, drying and shaping, cutting, packaging and molding floccules. The Gaosi cotton has the characteristics of strong air permeability and moisture absorption, low carbon, environmental protection, strong luster sensation, full hand feeling, high elasticity, high bulkiness, high flatness and high uniformity; and both the structure and the performance of prepared nascent fibers can satisfy the processing and use requirements of the textile products.

Owner:NANTONG HOURS 7 TEXTILE TECH

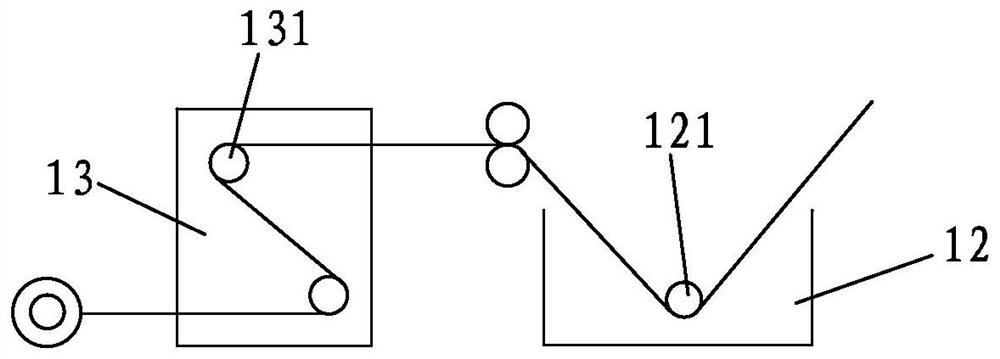

Fluorine-free anti-siphon high-density synthetic leather and production method thereof

The invention provides a fluorine-free anti-siphon high-density synthetic leather and a production method thereof. The method comprises the steps of that a non-woven fabric is unwinded through a clothstorage rack, the unwinding non-woven fabric enters into a soaking tank for soaking, and then enters a pre-coagulation tank for pre-coagulation after immersion; the pre-coagulated non-woven fabric isironed by an ironing device, and then the fabric is scraped by a coating device equipped with a coating knife; the non-woven fabric coated with the fabric is firstly coagulated in a triple fold coagulation tank to generate synthetic leather; the synthetic leather from the triple fold coagulation tank is washed in a water washing tank to obtain bass; the bass from the washing tank is pre-ironed byan ironing roller and then dried in the oven, and the dried bass is rolled up. The method has the advantages of having fluorine content meeting the environmental protection requirements, not causingharm to human health; good siphon prevention effect, and high stripping data; and full hand feeling and good rebound property of the bass.

Owner:ANAN CHINA

Nutrient enriched biscuit rich in marine chondroitin sulfate

InactiveCN111011430APrevent degradationFunction increaseDough treatmentPre-baking dough treatmentBiotechnologyNutrition

The invention provides a nutrient enriched biscuit rich in chondroitin sulfate. The nutrient enriched biscuit rich in chondroitin sulfate is produced from, by weight, 100 parts of flour, 4 parts of brown sugar, 10 parts of white granulated sugar powder, 10 parts of konjaku flour, 6 parts of chondroitin sulfate, 20 parts of superfine bone meal, 1 part of Bacillus subtilis, 100 parts of egg liquid,20 parts of milk powder, 5 parts of palm oil, 2 parts of table salt, 1 part of baking soda and 1 part of large yellow croaker roe phospholipid. The nutrient enriched biscuit rich in chondroitin sulfate is rich in chondroitin sulfate and organic calcium, has an obvious effect on treating osteoarthritis, rheumatic arthritis, gonitis and finger arthritis, and has the effects of regulating intestinaltracts, enhancing immunity and promoting in-vivo saturated fatty acid metabolism.

Owner:福州宏东食品有限公司

Ring spinning combed cotton 80-roving siro spinning technology

The invention provides a ring spinning combed cotton 80-roving siro spinning technology. The technology is characterized by comprising the steps of drawing and roving; According to the steps of drawing and roving, the end combination quantity is 2.2-2.5 g / m, the front roller speed is 340-360 meter / minute, and the light quantity selected by roving is 3.8-4.2 g / 10m; the roving twist factor is 110-113. The surface fiber of cotton 80-roving siro spun yarn is arranged in order, the structure is compact, the amount of hairiness is small, the fabric touch is soft and full, the fabric is unique in style, and the yarn has the characteristics of threads.

Owner:山东华晨彩装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com