Fluorine-free anti-siphon high-density synthetic leather and production method thereof

A production method and technology of synthetic leather, which is applied in the field of synthetic leather, can solve the problems of synthetic leather waterproof stability and environmental protection not meeting the requirements, and achieve the effect of good resilience, high peeling data, and full hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

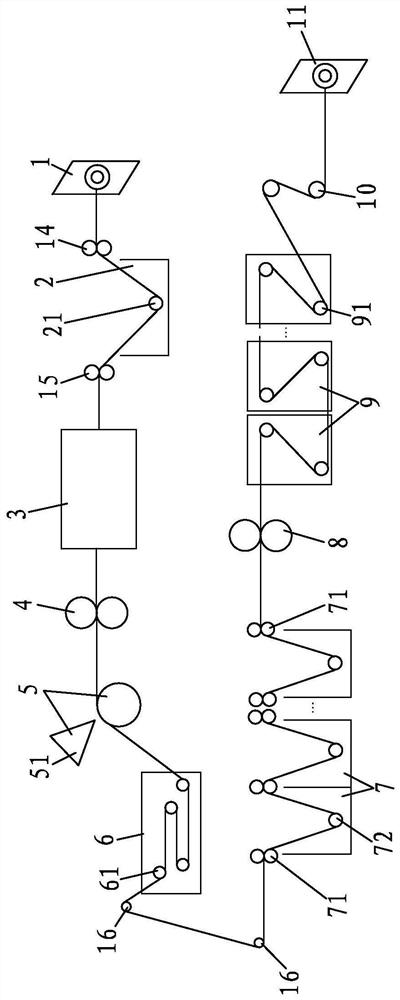

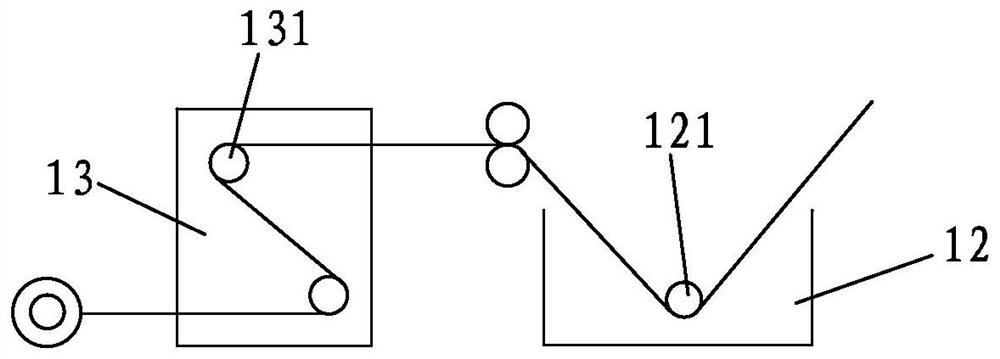

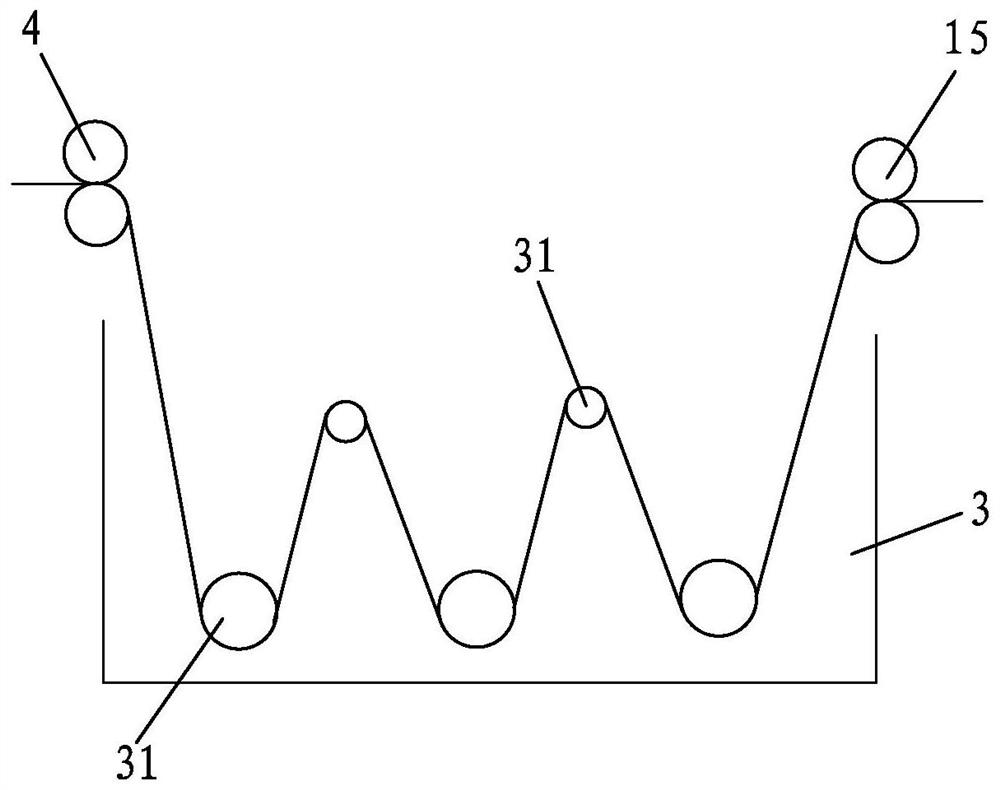

[0100] A method for producing fluorine-free anti-siphon high-density synthetic leather, comprising:

[0101] S1. The non-woven fabric is unrolled through the cloth storage rack, and the unrolled non-woven fabric enters the impregnation tank for impregnation. After impregnation, it enters the pre-solidification tank for pre-solidification; the pre-solidified non-woven fabric is ironed by the ironing device Processing, and then through the coating table device equipped with a coating knife for fabric scraping treatment.

[0102] In the step S1, the thickness of the non-woven fabric is 0.65mm, and the grammage is 195g / m 2 , blasting is 17kgf / cm 2 ; Tensile strength > 120N in warp direction, > 70N in weft direction; elongation at break > 80% in warp direction, and > 170% in weft direction. Before the non-woven fabric is unrolled, the non-woven fabric is subjected to water-repellent treatment with a water-based waterproof agent, and the non-woven fabric after the waterproof treat...

Embodiment 2

[0108] A method for producing fluorine-free anti-siphon high-density synthetic leather, comprising:

[0109] S1. The non-woven fabric is unrolled through the cloth storage rack, and the unrolled non-woven fabric enters the impregnation tank for impregnation. After impregnation, it enters the pre-solidification tank for pre-solidification; the pre-solidified non-woven fabric is ironed by the ironing device Processing, and then through the coating table device equipped with a coating knife for fabric scraping treatment.

[0110] In the step S1, the thickness of the non-woven fabric is 0.70mm, and the grammage is 200g / m 2 , blasting is 17kgf / cm 2 ; Tensile strength > 120N in warp direction, > 70N in weft direction; elongation at break > 80% in warp direction, and > 170% in weft direction. Before the non-woven fabric is unrolled, the non-woven fabric is subjected to water-repellent treatment with a water-based waterproof agent, and the non-woven fabric after the waterproof treat...

Embodiment 3

[0116] A method for producing fluorine-free anti-siphon high-density synthetic leather, comprising:

[0117] S1. The non-woven fabric is unrolled through the cloth storage rack, and the unrolled non-woven fabric enters the impregnation tank for impregnation. After impregnation, it enters the pre-solidification tank for pre-solidification; the pre-solidified non-woven fabric is ironed by the ironing device treatment, and then through the coating table device equipped with a coating knife for fabric scraping treatment.

[0118] In the step S1, the thickness of the non-woven fabric is 0.75mm, and the grammage is 205g / m 2 , blasting is 17kgf / cm 2 ; Tensile strength > 120N in warp direction, > 70N in weft direction; elongation at break > 80% in warp direction, and > 170% in weft direction. Before the non-woven fabric is unrolled, the non-woven fabric is subjected to water-repellent treatment with a water-based waterproof agent, and the non-woven fabric after the waterproof treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com