Windproof breathable fabric

A fabric and moisture-permeable technology, applied in the field of casual outerwear, can solve the problems of insufficient resilience, poor wearability, insufficient softness and softness, and achieve the effect of soft touch and excellent wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

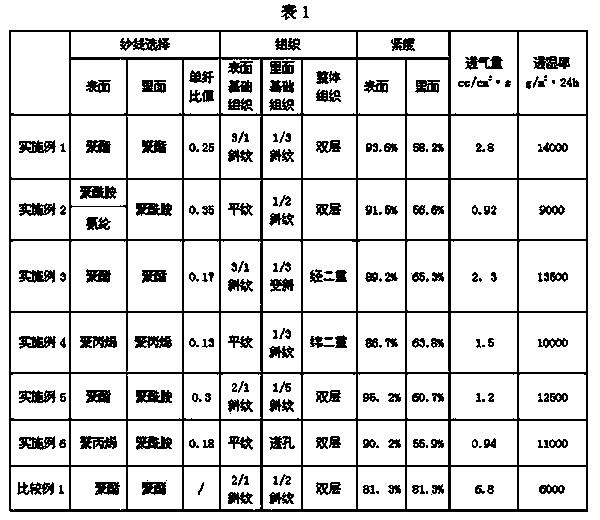

[0026] 83dtex-144f polyester fine denier fiber is selected for the surface of the fabric, 83dtex-36f polyester coarse denier fiber is selected for the inside, and the surface / inside single fiber fineness ratio is 0.25. The surface is 3 / 1 twill weave (the ratio of the number of intersecting weave points to the number of yarns is 0.5), and the inside is 1 / 3 twill weave (the ratio of the number of intersecting weave points to the number of yarns is 0.5), and the surface warp The arrangement ratio of the inside warp and the arrangement ratio of the surface weft and the inner weft are both 2, and the gray fabric woven on the water jet loom is finished with a surface tightness of 93.6% and an inner tightness of 58.2% after dyeing and finishing. Double layer fabric.

[0027] Its main processing projects and conditions are: refining (temperature 95°C, speed 50 m / min); drying (temperature 140°C, speed 40 m / min); intermediate setting (temperature 180°C, speed 50 m / min); disperse dyes D...

Embodiment 2

[0030] The surface of the fabric is made of 40 / 78dtex-68f polyamide fine-denier fiber spandex covered yarn, and the inside is made of 78dtex-24f polyamide coarse-denier fiber, and the surface / inside single fiber fineness ratio is 0.35. The surface is plain weave (the ratio of the number of intersecting weave points to the number of yarns is 1.0), the inside is 1 / 2 twill weave (the ratio of the number of intersecting weave points to the number of yarns is 0.67), and the surface warp and inner warp The arrangement ratio of the surface weft and the inner weft are both 2, and the gray fabric woven on the water jet loom is dyed and processed to obtain a double-layer fabric with a surface tightness of 91.5% and an inner tightness of 56.6%. .

[0031] Its main processing projects and conditions are: refining (temperature 95 °C, speed 50 m / min); intermediate setting (temperature 180 °C, speed 50 m / min); acid dyeing (temperature 90 °C, time 30 min); drying (temperature 140°C, speed 50...

Embodiment 3

[0034] 110dtex-144f polyester fine denier fiber is selected for the surface of the fabric, 110dtex-24f polyester coarse denier fiber is selected for the inside, and the surface / inside single fiber fineness ratio is 0.17. The surface is 3 / 1 twill weave (the ratio of the number of intersecting weave points to the number of yarns is 0.5), and the inside is 1 / 3 variable twill weave (the ratio of the number of intersecting weave points to the number of yarns is 0.5), the table The matching ratio of warp and inner warp is 2, and the gray fabric woven on the water-jet loom is dyed and processed to obtain a double warp fabric with a surface tightness of 89.2% and an inner tightness of 65.3%. Its main processing engineering and conditions are with embodiment 1.

[0035] The obtained warp double fabric has the characteristics of clear, fine and compact surface lines, fluffy and soft inside, and good drapability. Its performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com