Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Feel crisp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

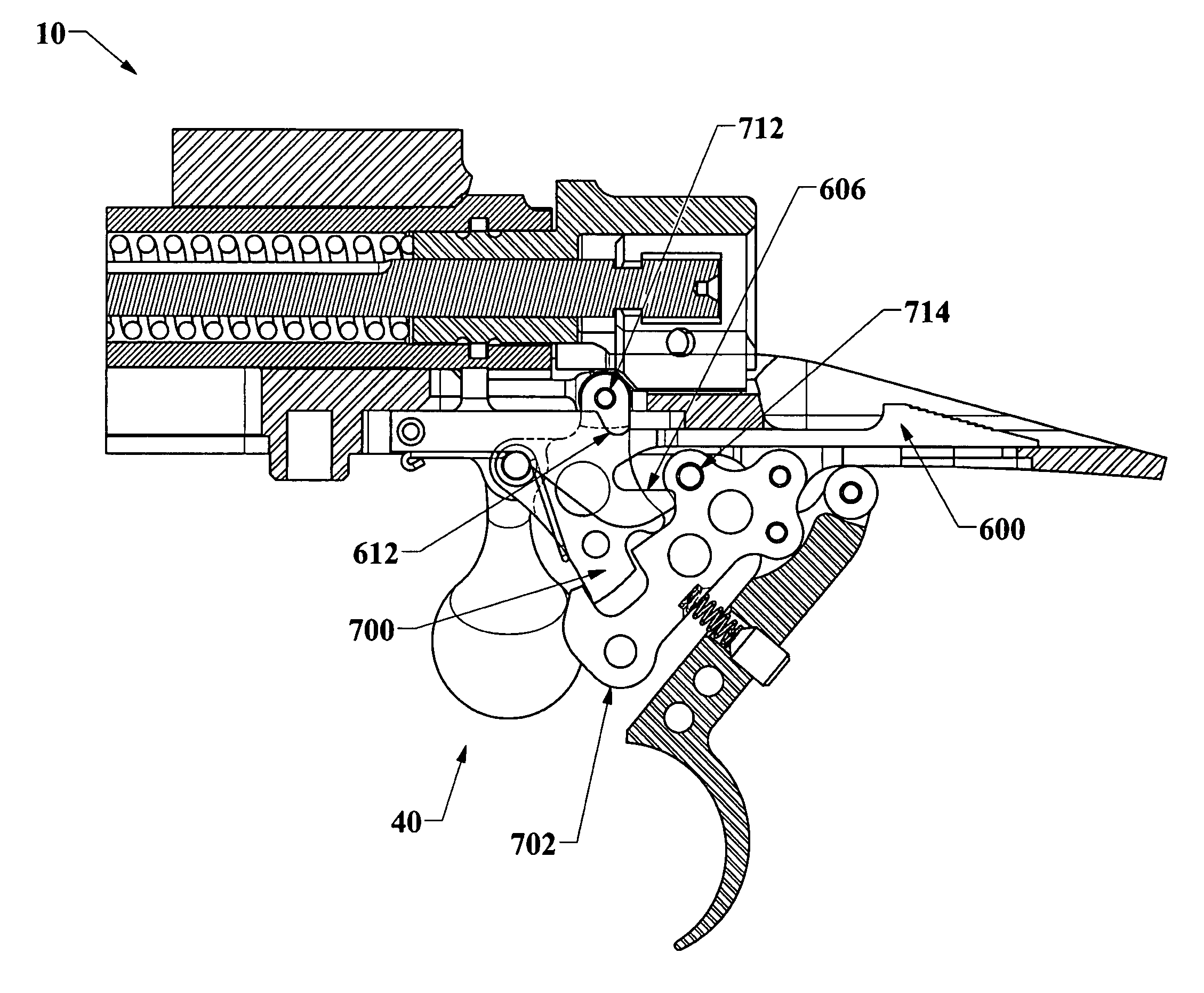

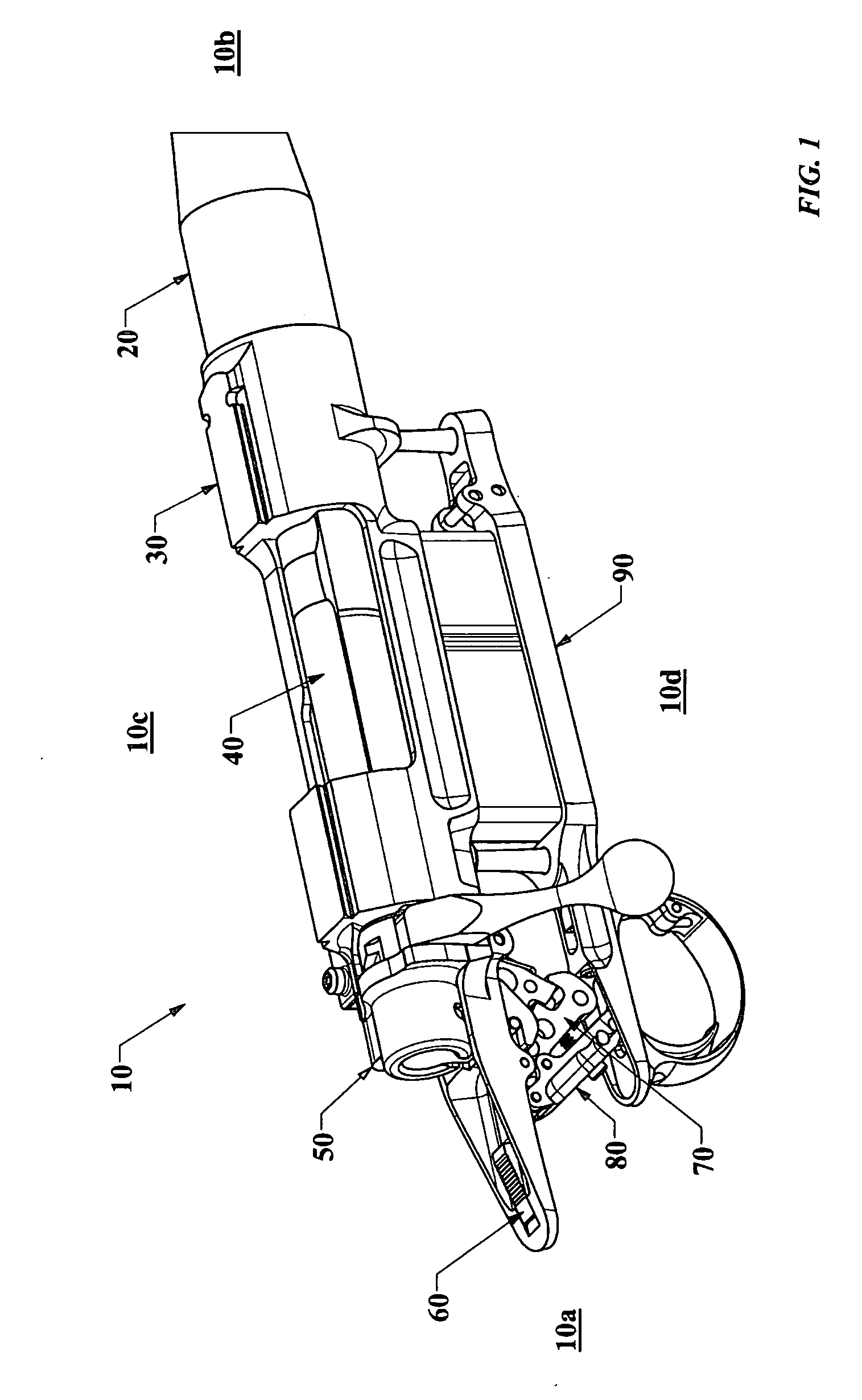

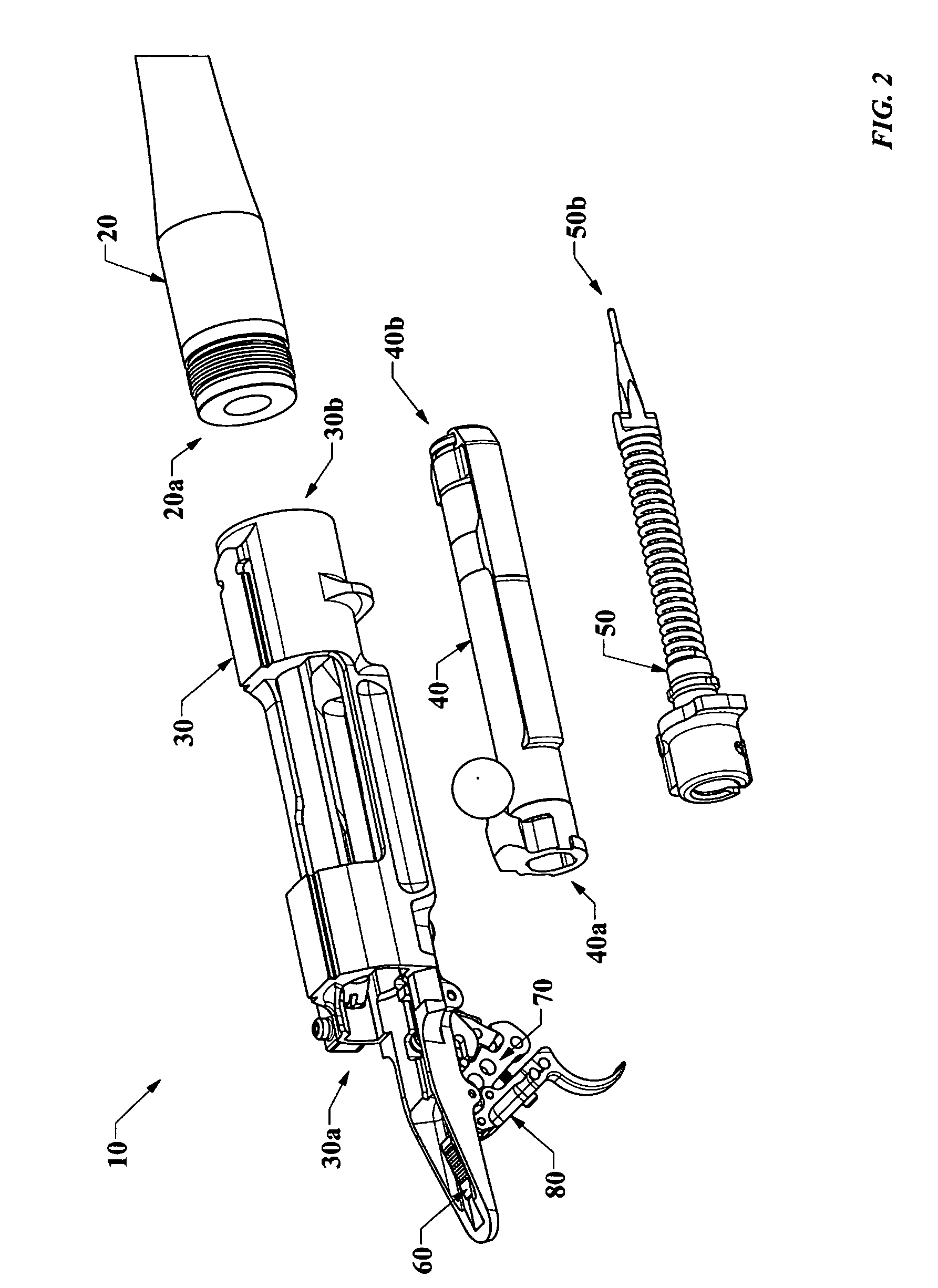

Trigger mechanism and a firearm containing the same

InactiveUS20070079539A1Reduce frictionCrisp feel dischargeFiring/trigger mechanismsBreech mechanismsPull forceJewel bearing

A firearm and a trigger mechanism having a small trigger pull force, small trigger pull distance, and a large sear engagement is provided. The firearm and trigger mechanism of the present invention provides a safe firearm having a light and crisp trigger pull. Certain embodiments of the present invention may also provide for a firearm or trigger mechanism having a ratio of sear engagement to trigger pull distance that is greater than or equal to 1.0. Certain embodiments of the present invention may also provide for a firearm and a trigger mechanism operably connected with one or more jewel bearings.

Owner:KARAGIAS THEODORE

Method for producing radioresistant worsted fabric

InactiveCN101413172AImprove the finishImprove the accuracy of weft insertionWoven fabricsYarnRadiation resistantWorsted

The invention relates to a production method for a radiation-resistant fine spun fabric, which mainly comprises the following steps: dyeing and recombing wool first, and then combing the wool into colored wool tops, mixing the colored wool tops and metallic short fiber strips in spinning and mixing processes to spin into metallic yarns, and weaving, dyeing and finishing the metallic yarns to produce the radiation-resistant fine spinning fabric. Through spinning and mixing the metallic short fibers, the production method for the fabric makes the metallic fibers distributed in the fabric more evenly and improves radiation-resistant effect; the diameters of the metallic short fibers are softer than that of fine fibers, and so on, so the fabric is softer and more subtle; through the control for the weaving, dyeing and finishing processes, the fabric also has the advantages of high-grade appearance, neat hand feel, fine and pure face and excellent wearing property at the same time of having radiation-resistant function; and the fabric has most popular natural memory fold function at present simultaneously. Therefore, the fabric is suitable for producing male and female fashion coats which can show grace, luxury, romance and grade after being worn.

Owner:JIANGSU SUNSHINE +1

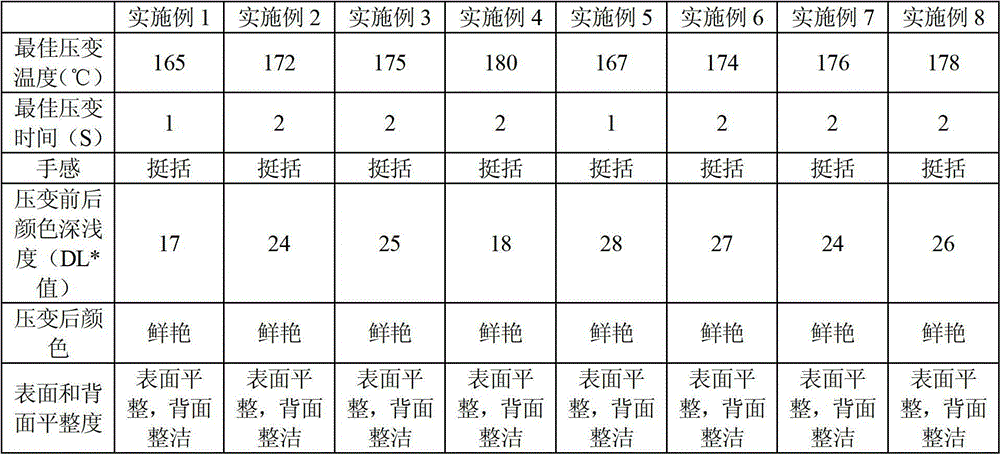

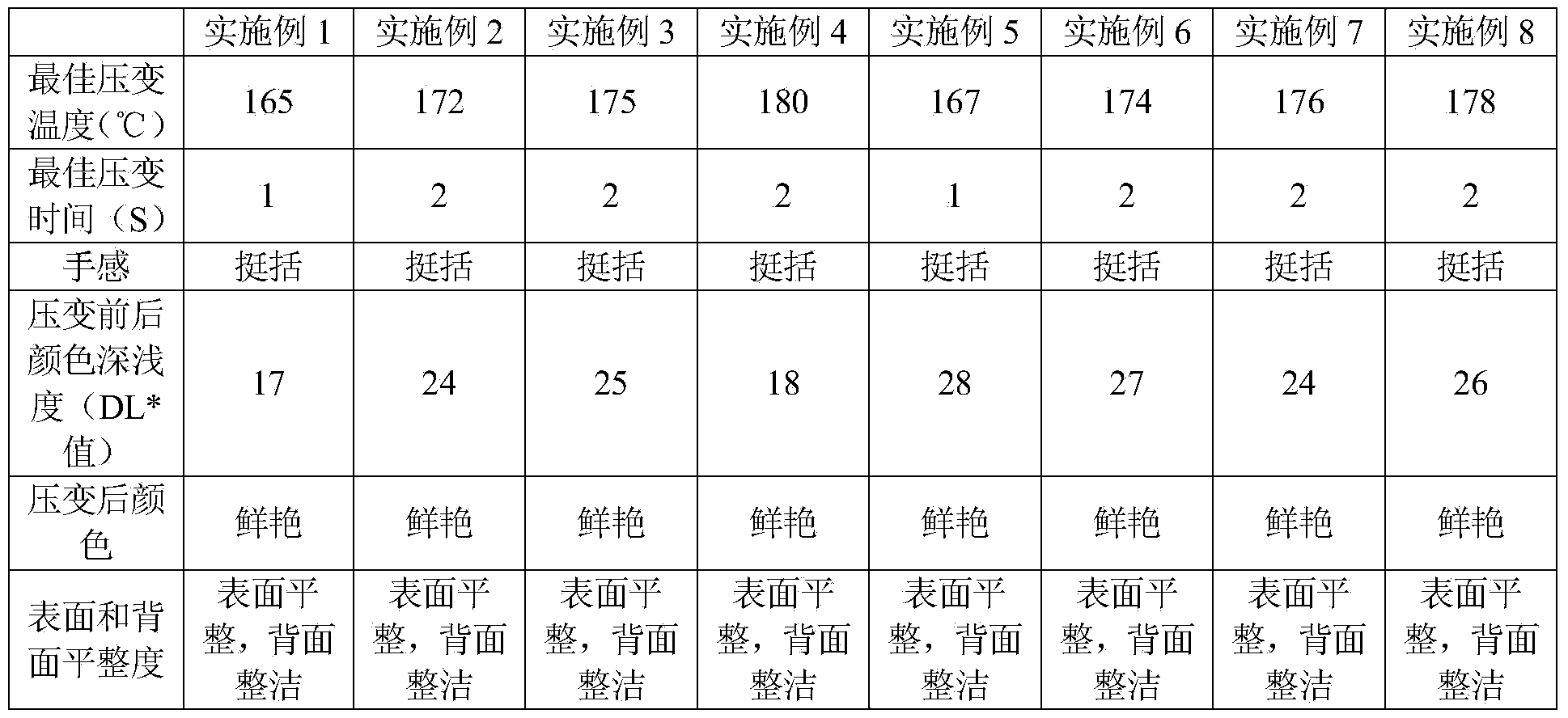

Manufacture method for PU embossed color-changing decoration leather

ActiveCN102747612AFeel crispFeel fullSynthetic resin layered productsLaminationThermal compressionSlurry

The invention provides a manufacture method for PU embossed color-changing decoration leather. According to the method, a layer of polyurethane work slurry prepared by using a wet method is coated onto a spunlaced non-woven fabric, and concrete steps of the method comprise: (a) preparing base cloth and unreeling and ironing the base cloth; (b) coating the polyurethane work slurry changeable at a pressure with a knife, wherein a formula for the work slurry comprises, by mass, 20 to 40 parts of high-modulus resin, 80 to 60 parts of low modulus resin, 90 to 200 parts of a solvent, 15 to 25 parts of a filling material, 3 to 15 parts of color paste, 0 to 4 parts of a microporous regulator, 0.1 to 1 part of an antifoaming agent and 0.1 to 1 part of a leveling agent; (c) carrying out solidification and rinsing; and (d) carrying out drying and reeling, wherein drying temperature is 120 to 155 DEG C. The prepared decoration leather has stiff and smooth touch, smooth surface and neat back; temperature for thermal changes of the decoration leather at a pressure is adjustable and is in a range of 165 to 180 DEG C; time for changes at a pressure is short; and the color of the decoration leather having undergone changes at a pressure is brilliant and full, presenting great contrast.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Stiffening agent and production method thereof

InactiveCN102454106AExcellent yarn cohesionDoes not affect shadeFibre treatmentPolymer sciencePolyvinyl acetate

The invention discloses a stiffening agent and a production method thereof. The stiffening agent is composed of 40% polyvinyl acetate emulsion, soluble starch, gelatin, and deionized water. With the stiffening agent, fabric is provided with a stiff and thick texture, and can be prevented from coiling. Finished fabric is prevented from moisture regaining and mellowing, and is provided with certain washing fastness. With the stiffening agent, the strength of the fabric can be maintained to a maximal extent, and a fabric gliding phenomenon can be prevented. The stiffening agent can be used in a same bath with most of finishing agents.

Owner:南通斯恩特纺织科技有限公司

Functional polyester-cotton conducting fiber blended yarn and processing method thereof

The invention discloses a functional polyester-cotton conducting fiber blended yarn and a processing method thereof, relating to the technical field of spinning engineering. The processing method comprises the following steps of: mixing polyester fibers with compound light-colored chinlon base organic conducting short fibers to manufacture mixed organic polyester conducting fiber raw strips; manufacturing cotton fibers into raw strips and fine combing the raw strips to manufacture fine combing cotton strips; then mixing the fine combing cotton strips and the mixed organic polyester conducting fiber raw strips and then processing the mixed strips through a coarse spinner and a spun yarn spinner; and finally, spooling. The functional polyester-cotton conducting fiber blended yarn can be manufactured into special clothes and textiles being static-free, dust-free, microwave protective, radiation protective, and the like. Proved by detection, the yarn has good electric conduction property and cannot be influenced by environment humidity. After the yarn is spun and processed, the yarn has stiff, smooth and flexible handfeel, drapability, good size stability, good abrasion resistance, comfort, skin fit, good coloring and bright and abundant color and conforms to the application requirement of high-grade clothing fabrics and fashionable dress fabrics.

Owner:NANTONG DOUBLE GREAT TEXTILE

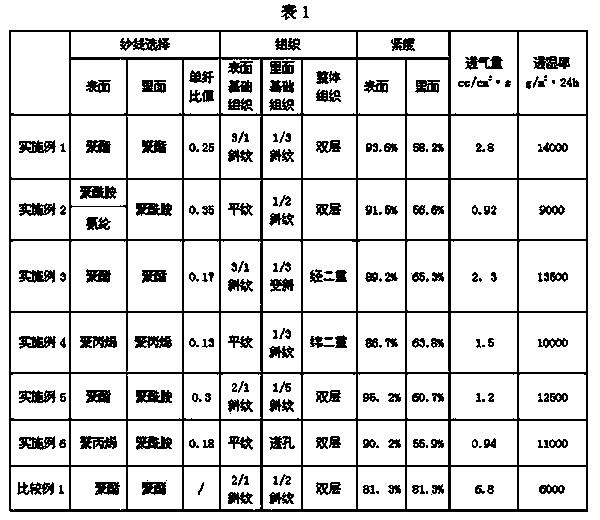

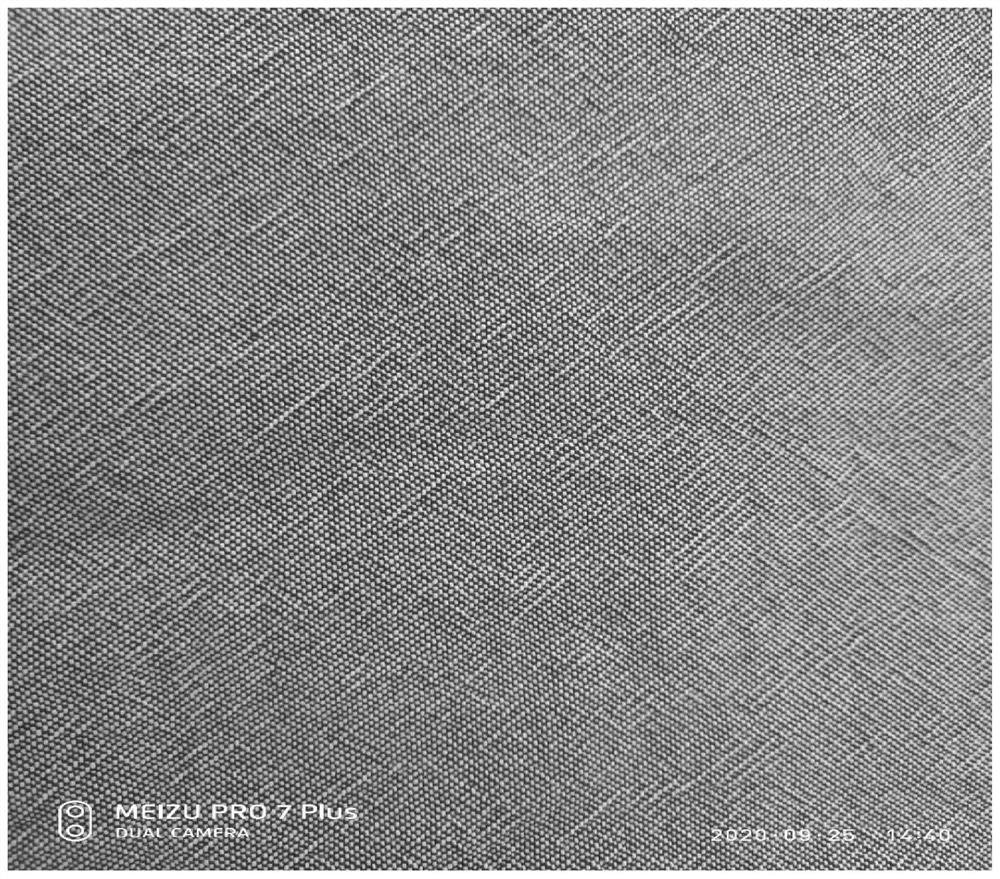

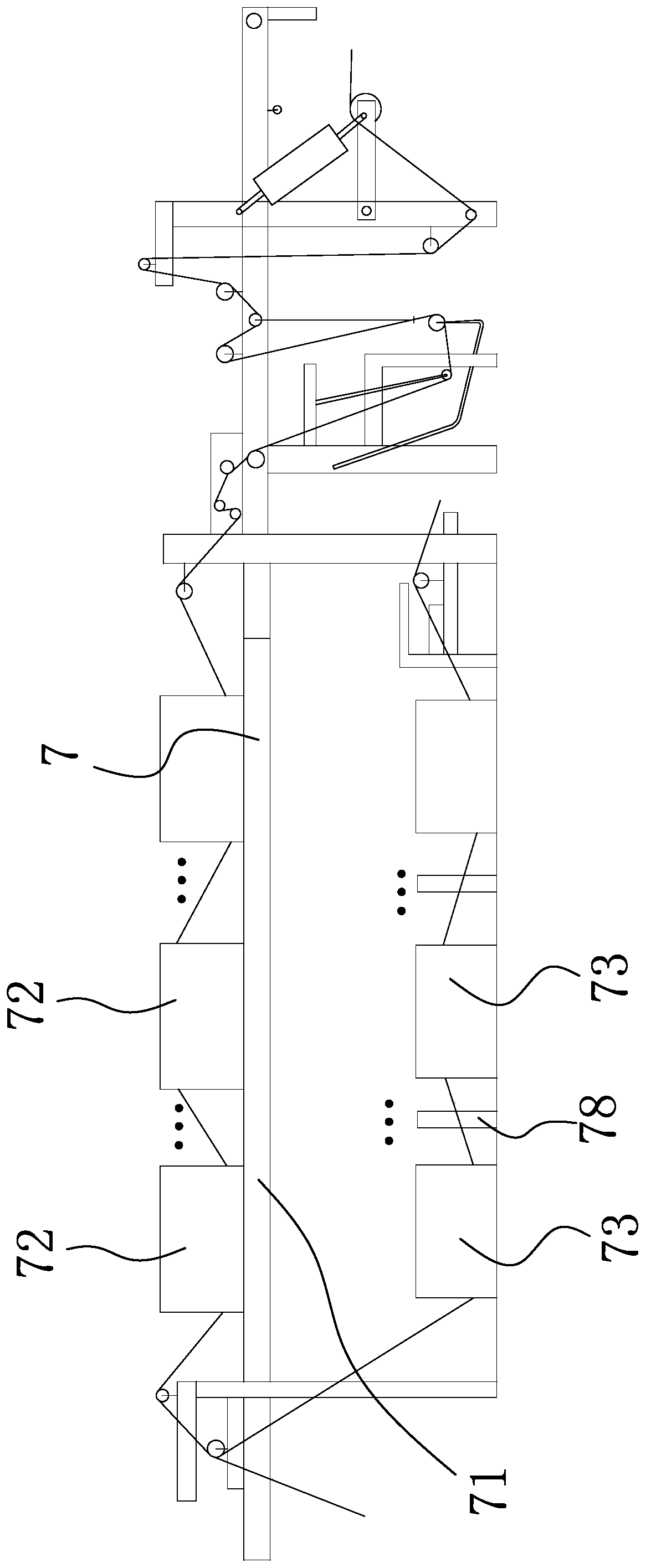

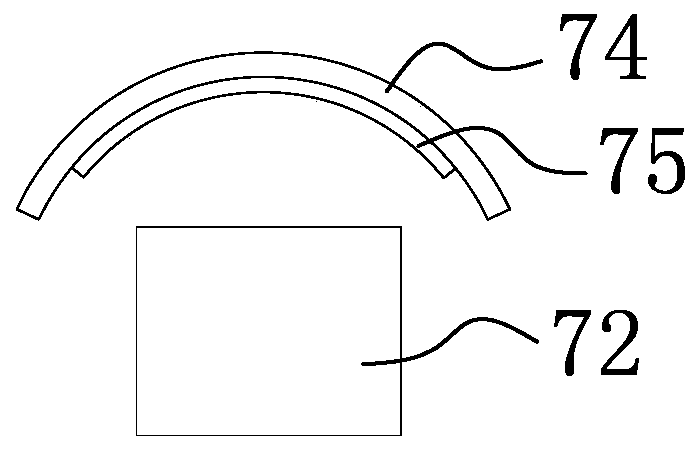

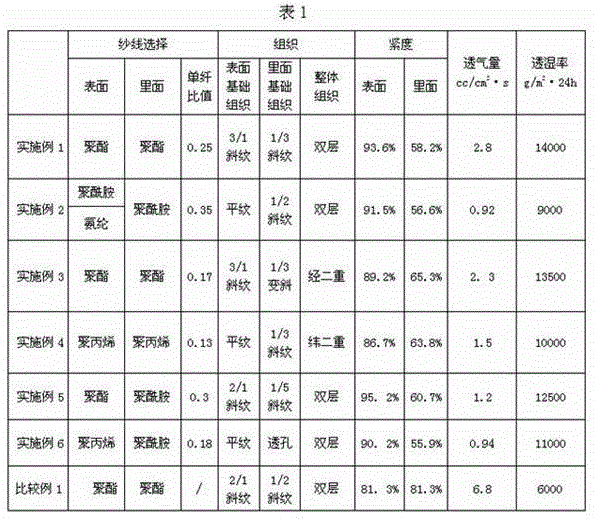

Windproof breathable fabric

The invention discloses windproof breathable fabric. The surface of the fabric is made of fine fibers, the inner layer of the fabric is made of coarse fibers, the structure of the fabric can be a warp-backed weave or a weft-backed weave or a double-layer weave, the surface tightness ranges from 85 percent to 100 percent, the inner layer tightness ranges from 55 percent to 70 percent, and the single fiber fineness ratio of the fine fibers to the coarse fibers ranges from 0.1 to 0.8. The air permeability is measured to be less than or equal to 3cc / cm<2> / s according to the standards of JISL1096, and the moisture permeability is measured to be 8000-15000g / m<2> / 24h according to the standards of GB / T12704.2. The fabric is low in production cost, good in moisture permeability, good in windproof performance, soft in hand feel, stiff and smooth, good in resilience and particularly suitable for manufacturing of high-end casual coat products.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Dyeing and finishing method of polyester-cotton knitted fabric with one-way moisture-wicking function

InactiveCN110747658ASmall dimensional change ratePrevents fine wrinkles and creasesHeating/cooling textile fabricsDry-cleaning apparatus for textilesDisperse dyePolymer science

The invention relates to a dyeing and finishing method of a polyester-cotton knitted fabric with a one-way moisture-wicking function, comprising the specific steps of (1) pretreating a gray fabric with an open width washing machine; (2) presetting; (3) dyeing, namely dyeing polyester with disperse dyes, carrying out reduction washing, dyeing cotton with reactive dyes, cleaning a sample, and soaping; (4) feeding a hydrophilic softening agent; (5) setting and drying; (6) carrying out waterproof finishing, to be specific, finishing the reverse cotton surface of the gray fabric on a rotary screenprinting machine; and (7) processing with a moisture-sucking sweat-wicking aid in a setting rolling channel to obtain a finished product. Compared with the conventional dyeing and finishing process, the dyeing and finishing method has the advantages that the operation is simple, the processing flow is smooth, the common polyester-cotton knitted fabric can be given the one-way moisture-wicking function, the added value and wearing comfort of the common polyester-cotton knitted fabric are improved, and the method has wide market potential.

Owner:ZHEJIANG YINHE PRINTING & DYEING

Permanent press finishing process of wool fabric

The invention provides a permanent press finishing process of a wool fabric. The process comprises the following steps: firstly, performing pad-roll treatment on a finishing solution consisting of 80g / L-100g / L of a 2D resin finishing agent, 1g / L-3g / L of a penetrating agent, 20g / L-50g / L of a softening agent and 10g / L-15g / L of a catalyst at room temperature for two times, wherein the padding rate is 70%-80%; secondly, folding and pressurizing by using a heavy hammer; thirdly, pre-drying at 80-90 DEG C for 3-5 minutes; fourthly, baking at 120-160 DEG C for 60-90 seconds; fifthly, steaming at 90-100 DEG C for 8-10 minutes; lastly, drying and doffing. The wool fabric treated with the finishing process provided by the invention has an excellent wash and wear effect, and is outstanding in rebound resilience and durable press performance, full in hand feel, smooth, thick and free from color change and color fading.

Owner:朱文潮

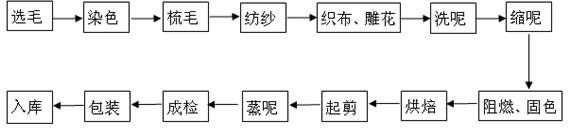

Ecological antiflaming engraved woolen cloth and preparation method thereof

The invention discloses an ecological antiflaming engraved woolen cloth and a preparation method thereof. Mercerized wool, bamboo fiber and hemp fiber are blended, 19S ecological fiber yarns with better evenness and strength are spun by a German Saurer textile machine production line, and with the cooperation of fashionable engraving colors and the combination of special after-treatment technologies such as fulling, softening, color fixing, inflaming retarding and the like, the ecological antiflaming engraved woolen cloth is produced. The product not only can meet the requirement of comfortable wearing of people, but also can be used as interior trim material for mansions, theatres, restaurants, planes, automobiles and the like, and has wide usages. The main technical indexes are that: pilling is in level 3.5, the oil content is 0.9%, the strength is higher than 165N, the color fastness is 3.5 degrees, the damage length is less than or equal to 150mm, the afterflame time is less than or equal to 5s, and the inflaming retarding time is less than or equal to 5s.

Owner:山东天翔毛纺织有限公司

Mercerized elastic fabric

InactiveCN102443933AStrong three-dimensional senseIncrease elasticityResilient fabricsKapok fiberRecovery performance

The invention discloses a mercerized elastic fabric, wherein warp yarns adopt the composition fiber formed by kapok fiber, soybean fiber and peanut fiber; and weft yarns adopt the composition fiber formed by wrapping polyurethane fiber in elastic composition fiber and purified cotton fiber. The percentage by weight of the fibers in the weft yarns is as follows: 10%-45% purified cotton fiber, 55%-90% elastic composition fiber, and 1.5%-2.0% polyurethane fiber. The percentage by weight of the fibers in the whole fabric is as follows: 12%-20% kapok fiber, 7%-15% soybean fiber, 0.5%-1.0% peanut fiber, 5%-35% purified cotton fiber, 40%-75% elastic composition fiber, and 1.0%-1.8% polyurethane fiber. The invention has the advantage that after receiving reasonable treatment, the fabric achieves a clear and fine surface texture, a criss-cross bamboo effect, strong stereoscopic sensation, a soft, stiff and smooth hand feeling and excellent elastic recovery performance, and is not liable to wrinkle.

Owner:SUZHOU CHUANGYU WEAVING

Mercerized cotton elastic fabric

InactiveCN105495796AStrong three-dimensional senseIncrease elasticityProtective garmentSpecial outerwear garmentsFiberYarn

The invention provides a mercerized cotton elastic fabric. The mercerized cotton elastic fabric is prepared from the following components: elastic composite fiber, polyurethane fiber, kawo kawo fiber, soybean fiber, peanut fiber, pure cotton fiber, polyurethane fiber, ramie yarns and polyolefin fiber. The fabric prepared by adopting the formula has the advantages that the lines of the fabric cover are clear, fine and smooth, and have the vertically and horizontally arranged bamboo joint effect, and the drizzle intricate effect, the three-dimensional sense is strong, the elasticity is extremely strong, the hand feel is soft, the level and smooth degree is good, wrinkling seldom occurs, the elastic recovery property is good, the wearing effect is unlike that of spandex elastic fabric, and in addition, the mercerized cotton elastic fabric is not limited by the wearing times and the washing times, is good in wearing comfort, and free of bound feeling, and the size of a finished garment after washing is stable.

Owner:RUGAO WEIBAO SUIT CO LTD

Anti-wrinkle tidying method for pure cotton fabric

InactiveCN101942750BImprove wrinkle resistanceImprove flatnessSucessive textile treatmentsFibre treatmentOrganic acidBrute force

Owner:TIANJIN TIANGE TEXTILE

Blueberry and anthocyanin composite granules and preparation method thereof

The invention relates to blueberry and anthocyanin composite granules and a preparation method thereof, in particular to blueberry and anthocyanin composite granules with an antioxidant effect and a preparation method thereof. At present, domestic anthocyanin products are mainly focused on a few types of beverage, fruit wine, effervescent tablets and capsules. The blueberry and anthocyanin composite granules enrich the types of the domestic anthocyanin products and have the antioxidant health care effect of anthocyanin. The blueberry and anthocyanin composite granules are prepared from a blueberry and anthocyanin concentrated solution, an agaric polysaccharide concentrated solution, white granulated sugar, citric acid and beta-cyclodextrin. The preparation method comprises the following steps: after the blueberry and anthocyanin concentrated solution and the agaric polysaccharide concentrated solution are prepared, adding white granulated sugar, citric acid and beta-cyclodextrin for fully mixing, kneading into dumplings which have low probability of looseness, and pelletizing with a wet method; drying the prepared granules, pelletizing again, dispersing into uniform dry granules, and thus obtaining finished products. The blueberry and anthocyanin composite granules have the antioxidant health care effect of anthocyanin and are a good health care product after being eaten for a long time.

Owner:NORTHEAST FORESTRY UNIVERSITY

Silkete cowboy face fabric

InactiveCN101429697BStrong three-dimensional senseIncrease elasticityWoven fabricsYarnFiberPulp and paper industry

Owner:CHANGZHOU OASIS TEXTILE

Stiffening agent and production method thereof

InactiveCN102454106BExcellent yarn cohesionDoes not affect shadeFibre treatmentEmulsionPolyvinyl acetate

Owner:南通斯恩特纺织科技有限公司

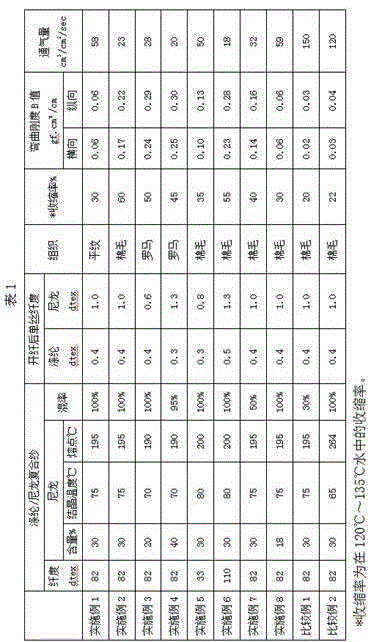

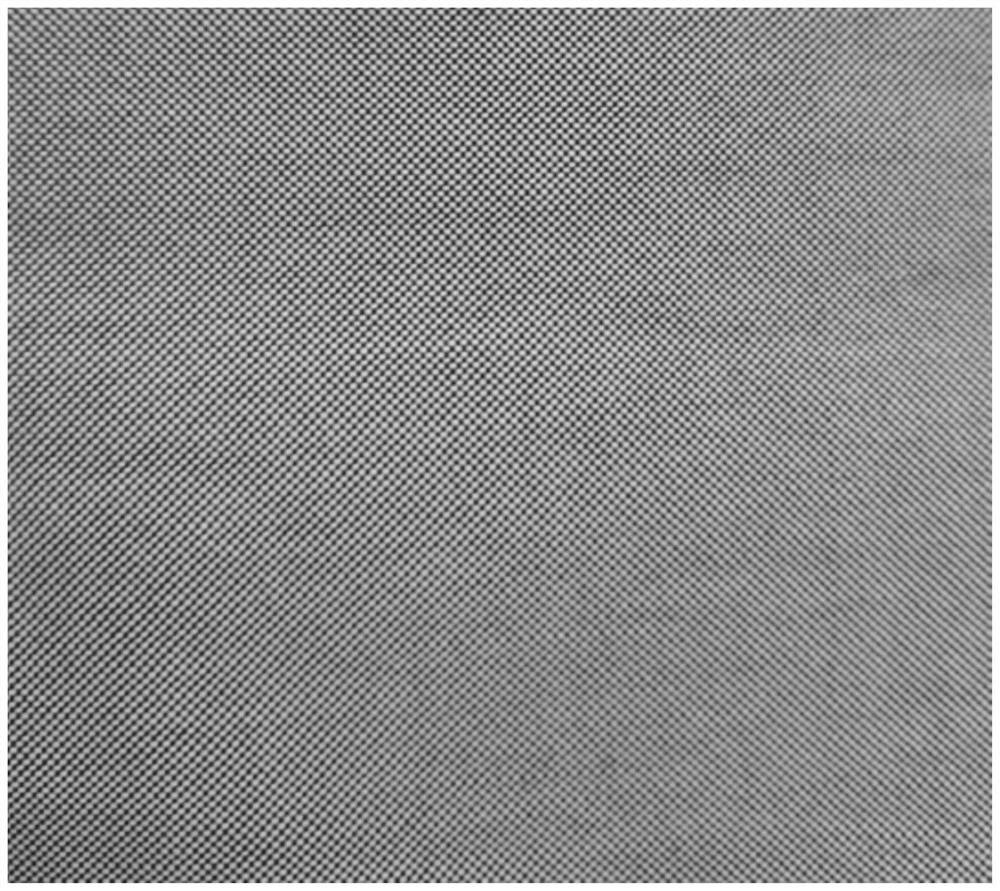

High-density knitted fabric, and production method and application thereof

The invention discloses a high-density knitted fabric, and a production method and an application thereof. More than 50% by weight of yarns of the high-density knitted fabric are split nylon-dacron composite yarns, the melting point of the nylon component of the nylon-dacron composite yarn ranges from 180 DEG C to 210 DEG C, the bending rigidity of the high-density knitted fabric is measured to be higher than 0.06 gf.cm<2> / cm through a KES method, and the ventilatory capacity of the high-density knitted fabric is measured to be lower than 60 cm<3> / cm<2> / sec through a JISL1096-2010 method. Through routine weight reducing processing of the high-density knitted fabric, a tight, stiff and smooth product can be obtained, and the high-density knitted fabric can be used for making jackets, wind coats or trousers or the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

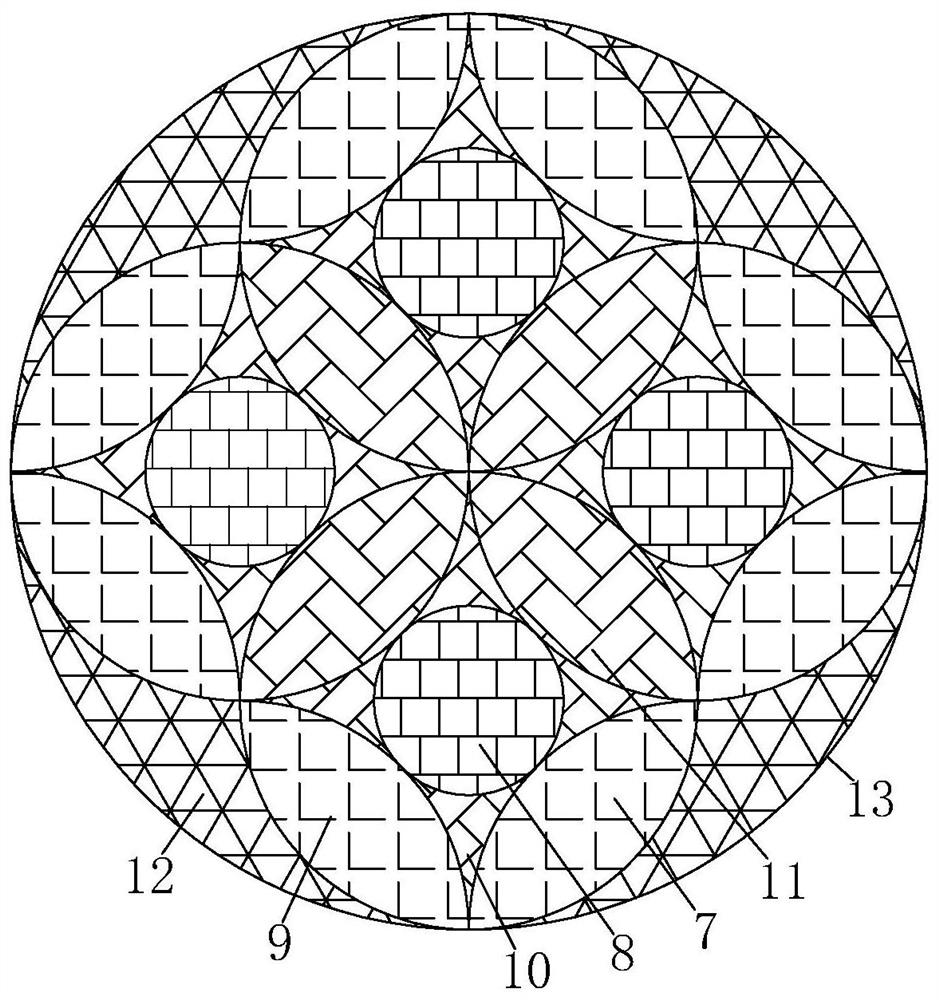

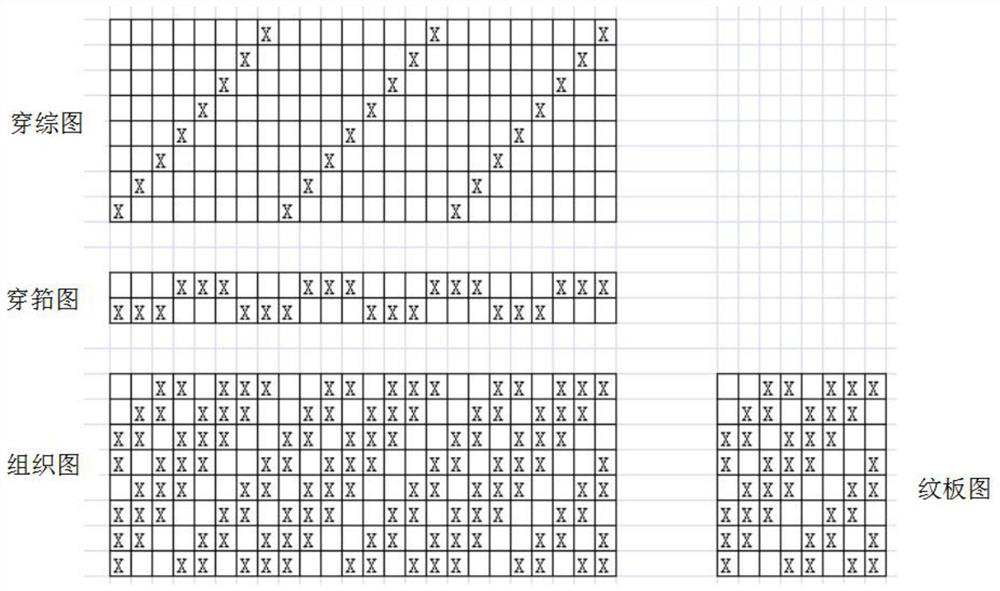

Geometric texture oxford spinning fabric and production process thereof

The invention belongs to the technical field of textile, and particularly relates to geometric texture oxford spinning fabric and a production process thereof. According to the geometric texture oxford spinning fabric, common ring spinning yarn is arranged in the warp direction of the fabric, siro spinning yarn is arranged in the weft direction of the fabric, 40-50 S yarn is adopted as warp yarn,and 8-12 S yarn is adopted as weft yarn; and the warp density of the fabric is 90-110 pieces per inch, the weft density of the fabric is 48-55 pieces per inch, and the texture of the fabric is 2 / 2 weft backed flat. The production process flow comprises the following steps of cotton assorting, opening picking, cotton carding, drawing, roving, spinning, spooling, dyeing, warping, slashing, denting,weaving, finishing, and garment water washing. By adjusting the yarn twist and the finishing process of conventional oxford spinning fabric, the produced fabric has the appearance of geometric texture, is leisure, novel, fashionable, soft in hand feeling, stiff and smooth, comfortable and good in air permeability, better meets the consumption requirements of different types, and has wide market space.

Owner:LUTAI TEXTILE

A kind of high-density knitted fabric and its production method and application

The invention discloses a high-density knitted fabric, and a production method and an application thereof. More than 50% by weight of yarns of the high-density knitted fabric are split nylon-dacron composite yarns, the melting point of the nylon component of the nylon-dacron composite yarn ranges from 180 DEG C to 210 DEG C, the bending rigidity of the high-density knitted fabric is measured to be higher than 0.06 gf.cm<2> / cm through a KES method, and the ventilatory capacity of the high-density knitted fabric is measured to be lower than 60 cm<3> / cm<2> / sec through a JISL1096-2010 method. Through routine weight reducing processing of the high-density knitted fabric, a tight, stiff and smooth product can be obtained, and the high-density knitted fabric can be used for making jackets, wind coats or trousers or the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

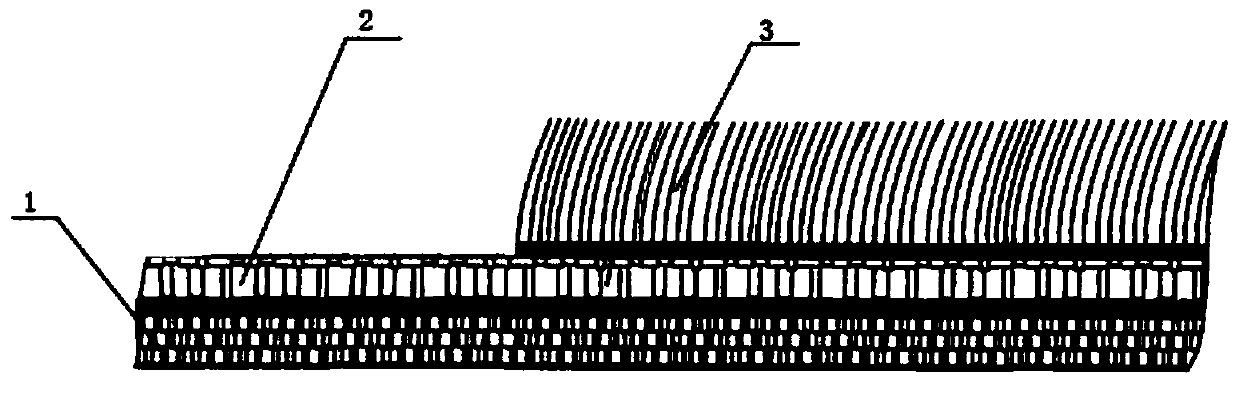

A kind of wool spinning composite flocking fabric and preparation method thereof

ActiveCN107399113BCrisp styleGood dimensional stabilityLiquid surface applicatorsWeft knittingEngineeringColored light

The invention provides a wool spinning compound flocking shell fabric and a preparation method thereof and belongs to the field of textiles. The wool spinning compound flocking shell fabric comprises back cloth, surface cloth and a flocking layer. The back cloth is a knitted double-sided shell fabric, the surface cloth is single-sided cloth of knitted plain weaves, the back cloth and the surface cloth are compounded on the reverse sides, and fluff on the flock layer is fixed on the front surface of the surface cloth by means of electrostatic flocking. At the same time, the invention also provides a preparation method of the wool spinning compound flocking shell fabric. The shell fabric obtained by the invention is stable in dimension, stiff and smooth in hand feel, novel in appearance pattern and high in cost performance, and solves the problems that the flocking shell fabric is easily subjected to fluff falling, fluff reversion, wrinkling and colored light change.

Owner:LILANG CHINA

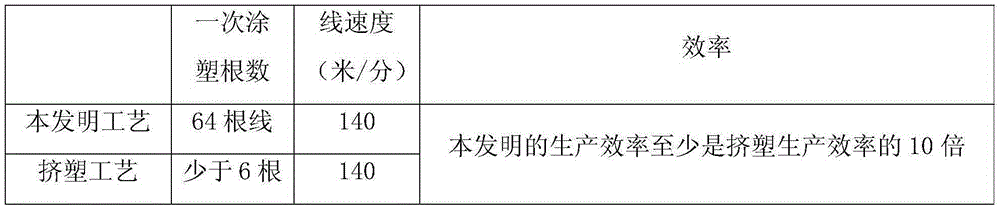

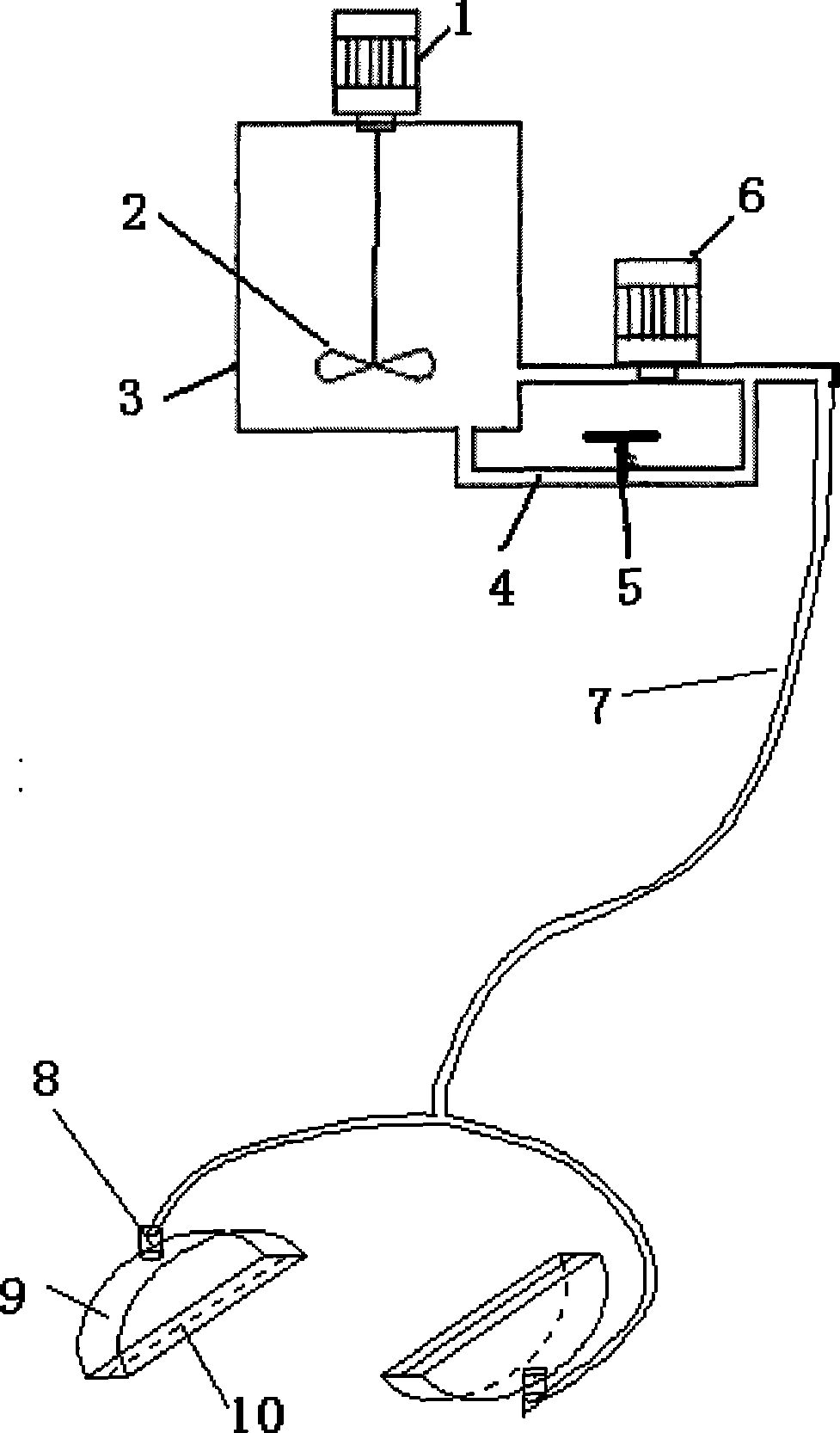

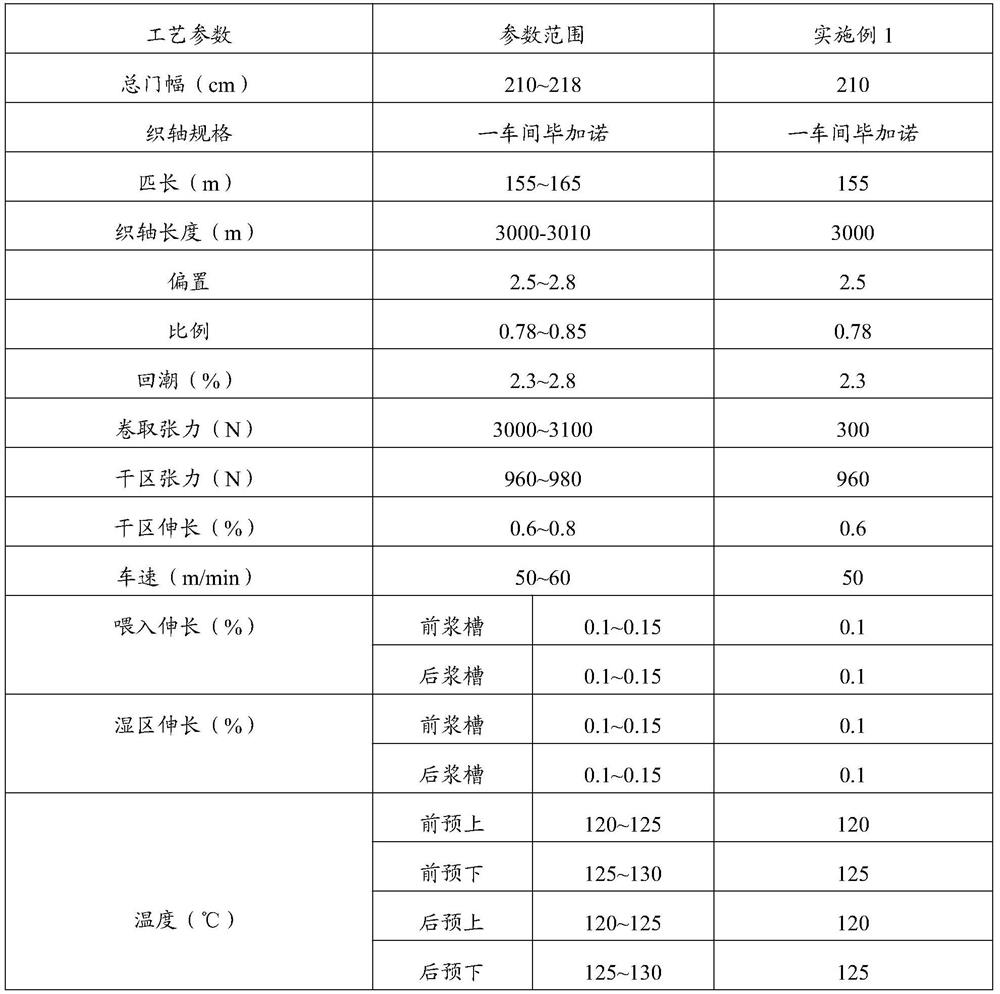

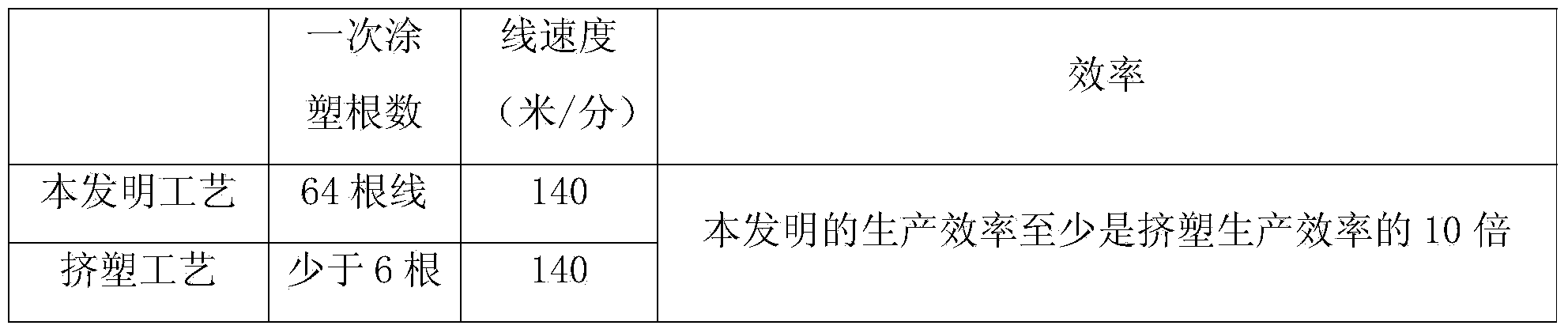

A production process of 15×12 mesh polyester plastic-coated pet net

InactiveCN103820916BHigh strengthNo harmLiquid surface applicatorsHeating/cooling textile fabricsPolyesterPolymer science

The invention provides a 15×12 mesh polyester plastic-coated pet net production process, which comprises the following steps: polyester filament → monofilament plastic coating → warping → weaving → shaping → cloth inspection. The present invention adopts: Z100 twisted polyester filaments coated with plastic, high-temperature plasticized, weaved, and high-temperature shaped. The production efficiency of the present invention is much higher than extrusion production, and the economic benefit is much higher than extrusion production, and the prepared 15×12 mesh polyester plastic-coated pet net with a fabric square meter weight not less than 400g / m2 has high strength, durability Wear resistance, folding resistance, crisp hand feeling, flame retardant, fire protection, UV protection, no harm to animals, etc.

Owner:TIANJIN HENGTONG IND & TRADE DEV CO LTD

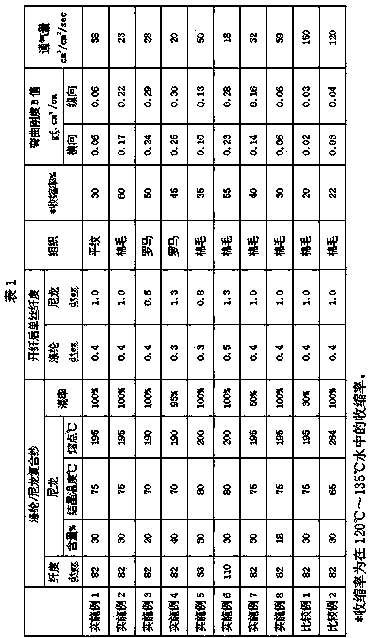

Production method of various new functional worsted fabrics

The invention relates to a production method for a worsted fabric having multi-novel functions. Blending weight ratio of the fabric is as follows: 50% of wool, 30% of a far-infrared magnetic fiber and 20% of a nano-antibacterial polyamide fiber. The method comprises the processes of recombing, spinning, weaving and dyeing and finishing. The dyeing and finishing process is as follows: singeing-scouring of wool fabric-crabbing-drying-in-process inspecting-function strengthened finishing-drying-brush clipping-conditioning-decating-conditioning-decating-obtaining a finished product. A functional agent employed by the function strengthened finishing is prepared by stirring 8% of nano ceramic, 28% of a negative ion finishing liquid, 10% of a emulsifying agent and 62% of water with high speed for 60 minutes at the temperature of 50 DEG C. The fabric can resist bacteria, irradiate far infrared rays, release negative ions and have a durable weak magnetic field function.

Owner:HEILAN HOME

Application of organosilicon surfactant in denim preshrunk and correlative device

InactiveCN101245559BSmall shrinkageImprove breathabilityFibre treatmentTextile treatment by spraying/projectingSEMI-CIRCLEDenim

The invention relates to the application of an organic silicon surfactant in jean preshrinking. A wetting feeding device applying the application is characterized by being provided with a stirrer; the stirring vane of the stirrer extends into a material stirring cylinder provided with the water liquor of the organic silicon surfactant; the side surface and the bottom part of the stirring cylinderare communicated with a bypass pressure adjusting tube which is provided with a booster pump and a strobe and communicated with the input ports of two spray heads by a transmission pipeline; the shell of the spray head is made into a semi-circle box body by stainless steel; the plane of the spray head is provided with a gap. The invention can lead the cloth washing shrinkage in a shrinking working procedure to be reduced to be about 5 percent. The application has the remarkable advantage of saving energy, can endow fabric with stiff, flexible, smooth and plump hand feeling, leads the fabric to have good ventilation, glossy surface and anti-friction property and is comfortable to be worn.

Owner:LANYAN GROUP

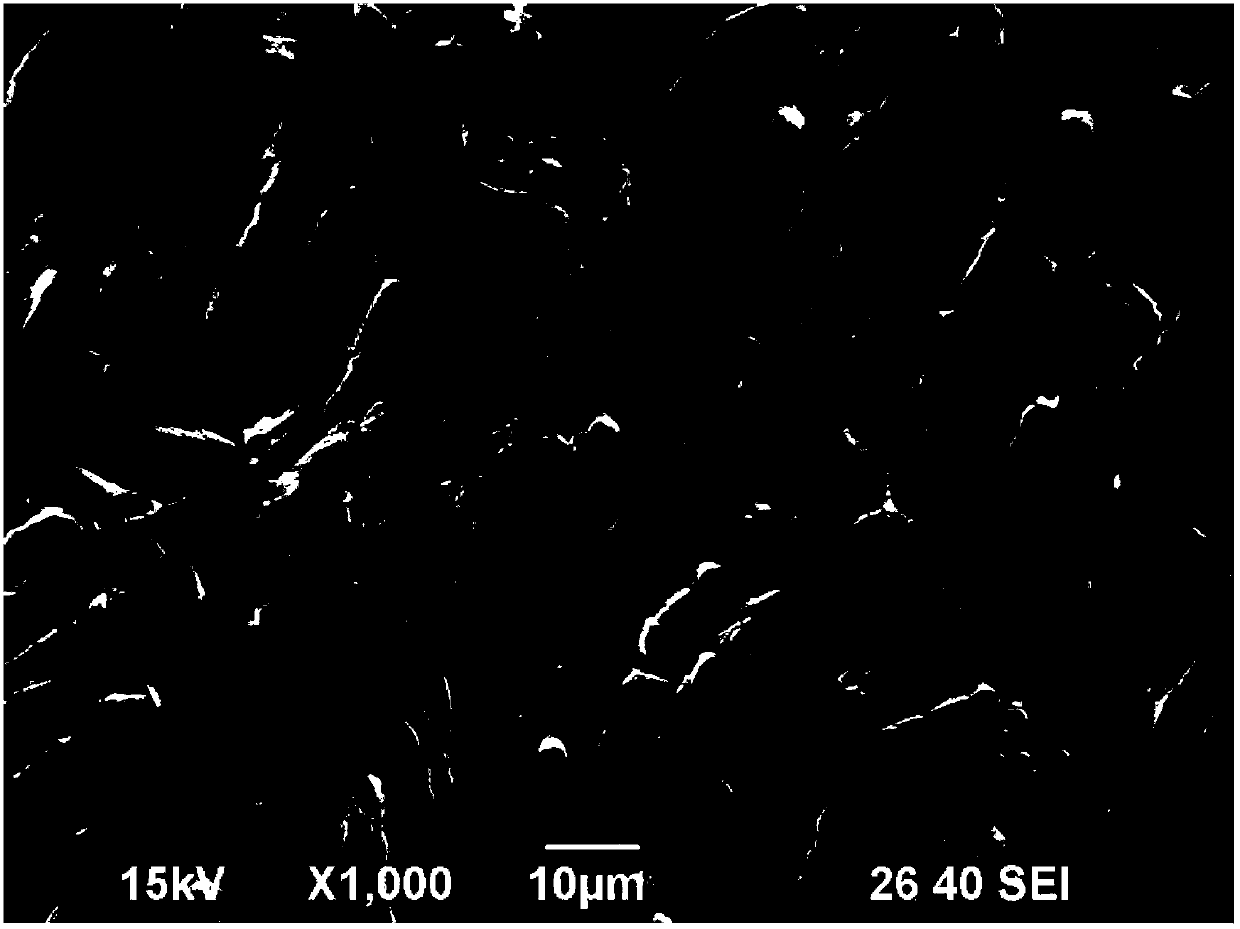

Flaky flat viscose fiber and preparation method thereof

ActiveCN102677208BSpecial glossAnti-pillingMonocomponent cellulose artificial filamentStretch-spinning methodsCelluloseState of art

The invention discloses a flaky flat viscose fiber and a preparation method thereof. The preparation method comprises the following steps of: (1) adding a carbonate solution in a viscose solution which finishes etiolation, uniformly mixing with the viscose solution so as to obtain a blend spinning viscose glue, wherein the addition of carbonate is 30-50wt% of armour fiber in a cellulose viscose glue; (2) shaping the blend spinning viscose glue through coagulating bath spinning; and (3) carrying out spray guide drafting on the nascent fiber after shaping, wherein the drafting rate of the spray guide drafting is 30-60%, and the flaky flat viscose fiber is prepared through plastication drafting and postprocessing steps. According to the invention, the copying of the flat viscose fiber can be realized without a spinneret plate in a special jet orifice shape, the traditional production mode of the flat viscose fiber is broken, and the flaky flat viscose fiber is a primary revolution of manufacturing heterotypic viscose fiber. Compared with the prior art, the equipment investment is reduced, and the commercial process is easy to realize.

Owner:赛得利(盐城)纤维有限公司

Printing and dyeing process of thermal fabric with mercerized flocking effect

ActiveCN108456984BAvoid damageVariety of colorsMercerising of indefinite length fabricsWeft knittingTextile printerProcess engineering

The invention belongs to the technical field of fabric processing, and particularly relates to a warm fabric printing and dyeing process with mercerizing flocking effect. The process solves the technical problems of unreasonable design and the like of the prior art. The process includes the following steps of A, weaving; B, degreasing; C, dyeing; D, mercerizing; E, whitening; F, electrostatic flocking; G, printing; H, steaming I; water washing; J, hair grabbing and K, softening and shaping. The process has the advantages of being warm and more reasonable in design.

Owner:ZHEJIANG FURUN DYEING & PRINTING

Manufacture method for PU embossed color-changing decoration leather

ActiveCN102747612BFeel crispFeel fullSynthetic resin layered productsLaminationSlurryNonwoven fabric

The invention provides a manufacture method for PU embossed color-changing decoration leather. According to the method, a layer of polyurethane work slurry prepared by using a wet method is coated onto a spunlaced non-woven fabric, and concrete steps of the method comprise: (a) preparing base cloth and unreeling and ironing the base cloth; (b) coating the polyurethane work slurry changeable at a pressure with a knife, wherein a formula for the work slurry comprises, by mass, 20 to 40 parts of high-modulus resin, 80 to 60 parts of low modulus resin, 90 to 200 parts of a solvent, 15 to 25 parts of a filling material, 3 to 15 parts of color paste, 0 to 4 parts of a microporous regulator, 0.1 to 1 part of an antifoaming agent and 0.1 to 1 part of a leveling agent; (c) carrying out solidification and rinsing; and (d) carrying out drying and reeling, wherein drying temperature is 120 to 155 DEG C. The prepared decoration leather has stiff and smooth touch, smooth surface and neat back; temperature for thermal changes of the decoration leather at a pressure is adjustable and is in a range of 165 to 180 DEG C; time for changes at a pressure is short; and the color of the decoration leather having undergone changes at a pressure is brilliant and full, presenting great contrast.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

A windproof and moisture-permeable fabric

The invention discloses a windproof and moisture-permeable fabric. The surface of the fabric is made of fine denier fibers, and the inside is made of coarse denier fibers. 100%, the inner tightness is 55-70%, and the single fiber fineness ratio of fine-denier fiber to coarse-denier fiber is 0.1-0.8. According to JIS? L? 1096 standard measured air flow is less than or equal to 3cc / c? m2·s, according to GB∕T? 12704.2 standard measured moisture permeability between 8000 ~ 15000g / m2·24h. The fabric has low production cost, good moisture permeability, excellent wind resistance, soft hand feeling, plump and crisp, good resilience, and is especially suitable for making high-end leisure outerwear products.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Method for producing radioresistant worsted fabric

InactiveCN101413172BWith anti-radiation functionWith natural memory fold functionWoven fabricsYarnWorstedRadiation resistant

Owner:JIANGSU SUNSHINE +1

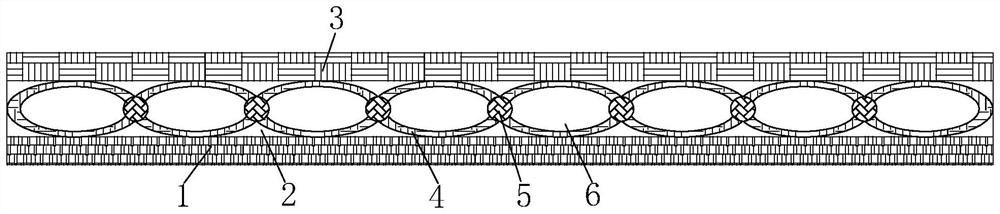

Camel hair loop yarn fiber fabric

The invention relates to a camel hair loop yarn fiber fabric, and belongs to the field of fiber fabrics. The fabric comprises an inner layer, a middle layer and an outer layer, the inner layer and the outer layer are arranged on the two sides of the middle layer respectively, and the fabric is structurally characterized in that loop yarn is arranged in the middle layer, the number of the loop yarn is multiple sets, nodes are formed between every two adjacent loop yarn, air holes are formed in the middles of the loop yarn, and the loop yarn comprises fiber units. Each fiber unit comprises a fiber unit inner core, a fiber unit outer layer and a fiber unit interlayer, the fiber unit outer layer is arranged on the outer side of the fiber unit inner core, the fiber unit interlayer is arranged between the fiber unit inner core and the fiber unit outer layer, the number of the fiber units is four, and the fiber units are arranged in the fiber unit inner core. A fiber unit overlapping layer exists between every two adjacent fiber units, and a fiber unit filling layer is arranged between the outer side of the fiber unit outer layer and the side wall of the loop yarn.

Owner:浙江赢时胜实业有限公司

Anti-pilling wool-like comfortable fabric and preparation method thereof

The invention belongs to the technical field of textile materials, and provides an anti-pilling wool-like comfortable fabric. Spandex fibers are added on the basis of polyester fibers and viscose fibers to prepare warp and weft yarns, so that the fabric has the advantages of being washable, wear-resistant, crease-resistant, stiff and smooth, and anti-pilling. By controlling the mass content of the polyester fibers in the warp and weft yarns, the pilling and fuzzing performance of the fabric is improved; by controlling the mass content of the spandex fibers in the warp and weft yarns, the washing size stability of the fabric is good; by controlling the twist of the warp and weft yarns, the fuzzing and pilling performance of the fabric is improved, and the fabric is washable and wear-resistant; by controlling the length and the fineness of single fibers in the warp yarns, the fabric is not prone to fuzzing and pilling; and by controlling the length and fineness of single fibers in the weft yarns, the fabric has a wool-like effect. The result of the anti-pilling wool-like comfortable fabric shows that the fuzzing and pilling of the anti-pilling wool-like comfortable fabric is at the grade 3-4.

Owner:正凯纺织有限公司

15*12-mesh polyester plastic-coated pet net production technology

InactiveCN103820916ASolve the problem that the winding tension is small and the monofilament is easy to break when it is coated with plasticHigh strengthLiquid surface applicatorsHeating/cooling textile fabricsGramEconomic benefits

The invention provides a 15*12-mesh polyester plastic-coated pet net production technology. The technology includes the following steps of polyester filament yarn preparing, monofilament plastic coating, warping, weaving, setting and cloth inspecting. According to the technology, Z100 twisted polyester filament yarn plastic coating, high temperature plasticizing, weaving and high temperature setting are adopted. The production efficiency of the production technology is much higher than that of extrusion molding production, the economic benefits are much higher than that of the extrusion molding production, and a manufactured 15*12-mesh polyester plastic-coated pet net with the gram weight per square meter of fabric no smaller than 400 g / m<2> has the advantages of being high in strength, resistant to abrasion and folding, stiff and smooth in hand feel, flameproof, fireproof, resistant to ultraviolet, free of injuries to animals and the like.

Owner:TIANJIN HENGTONG IND & TRADE DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com