Delustering treating agent for waterborne PVC automobile leather

A matting treatment and automotive leather technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor heat resistance and insufficient wear resistance of leather matting agents, and achieve good wear resistance and improved heat resistance. good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

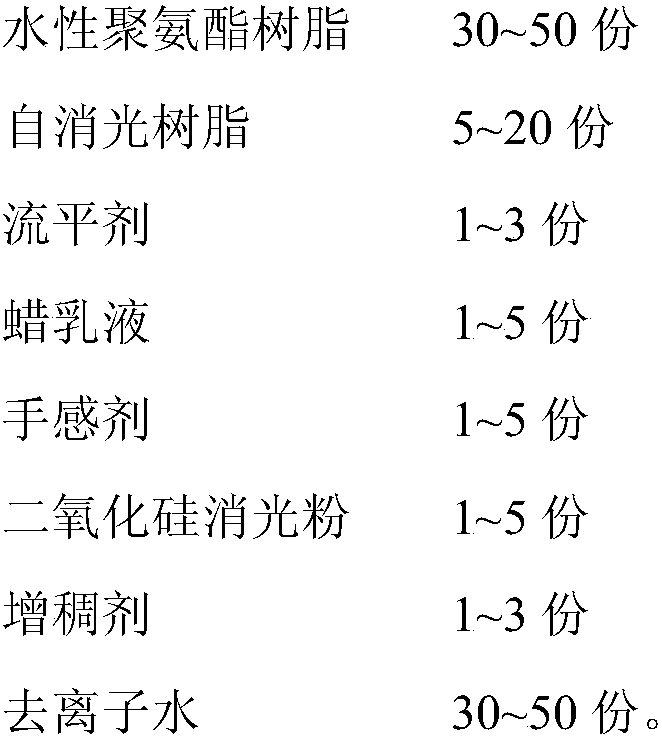

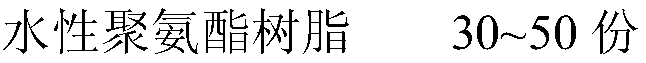

[0035] A water-based PVC automobile leather matting treatment agent, its raw material formula is as follows:

[0036]

[0037]

[0038] The preparation method is as follows:

[0039] Add water-based polyurethane resin and self-matting resin to the reaction kettle, start stirring, and raise the temperature to 70°C, keep it warm for 30 minutes; add silica matting powder, continue stirring for 30 minutes; then add leveling agent, wax emulsion, hand feeling agent and enhancer Thickener, continue to stir for 30 minutes; finally add deionized water, and stir for 30 minutes, cool and discharge to obtain water-based matting treatment agent for PVC automobile leather.

[0040] Results: The appearance of the water-based matting treatment agent for PVC automobile leather was milky white liquid without impurities, the solid content was 20%±2%, and the viscosity was 900CPS.

Embodiment 2

[0042] A water-based PVC automobile leather matting treatment agent, its raw material formula is as follows:

[0043]

[0044] The preparation method is the same as in Example 1, and the result: the appearance of the water-based matting treatment agent for PVC automobile leather is milky white liquid without impurities, the solid content is 20%±2%, and the viscosity is 1000CPS.

Embodiment 3

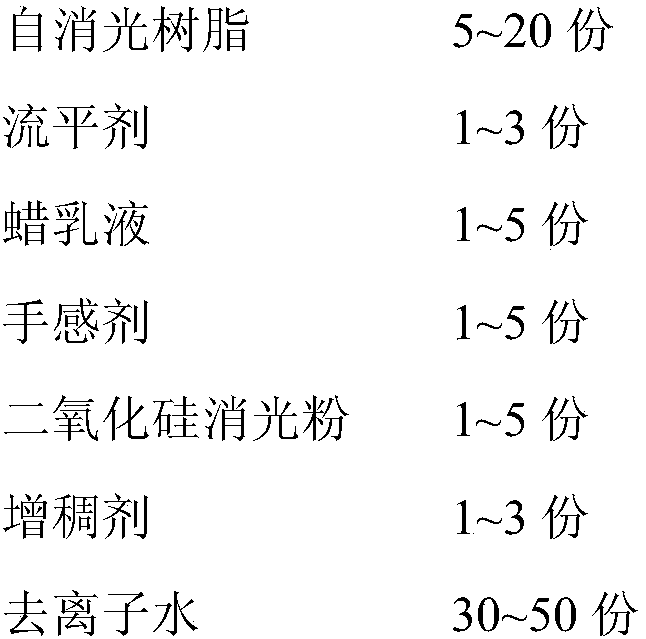

[0046] A water-based PVC automobile leather matting treatment agent, its raw material formula is as follows:

[0047]

[0048]

[0049] The preparation method is the same as in Example 1, and the result: the appearance of the water-based matting treatment agent for PVC automobile leather is milky white liquid without impurities, the solid content is 20%±2%, and the viscosity is 1200CPS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com