Red mud hollow plastic profile and preparation method thereof

A technology for plastic profiles and red mud, which is applied to the field of red mud hollow plastic profiles and their preparation, can solve the problems of increasing the number of turnovers, consuming large wood, and reducing the number of turnovers, so as to prolong the service life, reduce the production cost, and increase the additional cost. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

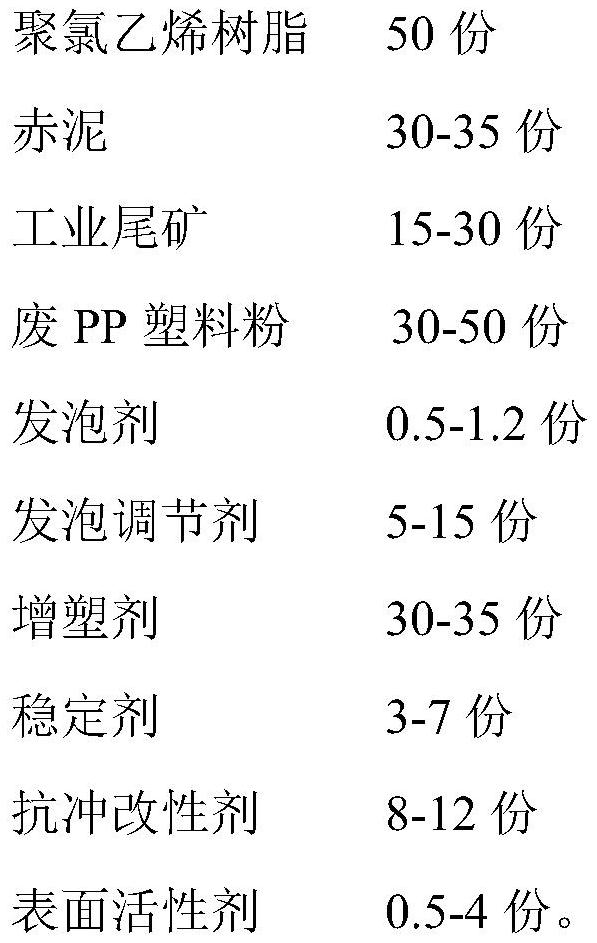

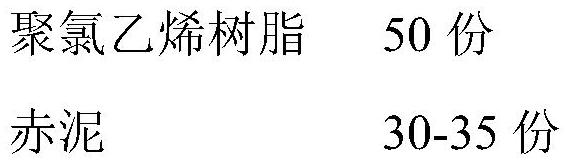

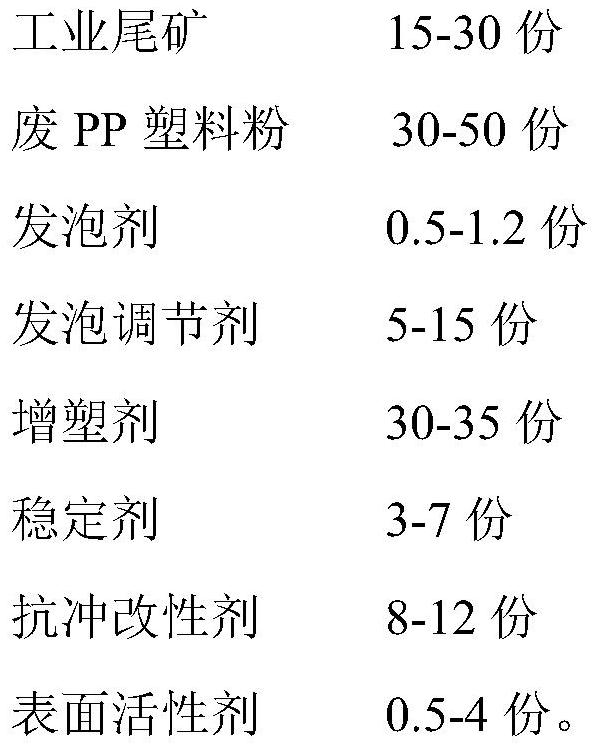

[0038] The red mud hollow plastic profile described in Example 1, in parts by mass, includes the following components as a raw material:

[0039]

[0040] in:

[0041] Industrial tailings are copper tailings.

[0042] The particle size of red mud is 600 mesh.

[0043] The foaming agent is a mixture of ammonium carbonate, azobisisobutyronitrile and toluene.

[0044] The foam regulator is methyl methacrylate.

[0045] The plasticizer is a mixture of dioctyl phthalate and dibutyl phthalate.

[0046] The stabilizer is a mixture of sodium stearate, potassium stearate and epoxidized triglycerides.

[0047] The impact modifier is a mixture of elastomeric rubber, chlorinated polyvinyl chloride and polyethylene wax. Improve the problems of low impact strength, stability and poor fluidity during PVC plastic processing, and improve the impact resistance of red mud hollow plastic profiles.

[0048] The surfactant is a mixture of sodium lauryl sulfate, polyvinyl alcohol and methac...

Embodiment 2

[0054] The red mud hollow plastic profile described in Example 2, in parts by mass, includes the following components as a raw material:

[0055]

[0056] in:

[0057] Industrial tailings are copper tailings.

[0058] The particle size of the red mud is controlled at 700 mesh.

[0059] The foaming agent is a mixture of ammonium carbonate, azobisisobutyronitrile and toluene.

[0060] The foam regulator is methyl methacrylate.

[0061] The plasticizer is dioctyl phthalate.

[0062] The stabilizer is a mixture of sodium stearate, potassium stearate and epoxidized triglycerides.

[0063] The impact modifier is a mixture of elastomeric rubber, chlorinated polyvinyl chloride and polyethylene wax. Improve the problems of low impact strength, stability and poor fluidity during PVC plastic processing, and improve the impact resistance of red mud hollow plastic profiles.

[0064] The surfactant is a mixture of sodium lauryl sulfate, polyvinyl alcohol and methacrylamide. Adding ...

Embodiment 3

[0073] The red mud hollow plastic profile described in Example 3, in parts by mass, includes the following components as a raw material:

[0074]

[0075]

[0076] in:

[0077] Industrial tailings are iron tailings.

[0078] The particle size of the red mud is controlled at 800 mesh.

[0079] The foaming agent is a mixture of ammonium carbonate, azobisisobutyronitrile and toluene.

[0080] The foam regulator is methyl methacrylate.

[0081] The plasticizer is a mixture of dioctyl phthalate and dibutyl phthalate.

[0082] The stabilizer is a mixture of sodium stearate, potassium stearate and epoxidized triglycerides.

[0083] The impact modifier is a mixture of elastomeric rubber, chlorinated polyvinyl chloride and polyethylene wax. Improve the problems of low impact strength, stability and poor fluidity during PVC plastic processing, and improve the impact resistance of red mud hollow plastic profiles.

[0084] The surfactant is a mixture of sodium lauryl sulfate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com