Wet-process polyurethane resin as well as preparation method and application thereof

A wet-process polyurethane and resin technology, applied in the field of polyurethane resin, can solve the problems of the backside of the substrate, the shelling on both sides of the compatible substrate, and the degradation of the grade, so as to achieve good hydrolysis resistance, good anti-siphon effect, and increase the processing range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

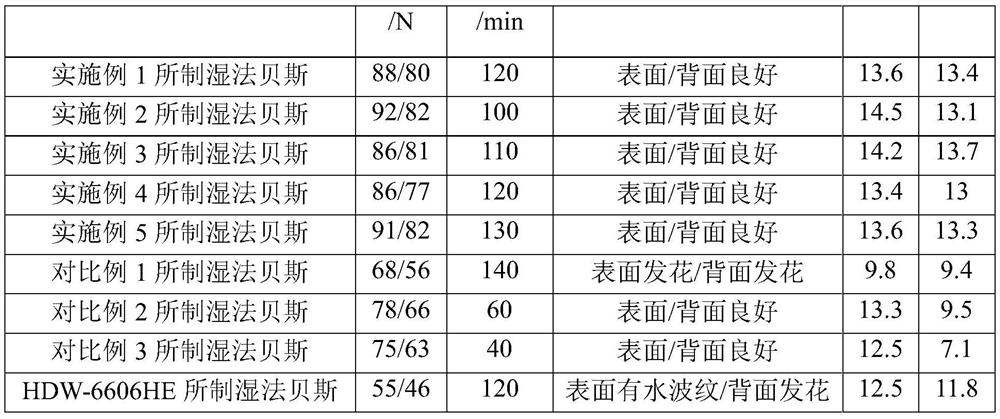

Examples

preparation example Construction

[0040] The present invention also proposes a kind of preparation method of wet process polyurethane resin, and described preparation method comprises the following steps:

[0041] Step 1: Prepolymerize dimer acid polyester diol, part of diphenylmethane-4,4'-diisocyanate and part of N,N-dimethylformamide until the viscosity of the reaction solution reaches At 100-180Pa·s (such as 100Pa·s, 120Pa·s, 140Pa·s, 160Pa·s or 180Pa·s) at 50°C, the prepolymerization reaction is over, and then the chain extender and the remaining N,N-di Methylformamide, after reacting for 1-2h (such as 1h, 1.5h, or 2h), add the remaining diphenylmethane-4,4'-diisocyanate to continue the reaction, when the final viscosity of the reaction solution is 100 at 25°C When ~300Pa·s (such as 100Pa·s, 150Pa·s, 200Pa·s, 250Pa·s or 300Pa·s), the reaction is terminated to obtain the first component;

[0042] Step 2: Mix dimer acid polyester diol, toluene diisocyanate and N,N-dimethylformamide, heat it to react under ...

Embodiment 1

[0052] The wet-process polyurethane resin of the present embodiment is prepared through the following steps:

[0053] (1) Preparation of dimer acid polyester diol: mix dimer acid and 2-butyl-2-ethyl-1,3-propanediol according to the molar ratio = 1:1.4, stir and heat up to 150 ℃, after reacting for 3 hours, gradually raise the temperature to 200℃, react for another 2 hours, add the catalyst tetrabutyl titanate, react for 2 hours, vacuumize and react for 4 hours, until the acid value is lower than 0.5mg KOH / g, and the hydroxyl value is 56mgKOH / g , cooling and discharging to obtain dimer acid polyester diol.

[0054] (2) Preparation of the first component: 185kg of dimer acid polyester diol, 21.8kg of diphenylmethane-4,4'-diisocyanate and 128kg of N,N-dimethylformamide were prepolymerized, The reaction temperature was controlled at 75°C. After 1.5 hours of reaction, when the viscosity of the reaction liquid reached 50°C and 100 Pa·s, 13.34kg of ethylene glycol, 2.42kg of 1,4-but...

Embodiment 2

[0058] The wet-process polyurethane resin of the present embodiment is prepared through the following steps:

[0059] (1) Preparation of dimer acid polyester diol: mix dimer acid and diethylpentanediol at a molar ratio of 1:1.1, stir and heat up to 140°C under nitrogen protection, and gradually heat up to 140°C after reacting for 5 hours. 220°C, react for another 3 hours, add catalyst tetrabutyl titanate, react for 3 hours, vacuumize and react for 6 hours, when the acid value is lower than 0.5 mg KOH / g, and the hydroxyl value is 28 mg KOH / g, cool down and discharge to obtain di Polyacid polyester diol.

[0060] (2) Preparation of the first component: Prepolymerize 160kg of dimer acid polyester diol, 9.6kg of diphenylmethane-4,4'-diisocyanate and 113kg of N,N-dimethylformamide, and react The temperature was controlled at 80°C. After 2.5 hours of reaction, when the viscosity of the reaction liquid reached 120 Pa·s at 50°C, 18.84kg of ethylene glycol and 565kg of N,N-dimethylfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com