Skin-friendly and environment-friendly polyurethane synthetic leather for earphone sleeve and preparing method of leather

An environmentally friendly polyurethane technology, applied in the field of polyurethane materials, can solve problems such as poor hydrolysis resistance and difficulty in meeting environmental protection pressure, and achieve full hand feeling, excellent environmental protection performance, and good hydrolysis resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

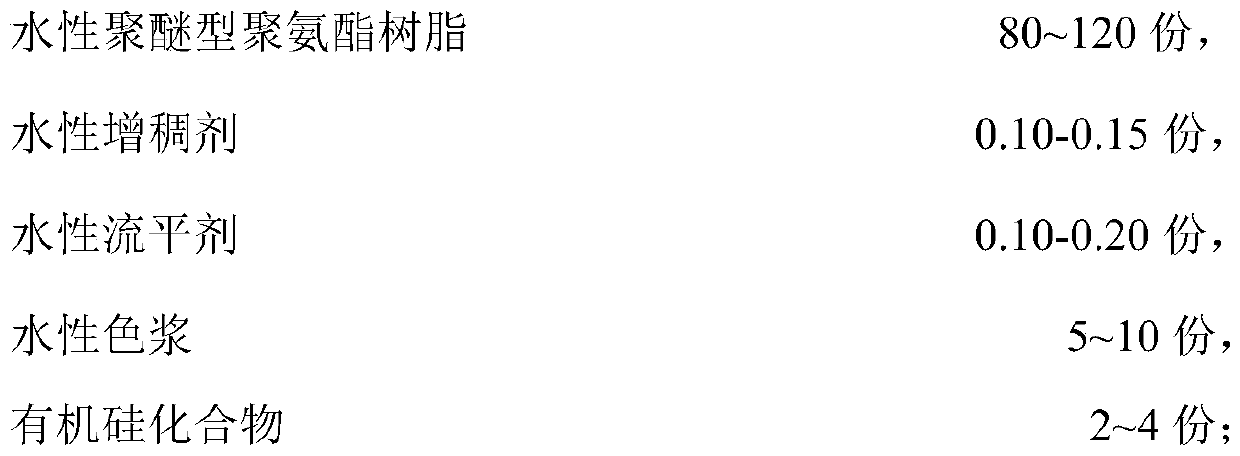

[0036] Mix 80 parts of water-based polyether polyurethane resin, 5 parts of black color paste WH-907, 0.10 parts of water-based leveling agent, 0.10 parts of water-based thickener, and 2 parts of organosilicon compound to make a dry surface layer slurry, and then mix the water-based 80 parts of polyether polyurethane resin, 5 parts of black colorant WH-907, 0.10 part of water-based leveling agent, and 0.10 part of water-based thickener were mixed to make the middle layer slurry, and the dry surface layer slurry was coated on the release paper. The coating thickness is 0.12mm. After drying and curing at 115 °C, a dry surface layer is formed. Then, the intermediate layer slurry is coated on the dry surface layer. The coating thickness is 0.15 mm. After drying and curing at 115 °C, middle layer;

[0037] Mix 100 parts of polyester polyol, 10 parts of aluminum hydroxide, 0.01 part of catalyst DY-5508, and 0.01 part of blowing agent DY-29588 to prepare material A, material B is iso...

Embodiment 2

[0040] Mix 100 parts of water-based polyether polyurethane resin, 8 parts of white color paste WH-101, 0.15 parts of water-based leveling agent, 0.12 parts of water-based thickener, and 3 parts of organosilicon compound to make a dry surface layer slurry, and then mix the water-based 100 parts of polyether polyurethane resin, 8 parts of white color paste WH-101, 0.15 parts of water-based leveling agent, and 0.12 parts of water-based thickener are mixed to make the middle layer slurry, and the dry surface layer slurry is coated on the release paper Above, the coating thickness is 0.15mm, dried and cured at 120℃ to form a dry surface layer, and then the middle layer slurry is coated on the dry surface layer with a coating thickness of 0.20mm, and dried and cured at 120℃ to form a dry surface layer middle layer;

[0041] Mix 100 parts of polyester polyol, 15 parts of aluminum hydroxide, 0.05 parts of catalyst DY-5508, and 0.05 parts of foaming agent DY-29580 to make material A. M...

Embodiment 3

[0044] Mix 120 parts of water-based polyether polyurethane resin, 10 parts of blue color paste WH-603, 0.20 parts of water-based leveling agent, 0.15 parts of water-based thickener, and 4 parts of organosilicon compound to make a dry surface layer slurry, and then mix the water-based 120 parts of polyether polyurethane resin, 10 parts of blue color paste WH-603, 0.20 parts of water-based leveling agent, and 0.15 parts of water-based thickener are mixed to make the middle layer slurry, and the dry surface layer slurry is coated on the release paper On the top, the coating thickness is 0.18mm, dried and cured at 135°C to form a dry surface layer, and then the middle layer slurry is coated on the dry surface layer with a coating thickness of 0.12mm, dried and cured at 135°C to form a dry surface layer middle layer;

[0045] Mix 100 parts of polyester polyol, 20 parts of aluminum hydroxide, 0.1 part of catalyst DY-5508, and 0.1 part of foaming agent DY-2958 to make material A, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com