A kind of manufacturing method of anti-siphon line

A manufacturing method and anti-siphon technology, which are applied in the manufacture of cables/conductors, insulation of conductors/cables, electrical components, etc., can solve the problems of low production efficiency of power lines and unstable product quality, and achieve high safety and reliability. , stable quality, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

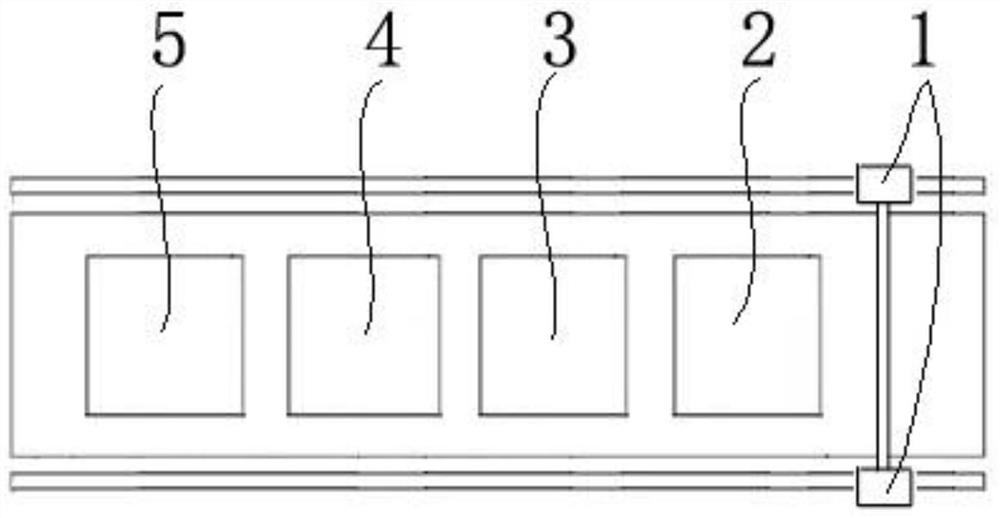

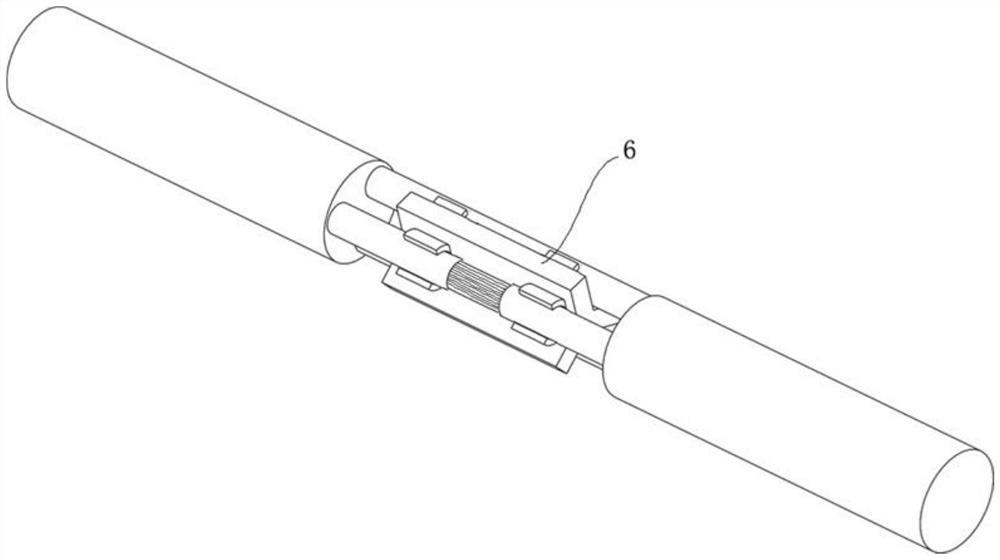

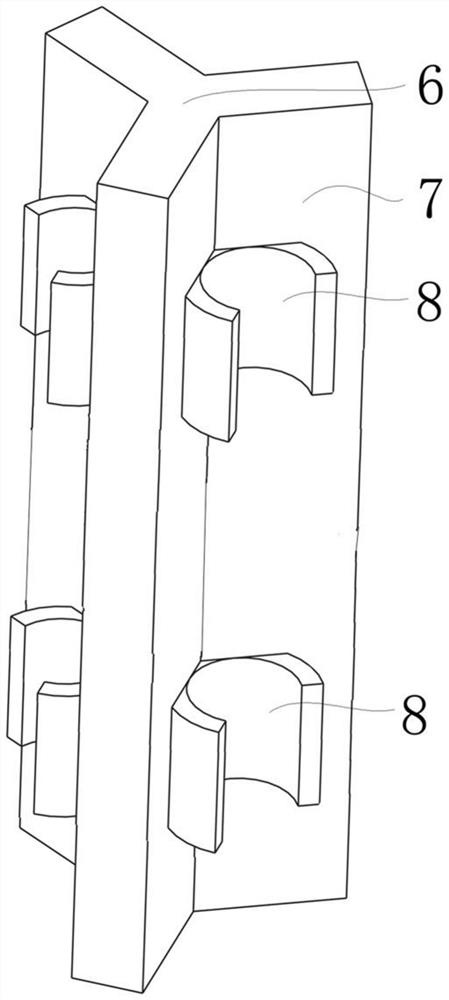

[0030] A method for manufacturing an anti-siphon thread according to an embodiment of the present invention, the method for manufacturing an anti-siphon thread is implemented by the following device, such as figure 1 , figure 2 with image 3 As shown, it includes: power cord pulling device 1, outer insulating layer stripping device 2, inner insulating layer stripping device 3, wire welding device 4 and insulation isolation bracket installation part 5; power cord pulling device 1 can pull the power cord and pass through it in sequence The outer insulating layer stripping device 2, the inner insulating layer stripping device 3 and the wire welding device 4, and the insulating isolating bracket is installed through the insulating isolating bracket installation part 5;

[0031] Specifically, in this embodiment, the power cord pulling device 1 includes two slide rails and two clamping devices that can slide synchronously along the two rails respectively. The clamping devices are ...

Embodiment 2

[0046] In this embodiment, the outer insulating layer stripping device 2 and the inner insulating layer stripping device 3 are arranged together, share the carbon dioxide laser cutting machine and the insulating layer rubbing and stripping device, and the first fixing device for the power cord and the second fixing device for the power cord are in phase. Adjacent to the setting, the gap between the friction wheels on the insulation layer rubbing and stripping device adopts an adjustable design, that is, when the outer insulation layer is peeled off, the gap between the friction wheels is adjusted to be slightly larger than the gap between the friction wheels when the inner insulation layer is peeled off, so that the entire The device is simpler and the utilization rate is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com