Novel polyimide film

A technology of polyimide film and molecular orientation, which is applied to other household appliances, synthetic resin layered products, chemical instruments and methods, etc., to achieve the effect of inhibiting dimensional change, reducing the amount of change, and reducing the rate of dimensional change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

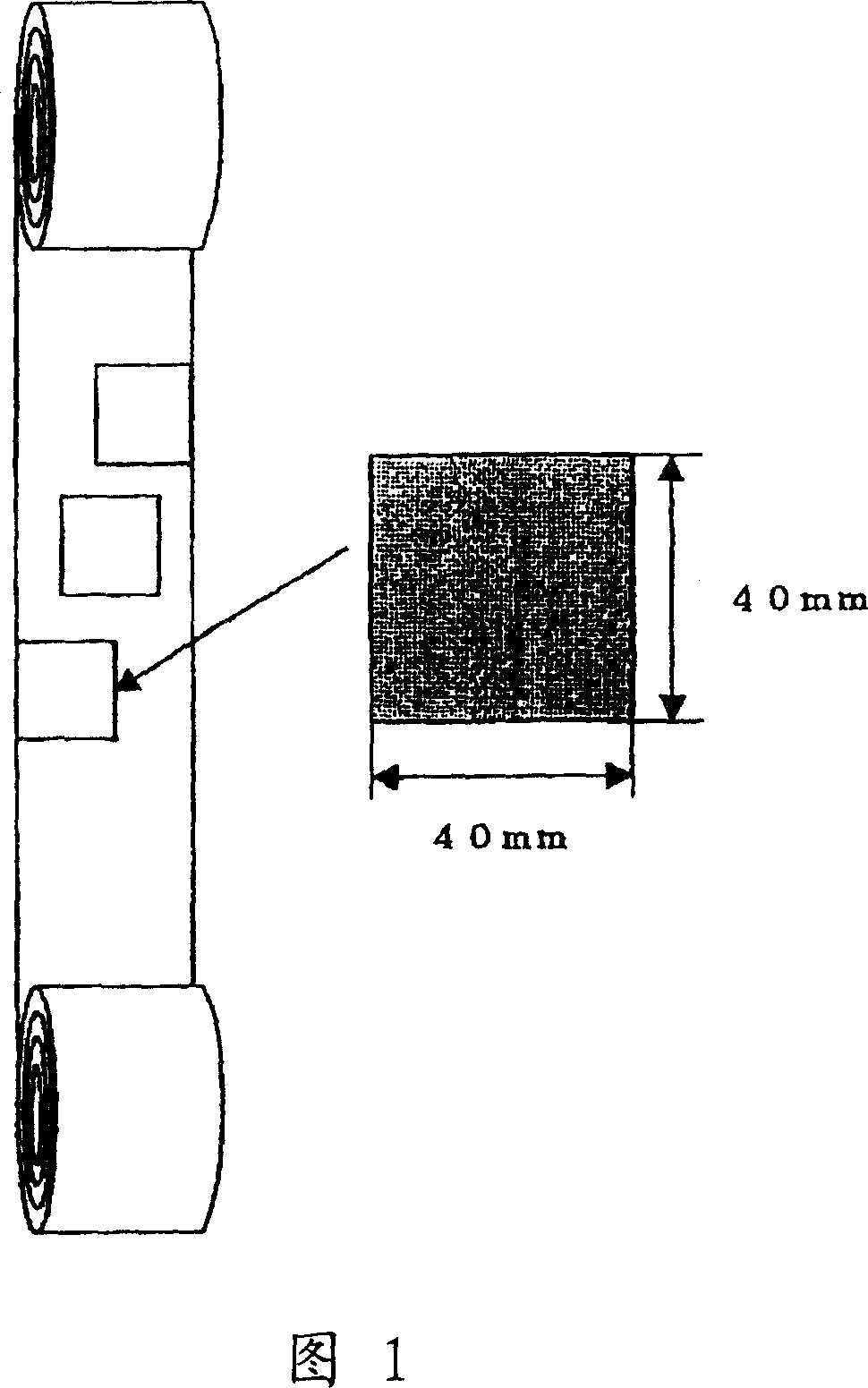

[0165] (Manufacture of polyimide film)

[0166] In this example, in N,N-dimethylformamide (DMF), with 45 mole % of 4,4-diaminodiphenyl ether (ODA), 55 mole % of p-phenylenediamine (p- PDA), 45 mol% of p-phenylene bis(trimellitic acid monoester anhydride) (TMHQ), and 55 mol% of pyromellitic dianhydride (PMDA) are added and polymerized to synthesize polyamic acid solution. In this polyamic acid solution, add 2.0 times the equivalent of acetic anhydride and 1.0 times the equivalent of isoquinoline relative to the equivalent of the amic acid, cast it on an endless belt with a width of 1100mm, and dry it with hot air at 100°C to 150°C for 2 Minutes, so that the final thickness is 20 μm, thereby obtaining a self-supporting gel film with a residual component ratio of 54% by weight. Then, the gel film was peeled off from the tape, and both ends in the width direction of the gel film were fixed on a continuously conveyed pin board. At this time, fixation without slack was performed ...

Embodiment 2

[0187] A polyimide film was produced by the same manufacturing method as in Example 1, except that the needle pitch was 1020 mm, the TD shrinkage ratio was 4.30, and the TD expansion ratio was 4.30 when it was fixed on a needle plate. The production conditions are shown in Table 1.

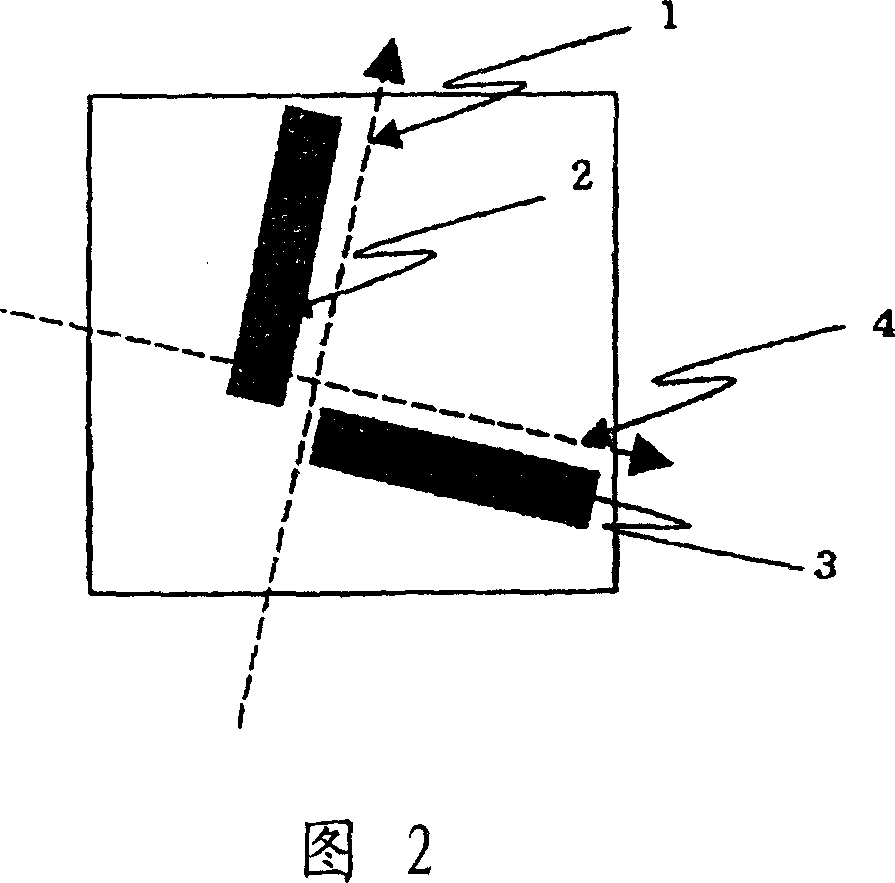

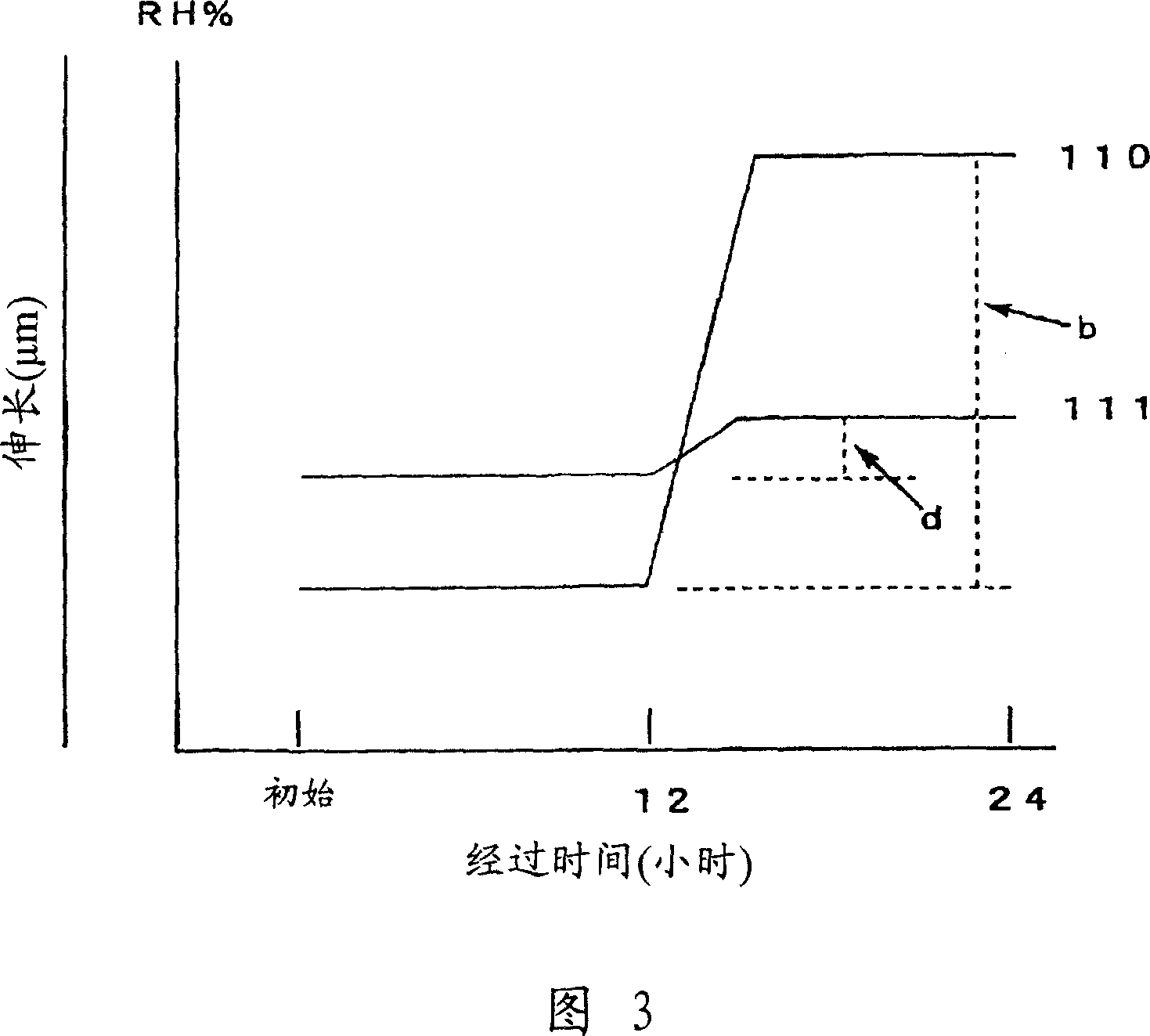

[0188] The physical property values of the polyimide film thus obtained were evaluated in the same manner as in Example 1. As a result, it can be confirmed that the polyimide film obtained is that the hygroscopic expansion coefficient ratio b / a over the entire width of the film is controlled to be 1.01 to 2.00, and the difference between the maximum value and the minimum value of the hygroscopic expansion coefficient ratio is controlled. It is controlled to be less than 0.30, and the molecular orientation angle is controlled to be less than 0±20°. Table 2 shows the physical property values of the obtained film.

Embodiment 3

[0190] In addition to making the remaining component ratio 60% by weight when manufacturing the gel film, when fixing it on the needle plate, it is fixed so that the needle pitch is 1060mm, the TD shrinkage ratio is 3.70, the TD expansion ratio is 0.00, and the temperature in the firing furnace is Except for 132 degreeC, 255, 350, 440, and 512 degreeC, the polyimide film was produced by the manufacturing method similar to Example 1. The production conditions are shown in Table 1.

[0191] The physical property values of the polyimide film thus obtained were evaluated in the same manner as in Example 1. As a result, it can be confirmed that the polyimide film obtained is that the hygroscopic expansion coefficient ratio b / a over the entire width of the film is controlled to be 1.01 to 2.00, and the difference between the maximum value and the minimum value of the hygroscopic expansion coefficient ratio is controlled. It is controlled to be less than 0.30, and the molecular or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com