Finishing method capable of preventing Modal fibers from pilling

A modal fiber and anti-pilling technology, which is applied to plant fibers and wear-resistant fibers, can solve problems such as poor mechanical properties, and achieve the effects of improving hand feeling, increasing dry modulus, and increasing dry modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

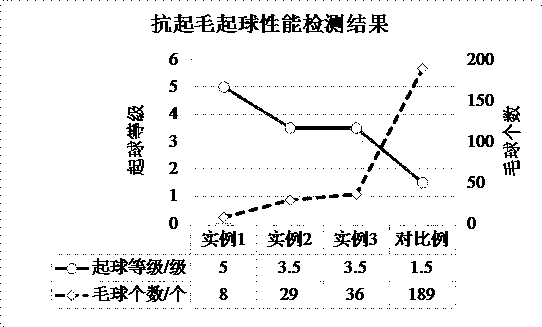

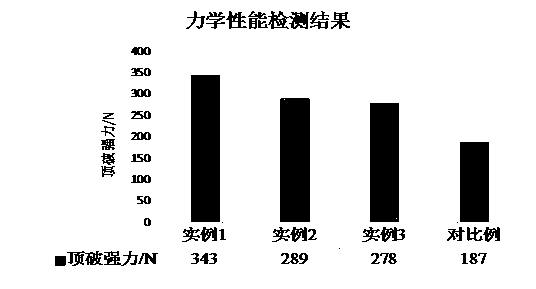

example 1

[0025] Mix the spider silk fiber and silk fiber in a beaker according to the mass ratio of 5:1, and add 0.16 times the protease of the spider silk fiber and 9 times the water of the spider silk fiber to the beaker in sequence, and move the beaker into a digital speed measuring constant temperature magnetic stirrer, At a temperature of 38°C and a rotation speed of 260r / min, stir and react at a constant temperature for 90 minutes to obtain a mixed fiber degradation liquid, transfer the mixed fiber degradation liquid into a rotary evaporator, and at a temperature of 85°C, a speed of 170r / min, and a pressure of Under the condition of 800Pa, rotate and concentrate for 100min to obtain the mixed fiber concentrate; mix the eucommia gum emulsion with the oxidizing agent at a mass ratio of 8:1, at a rotation speed of 300r / min, under room temperature, stir and react at a constant temperature for 5h to obtain the oxidized eucommia gum emulsion ; Mix the modal fiber and liquid ammonia in t...

example 2

[0027]Mix the spider silk fiber and silk fiber in a beaker according to the mass ratio of 5:1, and add 0.16 times the protease of the spider silk fiber and 9 times the water of the spider silk fiber to the beaker in sequence, and move the beaker into a digital speed measuring constant temperature magnetic stirrer, At a temperature of 38°C and a rotation speed of 260r / min, stir and react at a constant temperature for 90 minutes to obtain a mixed fiber degradation liquid, transfer the mixed fiber degradation liquid into a rotary evaporator, and at a temperature of 85°C, a speed of 170r / min, and a pressure of Under the condition of 800Pa, rotate and concentrate for 100min to obtain the mixed fiber concentrate; mix the modal fiber and liquid ammonia in the reaction kettle at a mass ratio of 1:15, and react at a constant temperature and pressure for 80min at a pressure of 3.5MPa at room temperature, and filter , to obtain activated modal fiber; mix the activated modal fiber and the ...

example 3

[0029] Mix the eucommia gum emulsion with the oxidizing agent at a mass ratio of 8:1, and stir and react at a constant temperature for 5 hours at a rotating speed of 300r / min at room temperature to obtain the oxidized eucommia gum emulsion; mix the modal fiber and liquid ammonia at a mass ratio of 1:15 in In the reaction kettle, under the pressure of 3.5MPa and room temperature, react at constant temperature and pressure for 80 minutes, filter to obtain activated modal fiber; mix the activated modal fiber and oxidized eucommia gum emulsion in a beaker at a mass ratio of 1:8, and pour into the beaker Add a catalyst 0.3 times the mass of the activated modal fiber to the mixture, under the conditions of temperature 75°C and rotation speed 350r / min, stir and react at constant temperature for 3 hours, then filter to obtain pretreated modal fiber, first move the pretreated modal fiber into the oven, and then At a temperature of 85°C, pre-bake for 23 minutes, then move the pre-baked m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com