Geometric texture oxford spinning fabric and production process thereof

A production process, Oxford spinning technology, applied in textiles, embossed fabrics, textiles and papermaking, etc., can solve the problems of lack of fashion, old-fashioned, long finishing process, etc., to achieve unique geometric texture appearance, crisp and broad feel The effect of market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

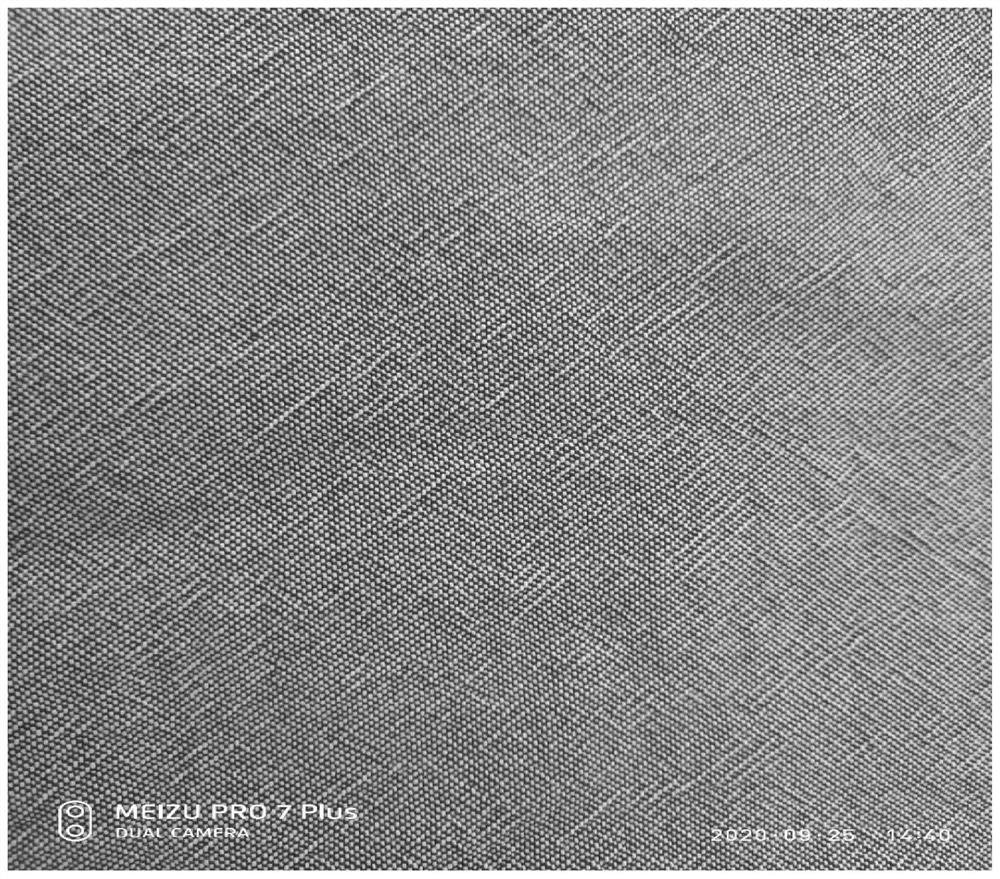

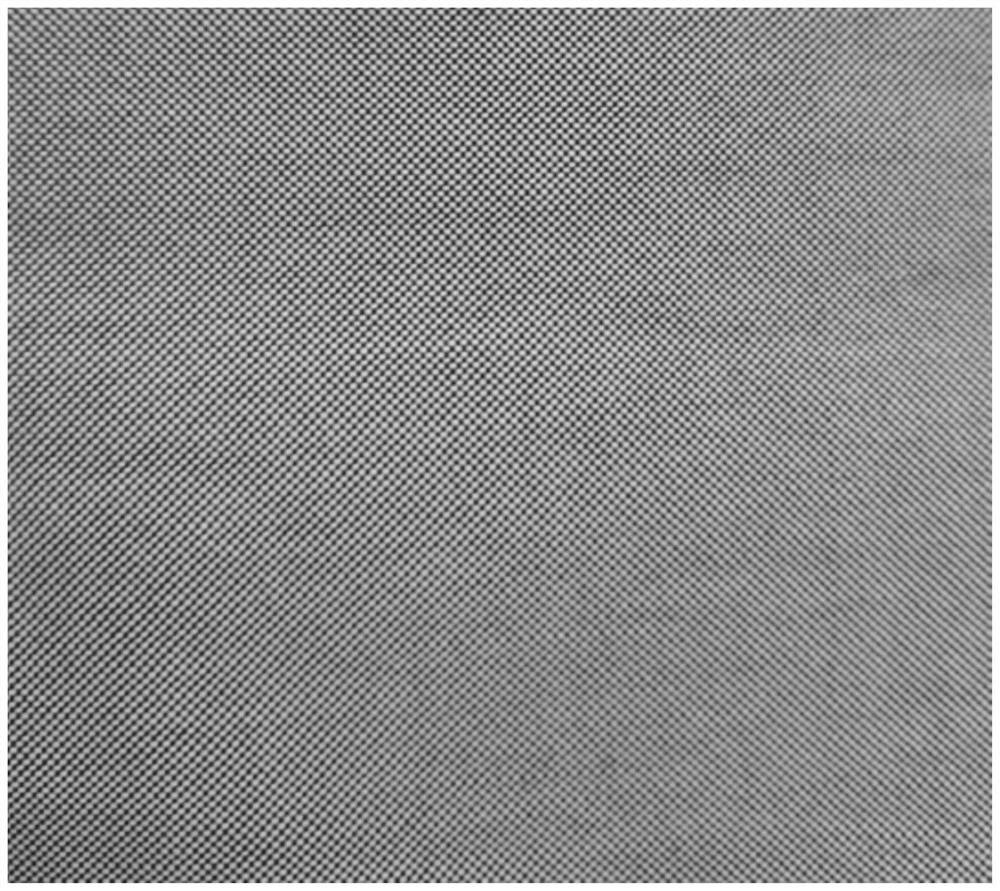

Image

Examples

Embodiment 1

[0033] The fabric production process is as follows: cotton blending - opening and cleaning - carding - drawing - roving - spun yarn - winding - dyeing - warping - sizing - reeding - weaving - finishing - garment washing. Based on the design of ordinary ring-spun yarns, the yarn used in the weft direction of the fabric is changed to Siro pure cotton 10S fine-staple cotton yarn with a twist of 18 twists / inch. The yarn count of the fabric is CM40S*CM10S, and the warp density 100 threads / inch, weft density is 50 threads / inch, weave is 2 / 2 weft heavy flat.

[0034] 1. Cotton blending: fine-staple cotton is selected as the raw material, and the parts by weight are 8 batches.

[0035] 2. Cotton opening and cleaning: The process of the combined opening and cleaning machine is 450g / m of cotton lap weight, 10kg of cotton lap weight, 500r / min of carding roller speed, and 800r / min of comprehensive beaters.

[0036] 3. Carding: The process of the carding machine is set at a licker-in spee...

Embodiment 2

[0050] The fabric production process is as follows: cotton blending - opening and cleaning - carding - drawing - roving - spun yarn - winding - dyeing - warping - sizing - reeding - weaving - finishing - garment washing. Based on the design of ordinary ring-spun yarns, the yarn used in the weft direction of the fabric is changed to Siro pure cotton 8S fine-staple cotton yarn with a twist of 16 twists / inch. The yarn count of the fabric is CM40S*CM8S, and the warp density 90 threads / inch, weft density is 48 threads / inch, weave is 2 / 2 weft heavy flat.

[0051] 1. Cotton blending: fine-staple cotton is selected as the raw material, and the parts by weight are 8 batches.

[0052] 2. Cotton opening and cleaning: The process of the combined opening and cleaning machine is 420g / m of cotton lap weight, 9kg of cotton lap weight, 480r / min of carding roller speed, and 750r / min of comprehensive beater.

[0053] 3. Carding: The process of the carding machine is set at a licker-in speed of ...

Embodiment 3

[0067] The fabric production process is as follows: cotton blending - opening and cleaning - carding - drawing - roving - spun yarn - winding - dyeing - warping - sizing - reeding - weaving - finishing - garment washing. Based on the design of ordinary ring-spun yarns, the yarn used in the weft direction of the fabric is changed to Siro pure cotton 12S fine-staple cotton yarn with a twist of 20 twists / inch. The yarn count of the fabric is CM50S*CM12S, and the warp density 110 threads / inch, weft density is 55 threads / inch, weave is 2 / 2 weft heavy flat.

[0068] 1. Cotton blending: fine-staple cotton is selected as the raw material, and the parts by weight are 10 batches.

[0069] 2. Cotton opening and cleaning: The process of the combined opening and cleaning machine is 450g / m of cotton lap weight, 10kg of cotton lap weight, 500r / min of carding roller speed, and 800r / min of comprehensive beaters.

[0070] 3. Carding: The process of the carding machine is set at a licker-in spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com