A kind of wool spinning composite flocking fabric and preparation method thereof

A fabric and flocking technology, applied in the field of woolen composite flocking fabrics and their preparation, can solve the problems of uneven color and light on the surface of the fabric, the fluff is disordered, affecting the style of the fabric, etc., and achieves the solution of itchiness, stiff hand and good dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

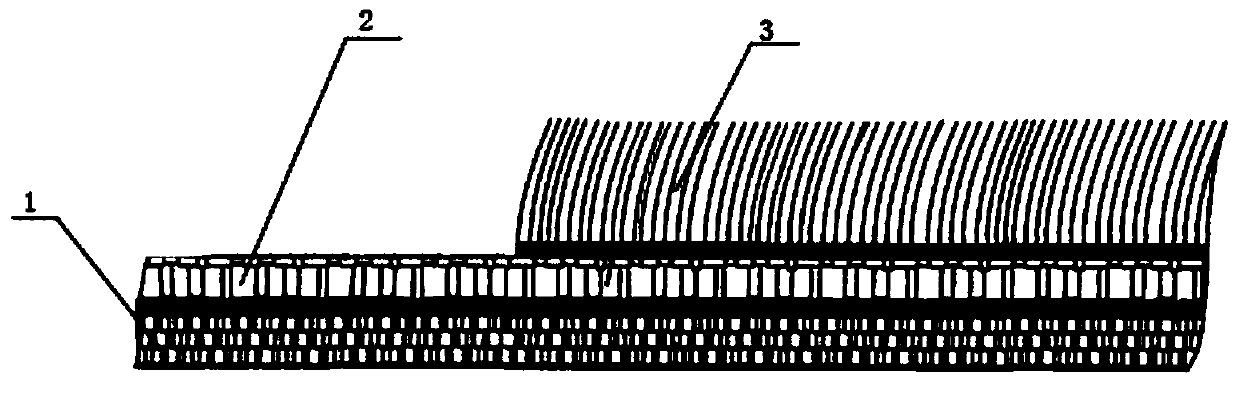

[0026] A woolen composite flocking fabric, such as figure 1 As shown, it comprises base cloth 1, face cloth 2 and flocking layer 3, base cloth 1 is a knitted double-sided fabric, face cloth 2 is a single face cloth of knitted plain weave, the reverse side of the base cloth and face cloth is compounded, and the fluff Layer 3 fixes the pile on the front of the face cloth by electrostatic flocking.

[0027] The base fabric is made of 60D polyester filament. The base fabric has 50 warp stitches and 50 weft stitches. The weight of the base fabric is 200g / ㎡. The yarn size is 25, the number of weft needles is 55, the yarn specification is 52S / 2 worsted yarn, and the weight of the face fabric is 280g / ㎡; the flocking fluff is 1.5D nylon fluff, and the length is 0.8mm. The back of the base fabric and the face fabric are bonded by hot-melt adhesive, and the fluff layer is a preset pattern / pattern, and the grammage of the obtained wool-spun composite flocking fabric is 480g / ㎡.

[0028] ...

Embodiment 2

[0035] A woolen composite flocking fabric, such as figure 1 As shown, it comprises base cloth 1, face cloth 2 and flocking layer 3, base cloth 1 is a knitted double-sided fabric, face cloth 2 is a single face cloth of knitted plain weave, the reverse side of the base cloth and face cloth is compounded, and the fluff Layer 3 fixes the pile on the front of the face cloth by electrostatic flocking.

[0036] The base fabric is made of 50D polyester filament. The base fabric has 45 warp stitches and 45 weft stitches. The weight of the base fabric is 180g / ㎡. The yarn size is 20, the number of weft needles is 50, the yarn specification is 52S / 2 worsted yarn, and the grammage of the face fabric is 260g / ㎡; the flocking fluff is made of 0.5D polyester fluff, and the length is 0.6mm. The back of the base fabric and the face fabric are bonded by hot-melt adhesive, and the fluff layer is a preset pattern / pattern, and the grammage of the obtained wool-spun composite flocking fabric is 440g...

Embodiment 3

[0044] A woolen composite flocking fabric, such as figure 1 As shown, it comprises base cloth 1, face cloth 2 and flocking layer 3, base cloth 1 is a knitted double-sided fabric, face cloth 2 is a single face cloth of knitted plain weave, the reverse side of the base cloth and face cloth is compounded, and the fluff Layer 3 fixes the pile on the front of the face cloth by electrostatic flocking.

[0045] The base fabric is made of 55D polyester filament. The base fabric has 48 warp stitches and 48 weft stitches. The weight of the base fabric is 190g / ㎡. The raw material of the face fabric is 66S Australian wool. The specification is 52S / 2 worsted yarn, the number of warp needles of the face fabric is 20, the number of weft needles is 50, and the weight of the face fabric is 270g / ㎡; the flocking fluff is made of 0.7D nylon fluff, and the length is 1.0mm. The back of the base fabric and the face fabric are bonded by hot-melt adhesive, and the fluff layer is a preset pattern / patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com