Wet type polyurethane resin, production process and application method thereof

A wet-process polyurethane and production process technology, which is applied in the chemical industry, can solve problems such as poor crystallinity, poor structural regularity and strength, and weak hydrogen bonds, and achieve increased density, full hand feeling, improved hydrolysis resistance and peeling The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

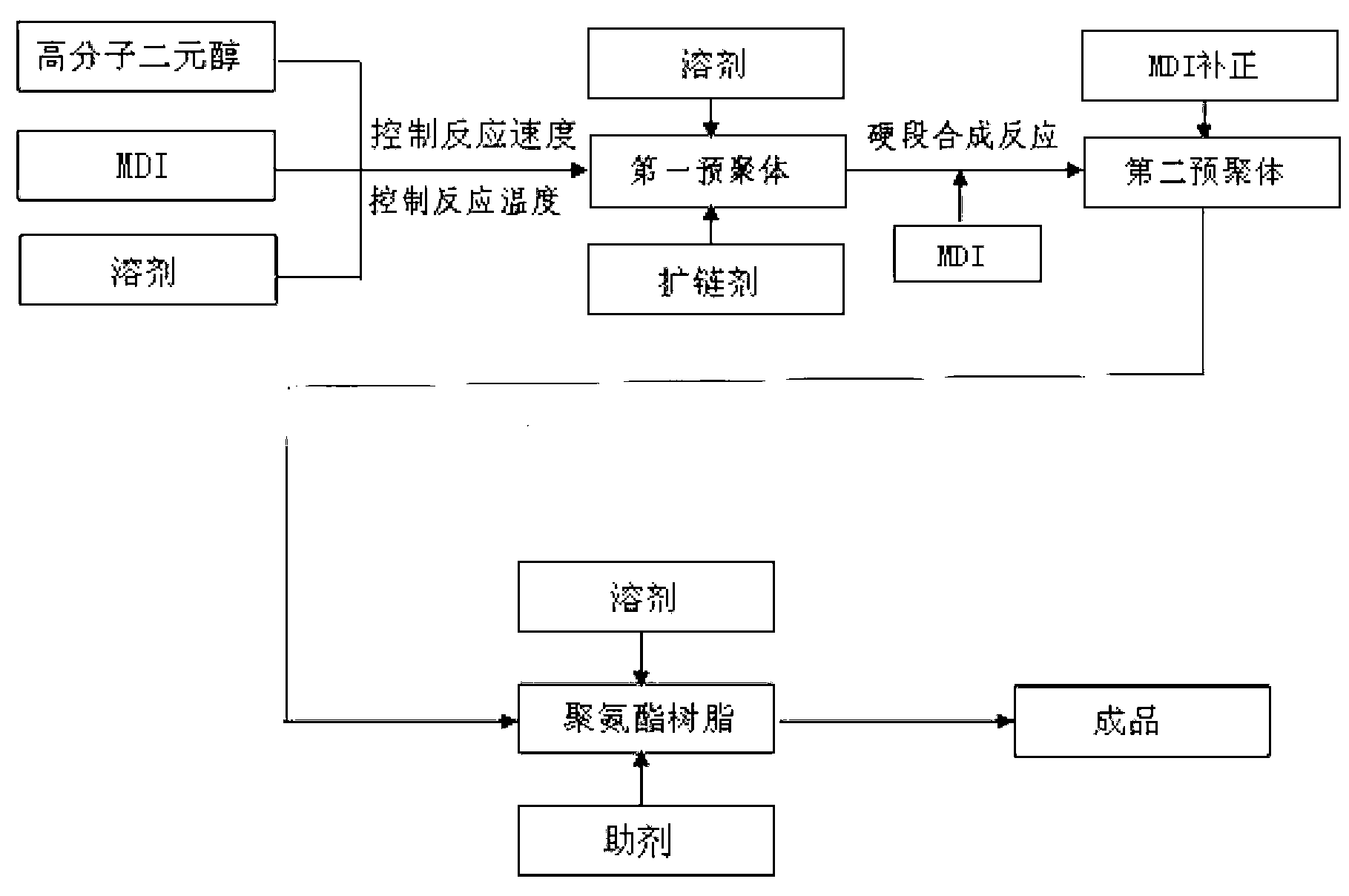

Method used

Image

Examples

Embodiment 2

[0040] Proceed as follows:

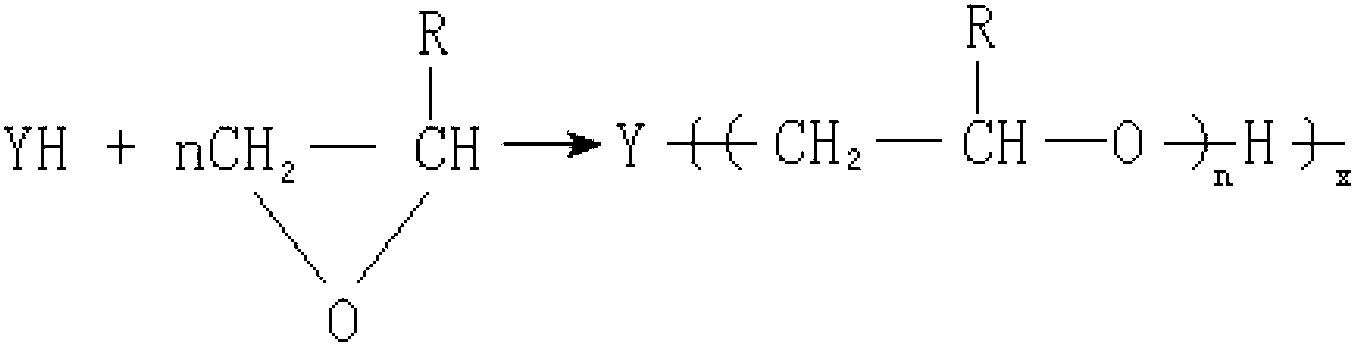

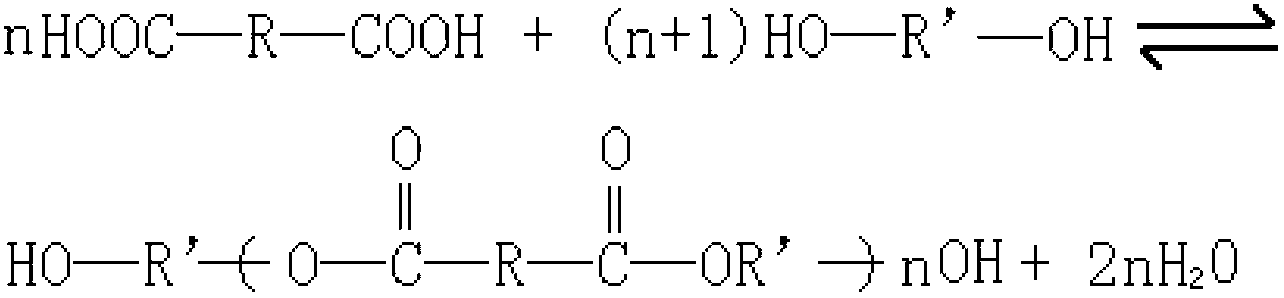

[0041]1. The so-called soft segment is synthesized into polyether polyol (PTMEG), poly(1,4-butylene adipate (BA) and polyethylene adipate (EA) in a molar ratio of 4:3:3 The mixture and diphenylmethane diisocyanate (MDI) are dissolved in the solvent N,N-dimethylformamide and then synthesized; the weight of the mixed polymer diol, diphenylmethane diisocyanate and solvent accounts for the total weight of the formula 33% by weight, the reaction stirring speed of the soft segment synthesis is 30 rpm, the temperature is controlled at 65° C., and the time is 2.5 hours.

[0042] 2. Add the product of the synthesis reaction to a solvent with 15% of the total weight of the formula to carry out the first prepolymer reaction. The reaction stirring speed of the first prepolymer reaction is 30 rpm, the reaction temperature is 65°C, and the reaction time is 2.5 hours , the reaction viscosity of the soft segment is 100,000.

[0043] 3. After the first prepolyme...

Embodiment 3

[0047] Proceed as follows:

[0048] 1. The so-called soft segment is synthesized into polyether polyol (PTMEG), poly(1,4-butylene adipate (BA) and polyethylene adipate (EA) in a molar ratio of 4:3:3 The mixture and diphenylmethane diisocyanate (MDI) are dissolved in the solvent N,N-dimethylformamide and then synthesized; the weight of the mixed polymer diol, diphenylmethane diisocyanate and solvent accounts for the total weight of the formula 35% by weight, the reaction stirring speed of soft segment synthesis is 30 rpm, the temperature is controlled at 70°C, and the time is 2.3 hours.

[0049] 2. Add the product of the synthesis reaction to a solvent with 15% of the total weight of the formula to carry out the first prepolymer reaction. The reaction stirring speed of the first prepolymer reaction is 30 rpm, the reaction temperature is 70°C, and the reaction time is 2.0 hours , the reaction viscosity of the soft segment is 120,000.

[0050] 3. After the first prepolymer rea...

Embodiment 4

[0055] It includes the following weight ratio: 100 parts of polyurethane (PU) resin, 12 parts of color paste, 0.7 parts of anionic surfactant (GB-11), 2 parts of nonionic surfactant (GB-7), and 45 parts of DMF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com