High-strength cement-based self-leveling mortar

A technology of mortar and cement, which is applied in the field of one-component cement-based self-leveling mortar and its raw material composition, and can solve problems such as high wear resistance requirements, peeling, and insufficient flatness of the mortar surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] The lithium carbonate of 0.1 weight part, the water reducer of 0.1 weight part, the tartaric acid (citric acid) of 0.1 weight part, the cellulose ether (E230X) of 0.1 weight part, the defoamer (77-P) of 0.12 weight part and 2.0 parts by weight of dispersible latex powder (FL2211) were mixed evenly to make a reagent pack with 26 parts by weight of ordinary Portland cement (P.O42.5), 7 parts by weight of aluminate cement (CA50), 6 parts by weight Parts of anhydrite, 3 parts by weight of lime calcium (calcium hydroxide), 10 parts by weight of heavy calcium (or calcite, 500 mesh), 45.48 parts by weight of plain white sand (or quartz sand, wherein 27.29 parts by weight of 40-70 Mesh sand, 18.19 parts by weight of 70-150 mesh sand) are mixed and stirred evenly to make mortar powder.

[0121] Self-leveling mortar: It is made by mixing mortar powder and water at a weight ratio of 1:0.22.

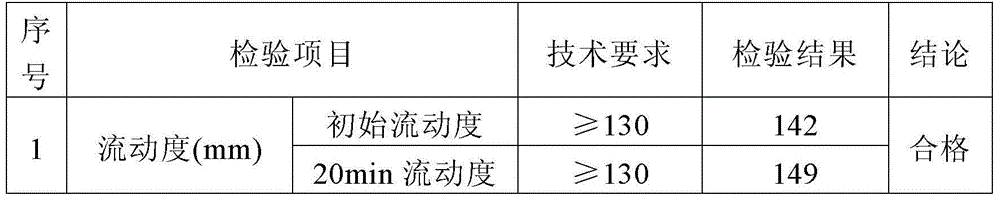

[0122] According to JC / T985-200 inspection, the results are shown in Table 1 below, all me...

Embodiment 2

[0128] The lithium carbonate of 0.15 parts by weight, the water reducer of 0.12 parts by weight, the tartaric acid of 0.12 parts by weight, the cellulose ether (E230X) of 0.12 parts by weight, the defoamer (77-P) of 0.12 parts by weight and 2.0 parts by weight of Dispersible latex powder (F2211) is mixed uniformly and made into a reagent pack with 26 parts by weight of ordinary Portland cement (P.O42.5), 7 parts by weight of aluminate cement (CA50), 6 parts by weight of anhydrous Gypsum, 3 parts by weight of lime calcium, 10 parts by weight of heavy calcium (or calcite, 500 mesh), and 45.48 parts by weight of plain white sand (or quartz sand, 70-150 mesh) are mixed and stirred evenly to make mortar powder.

[0129] Self-leveling mortar: It is made by mixing mortar powder and water at a weight ratio of 1:0.22.

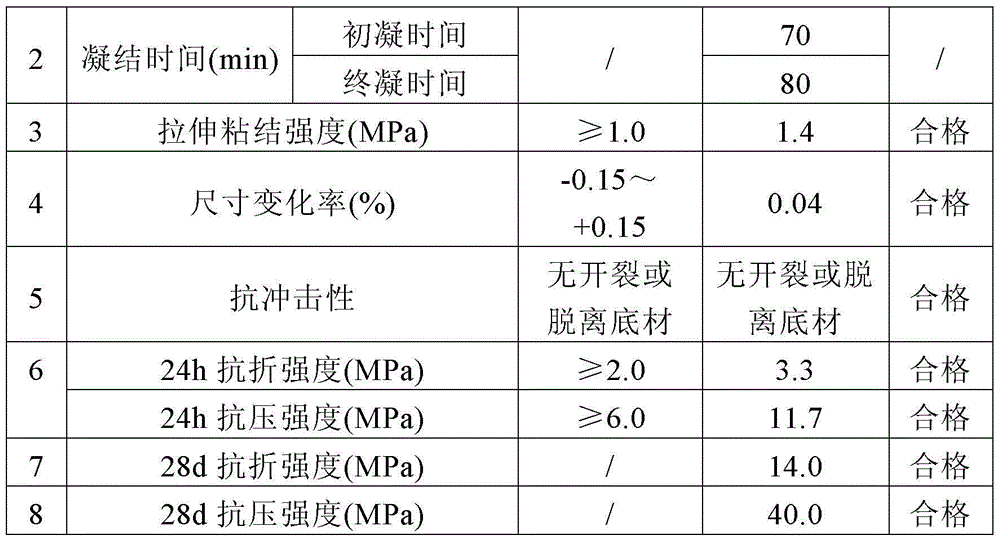

[0130] The inspection was carried out according to JC / T985-200, and the results are shown in Table 2 below, all of which meet the requirements.

[0131] The performanc...

Embodiment 3

[0135] 0.15 parts by weight of lithium carbonate, 0.15 parts by weight of water reducer, 0.10 parts by weight of tartaric acid, 0.1 parts by weight of cellulose ether (E230X), 0.12 parts by weight of defoamer (77-P) and 2.0 parts by weight of Dispersible latex powder (F2211) is mixed uniformly and made into a reagent pack with 26 parts by weight of ordinary Portland cement (P.O42.5), 7 parts by weight of aluminate cement (CA50), 6 parts by weight of anhydrous Gypsum, 3 parts by weight of lime calcium, 10 parts by weight of heavy calcium (or calcite, 500 mesh), and 45.48 parts by weight of plain white sand (or quartz sand, 40-70 mesh) are mixed and stirred evenly to make mortar powder.

[0136] Self-leveling mortar: It is made by mixing mortar powder and water at a weight ratio of 1:0.22.

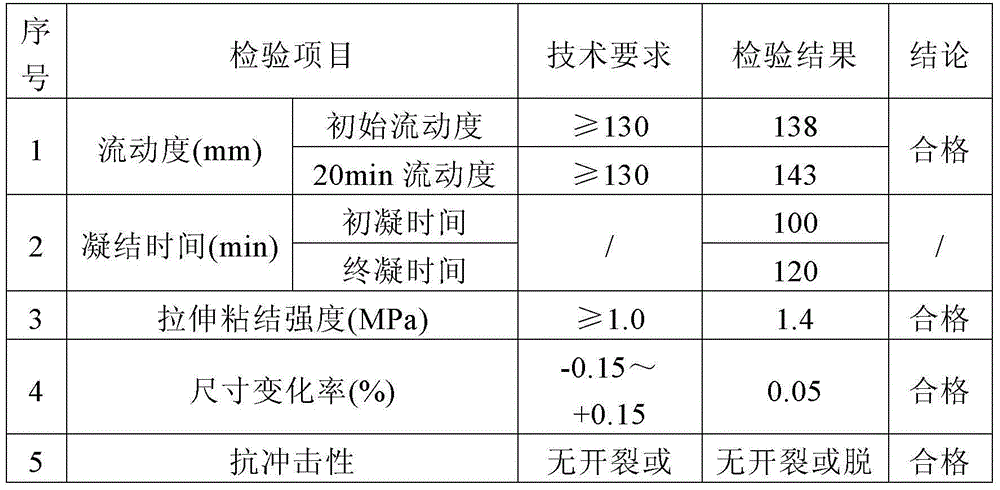

[0137] According to JC / T985-200 inspection, the results are shown in Table 3 below, all meet the requirements.

[0138] The performance of the self-leveling mortar prepared by the embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com