Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Small dimensional change rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method for enabling pure mulberry silk fabric to have natural elasticity style in weft direction

ActiveCN101634097AWeft stress balance and stabilityGuaranteed uniformityLiquid/gas/vapor removalHeating/cooling textile fabricsFiberMoisture absorption

The invention discloses a production method for enabling a pure mulberry silk fabric to have a natural elasticity style in a weft direction. The technological processes sequentially comprise blank silk weaving, preprocessing, cooked smelting, bleaching, water washing, pickling, dewatering or squeezing, coiling, baking stentering and check mounting, wherein the cooked smelting comprises primary smelting and secondary smelting. The baking stentering comprises the following steps: firstly, carrying out baking shaping on a wool carpet finishing machine and then at least carrying out stentering processing for more than two times on a stentering machine. The technological processes of the blank cloth weaving comprise the selection of wefts, the selection of the twisting degree and the twisting direction of the wefts and the twisting direction arrangement of weft combination. Because the pure mulberry silk fabric does not depend on elastic fibre, such as urethane elastic fibre and the like, and adopts blank silk woven by super-strong twisting real silk wefts to carry out the methods of degumming, stentering, shaping and processing so as to enable a pure real silk fabric to obtain better weft direction elasticity and excellent elastic restoring force, the fabric is not easy to crack and has relatively flexible hand feel and good moisture absorption and air permeability, and a dress article made by the fabric shapes the body and has convenient movement, good form retention, small dimensional change rate and small seam slippage.

Owner:DALI SILK ZHEJIANG

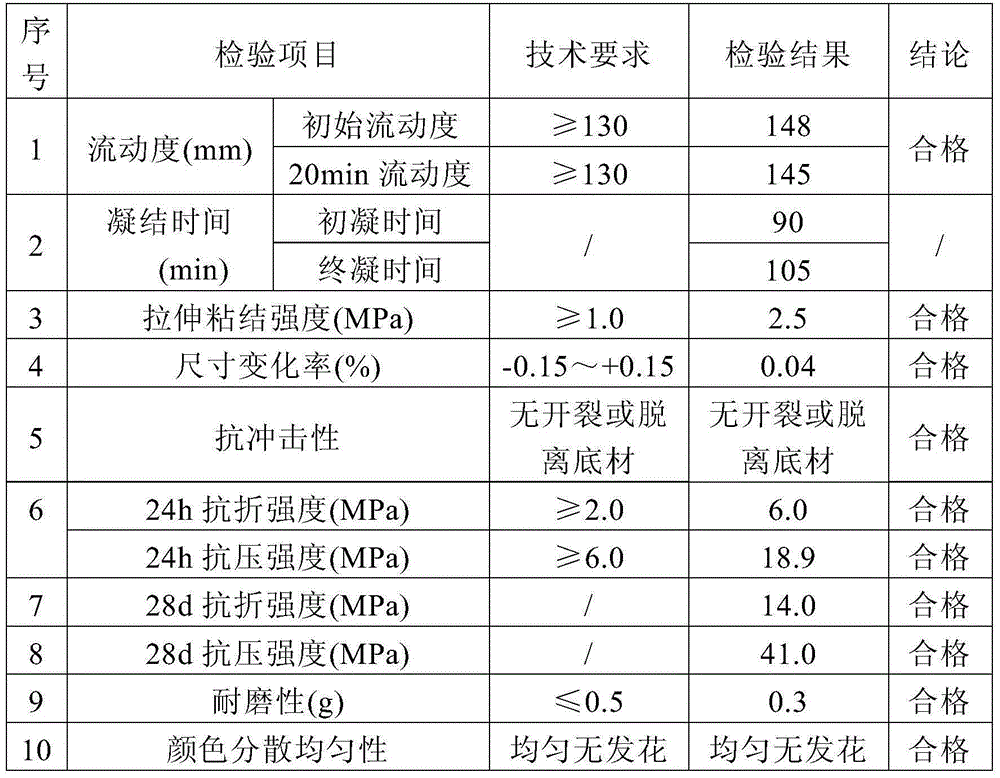

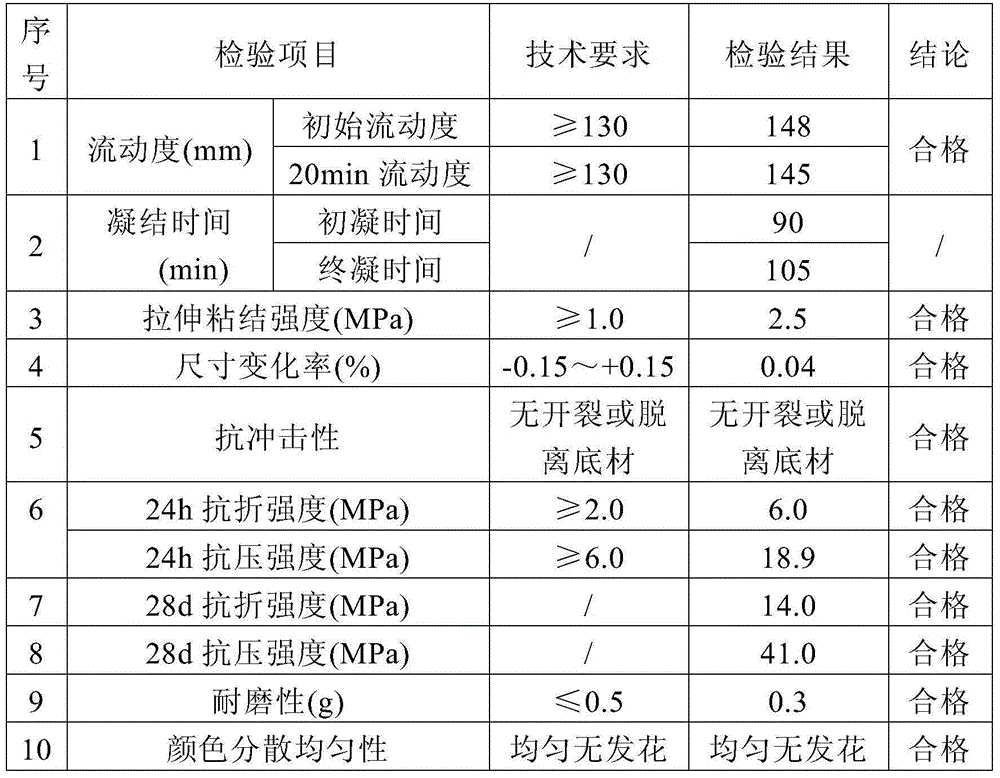

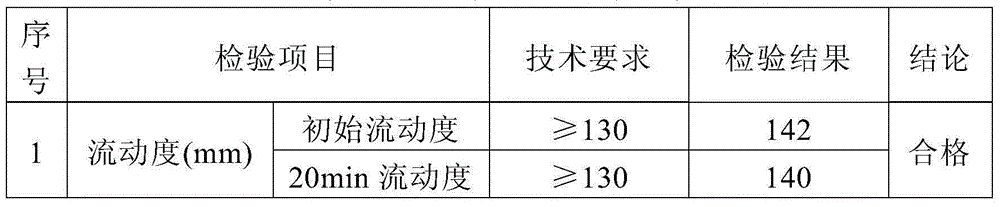

High-strength cement-based self-leveling mortar

The invention discloses high-strength cement-based self-leveling mortar powder and slurry. The mortar powder specifically comprises the following components in parts by weight: 25-27 parts of silicate cement, 5-10 parts of aluminate cement and / or sulphate aluminium cement, 5-8 parts of gypsum and a very small amount of aids, wherein the very small amount means that the weight of every single additive accounts for 0.05-0.5wt% of the total weight of the mortar powder. According to the mortar disclosed by the invention, the mortar body added with water in proportion is good in peaceability, and during the construction time, good flowability can be continuously maintained, and the loss is less; the mortar is high in hardening speed, and after 6-8 hours, people can walk on the mortar; the mortar is high in strength and can be used as a heavy load floor cushion. The self-leveling mortar product is good in workability, hard to crack in construction at a low temperatures (5-10 DEG C) and convenient to store.

Owner:NIPPON PAINT CHINA

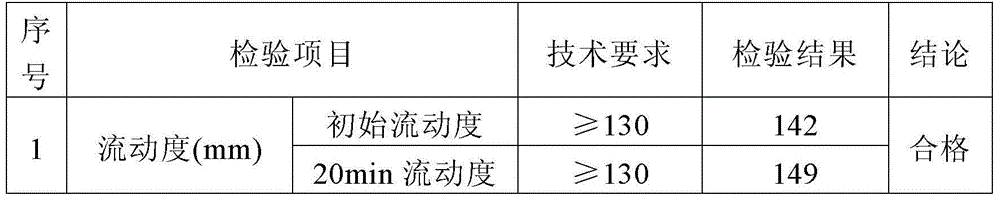

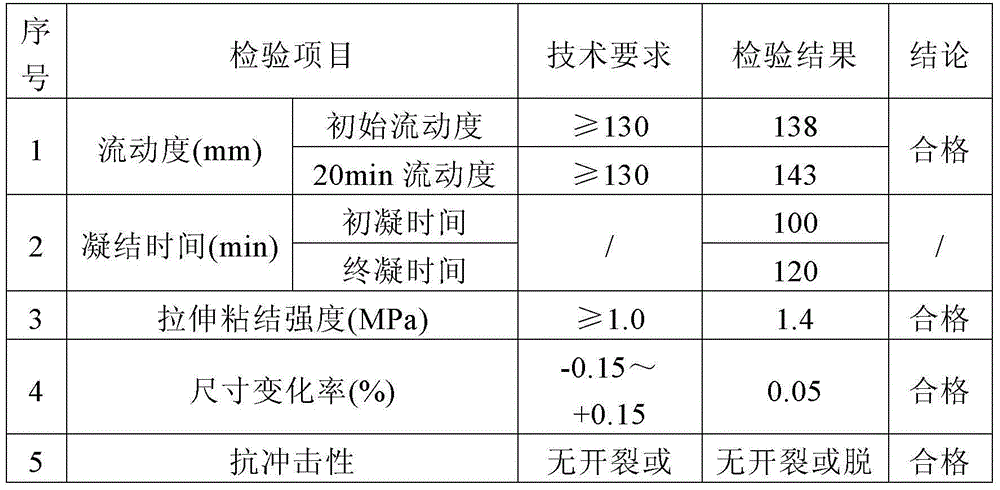

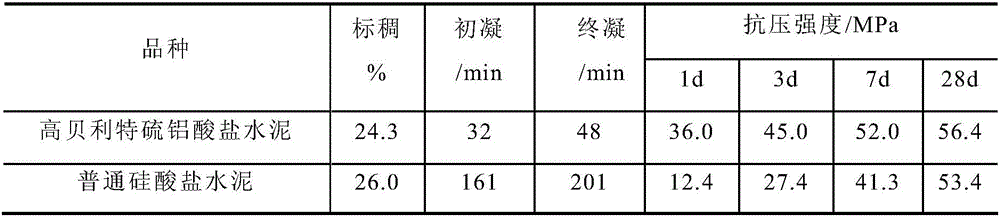

High belite sulphoaluminate cement based self-leveling mortar

The invention discloses high belite sulphoaluminate cement based self-leveling mortar. The mortar comprises the following powder raw materials in parts by weight: 30-40 parts of high belite sulphoaluminate cement, 5-7 parts of anhydrite, 12-15 parts of heavy calcium powder, 40.5-45 parts of river sand, 2-2.5 parts of emulsion powder, 0.35-0.45 part of water reducing agent, 0.35-0.45 part of defoaming agent, 0.1-0.2 part of cellulose ether, 0.1-0.2 part of tartaric acid, and 0.05-0.1 part of lithium carbonate. According to the high belite sulphoaluminate cement based self-leveling mortar, the high belite sulphoaluminate cement is used as the only cement-based gel material, so that the performances are outstanding, and various additives can be specifically selected, and as a result, the adaptability of the gel material and the various additives can be obviously improved; the preparation technology processes of the self-leveling mortar can be greatly simplified, and moreover, the product performance stability can be greatly improved; meanwhile, the cost can be decreased.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

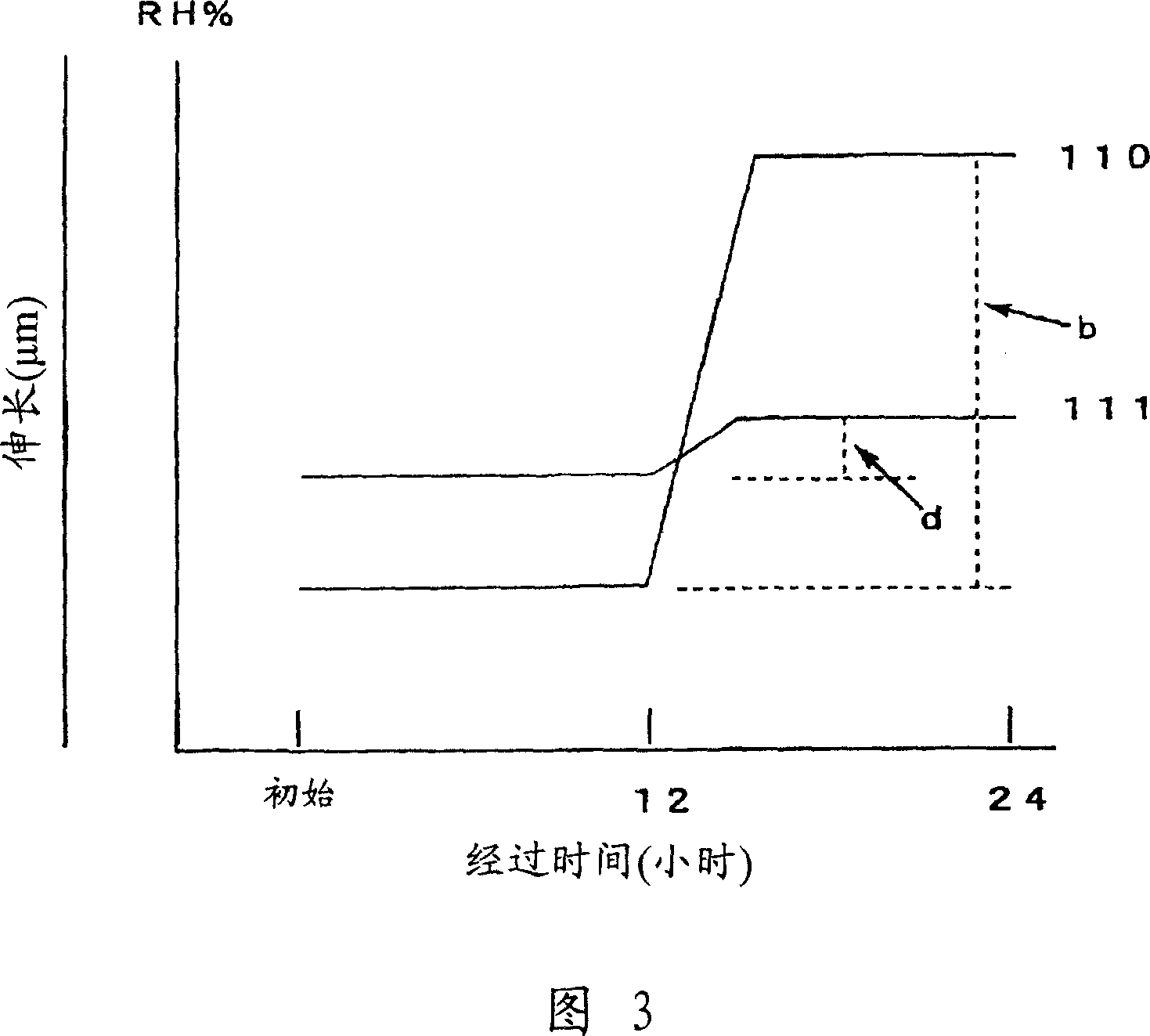

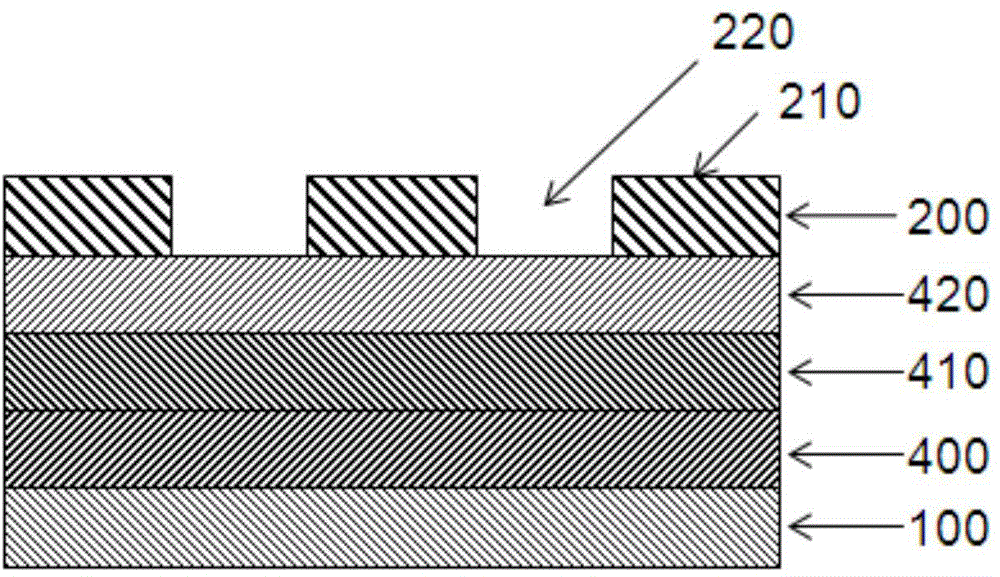

Laminate optical body, optical film, liquid crystal display device using said optical film, and method for manufacturing laminate optical body

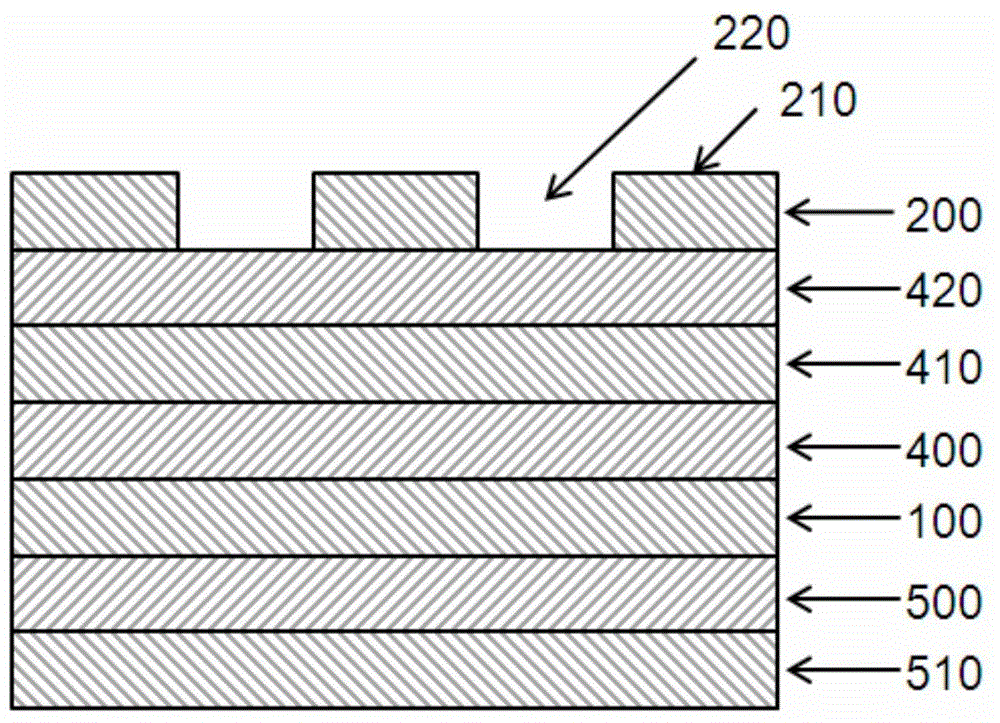

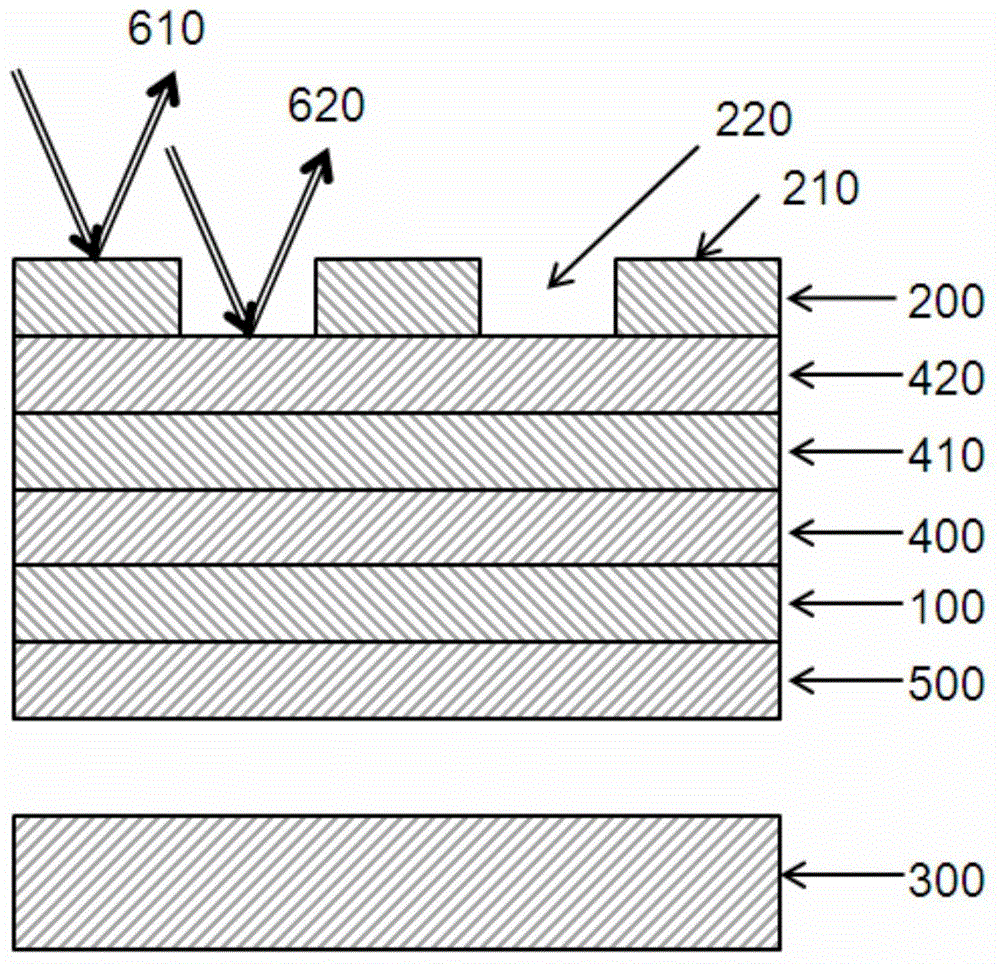

InactiveCN102317821ASmall dimensional change rateReduce distortionSynthetic resin layered productsPolarising elementsPhase retardationLiquid-crystal display

Disclosed is a laminate optical body with which a liquid crystal display device having excellent manufacturing efficiency, extremely little axial misalignment, and little display nonuniformity can be obtained. This laminate optical body is equipped with: an elongated polarizing film having an absorption axis in the short-side direction and containing a base material layer and a hydrophilic polymer layer to which a dichroic material is absorbed; and an elongated phase retardation film having a slow axis in the lengthwise direction. The polarizing film is a laminate body containing a base material layer and a hydrophilic polymer layer to which a dichroic material is absorbed. This laminate optical body is elongated. The thickness of the hydrophilic polymer layer preferably is 1-10 [mu]m.

Owner:NITTO DENKO CORP

Fiber-reinforced carbonated hydraulic inorganic molded plate and method for producing same

ActiveUS20160289119A1High bulk specific gravityGood paintabilitySolid waste managementReaction rateFlexural strength

Provided is a fiber-reinforced carbonated hydraulic inorganic molded plate having a high bulk specific gravity, a high flexural strength, and a small dimensional change rate per specific gravity. (1) A fiber-reinforced carbonated hydraulic inorganic molded plate including: a cement component, a pulp, and a reinforcing fiber having an aspect ratio in a range of 40 to 1000; and being a carbonation-cured molded plate. (2) A molded plate being a cured product of a composition including at least a cement component, a pulp, and a reinforcing fiber, wherein the molded plate is a fiber-reinforced carbonated hydraulic inorganic molded plate and has a carbonation reaction rate of higher than or equal to 30%.

Owner:KURARAY CO LTD

High-temperature-resistant high-density polyethylene geomembrane and preparation method thereof

InactiveCN110483873AImprove mechanical propertiesImproved melt strength and creep resistanceCarbon blackHigh-density polyethylene

The invention relates to the technical field of high-density polyethylene geomembranes, in particular to a high-temperature-resistant high-density polyethylene geomembrane and a preparation method thereof. The high-temperature-resistant high-density polyethylene geomembrane is prepared from the following raw materials in parts by mass: 40 to 70 parts of high-density polyethylene, 30 to 60 parts ofmedium-density polyethylene, 5 to 8 parts of antioxidant master batch and 5 to 8 parts of carbon black master batch. Various performance detection results of the high-temperature-resistant high-density polyethylene geomembrane prepared by the invention are all superior to GRI GM13 standard indexes; compared with the prior art, the high-density polyethylene geomembrane has excellent dimensional stability, the dimensional change rate is lower than + / -0.5% under the condition of 100 DEG C, the oxidation resistance is greatly improved, and the reliability and safety of engineering under the high-temperature condition are enhanced; the invention also provides the preparation method thereof.

Owner:SHANDONG TIANHE PLASTIC

Dyeing and finishing method of polyester-cotton knitted fabric with one-way moisture-wicking function

InactiveCN110747658ASmall dimensional change ratePrevents fine wrinkles and creasesHeating/cooling textile fabricsDry-cleaning apparatus for textilesDisperse dyePolymer science

The invention relates to a dyeing and finishing method of a polyester-cotton knitted fabric with a one-way moisture-wicking function, comprising the specific steps of (1) pretreating a gray fabric with an open width washing machine; (2) presetting; (3) dyeing, namely dyeing polyester with disperse dyes, carrying out reduction washing, dyeing cotton with reactive dyes, cleaning a sample, and soaping; (4) feeding a hydrophilic softening agent; (5) setting and drying; (6) carrying out waterproof finishing, to be specific, finishing the reverse cotton surface of the gray fabric on a rotary screenprinting machine; and (7) processing with a moisture-sucking sweat-wicking aid in a setting rolling channel to obtain a finished product. Compared with the conventional dyeing and finishing process, the dyeing and finishing method has the advantages that the operation is simple, the processing flow is smooth, the common polyester-cotton knitted fabric can be given the one-way moisture-wicking function, the added value and wearing comfort of the common polyester-cotton knitted fabric are improved, and the method has wide market potential.

Owner:ZHEJIANG YINHE PRINTING & DYEING

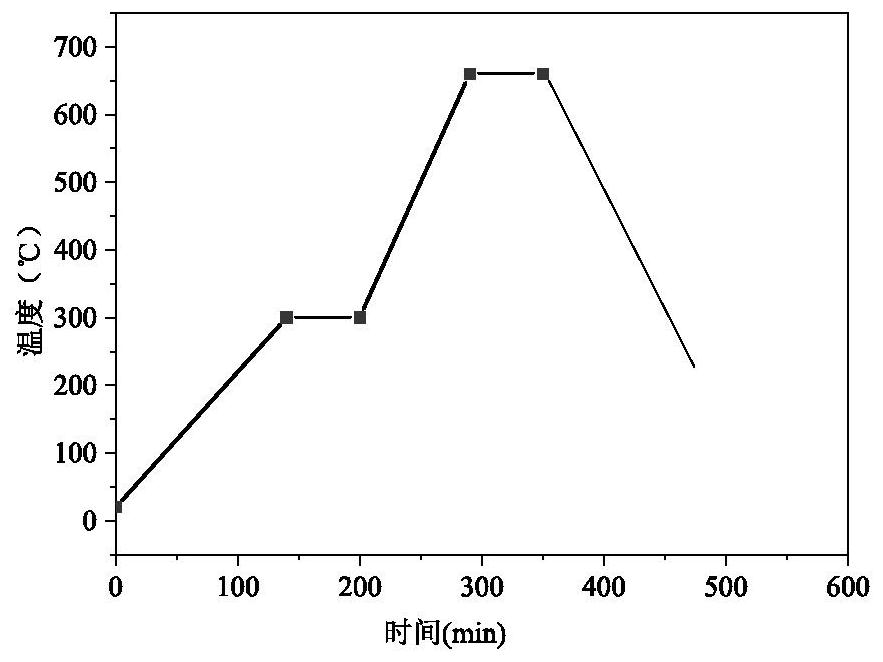

Method for manufacturing thick polyimide flexible metal-clad laminate

InactiveCN102529302AImprove adhesionSmall dimensional change ratePretreated surfacesLaminationThermal dilatationImide

The invention relates to a method for manufacturing a thick polyimide flexible metal-clad laminate. Provided is the method for manufacturing a flexible metal-clad laminate using a casting method, including: (a) forming a first polyimide layer having a coefficient of linear thermal expansion of 25 ppm / K or less above a metal layer; (b) plasma-treating a surface of the first polyimide layer; and (c) forming a second polyimide layer having a coefficient of linear thermal expansion of 25 ppm / K or lower above the first polyimide layer. The flexible metal-clad laminate according to the present invention can have excellent adhesion between the polymer film and the metal conductive layer, a low dimensional change, and a low production cost, because of superior casting workability, even though the thickness of polyimide becomes increased.

Owner:NEXFLEX CO LTD

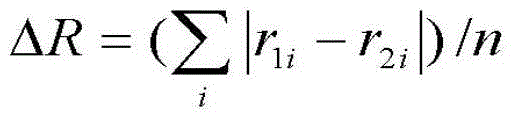

Polyimide Film

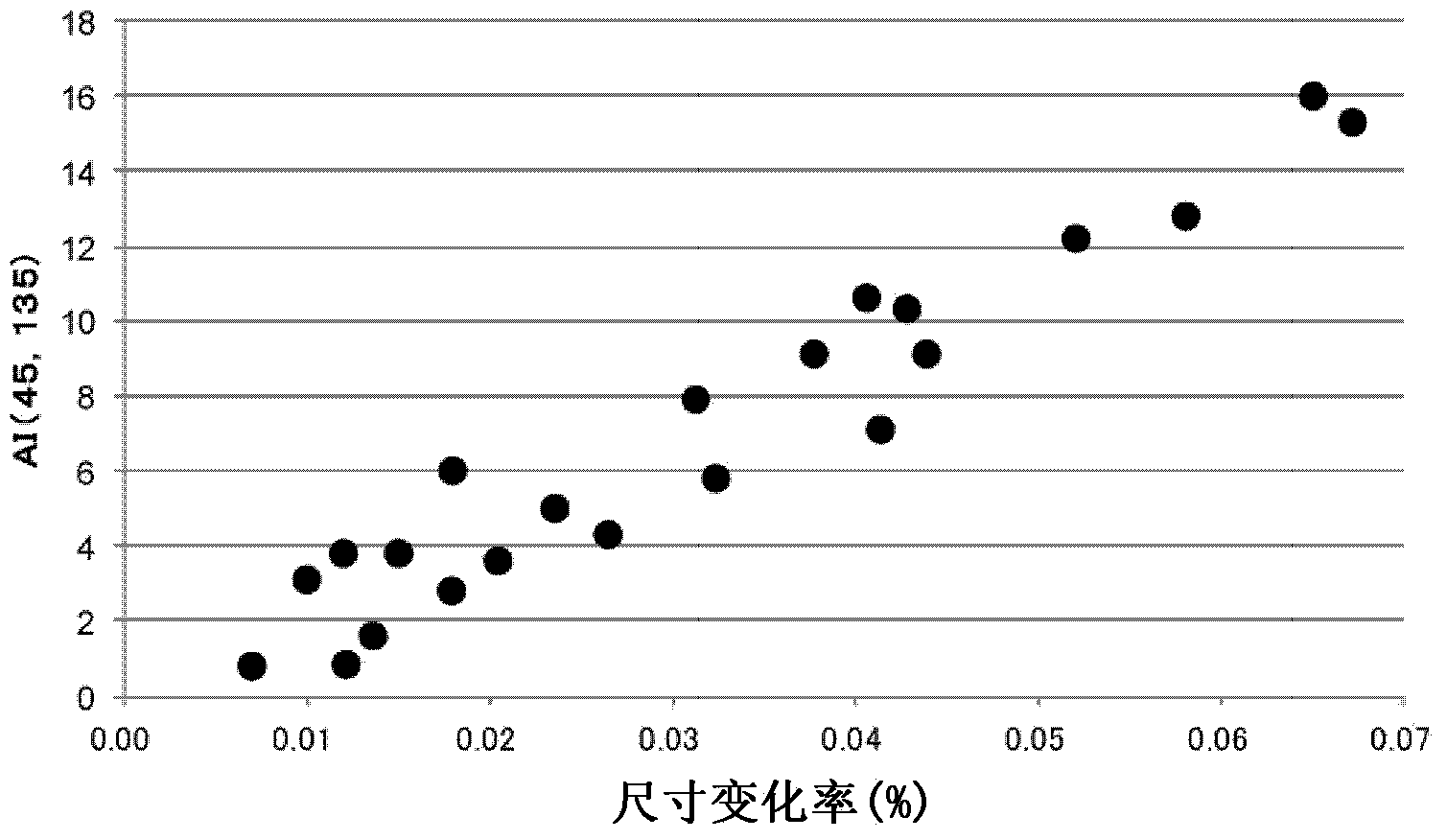

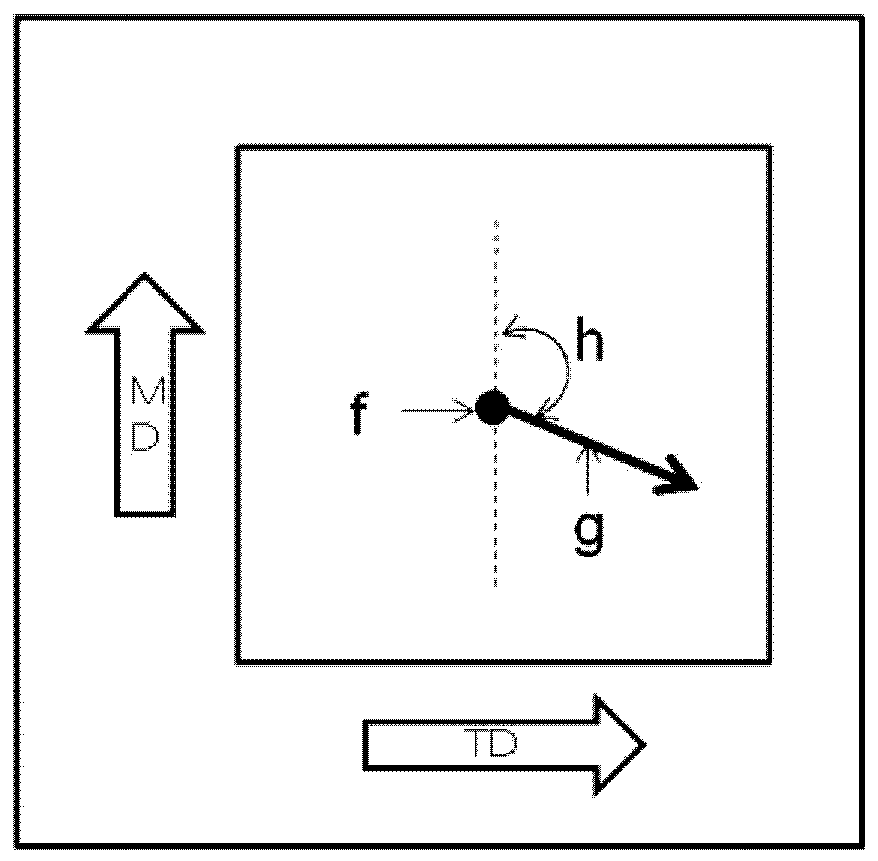

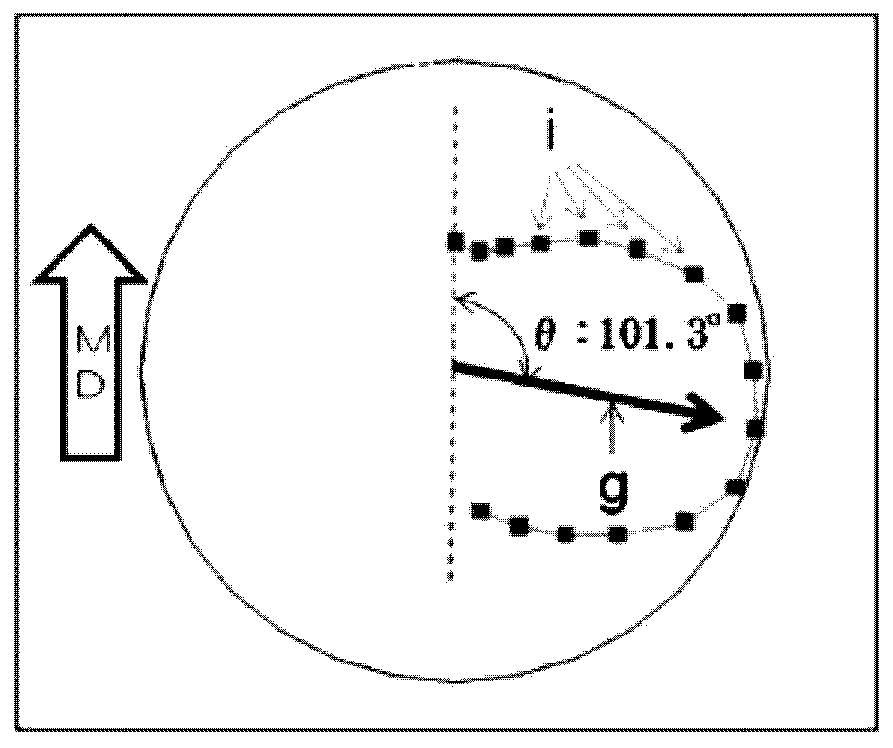

ActiveCN104250529ASmall dimensional change rateDimensional change rate is stableFilm/foil adhesivesMetal layered productsMetal foilMicrometer

The present invention provides a polyimide film, a glue film restraining the size change in a diagonal direction and a flexible metal laminating plate formed by adhering a metal foil. The diagonal is characterized in that the width of the film is greater than 1 m, when the propagation velocity V of an ultrasonic pulse of which the film orientation angle theta is 45-degree and 135-degree by taking the film mechanical transmission direction as the reference, is measured, the anisotropic index represented by formula 1 is below 12 in the overall width, and the size change rate of the flexible metal laminating plate in the diagonal (45-degree, 135-degree) direction before and after etching processing in the overall width is about -0.05-0.05%. A thermoplastic polyimide layer of which the thickness is 0.5-20 micrometers is formed on at least a single surface of the polyimide film.

Owner:DUPONT TORAY CO LTD

Slurry direct writing forming method of diamond tool

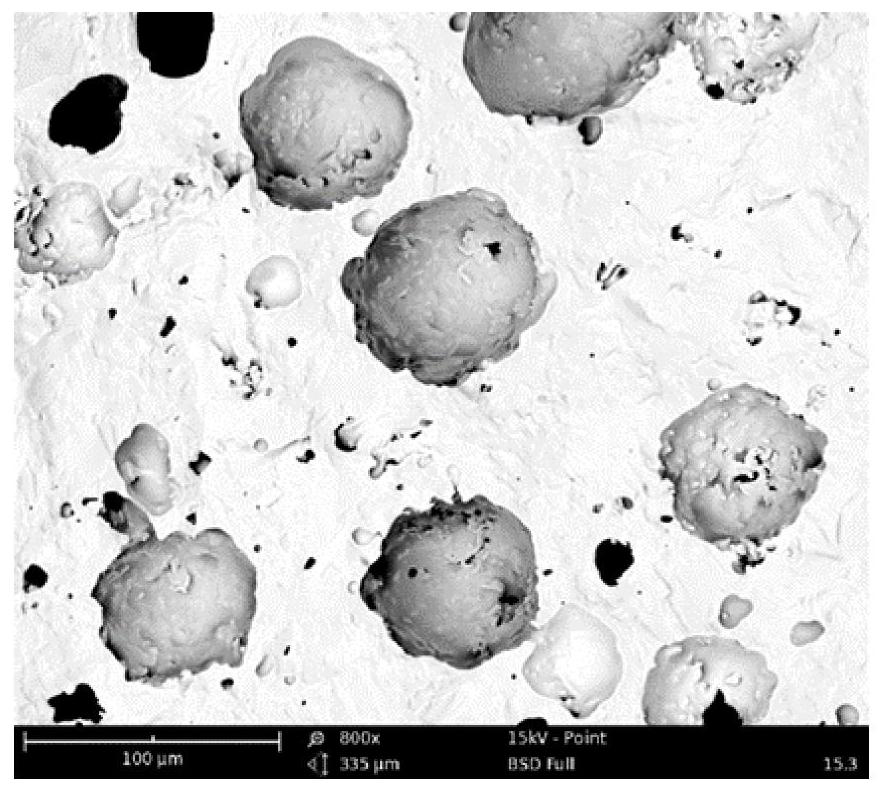

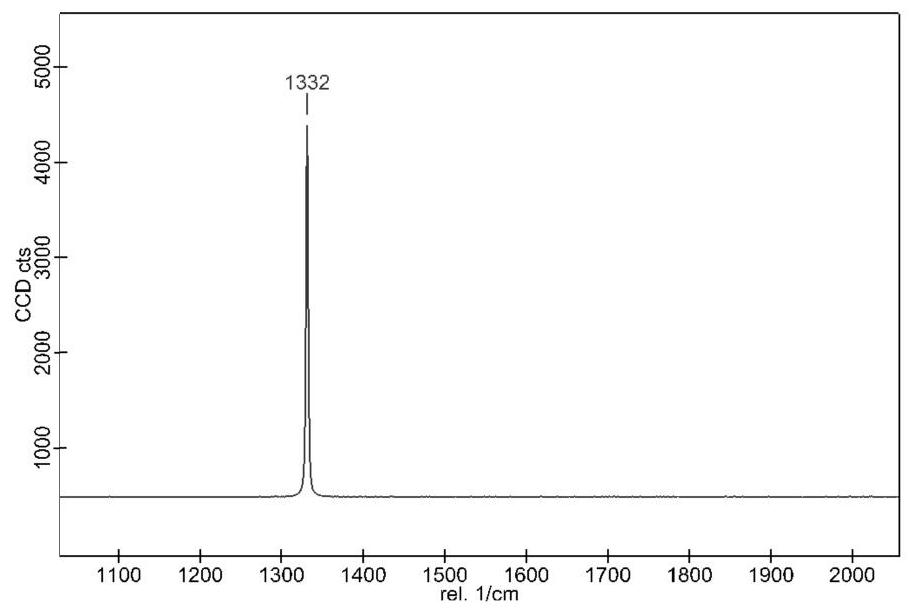

ActiveCN112723902APromote self-sharpeningUniform stomataAdditive manufacturing apparatusAbrasion apparatusPolymethyl methacrylateNanoceramic

The invention discloses a slurry direct writing forming method of a diamond tool, which comprises the following steps: (1) fully mixing nano ceramic powder, PMMA (polymethyl methacrylate) and diamond microparticles to obtain mixed powder; (2) fully dispersing xanthan gum in deionized water to obtain a xanthan gum solution; (3) uniformly mixing the mixed powder prepared in the step (1) with the xanthan gum solution obtained in the step (2) to obtain slurry; (4) adding the slurry prepared in the step (3) into a needle cylinder of slurry direct writing forming equipment, and printing into a designed shape in a layer-by-layer overlapping manner to obtain a green body; and (5) drying the green body prepared in the step (4) to constant weight, and then sintering to obtain the diamond tool. The diamond tool with a complex structure can be manufactured at a time through slurry direct writing forming, and the diamond tool has high consistency, proper mechanical property, controllable porosity and high shape precision.

Owner:HUAQIAO UNIVERSITY

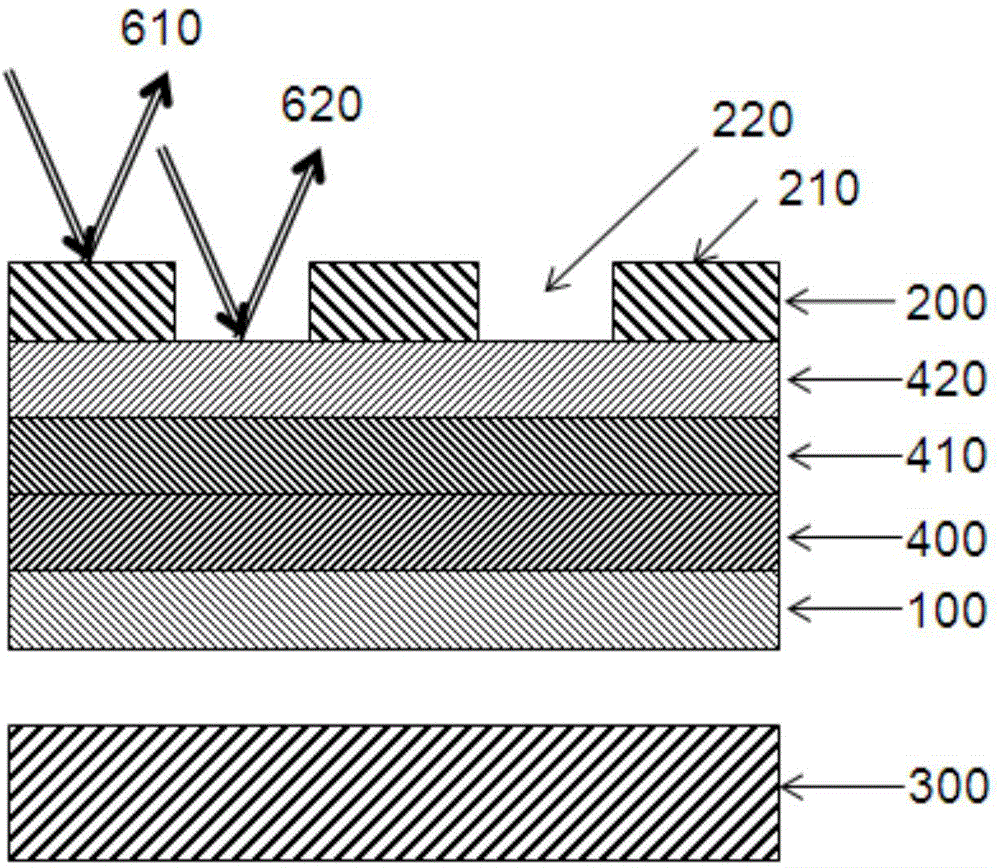

Transparent conductive optical sheet having high invisibility of pattern

ActiveCN105528107AGood dry effectNo loss of clarityInput/output processes for data processingOptical elementsElectrical devicesDisplay device

The invention relates to a transparent conductive optical sheet having high invisibility of a pattern. The transparent conductive optical sheet comprises an ITO layer via etching of a pattern. Via a thin film drying effects of a reflectivity matching layer of the optical sheet, difference between the reflectivity and reflecting color between a non-etching part and an etching part of the ITO layer is corrected, and a user is allowed to fail to recognize the non-etching part and the etching part visually, so definition for display of a display panel on a lower part will not be reduced. In particular, when thickness of the ITO layer is changed for adjustment of surface resistance, even if the reflectivity and thickness of a transparent base layer or the reflectivity matching layer are changed, the thin film drying effects can be well maintained. Thus, the optical sheet can be suitable for touch display panel field of display panels of all kinds of electrical devices.

Owner:爱思开迈克沃解决方案有限公司

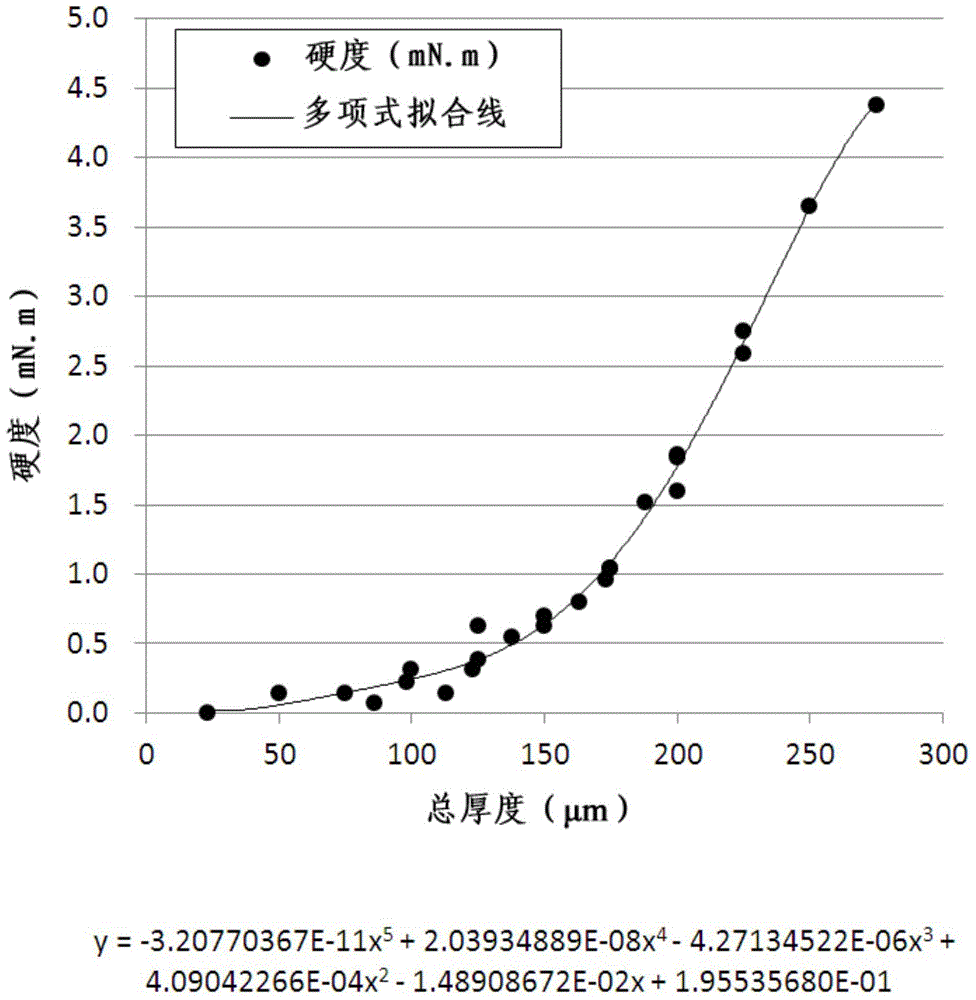

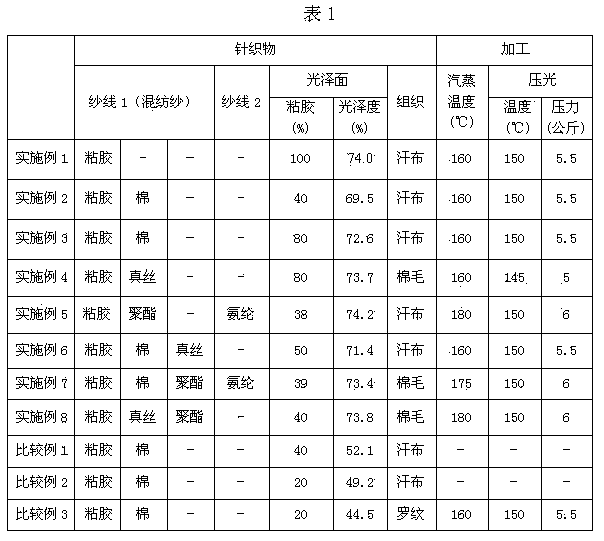

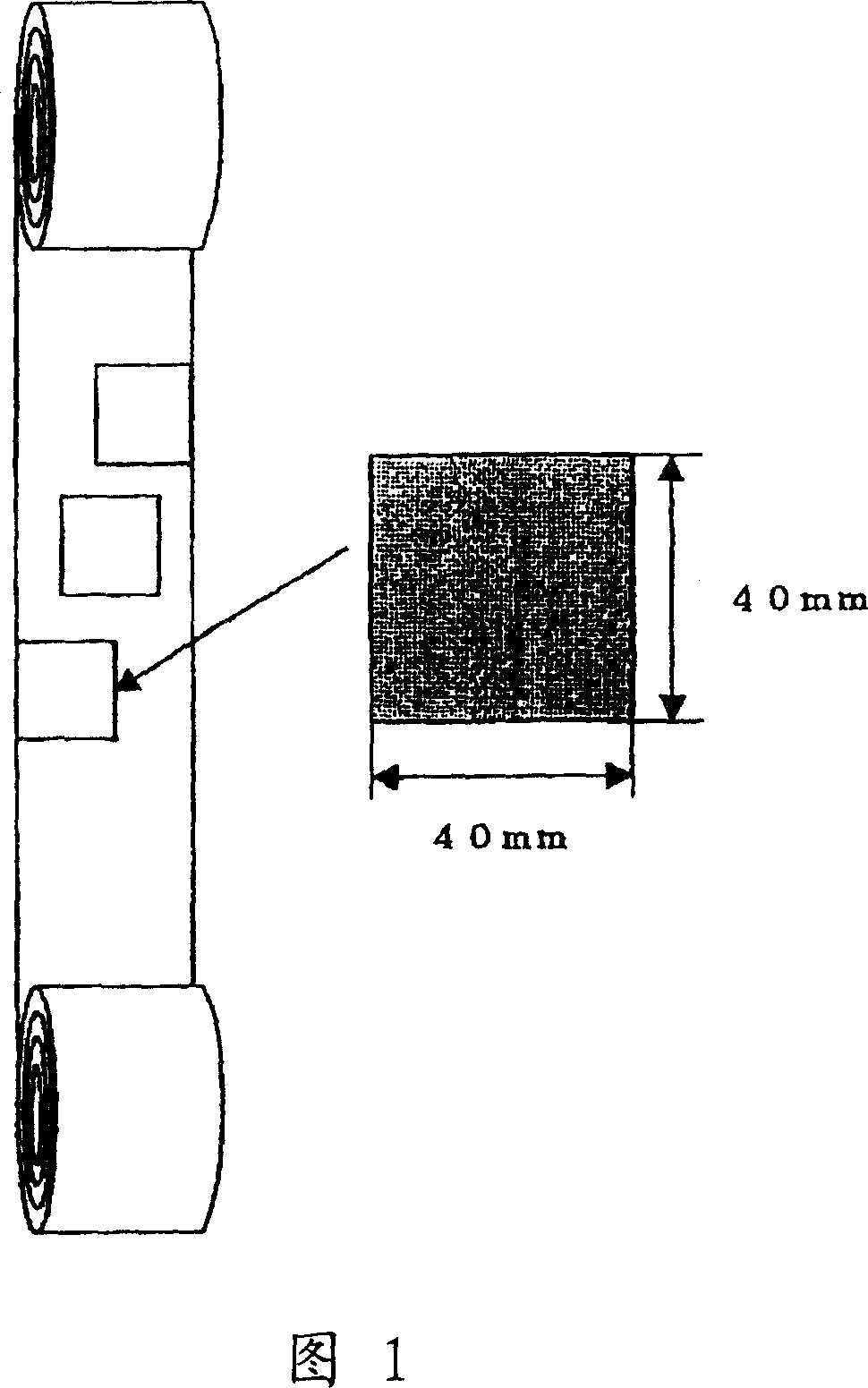

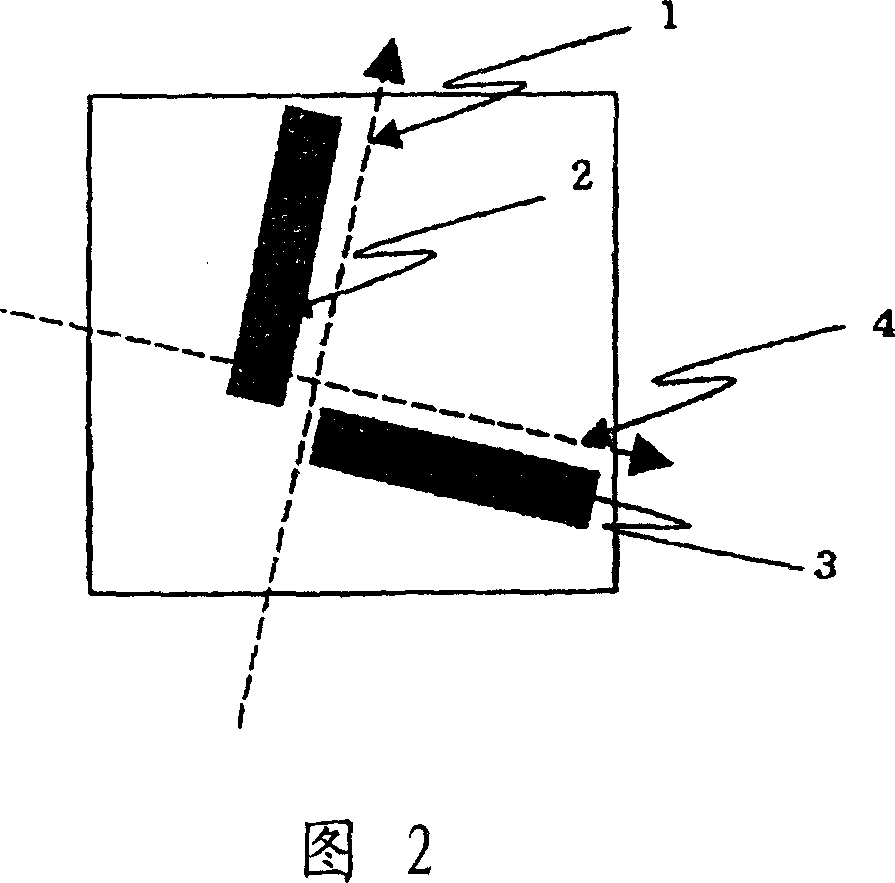

Glossy knitted fabric and production method thereof

The invention discloses a glossy knitted fabric and a production method thereof. The knitted fabric is a single knitted fabric or a double knitted fabric formed by at least viscose-containing staple fiber yarns, and more than 30 weight percent of viscose is arranged on a glossy surface. After the knitted fabric is subjected to high temperature steaming and felt calendaring, the gloss of the glossy surface of the obtained product is 60 to 75 percent through a test according to an FZ / T01097-2006 standard. The knitted fabric is soft in handfeel, low in dimensional change rate, high in form stability and high in gloss and is particularly suitable for manufacturing underwear products.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Weaving process of wool blended fabrics

InactiveCN103866577AIncreased amorphous zoneEasy to acceptWeft knittingUltrasonic/sonic fibre treatmentYarnCITRATE ESTER

The invention relates to a weaving process of wool blended fabrics. The weaving process comprises the steps of (1) winding wool fibers around pearl fibers as yarn cores in one direction, and then carrying out ultrasonic treatment, (2) winding cotton fibers around the treated wool fibers in an opposite direction to obtain composite yarns and weaving the composite yarns to obtain a surface fabric, (3) coating the surface fabric with a crease-resisting hot melt adhesive which comprises the following components in parts by weight: 30-40 parts of polytetramethylene ether glycol, 20-25 parts of butyl acrylate, 15-18 parts of citrate, 12-15 parts of diethylene glycol diglycidyl ether, 50-60 parts of polyamide, 5-10 parts of sodium alginate and 5-8 parts of dioctyl phthalate, and (4) carrying out melt-bonding on the surface fabric and a lining fabric by using a press machine, and then carrying out a finishing process to form the wool blended fabrics. By adopting the weaving process of the wool blended fabrics, the drapability and the structure tightness of the fabrics are improved.

Owner:汕头市英华织造实业有限公司

Novel polyimide film

ActiveCN1976980AImprove qualitySuppresses dimensional changesRecord carriersSynthetic resin layered productsPolyimide membraneMetal

A polyimide film that can provide a flexible metal-clad laminate plate which causes no significant dimensional change upon etching of the metal layer. The polyamide film is characterized in that, in the whole width of a continuously produced polyimide film, the ratio of the hygroscopic swelling coefficient in a direction (b) perpendicular to the molecular orientation axis to the hygroscopic swelling coefficient in a direction (a) parallel to the molecular orientation axis, i.e., b / a, is not less than 1.01 to not more than 2.00 and the difference between the maximum value of the hygroscopic swelling coefficient ratio and the minimum value of the hygroscopic swelling coefficient ratio is not more than 0.30.

Owner:KANEKA CORP

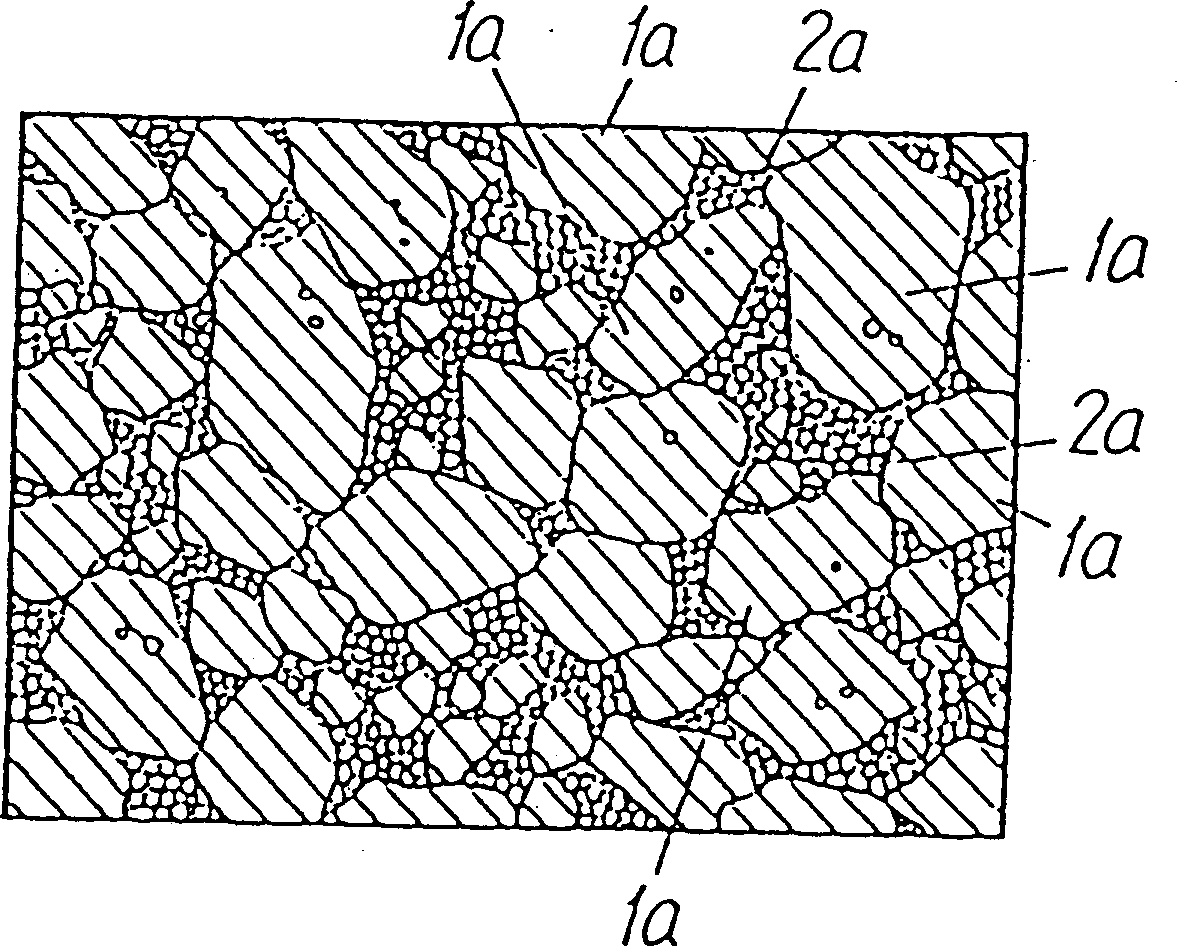

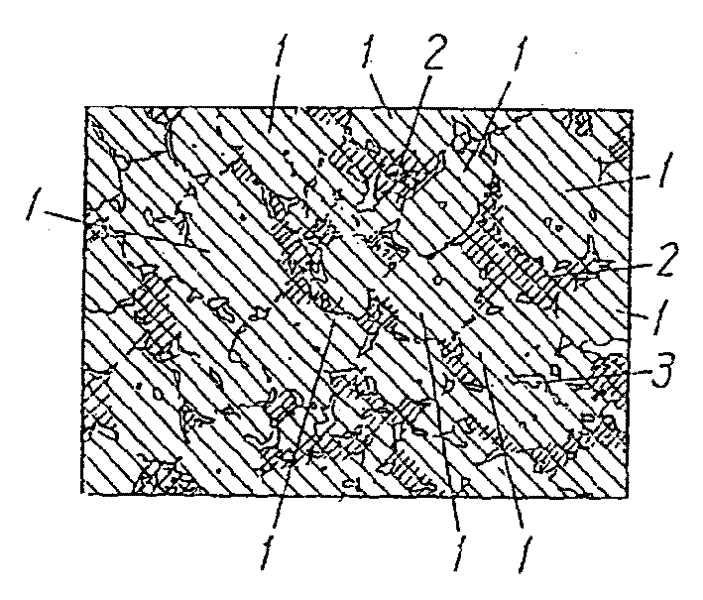

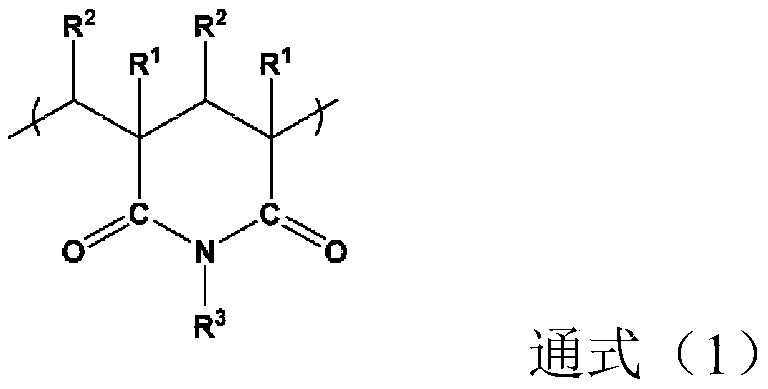

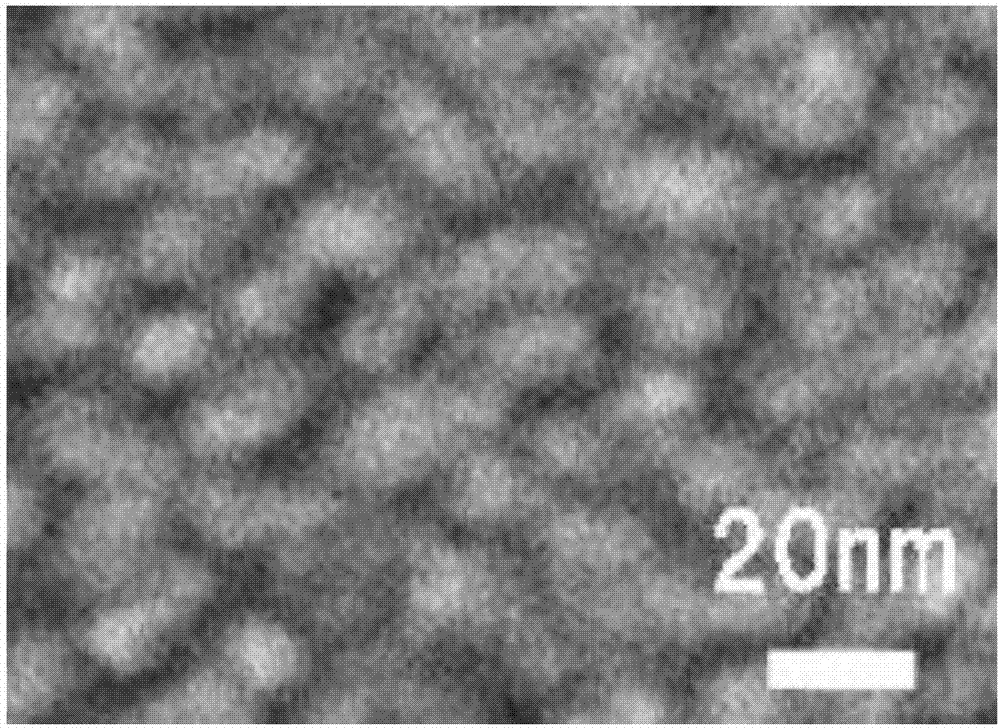

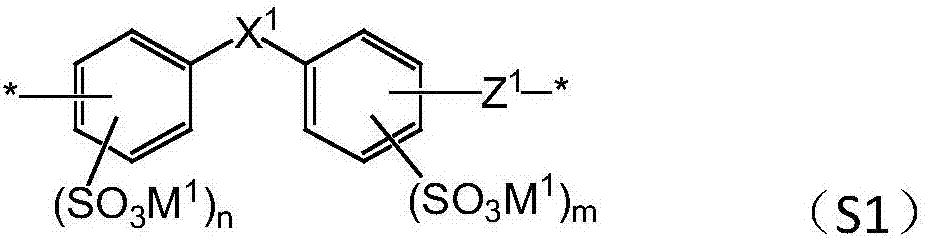

COMPOSITE POLYMER ELECTROLYTIC MEMBRANE, AND MEMBRANE ELECTRODE COMPOSITE AND SOLID POLYMER FUEL CELL USING the SAME

ActiveCN108701847AHigh outputImprove proton conductivityFinal product manufactureConductive materialFiberPolymer electrolytes

Provided are a composite polymer electrolytic membrane that has excellent proton conductivity even under low-humidification and low-temperature conditions, a small dimensional change rate, and excellent mechanical strength and chemical stability, and that is capable of achieving a high output and excellent physical durability when being used in a solid polymer fuel cell; and a membrane electrode composite and a solid polymer fuel cell using the composite polymer electrolytic membrane. This composite polymer electrolytic membrane has a composite layer formed by combining a polyazole-containingnanofiber unwoven fabric (A) and an ionic-group-containing polymer electrolyte (B), and is characterized in that the polyazole-containing nanofiber unwoven fabric (A) is basic.

Owner:TORAY IND INC +1

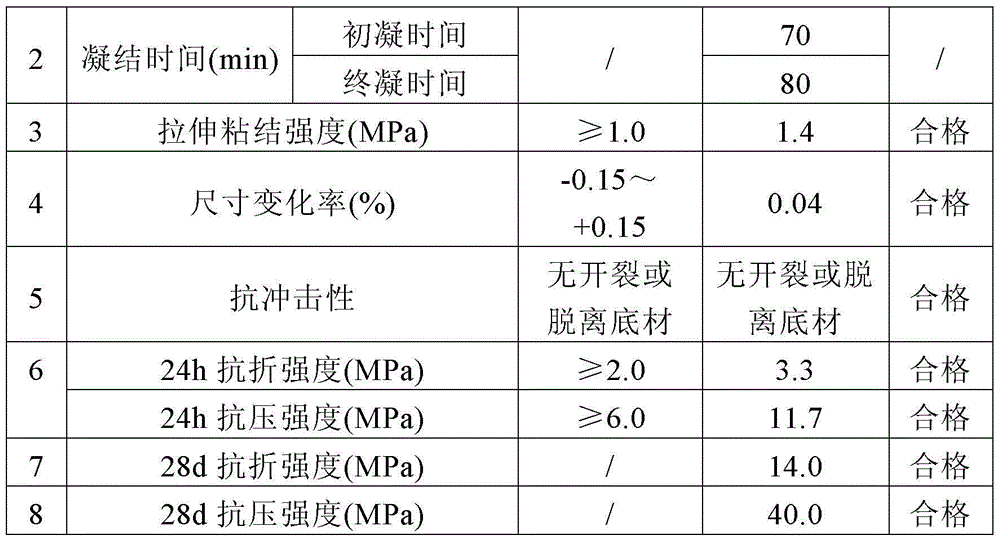

Decorative colored cement-based surface self-leveling mortar

The invention relates to mortar, specifically to colored surface cement-based self-leveling mortar which can be used on concrete or a mortar base-material, has good workability, wear resistance and high strength, is not easy to crack at low temperature (5-10 DEG C) during construction, has uniformly-dispersed color and has strong decorative performance, and a material composition thereof.

Owner:NIPPON PAINT CHINA

Transparent conductive optical sheet having high invisibility of pattern

ActiveCN105005425AExcellent crystallization rateSmall dimensional change rateNon-insulated conductorsLayered productsDisplay deviceOperability

The invention relates to a transparent conductive optical sheet comprising an ITO layer, and the ITO layer comprises etching formed patterns and the like. By means of the interference effects of refractive index matching layers, the reflectivity difference between a non-etching part and an etching part of the ITO layer and the reflection color difference between the non-etching part and the etching part of the ITO layer are corrected, users cannot visually identify the non-etching part and the etching part, and therefore the definition of images which are displayed on a lower display is not reduced. Furthermore, when the transparent conductive optical sheet is subjected to heat treatment, the crystallizing rate of the ITO layer is high, the dimensional change rate of the ITO layer is low, and therefore the transparent conductive optical sheet is high in stability and reliability, good in surface hardness and high in operability. Thus, the transparent conductive optical sheet can be widely applied to the field of touch screen panels which are used for display panels of various electronic devices.

Owner:爱思开迈克沃解决方案有限公司

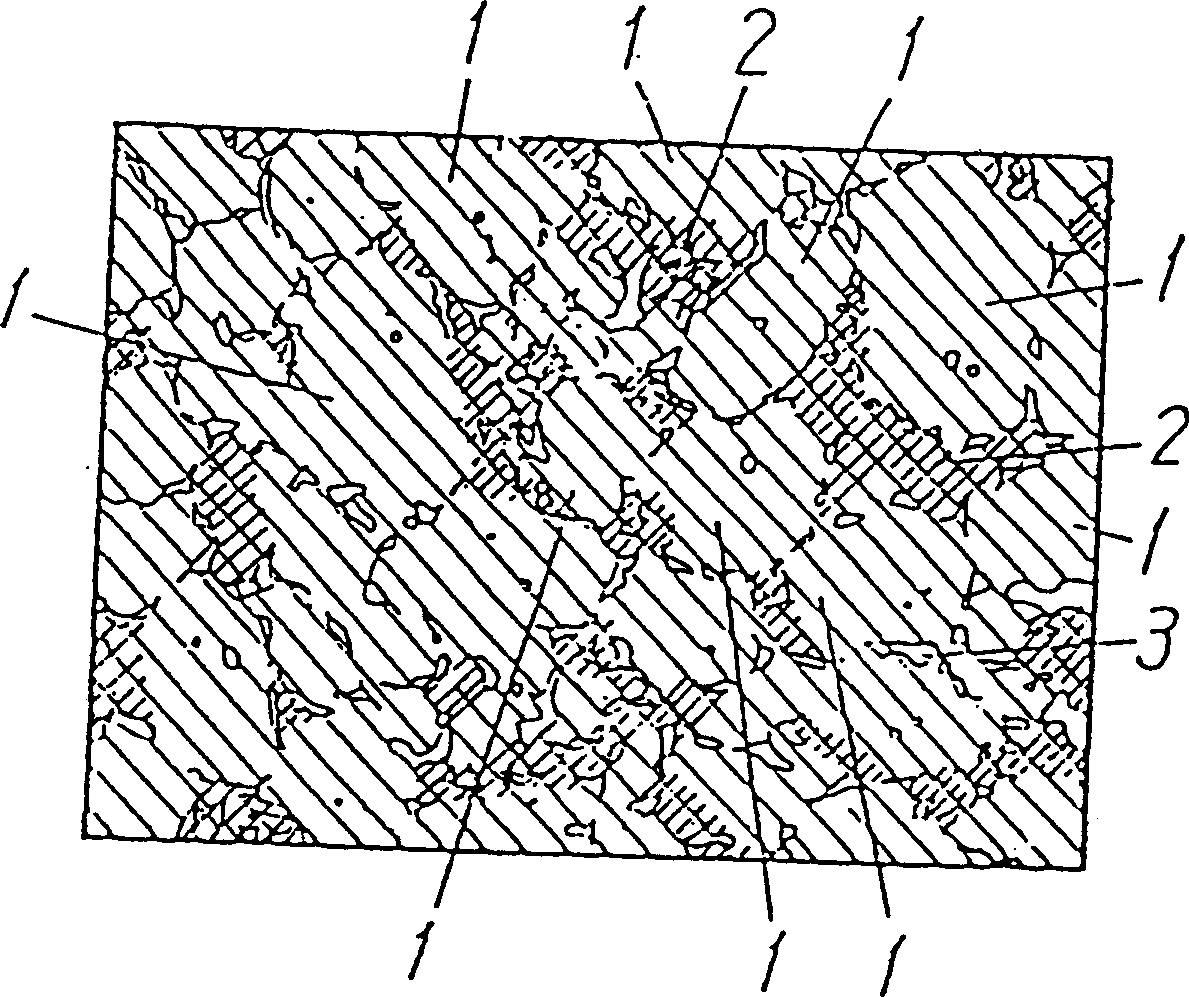

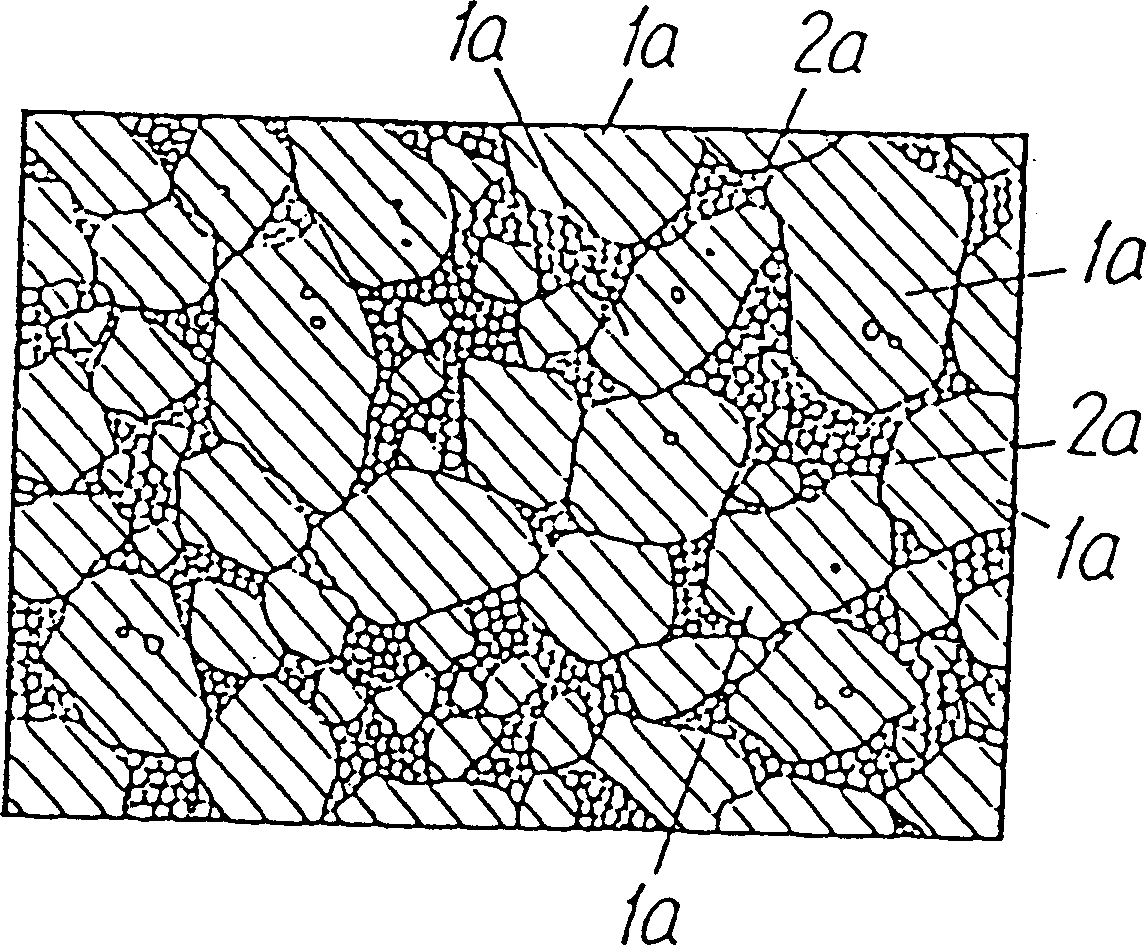

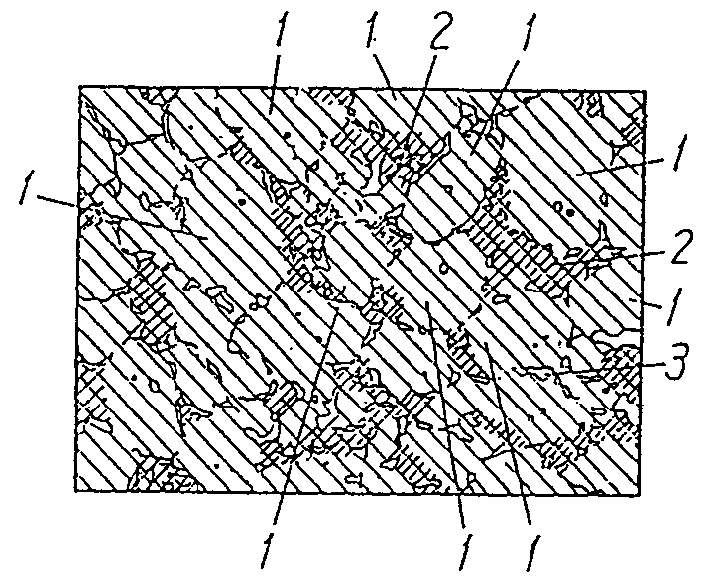

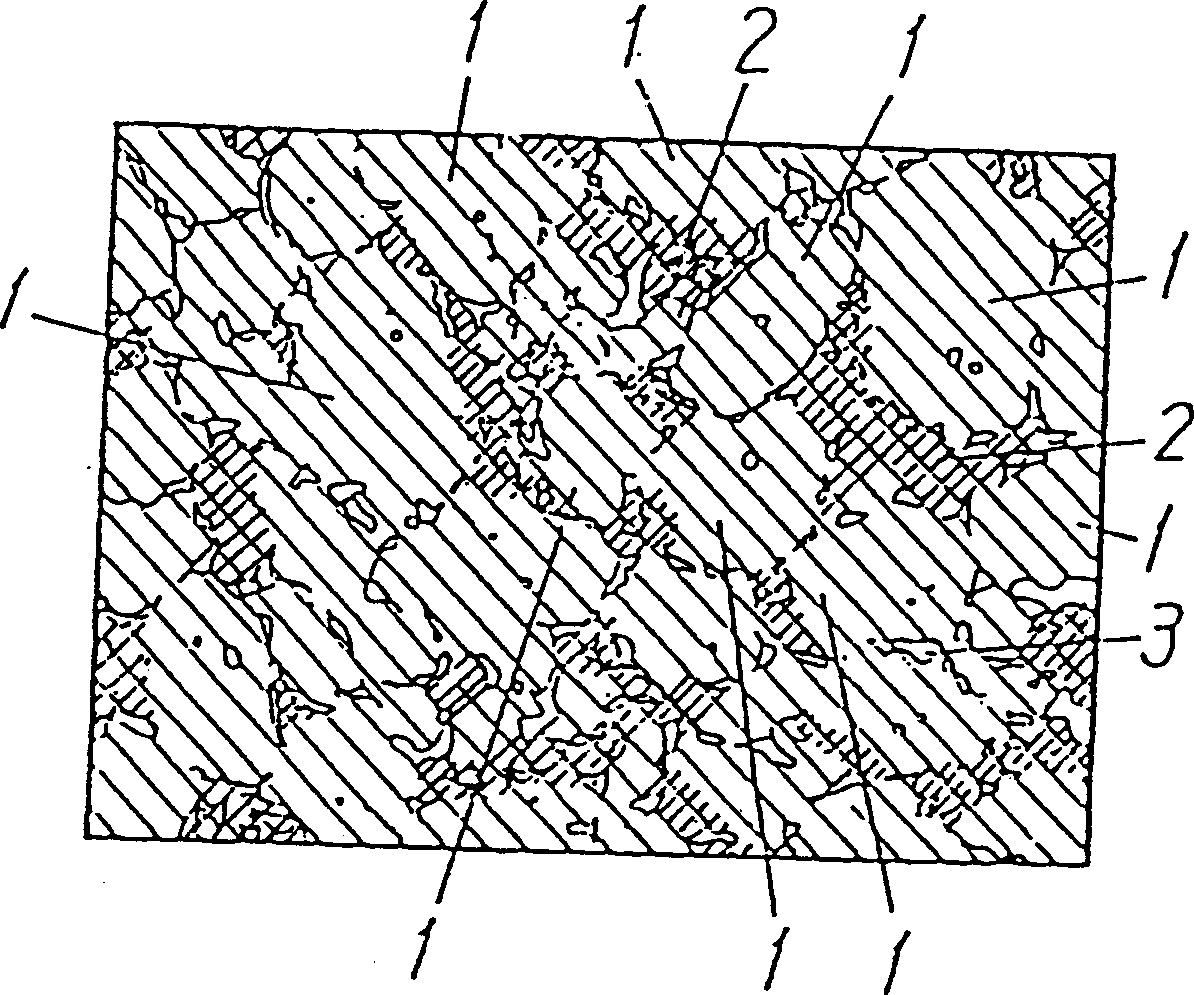

Ceramic and its making method

This invention relates to a ceramics and its manufacturing method, and this is to offer a ceramics showing very little dimensional change after sintering and high dimensional accuracies, so that the characteristics of inorganic functional material can be fully maintained and utilized. The ceramics comprises: (a) alumia particles, and (b) Si2Al6O13 particles diffused in alumia particles formed by oxidation reaction of baking mixture of Al, Si and Ta2O5; wherein, the Si2Al6O13 particles swelled when baking, and Si2Al6O13 particles filled in gaps of alumia particles.

Owner:PANASONIC CORP

Ceramic and its making method

This invention relates to a ceramics and its manufacturing method, and this is to offer a ceramics showing very little dimensional change after sintering and high dimensional accuracies, so that the characteristics of inorganic functional material can be fully maintained and utilized. The ceramics comprises: (a) alumia particles, and (b) MgAl2O4 particles diffused in alumia particles formed by oxidation reaction of baking mixture of Al, MgO and at least one slected from GeO2, Ge2O3, Y2O3 and Ag2O; wherein, the MgAl2O4 particles swelled when baking, and MgAl2O4 particles filled in gaps of alumia particles.

Owner:PANASONIC CORP

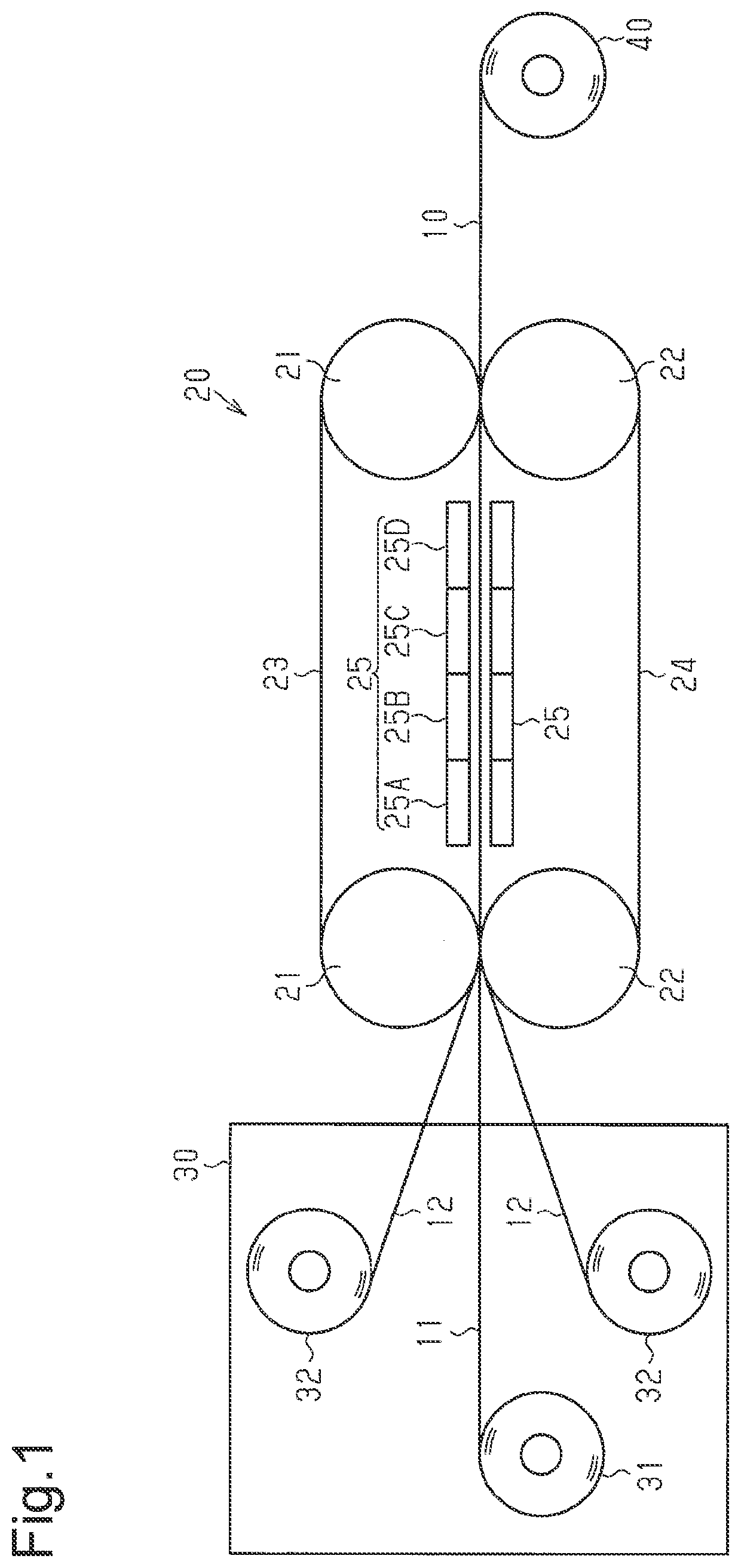

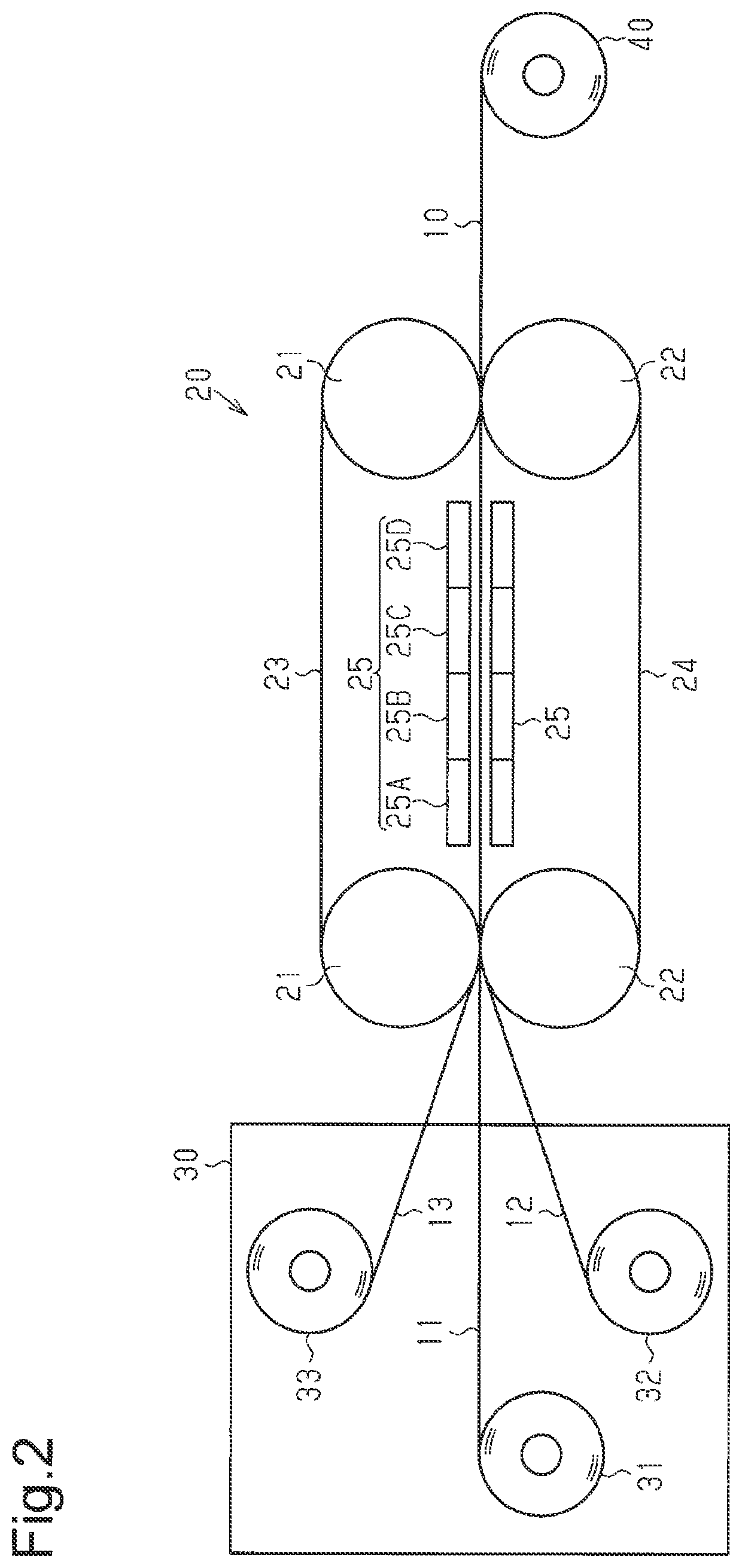

Method for manufacturing liquid crystal panel

InactiveUS20110192529A1Extended warrantySmall size changeLaminationLamination apparatusManufacturing technologyThin layer

There is provided a method for manufacturing a liquid crystal panel comprises the steps of:(Step A1) manufacturing a polarizing film including a laminate composed of a first base film and a polarizing thin layer, the step including: applying a vinyl alcohol-based polymer on a surface of the first base film to form a vinyl alcohol-based polymer thin layer; and wet dyeing the vinyl alcohol-based polymer thin layer after stretching the thin layer together with the first base film to obtain a polarizing thin layer, and(Step B1) adhering the polarizing film without an adhesion layer during storage and transportation at least to one surface of a liquid crystal cell through an adhesion layer in a liquid crystal panel manufacturing process.

Owner:NITTO DENKO CORP

Perfluorosulfonic acid ion exchange membrane with high proton conduction and preparation method thereof

PendingCN111808309AGood dispersionReduce resistanceFuel cellsPhysical chemistryIon-exchange membranes

The invention relates to a perfluorosulfonic acid ion exchange membrane with high proton conduction and a preparation method thereof, and belongs to the technical field of ion exchange membranes. Theperfluorosulfonic acid ion exchange membrane with high proton conduction is prepared from sulfonated graphene doped perfluorosulfonic acid resin master batch and perfluorosulfonic acid resin through melt extrusion. The perfluorosulfonic acid ion exchange membrane with high proton conduction disclosed by the invention has high proton conductivity and dimensional stability; meanwhile, the inventionfurther provides a preparation method which is scientific and reasonable in design, simple and easy to implement.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

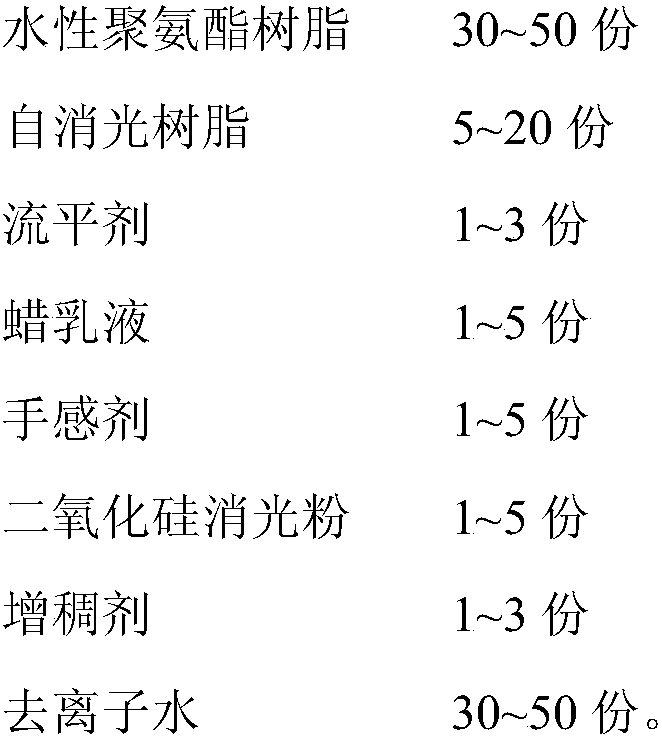

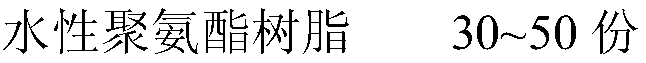

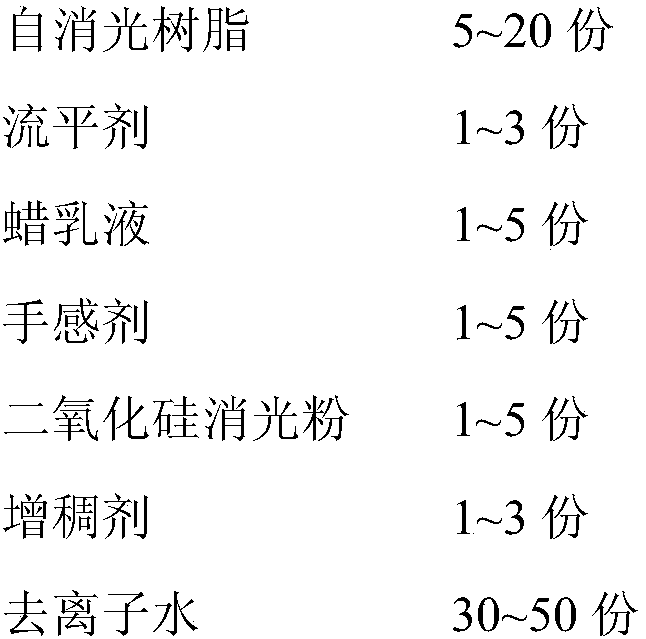

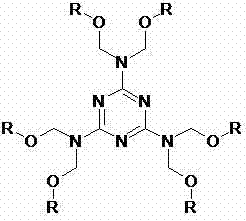

Delustering treating agent for waterborne PVC automobile leather

InactiveCN108047913AImprove heat resistanceSmall dimensional change ratePolyurea/polyurethane coatingsWaxEmulsion

The invention discloses a delustering treating agent for waterborne PVC automobile leather. The delustering treating agent comprises, by weight, 30-50 parts of waterborne polyurethane resin, 5-20 parts of self-extinction resin, 1-3 parts of flatting agent, 1-5 parts of wax emulsion, 1-5 parts of hand feeling agent, 1-5 parts of silica extinction powder, 1-3 parts of thickening agent and 30-50 parts of deionized water. The delustering treating agent for the waterborne PVC automobile leather has good heat resistance, wear resistance, non-adhesion property and friction color fastness.

Owner:浙江新诺高分子材料有限公司

Flame retardant polyurethane spray coating foamed plastic

ActiveCN102558484BReduce intensityImprove heat resistancePolyurea/polyurethane coatingsPhosphoric Acid EstersPolymer science

The invention discloses a flame retardant polyurethane spray coating foamed plastic, which is composed of a combination white material and isocyanate with mass ratio as 1: 1-1.2. The combination white material includes the following components by mass: 65 to 75 parts of trihydroxyl-amino resin, 5 to 15 parts of trihydroxyl phosphate, 8 to 20 parts of poly-phosphate amine, 10 to 15 parts of glycerin, 2.5 to 3 parts of silicon-carbon bond non-hydrolysis polysiloxane- polyether copolymer, 0.6 to 0.8 part of water, 0.25 to 0.3 part of N,N,N,N,N-pentamethyl-diethylenetriamine, 0.8 to 1 part of dimethylcyclohexylamine, 1.8 to 2 parts of dipropylene glycol solution of triethylene diamine of 33+ / -1Wt.%, 0.15 to 0.2 part of dibutyltin dilaurate catalyst, 3 to 3.5 parts of hexahydro-triazine, 11 to 15 parts of fatty alcohol-polyoxyethylene ether, 25 to 35 parts of 4(2-chloride ethyl) diethylene-ether-diphosphate and 30 to 38 parts of fluorine ethylene dichloride. The flame retardant polyurethane spray coating foamed plastic is good in heat resistance, fire penetration resistance and flexibility and high in strength. According to the detection, the inflaming retarding grade of the product can reach the B grade according to GB / T8624-2006 standard, so that the flame retardant polyurethane spray coating foamed plastic can be used in various fireproof building fields.

Owner:JIANGSU CHANGNENG ENERGY SAVING NEW MATERIALS SCI & TECH

Preparation method of rigid spraying polyurethane blended materials for refrigeration house

InactiveCN101735425BIndustrial simplicityFlexible constructionPolyurea/polyurethane coatingsCross-linkPolyester

The invention relates to a preparation method of rigid spraying polyurethane blended material for a refrigeration house. The rigid spraying polyurethane blended material is prepared by using polyether glycol, polyester polyol, a cross-linking agent, a catalyst, a foam stabilizing agent, a foaming agent, a flame retardant and the like as white materials and using multisubunit, multibenzylalkyl and polyisocyanates as black materials, mixing the white materials and the black materials by using special equipment, reacting and spraying to form a finished product. The white materials and black materials are mixed and sprayed on a wall body under a certain condition, and automatically foamed and formed to prepare a polyurethane thermal insulation material. Therefore, the method has the advantages of simple industry, flexible construction, no need of moulds, high labor productivity, and is extremely suitable for surfaces with complicated shapes. Because of excellent thermal insulation performance, and small size change ratios, the use materials are ideal in the field of thermal insulation of the refrigeration house.

Owner:无锡双象新材料有限公司

Stretched film and method for producing stretched film

ActiveCN110267794ASmall dimensional change rateExcellent mechanical propertiesSynthetic resin layered productsPolarising elementsPolymer scienceAcrylic resin

Provided are: a stretched film having excellent heat resistance, dimensional stability, mechanical properties, and adhesiveness; and a method for producing a stretched film. The present invention relates to: a stretched film containing acrylic rubber particles and an acrylic resin having a glass transition temperature of 120DEG C or higher, the stretched film being characterized by having a shrinkage rate of 1.5% or less when left standing at 85DEG C and 85% RH for 120 hours, and having an endurable number of cycles, by MIT flex test, of 350 times or more; and a method for producing a stretched film.

Owner:KANEKA CORP

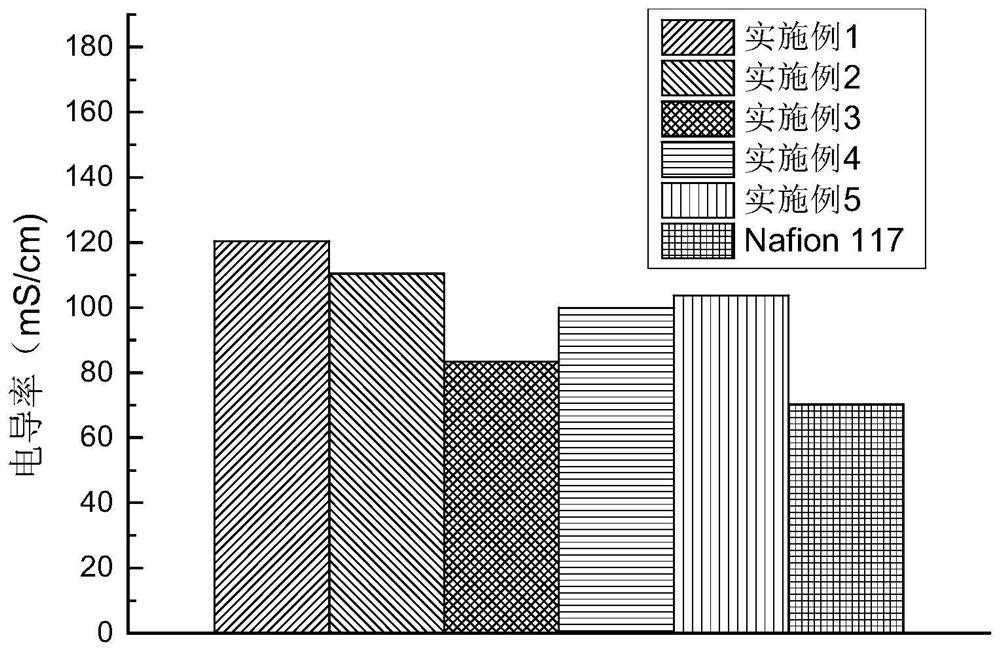

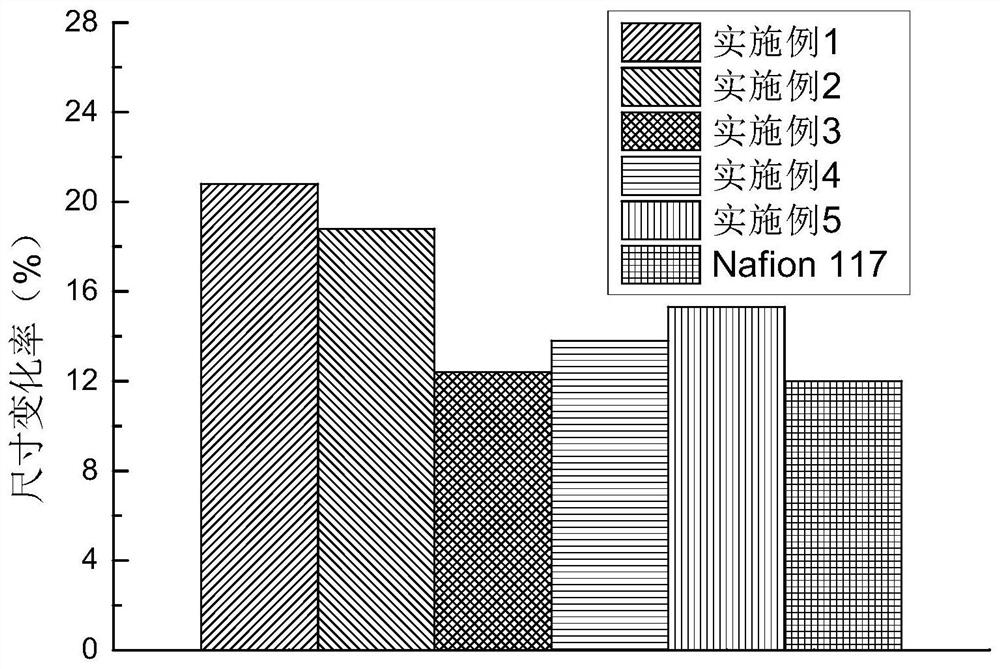

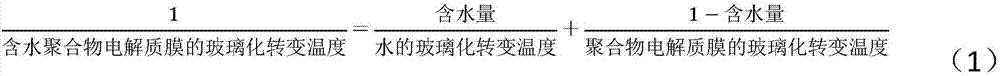

Polymer electrolyte membrane and preparation method thereof

ActiveCN107887642ASmall dimensional change rateImprove performanceFinal product manufactureElectrolyte accumulators manufacturePolymer electrolytesPolymer science

The invention provides a polymer electrolyte membrane and a preparation method thereof. The polymer electrolyte membrane has ultralow dimensional change rate and high ion exchange capacity. Accordingto the invention, a method of stretching a water-containing membrane at low temperature is firstly adopted for preparing the polymer electrolyte membrane, and the polymer electrolyte membrane with lowdimensional change rate and maintaining high ion exchange capacity, proton conductivity and mechanical properties can be obtained by adopting a simple and low-energy-consumption method, so that durability of the polymer electrolyte membrane is greatly improved, service life of the polymer electrolyte membrane is greatly prolonged, and application prospect is clearer.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

Flexible laminated board and multilayer circuit board

PendingUS20210153348A1Small dimensional change rateReduce conductionAdhesive articlesElectrical connection printed elementsMetallic foilCeiling temperature

A flexible laminated sheet manufacturing method includes thermocompression-bonding an insulation film formed of a liquid crystal polymer onto a metal foil between endless belts to form a flexible laminated sheet. The thermocompression bonding includes heating the flexible laminated sheet so that the maximum temperature of the sheet is in the range from a temperature that is 45° C. lower than the melting point of the liquid crystal polymer to a temperature that is 5° C. lower than the melting point. The thermocompression bonding also includes slowly cooling the flexible laminated sheet so that an exit temperature, which is a temperature of the sheet when transferred out of the endless belts, is in the range from a temperature that is 235° C. lower than the melting point of the liquid crystal polymer to a temperature that is 100° C. lower than the melting point.

Owner:UBE NITTO KASEI CO LTD

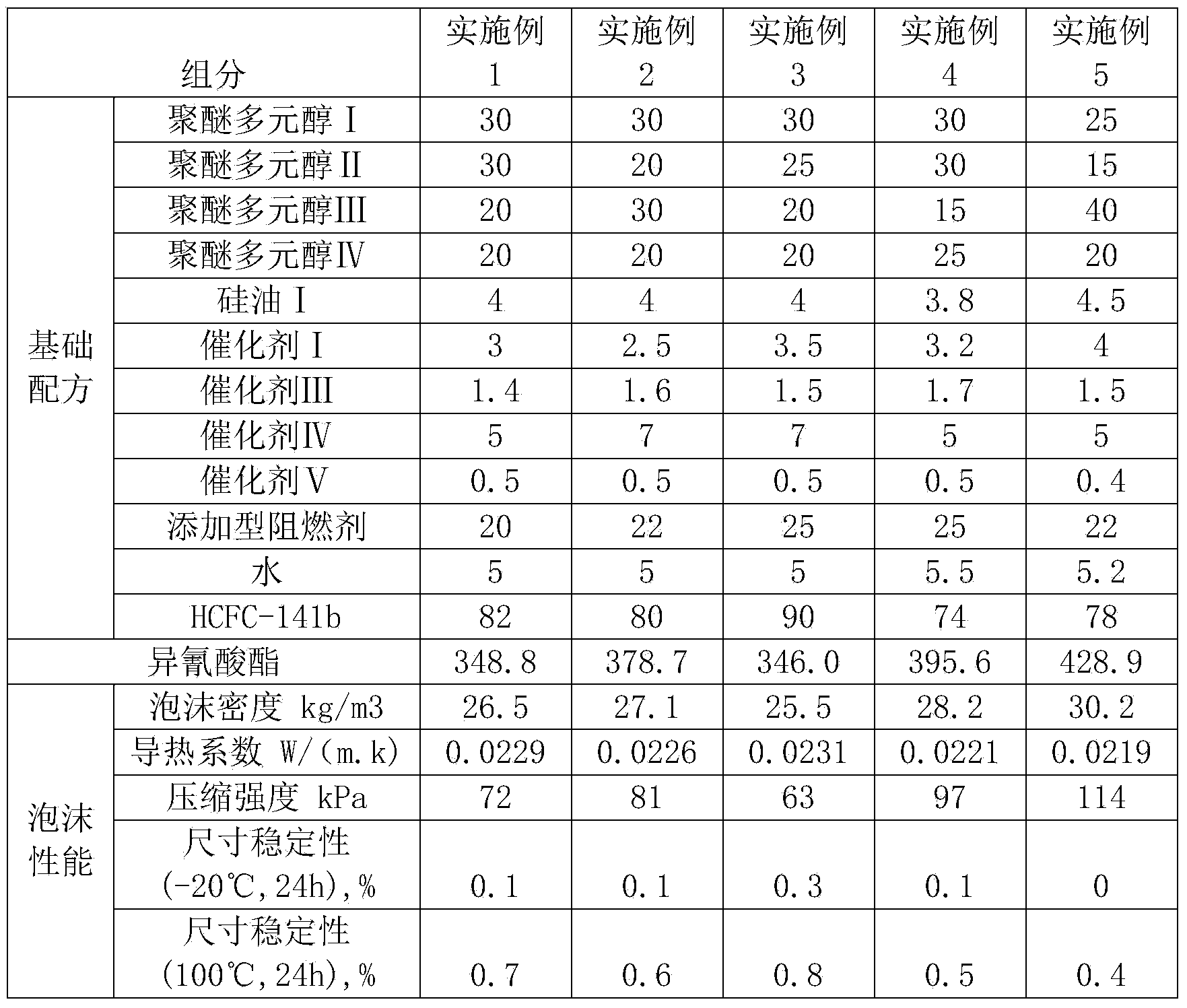

Polyether polyol system for external wall spraying and preparation method

InactiveCN102585138BImprove insulation effectSmall dimensional change rateEnvironmental resistancePolyol

The invention relates to a low-density conjugate polyether for external wall spraying. The low-density conjugate polyether comprises the following components in parts by weight: 10-40 parts of polyether polyol I, 0-50 parts of polyether polyol II, 0-50 parts of polyether polyol III, 15-30 parts of polyether polyol IV, 0.6-4 parts of catalyst I, 0-2 parts of catalyst III, 0-10 parts of catalyst IV, 0-1 part of catalyst V, 0-5 parts of silicone oil I, 10-35 parts of additive flame retardant, 2.6-10 parts of water and 36-150 parts of HCFC-141b (Hydrochlorofluorocarbon-141b). The preparation method for the low-density conjugate polyether comprises the following step of: putting the raw materials into a container in percentage by weight and uniformly stirring to obtain the low-density conjugate polyether for the external wall spraying. The shaping density of rigid polyurethane foaming plastic prepared from the low-density conjugate polyether is 25-34kg / m<3>, and the rigid polyurethane foaming plastic can maintain excellent thermal insulation properties and dimension stability and has a self-quenching function. The low-density conjugate polyether has the advantages of flexibility and convenience in construction and low cost, conforms to the requirements of energy conservation, emission reduction, safety, environmental protection of China and is an ideal material of the external wall thermal insulation field.

Owner:绍兴广佳庄鑫建材制造有限公司

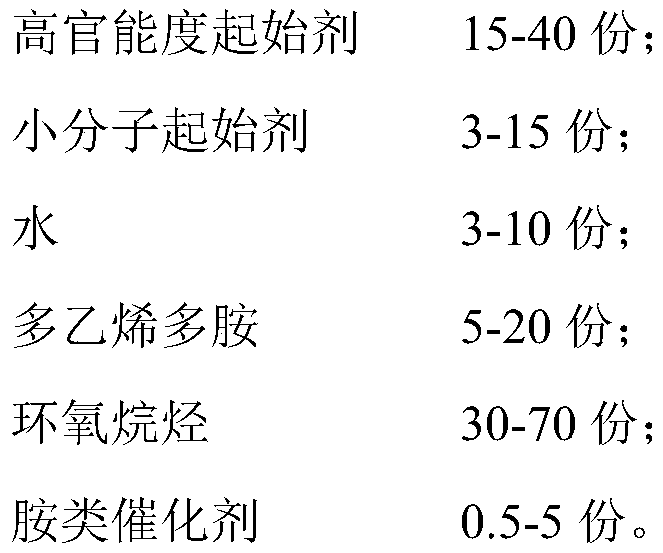

Preparation method of novel hard foam polyether polyol

InactiveCN110885438AGuaranteed polymerization reactivitySimple manufacturing processAlkanePolymer science

Belonging to the technical field of polyether polyol synthesis, the invention particularly relates to a preparation method of novel hard foam polyether polyol. The preparation method includes the steps of: (1) adding a high-functionality initiator, a small molecular initiator, water, an amine catalyst and polyethylene polyamine into a reaction kettle, conducting nitrogen displacement, then controlling the temperature at 70-90DEG C, adding alkylene oxide for reaction, and conducting curing; (2) performing dehydration under a vacuum condition; (3) adding an amine catalyst, controlling the temperature at 105-130DEG C, adding alkylene oxide for reaction, and conducting curing; (4) adding an amine catalyst and alkylene oxide, and performing curing; and (5) carrying out vacuum pumping to removeunreacted polymerization monomers, thereby obtaining the product. The method provided by the invention has the characteristics of high production efficiency, good reaction activity and small residualamount of later polymerization monomers, and the compound amine catalyst and olefin oxide are subjected to polymerization reaction and retained in a polyether system, thus ensuring shortening of the curing time in the polyether foaming process, and meeting the foam application requirements for high strength and low dimensional change rate.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

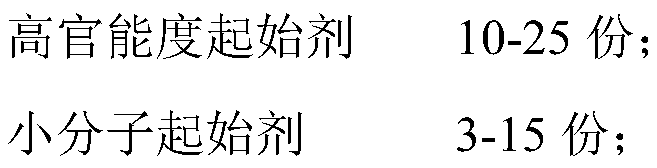

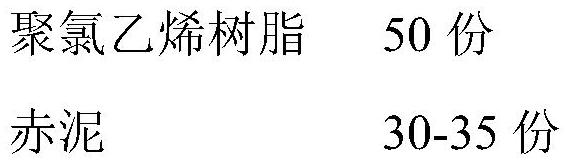

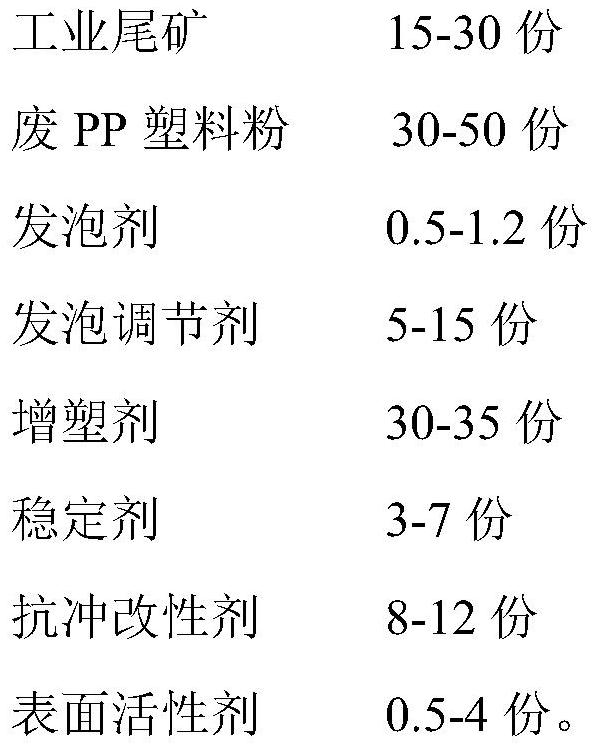

Red mud hollow plastic profile and preparation method thereof

The invention belongs to the technical field of red mud recycling, and particularly relates to a red mud hollow plastic profile and a preparation method thereof. The red mud hollow plastic profile isprepared from the following raw materials in parts by weight: 50 parts of polyvinyl chloride resin, 30-35 parts of red mud, 15-30 parts of industrial tailings, 30-50 parts of waste PP plastic powder,0.5-1.2 parts of a foaming agent, 5-15 parts of a foaming regulator, 30-35 parts of a plasticizer, 3-7 parts of a stabilizer, 8-12 parts of an impact modifier and 0.5-4 part of a surfactant. A productprepared from the red mud hollow plastic profile is good in processing property, excellent in ageing resistance and flame retardance, low in water absorption rate, good in toughness, high in acid andalkali resistance and small in size change rate.

Owner:山东新迪丹环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com